Metal/wooden composite materials and production thereof

A new type of material and production method technology, applied in the direction of wood processing appliances, wood veneer bonding, manufacturing tools, etc., can solve the problems of large specific gravity, limited application surface, insufficient mechanical strength, and insufficient conductive nail holding force, and achieves High mechanical strength, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

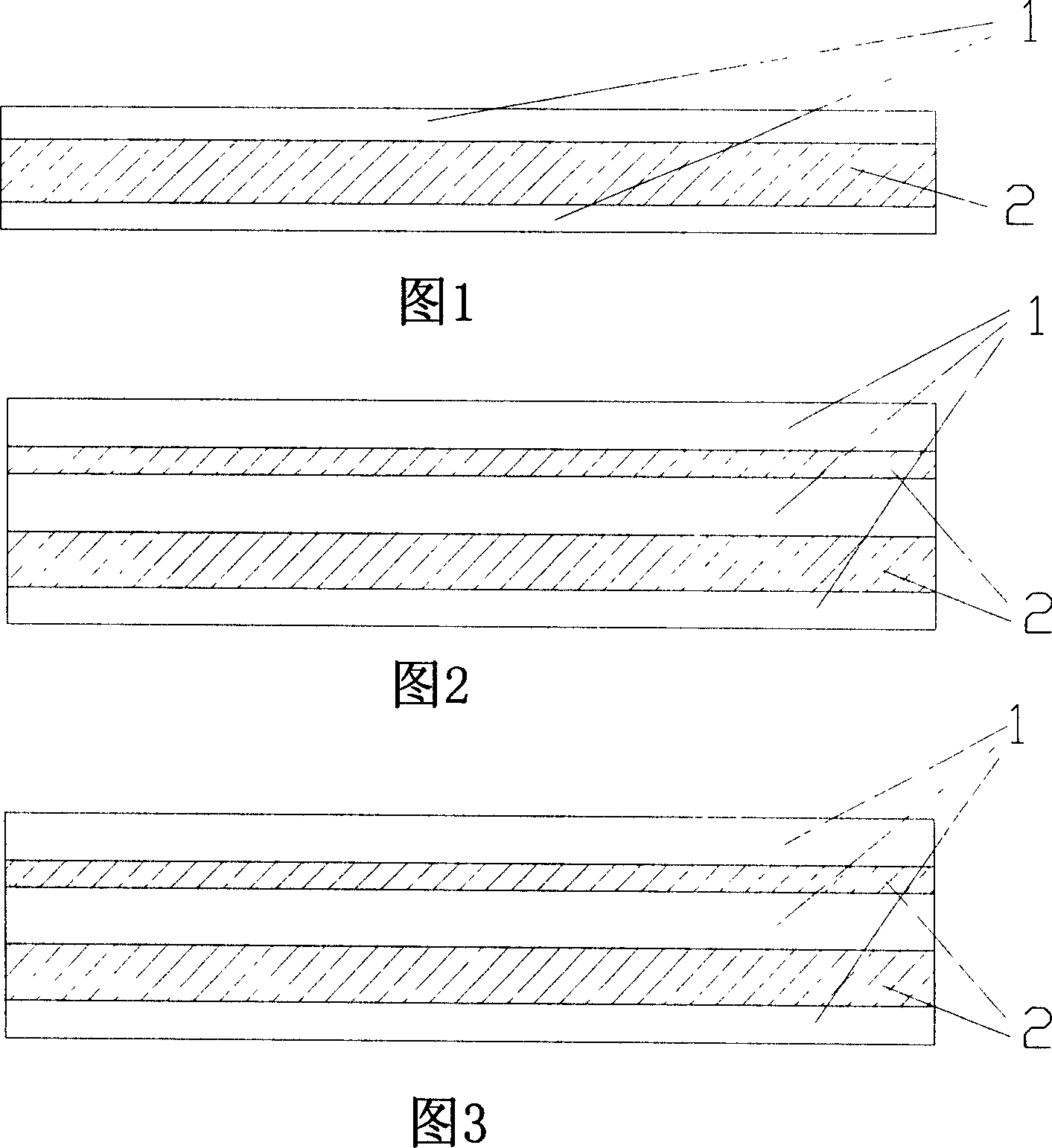

[0022] As shown in Figure 1, it includes two layers of veneer 1, a layer of metal plate 2 is arranged between the veneers, the veneer is rotary cut wood veneer or sliced wood veneer, metal The board is an aluminum board, and the wooden veneer and the aluminum board are fixed with low-free formaldehyde cold-press glue. The cold pressing machine carries out cold pressing, and the cold pressing pressure is 10kg / m2.

Embodiment 2

[0024] As shown in Figure 2, it includes a three-layer veneer 1, two layers of metal plates 2 are respectively arranged between the veneers, the veneer is sliced wood veneer, and the metal plate is thin iron plate, the veneer and the thin iron plate are fixed with low free formaldehyde cold-press glue, the thin iron plate is double-sided with glue, the amount of glue is 250 g / M2, the veneer and the metal plate are stacked in sequence, and sent Enter the cold press and carry out cold pressing, and the cold pressing pressure is 20kg / m2.

Embodiment 3

[0026] As shown in Fig. 3, it comprises three-layer veneer 1, is characterized in that two-layer metal plate 2 is arranged between described veneer, described veneer is rotary-cut wooden veneer, and metal plate is Alloy plate, the wooden veneer and the alloy plate are fixed with waterproof glue, the alloy plate is double-sided with glue, the amount of glue is 230 g / M2, the veneer and the alloy plate are stacked in sequence, and sent to the cold press Carry out cold pressing, and the cold pressing pressure is 15kg / m2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com