Core detaching tool for optical fiber cable

An optical cable and core wire technology, applied in the field of core wire extraction tools, can solve problems such as increasing transmission loss, and achieve the effect of suppressing the increase in transmission loss and suppressing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described based on the drawings.

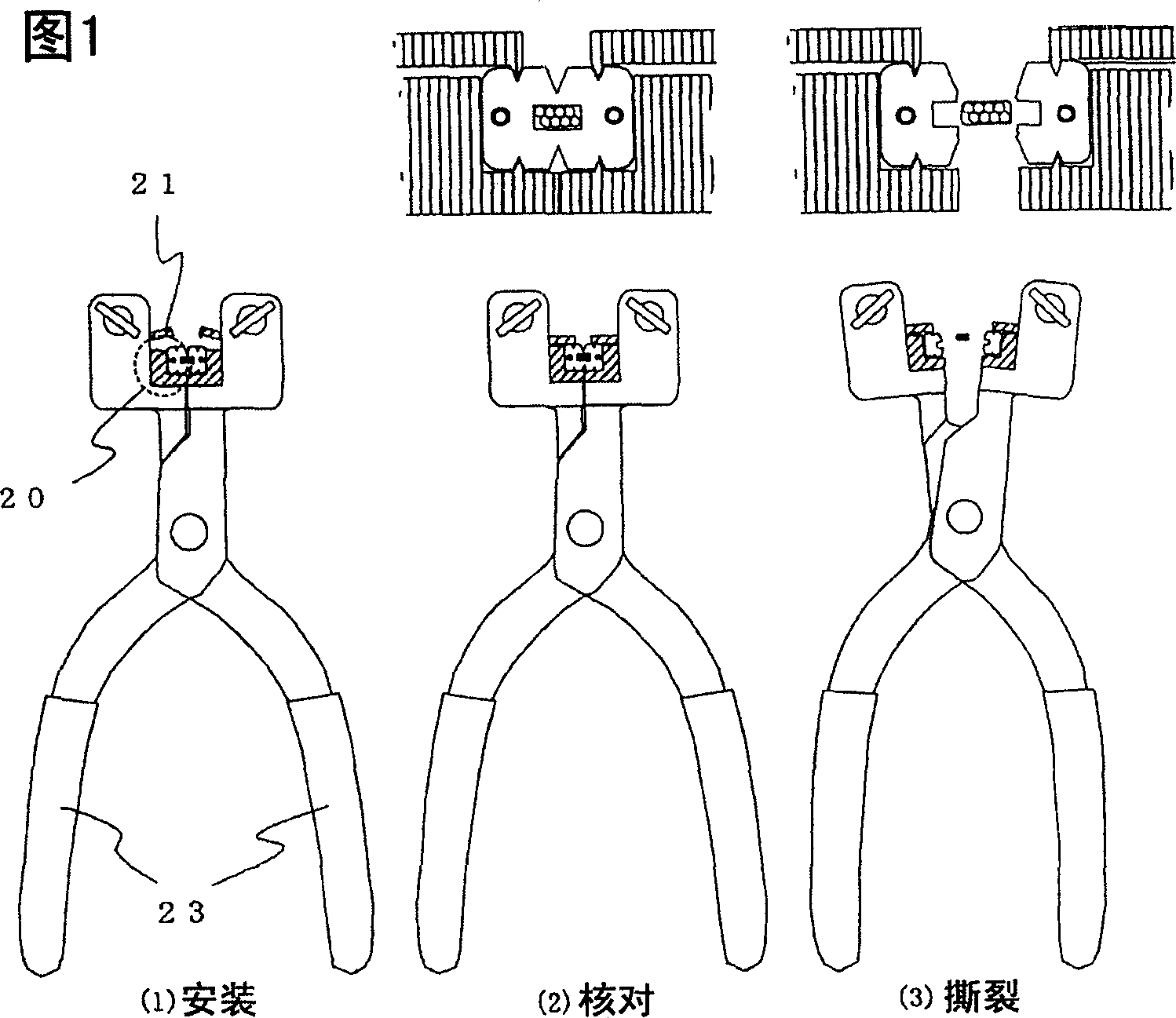

[0025] What is shown in FIG. 1 is a preferable embodiment of the core wire extraction tool for optical cables of this invention. The core wire extraction tool for the optical cable of Fig. 1 is the same as the prior art, and has a pair of cable gripping parts 20 consistent with the size of the optical cable with a slightly rectangular cross section. There are protrusions (for example, check claws) 21 . The movement mechanism part of the cable holding part is formed by attaching a pair of cable holding parts to the front end of the shelf-shaped movable handle 23, and the pair of cable holding parts can be opened and closed. A well-known open-type pliers method in which the cable gripping portion is opened by holding the handle 23 so that the distance is reduced can be used. In addition, the present invention is not limited to this embodiment, and a closed type may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com