Universal vacuum cleaner telescopic tube

A telescoping tube and vacuum cleaner technology, which is applied in the direction of vacuum cleaners, suction hoses, cleaning equipment, etc., can solve the problem that the axial direction of the vacuum tube cannot form a certain angle and is inconvenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

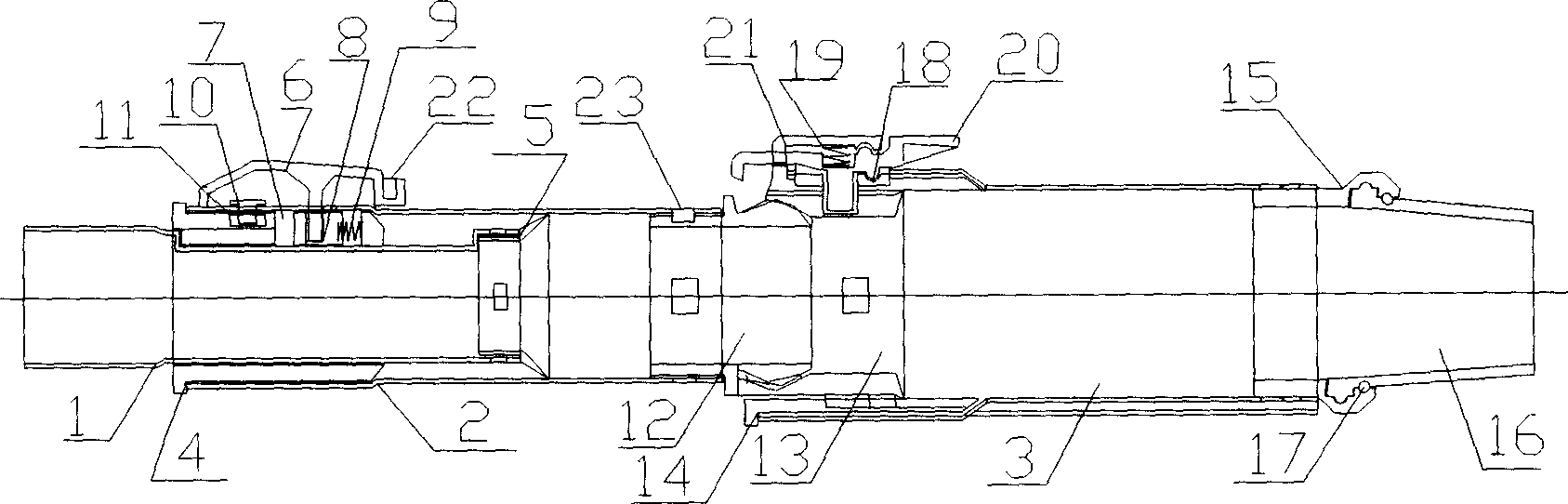

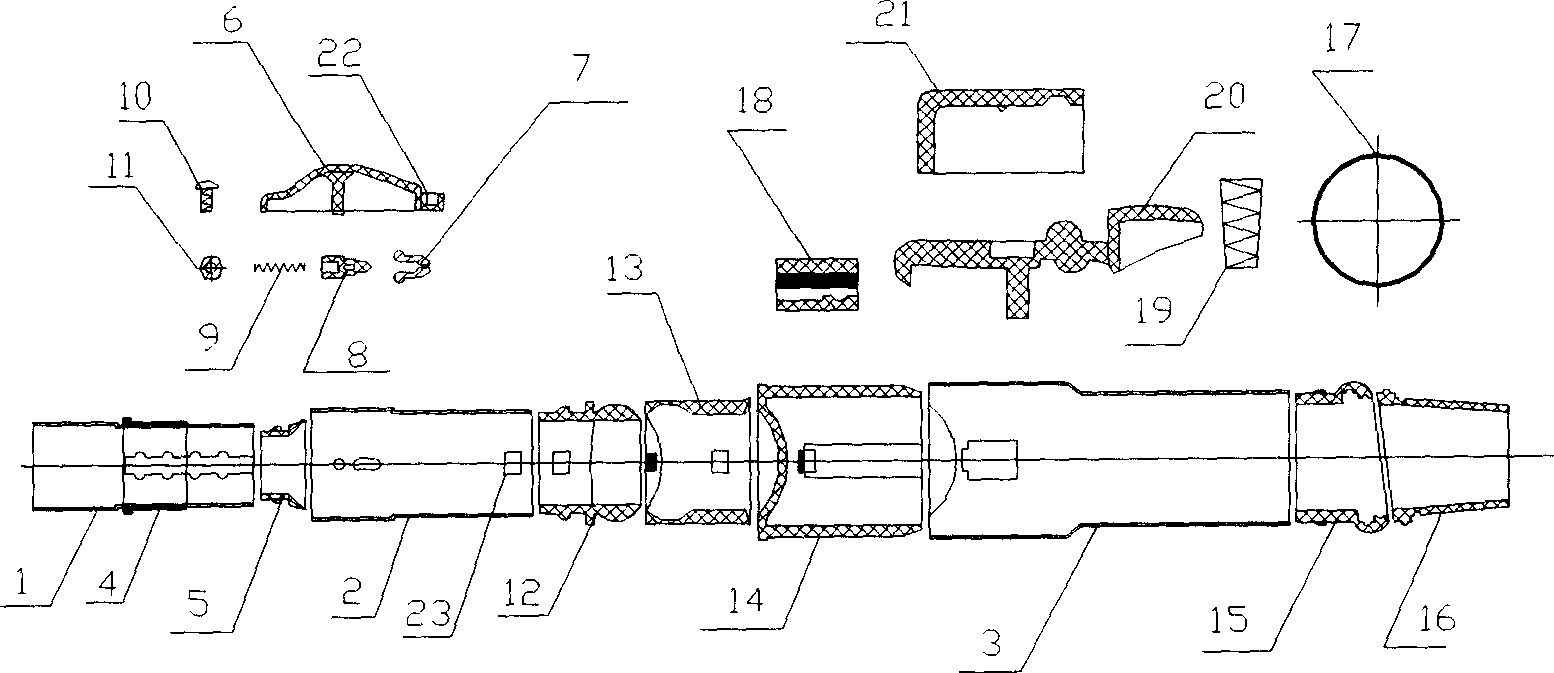

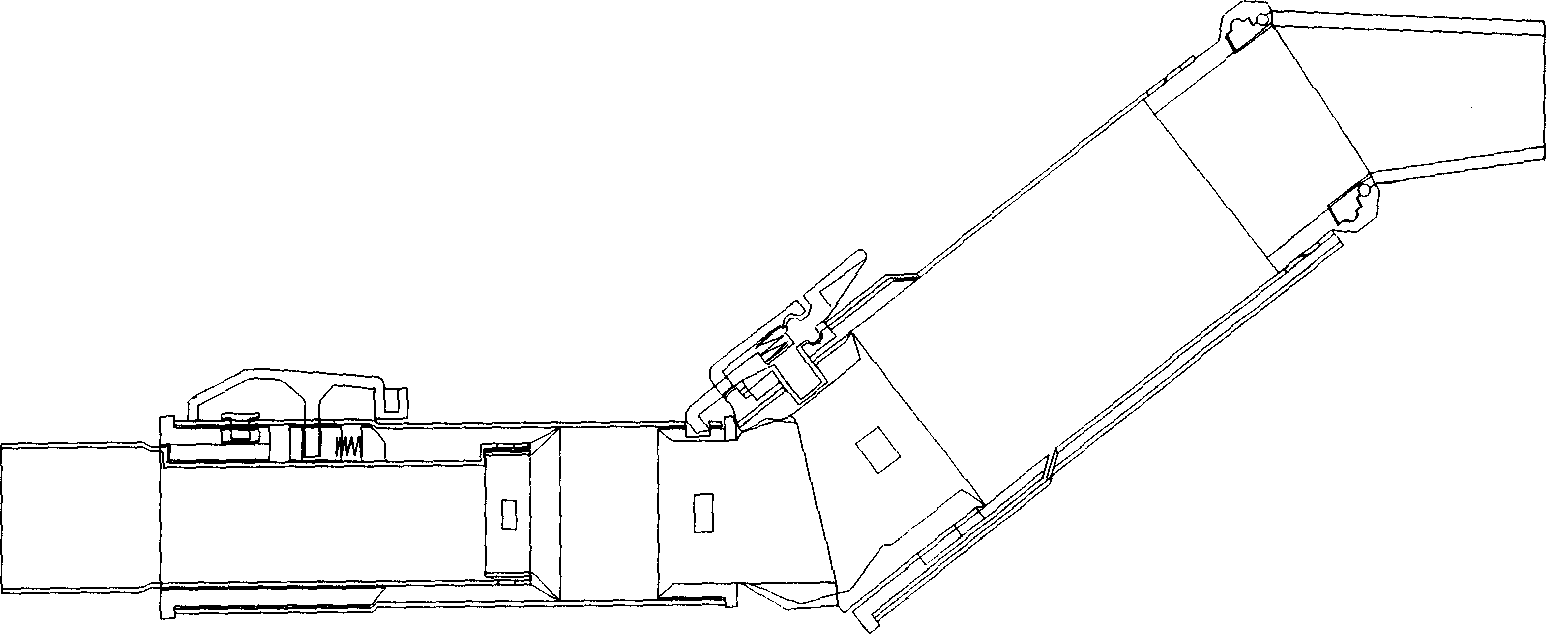

[0013] The telescoping tube of the universal vacuum cleaner of the present embodiment is as follows: figure 1 , 2 , 3, the main parts are as follows: core tube 1, inner tube 2, outer tube 3, small inner bushing 4, sealing ring 5, button push plate 6, movable locking block 7, movable slider 8, spring 9, screw 10. Nut 11, ball hinge head 12, ball hinge sleeve 13, large inner bushing 14, elbow movable connection seat 15, elbow movable connection head 16, O-ring 17, button lock seat 18, tapered Spring 19, button lock 20, button lock cover 21, outer tube indentation locking hole 22, bending locking hole 23.

[0014] The core pipe 1 is telescopically inserted into the inner pipe 2 through the small inner bushing 4 fixed on the flaring section of the inner pipe 2 . The second locking mechanism that button push plate 6, movable lock block 7, movable slide block 8, spring 9, screw 10, nut 11 constitute is installed in the flaring section of inner pipe, wherein movable lock block 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com