Ball grinding machine dust suction device for ceramic tile machining

A technology for a vacuum cleaner and a grinding machine, which is applied in the directions of removing smoke and dust, cleaning methods and utensils, cleaning hollow objects, etc. Efficiency and convenience, easy to use, flexible and adjustable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

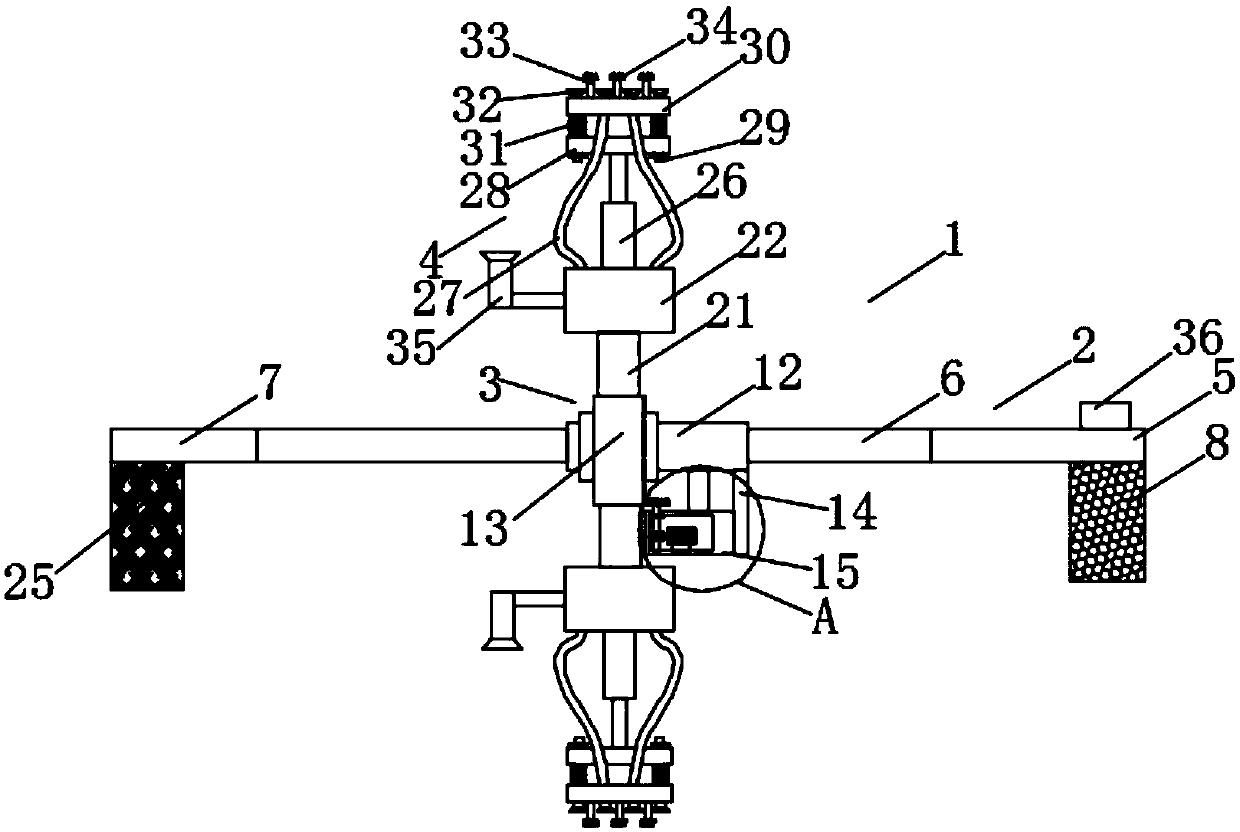

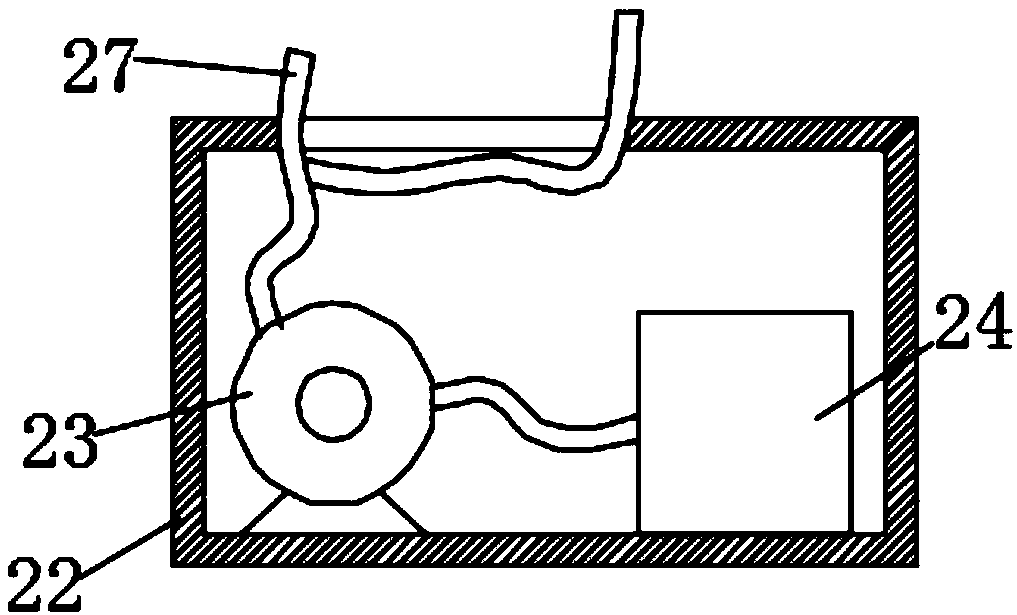

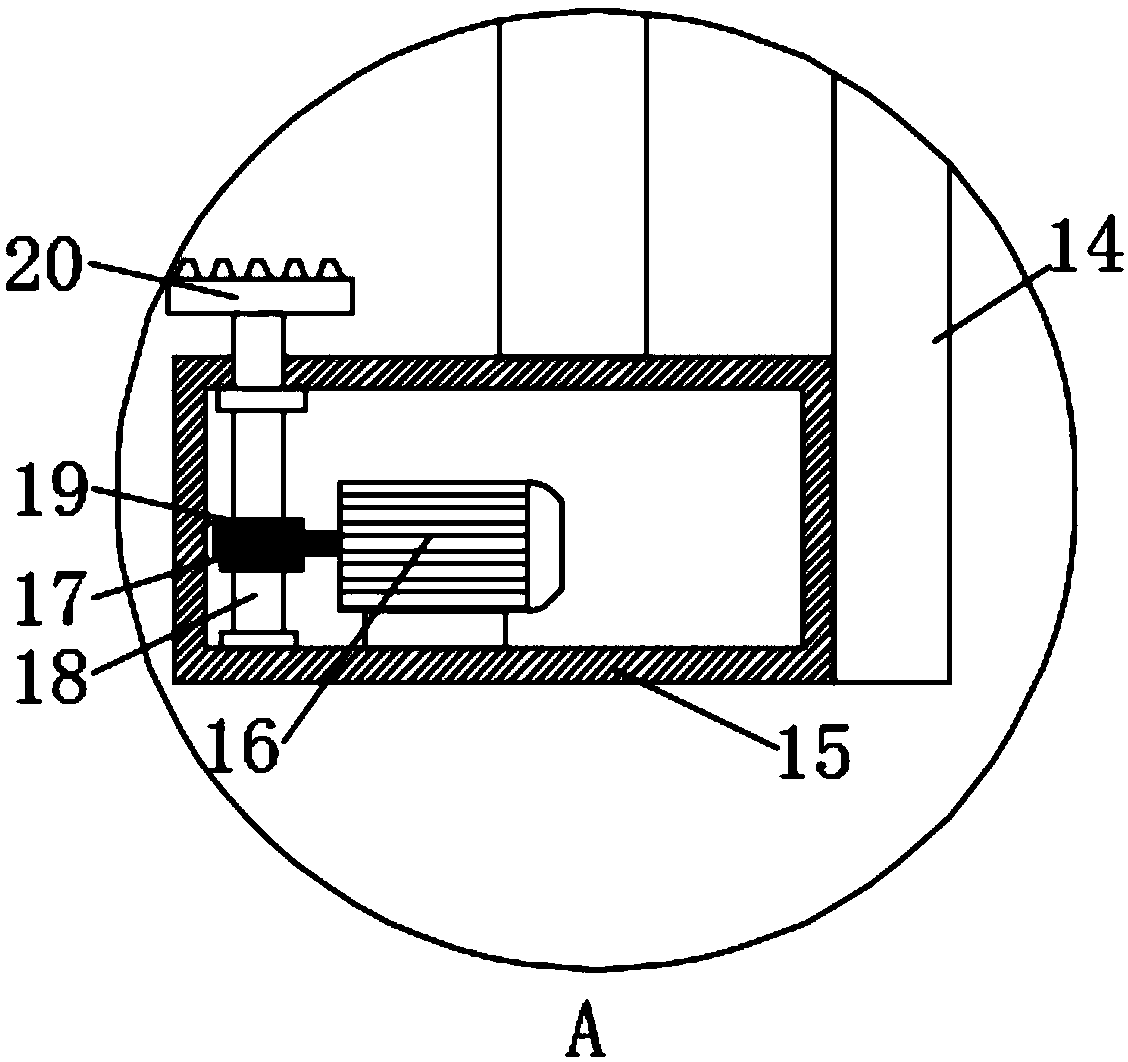

[0020] like Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a ball mill dust collection device for ceramic tile processing, including a dust collection device body 1, and the dust collection device body 1 is composed of a support mechanism 2, a rotating mechanism 3 and a dust collection mechanism 4 , the support mechanism 2 is composed of a first fixed plate 5, a grafted sliding rod 6, a second fixed plate 7, a first fixed electromagnet 8, a first electric telescopic rod 9, a connecting plate 10, a distance adjustment push rod 11 and a moving slide Composed of columns 12, one end of the first fixed plate 5 is threadedly connected with two grafted slide bars 6, and the ends of the two grafted slide bars 6 away from the first fixed plate 5 are threaded with a second fixed plate 7, so The bottom of the first fixed plate 5 is fixedly connected with a first fixed electromagnet 8, the bottom of the second fixed plate 7 is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com