Negative pressure vacuum honeying tank

A vacuum and honey making technology, applied in food science, food preservation, application, etc., can solve the problems of inconvenient storage of candied fruit, poor sealing performance, etc., and achieve the effect of convenient vacuum suction, convenient operation, and air leakage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

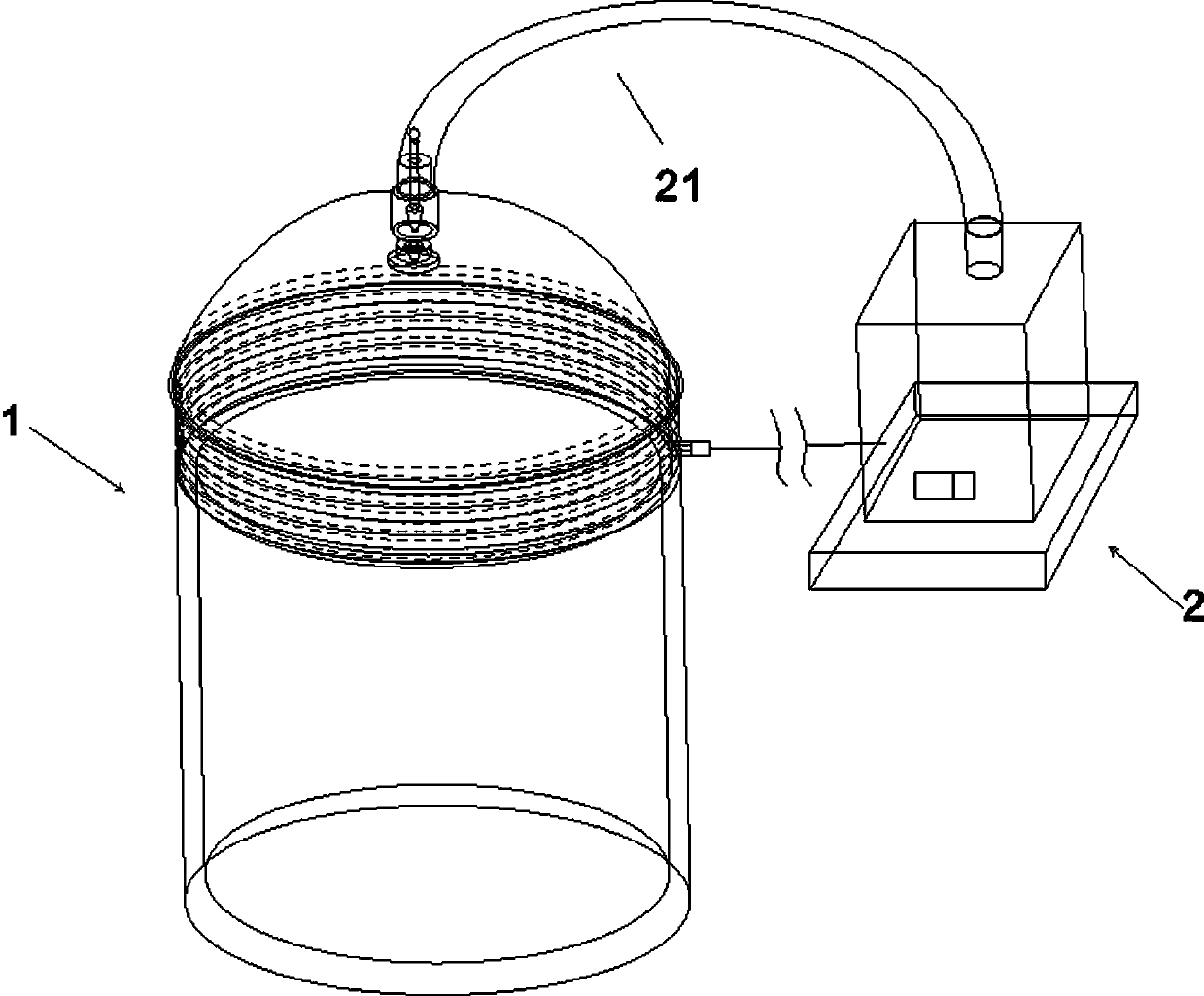

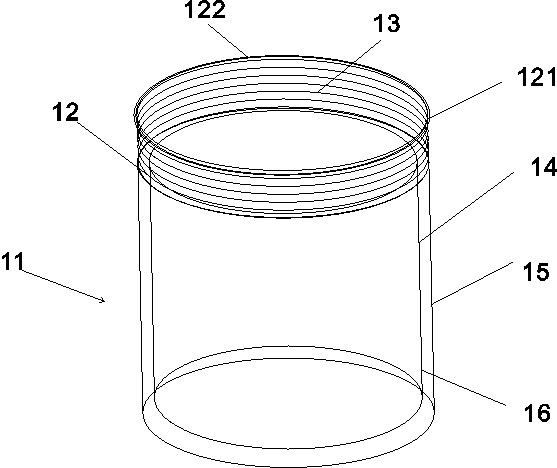

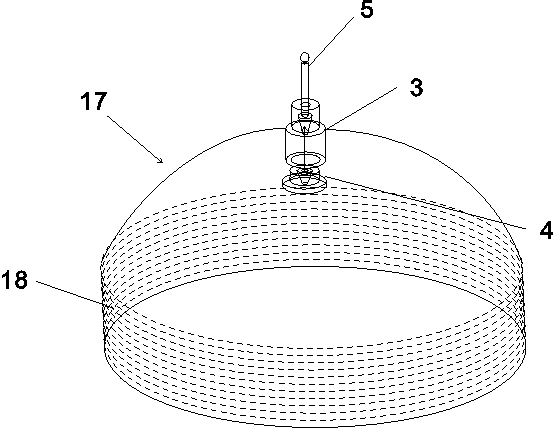

[0028] Such as Figure 1 to Figure 6 As shown, a negative pressure vacuum honey making tank of this embodiment includes a honey making tank 1 and an electric pump 2 having a switch and a power cord, and a power plug is provided on the power cord. The electric pumping pump used in this embodiment is CQB-2, which is used for vacuuming the honey tank. The electric pumping pump 2 is provided with a suction pipe, and a hose 21 is sleeved on the suction pipe. , Which is used to connect to the honey making tank to be able to vacuum the honey making tank. The honey making tank 1 includes a tank body 11 and a tank cover 17 screwed on the tank body 11, and the tank body 11 includes The inner layer 14 and the outer layer 15 are provided with a vacuum layer 16 between the inner layer 14 and the outer layer 15, which can more effectively preserve the preserved preserves placed in the tank. It should be noted that the preserved preserves are placed in the inner layer. An extended mouth 12 is...

Embodiment 2

[0039] By referring to the instructions attached Figure 1-6 The device structure of the present invention has been described, and the use of the present invention will be described here.

[0040] In use, the preserved candied fruit needs to be sealed and placed in the inner layer of the tank, and then the tank cover is screwed and sealed on the top surface of the tank body. A negative pressure vacuum part is provided on the tank cover. A rubber plug is installed on the part. When vacuum operation is required, the plug is equipped with a valve stem component in the negative pressure vacuum part. Lift it up, and then connect it to the electric pump through a hose, and the electric pump is equipped with Connect the power plug on the power cord to the external power supply, press the switch of the electric pump to start the electric pump, thereby vacuuming the honey pot, and then pressing the valve stem part down after the suction is completed. Negative pressure vacuum part, to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com