Patents

Literature

53results about How to "Easy to vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

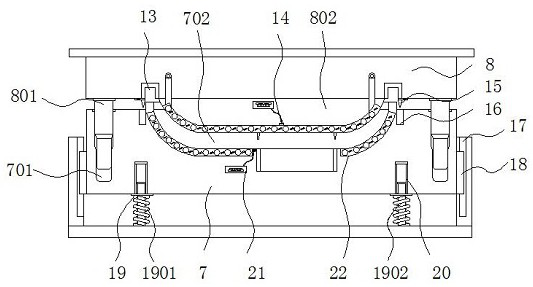

Food package vacuum sealing machine

InactiveCN110435965ASmall vacuum extraction volumeLow costPackaging by pressurising/gasifyingWrapper twisting/gatheringVacuum pumpingFood packaging

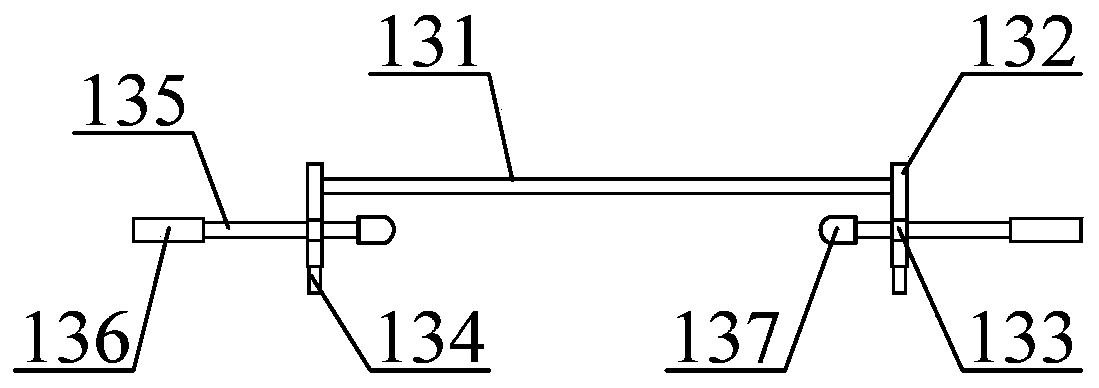

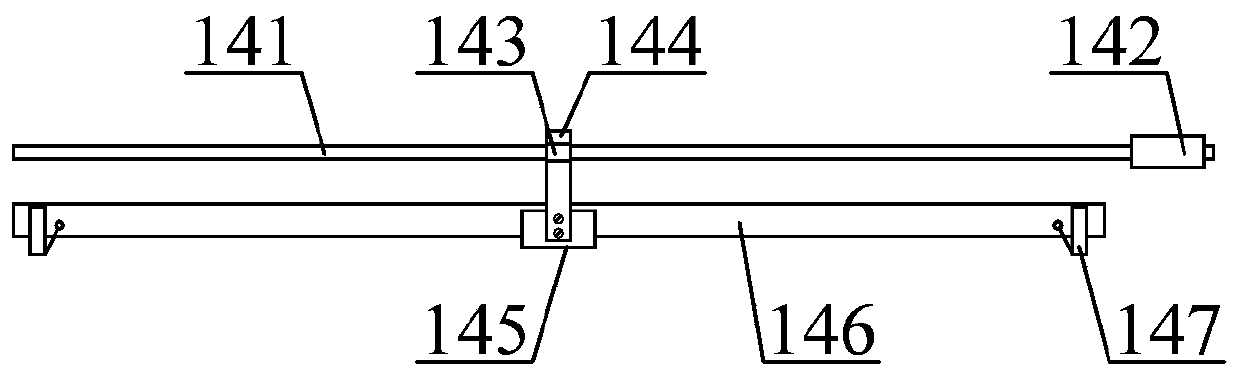

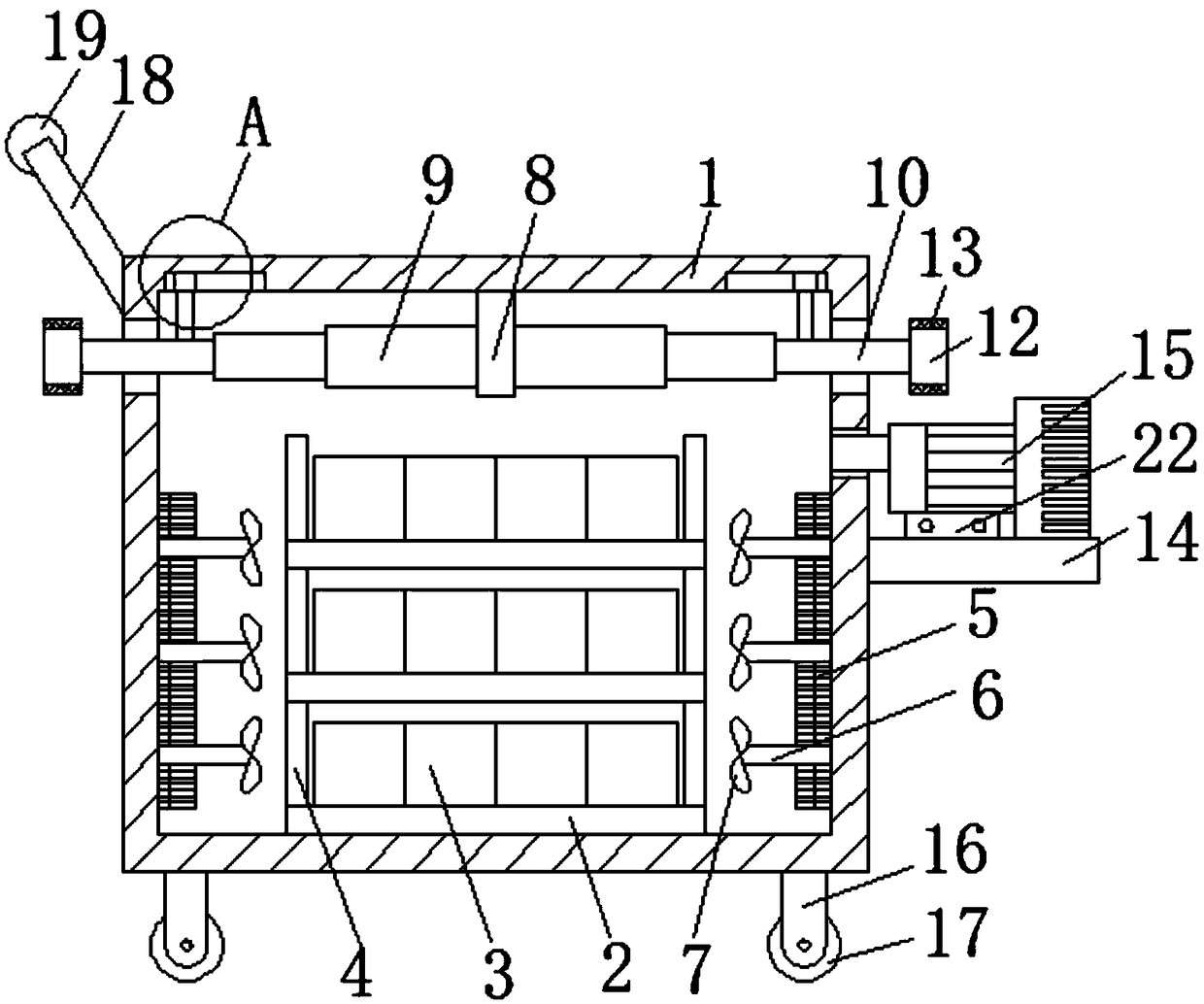

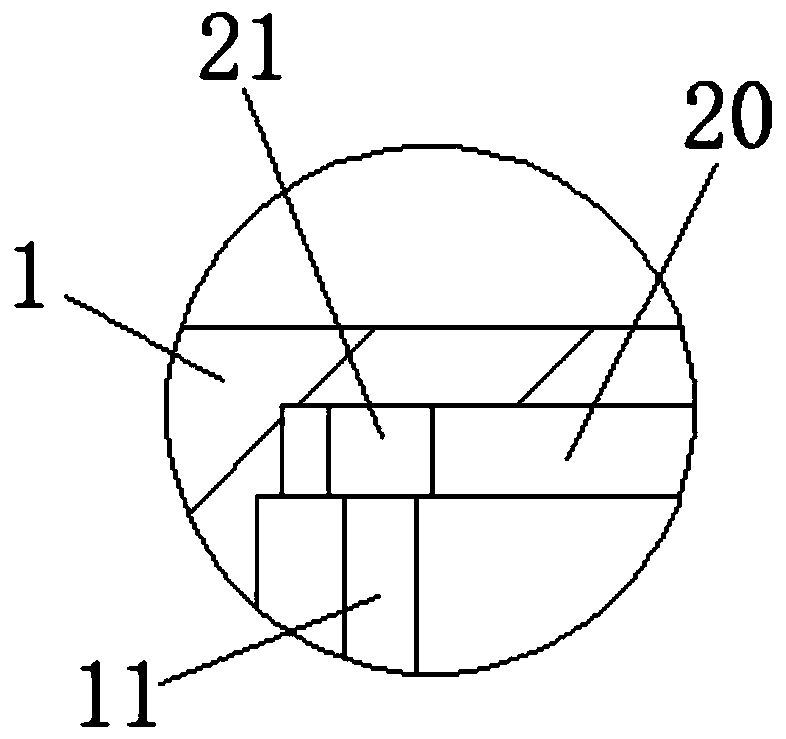

The invention discloses a food package vacuum sealing machine which comprises a worktable. A rail box is fixedly installed on the worktable. A rail groove is formed in the rail box. A sliding block isinstalled in the rail groove in a sliding manner, and multiple fixing rods are symmetrically fixedly installed at the lower end of the sliding block. A sealing plate is commonly fixedly installed atthe lower ends of the multiple fixing rods. The sealing plate is provided with a clamping sealing mechanism and a hot sealing mechanism. By means of the food package vacuum sealing machine, the sliding block is used for driving the clamping sealing mechanism and the hot sealing mechanism to move vertically, packaging bags with different height sizes can be subjected to vacuum sealing, an air guidepipe and the packaging bags can be sealed more tightly through the clamping sealing mechanism, vacuum pumping operation can be conducted conveniently, the hot sealing mechanism is used for driving aheating sealing bar to clamp the packaging bags for sealing through rotation of clamping plates, the speed is high, sealing is firm, the structures of the clamping sealing mechanism and the hot sealing mechanism are simple, the size is small, compared with a vacuum cavity, the occupied area is smaller, the cost is lower, and low-cost investment is facilitated.

Owner:何明

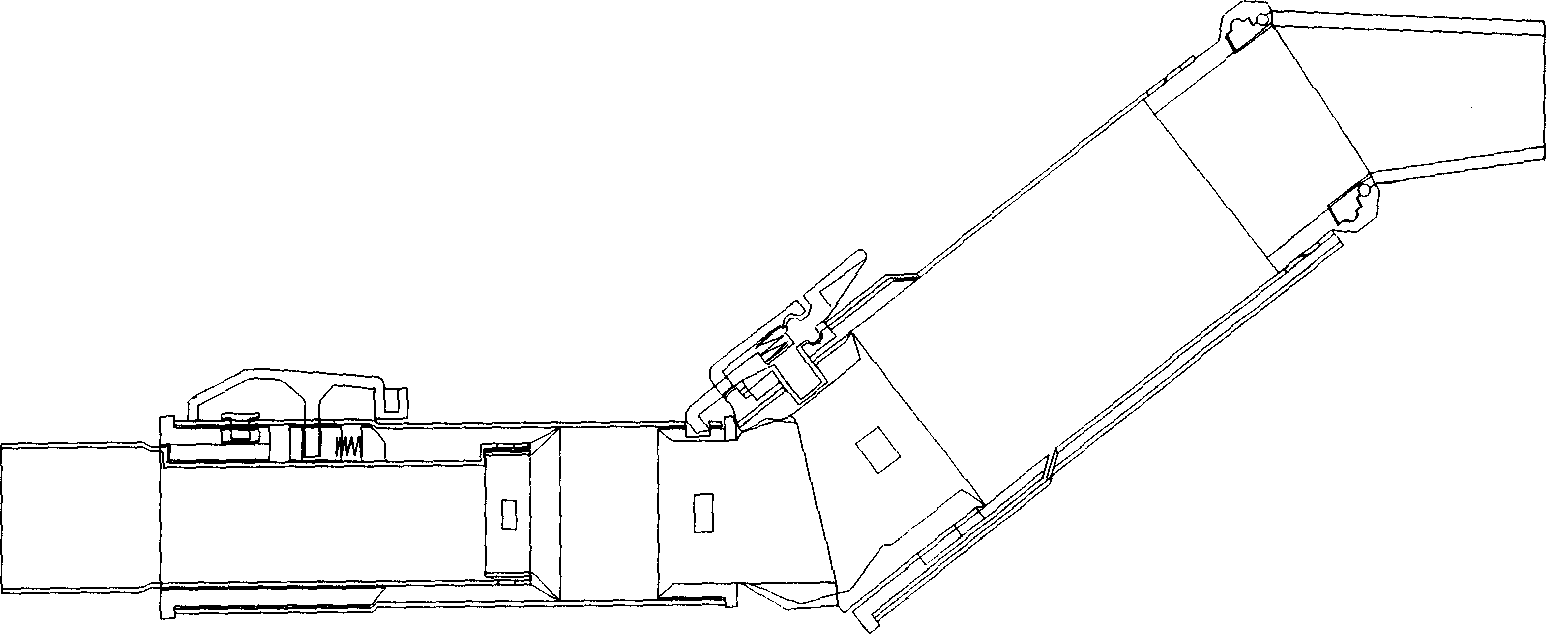

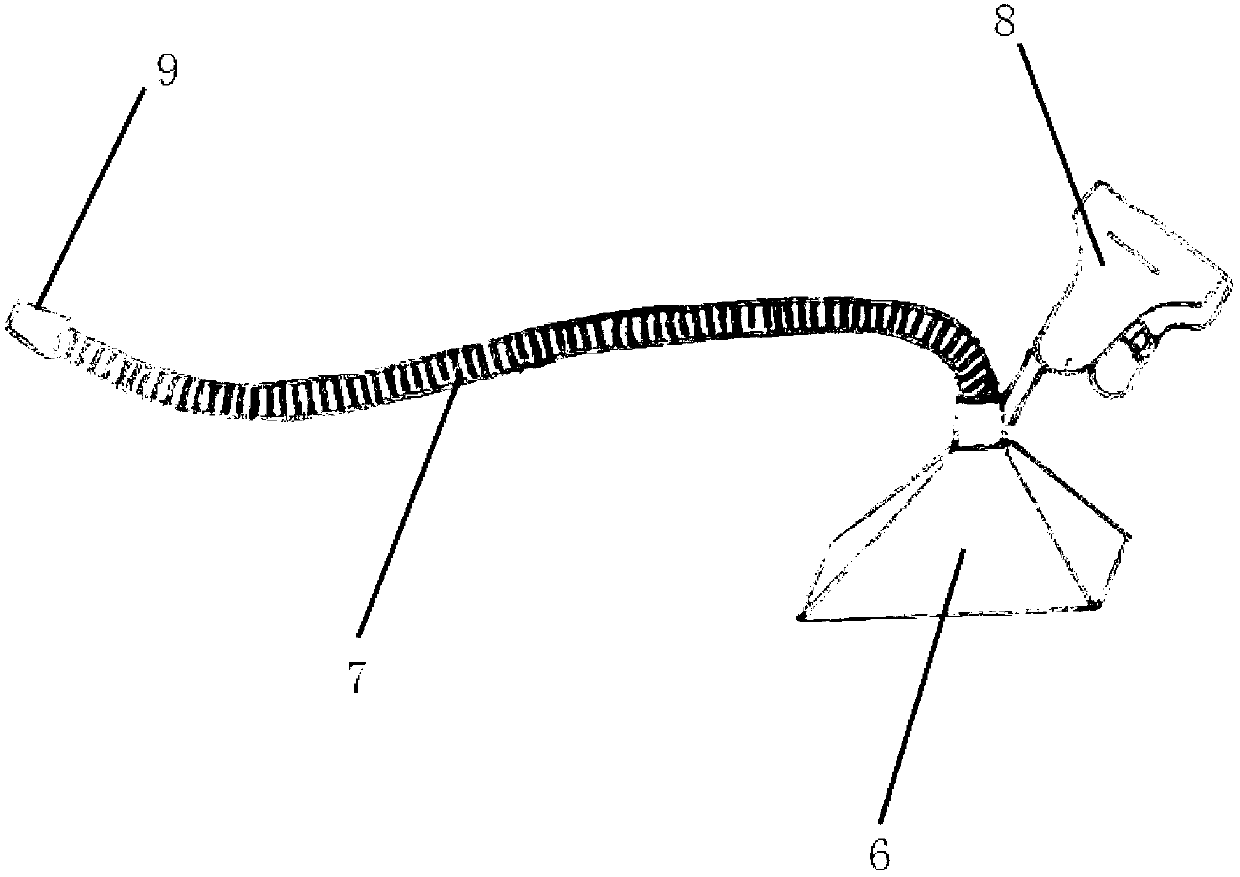

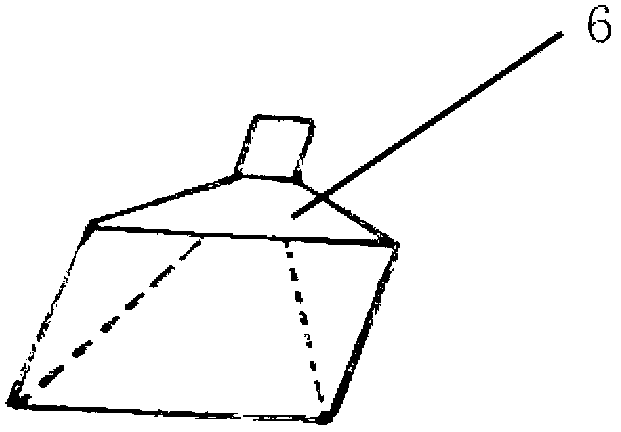

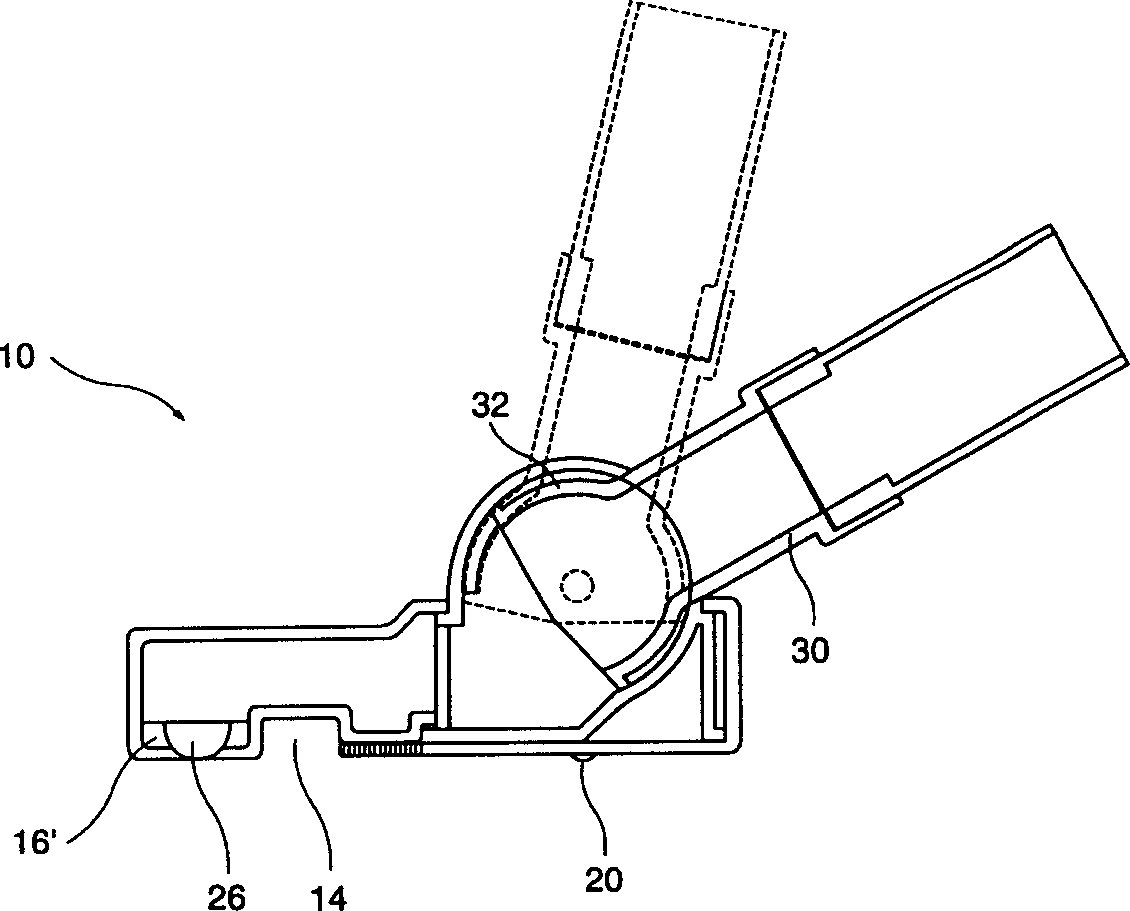

Universal vacuum cleaner telescopic tube

The present invention relates to a kind of telescopic tube locking mechanism in improved structure for vacuum cleaner, and belongs to the field of household appliance technology. The universal telescopic tube locking mechanism for vacuum cleaner includes at least two sections of telescopic inner tube and outer tube with locking mechanism in between. The improved structure has spherical hinge pair comprising one hinge ball in one end of the inner tube and one hinge sleeve inserted inside the outer tube. After the inner tube is withdrawn from the outer tube, the axial inclination angle between two tubes may be regulated through the spherical hinge structure for convenient dust collecting operation in different positions.

Owner:沈盘根

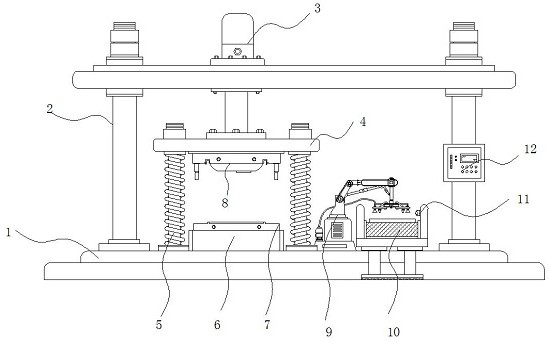

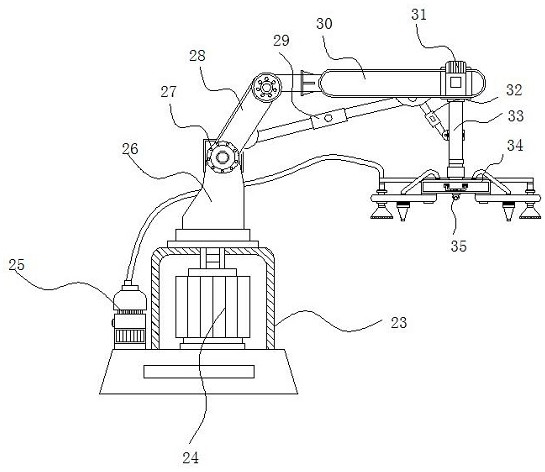

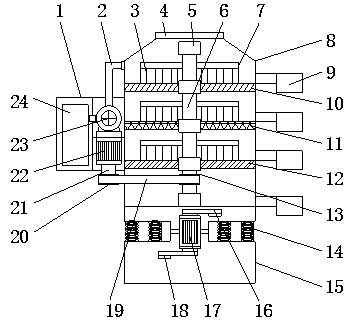

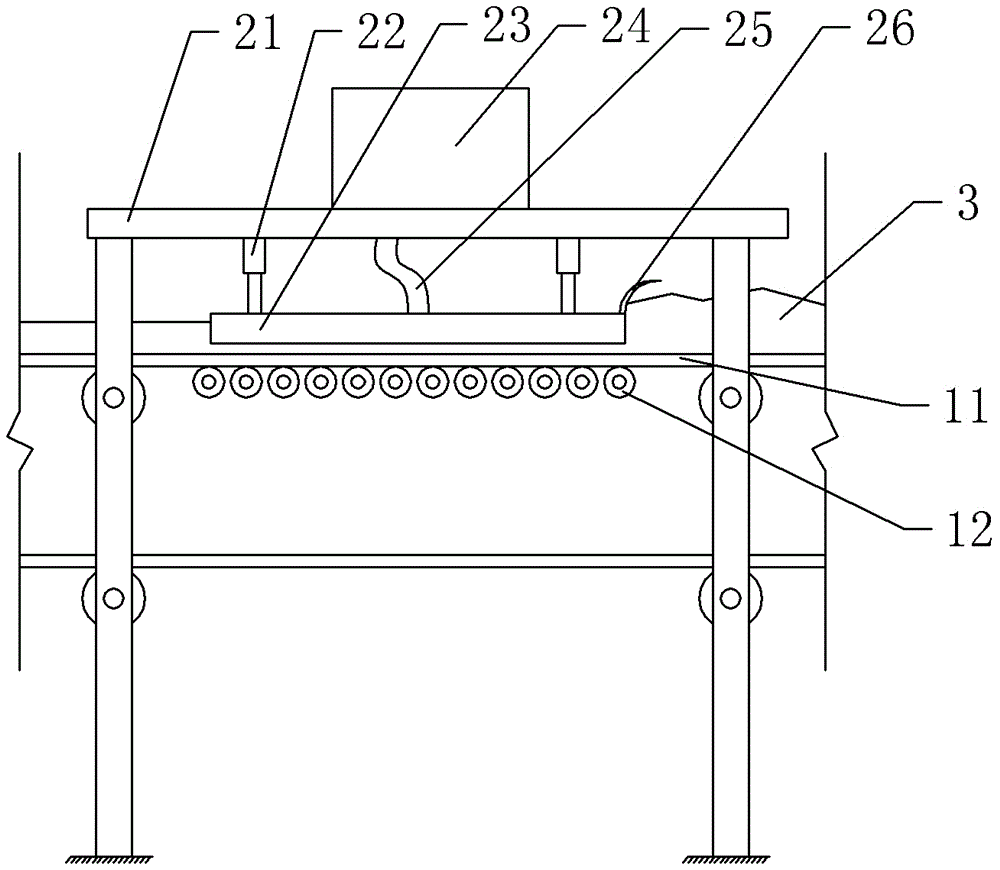

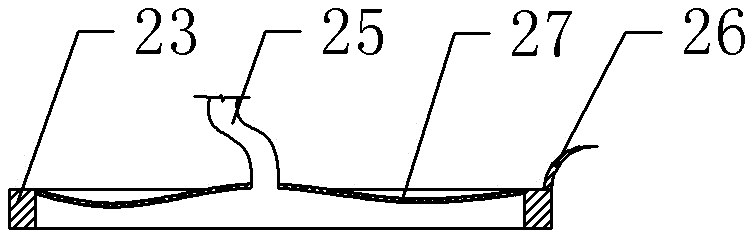

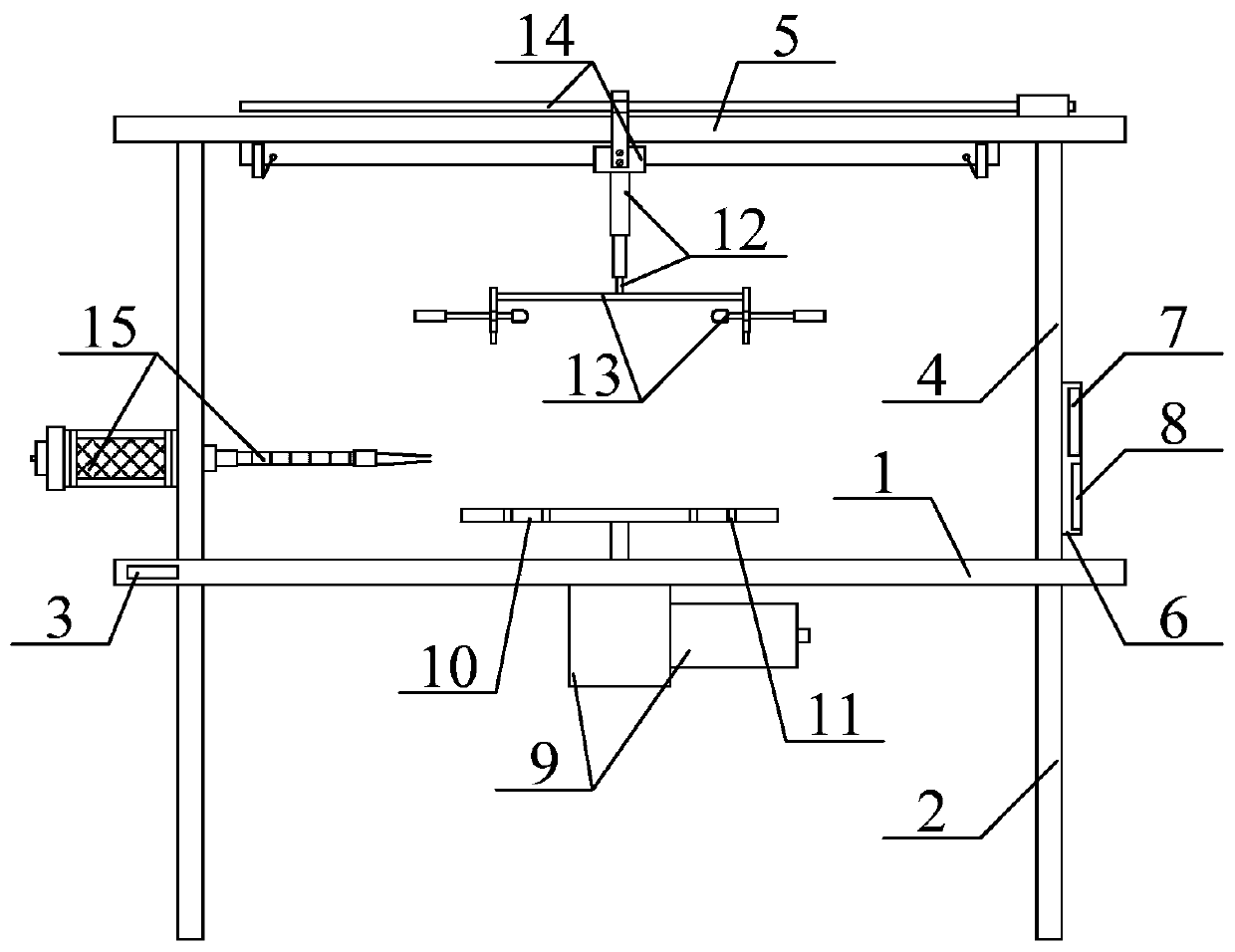

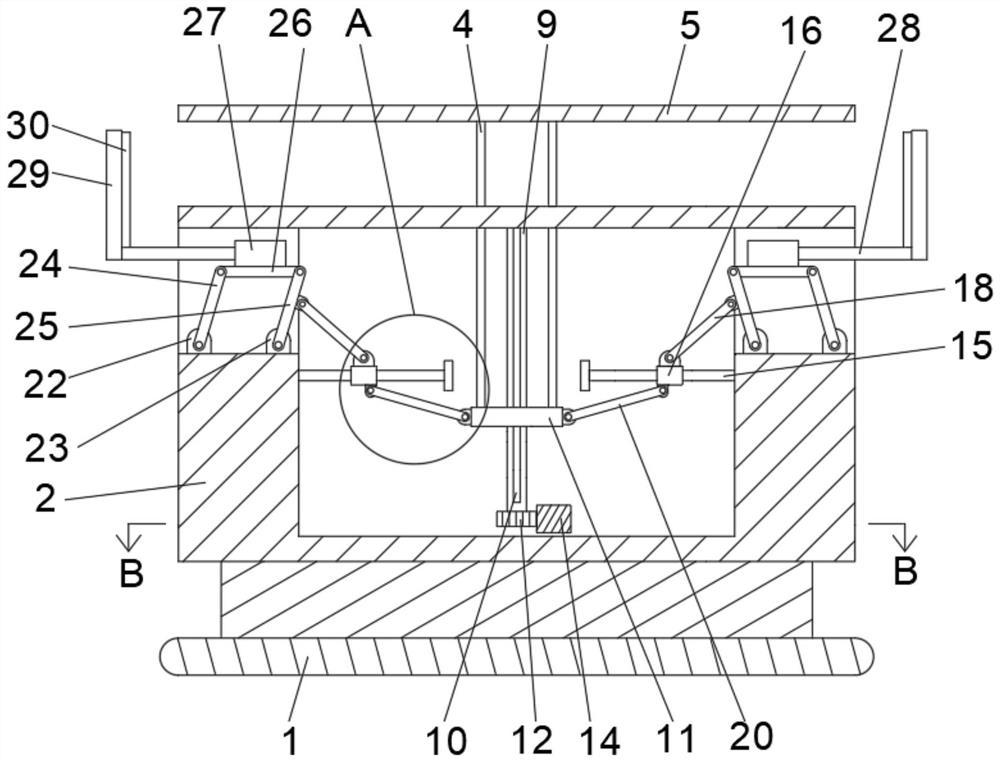

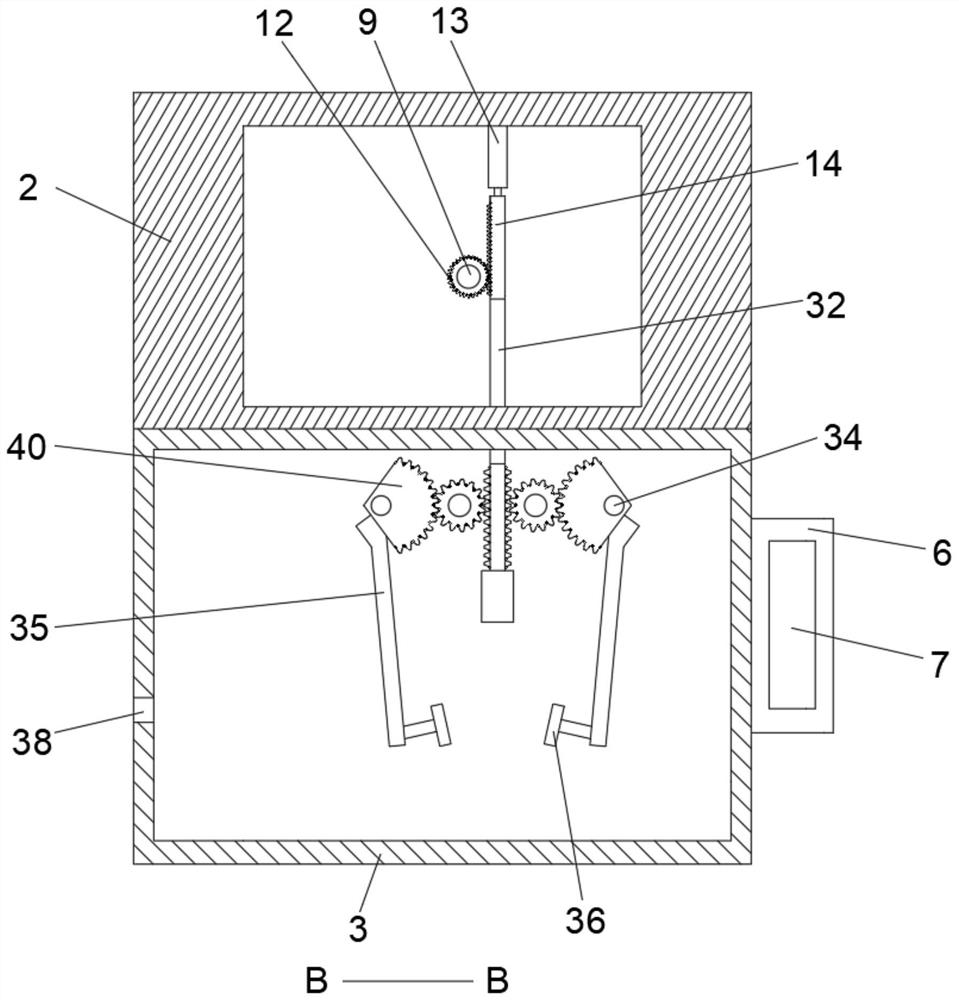

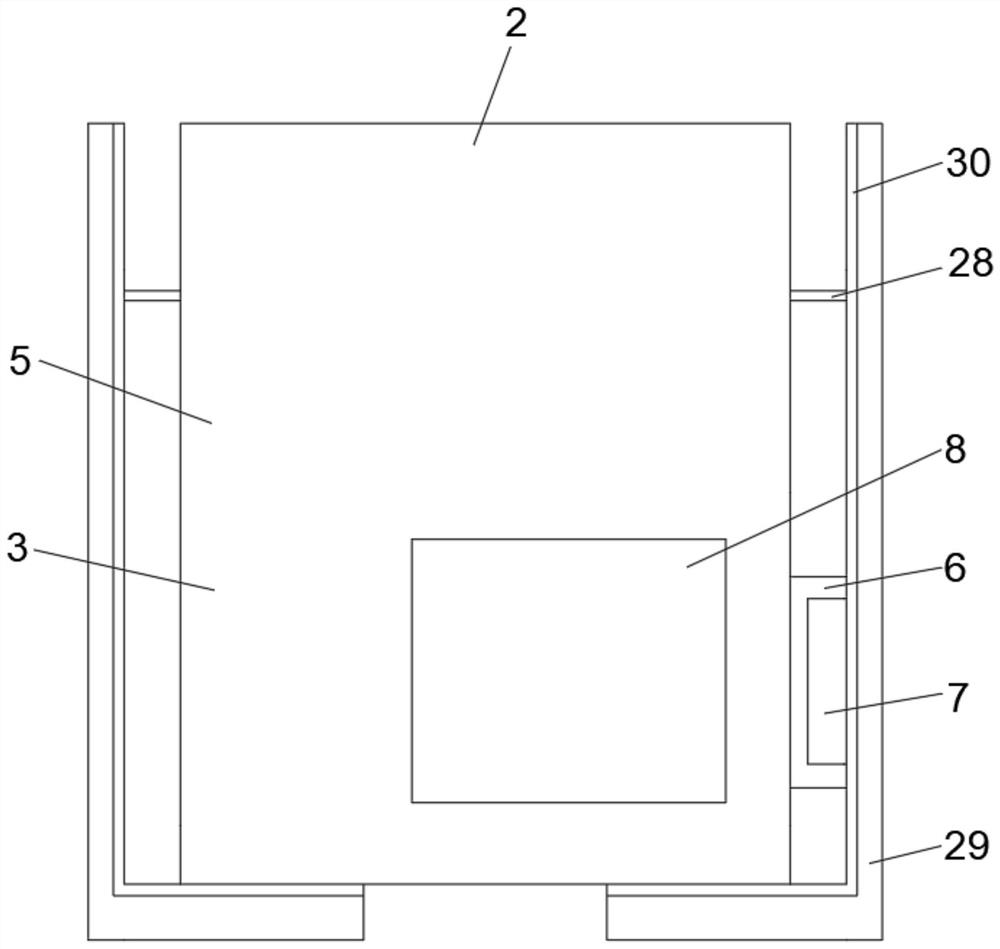

Automobile roof hot-press forming device with edge cutting function and automatic discharging function

InactiveCN112060552AEase of mass productionEasy to useDirt cleaningDomestic articlesHydraulic cylinderStructural engineering

The invention discloses an automobile roof hot-press forming device with an edge cutting function and an automatic discharging function. The automobile roof hot-press forming device specifically comprises a base, a lower die, an upper die, a transferring mechanism and a mounting arm, wherein a frame body is arranged at the top end of the base, and a control face plate is fixed to the middle position of one side of the frame body; and a hydraulic cylinder is arranged on the side, far away from the control face plate, of the top of the frame body, a pressing plate is arranged at the output end of the hydraulic cylinder, stamping guide columns penetrate through the four corners of the pressing plate, and the bottom ends of the stamping guide columns are connected with the base. According to the automobile roof hot-press forming device with the edge cutting function and the automatic discharging function, the transferring mechanism and a conveying belt are arranged, the transferring mechanism can suck materials to be hot-pressed through vacuum suckers and transfer the materials to be hot-pressed into a forming groove to achieve automatic feeding, formed automobile roofs can be automatically transferred back to the conveying belt to be conveyed out after hot pressing is completed, and manual carrying is not needed in the whole process, so that use is more convenient, and batch production of the automobile roofs is more convenient.

Owner:东莞市达盛机电设计有限公司

Rotaryvibration sieve for building garbage screening with anti-blocking function

InactiveCN108554799AWith anti-clogging functionAvoid cloggingSievingScreeningDrive wheelSecond screen

The invention discloses a rotary vibration sieve for screening building garbage with anti-blocking function, which comprises a base, wherein a first screen, a second screen, a third screen are arranged inside amounting shell, a first fixing rod is arranged on the connecting rod above the first screen, the second screen and the third screen, a second fixing rod is arranged on the first fixing rod,adriven wheel is arranged on the connecting rod below the third screen, a protective shell is arranged on one side of the mounting shell, a motor is arranged inside the protection shell,the output endof the motor is provided with a driving wheel through a rotating shaft,the driving wheel is connected with the driven wheel through a belt; a dust suction machine is arranged inside the protective shell above the motor, and a dust collecting box is arranged inside the installation shell on one side of the motor.The rotary vibration solves the problems of no blockage and no internal dust removal by arranging the motor, the first fixing rod, the second fixing rod, the vacuum cleaner and the dust collecting box structure.

Owner:XINXIANG DONGZHEN MACHINERY

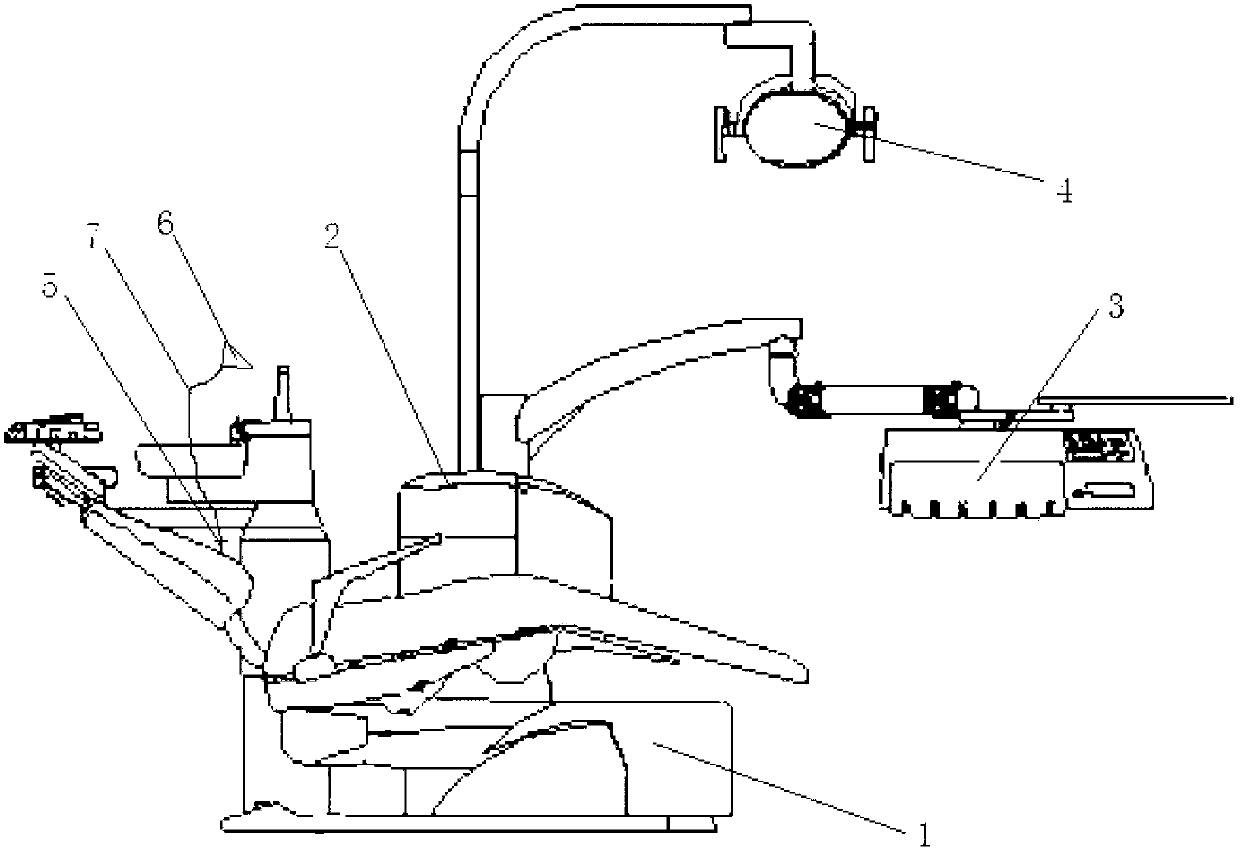

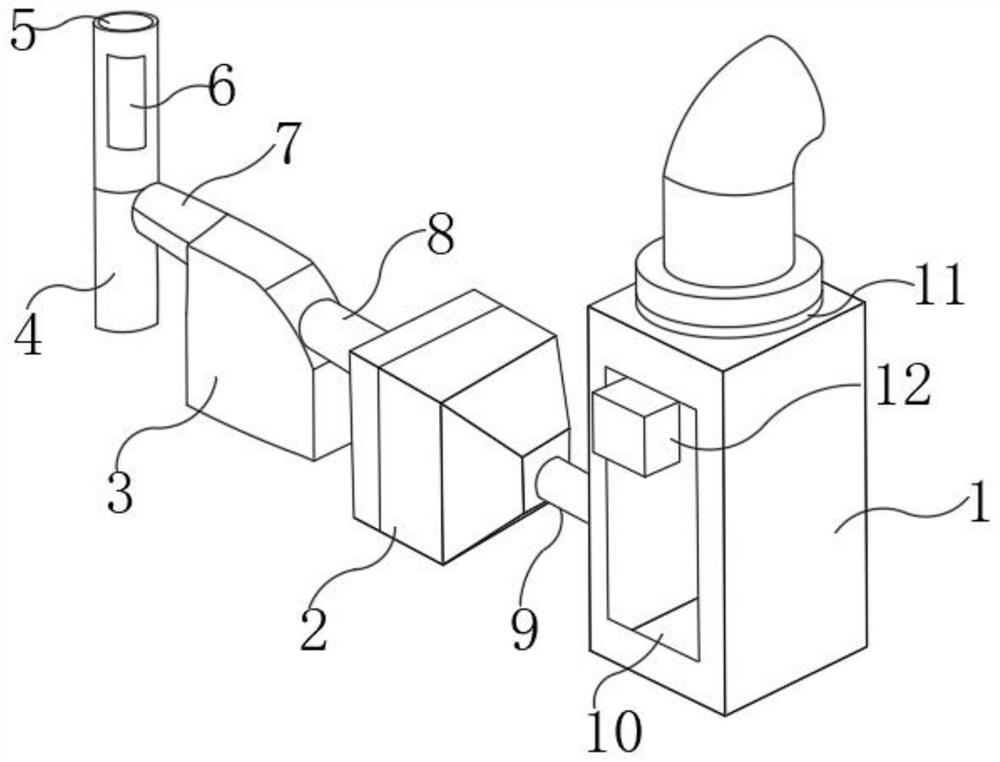

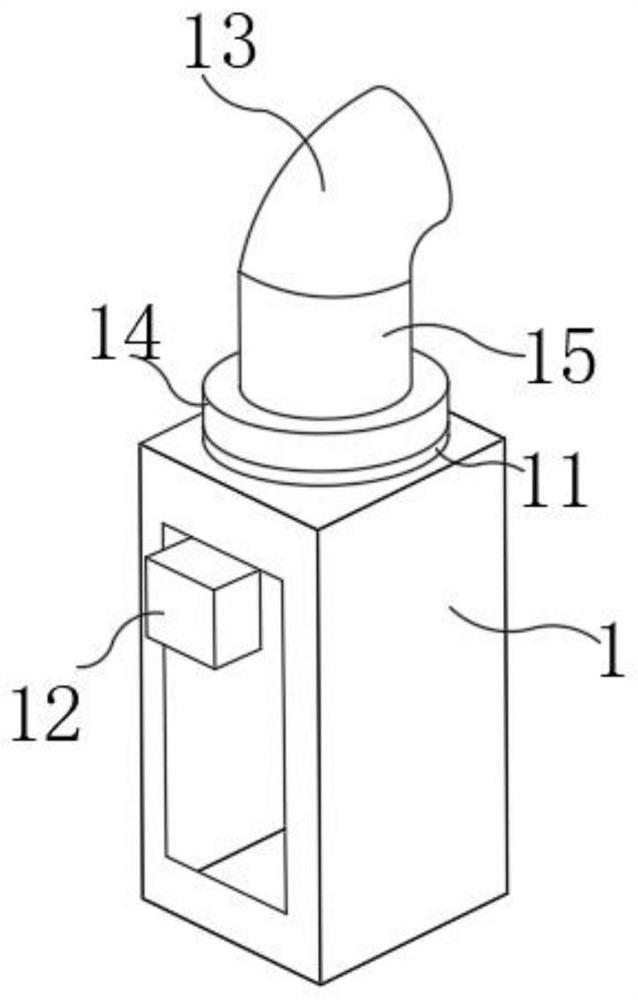

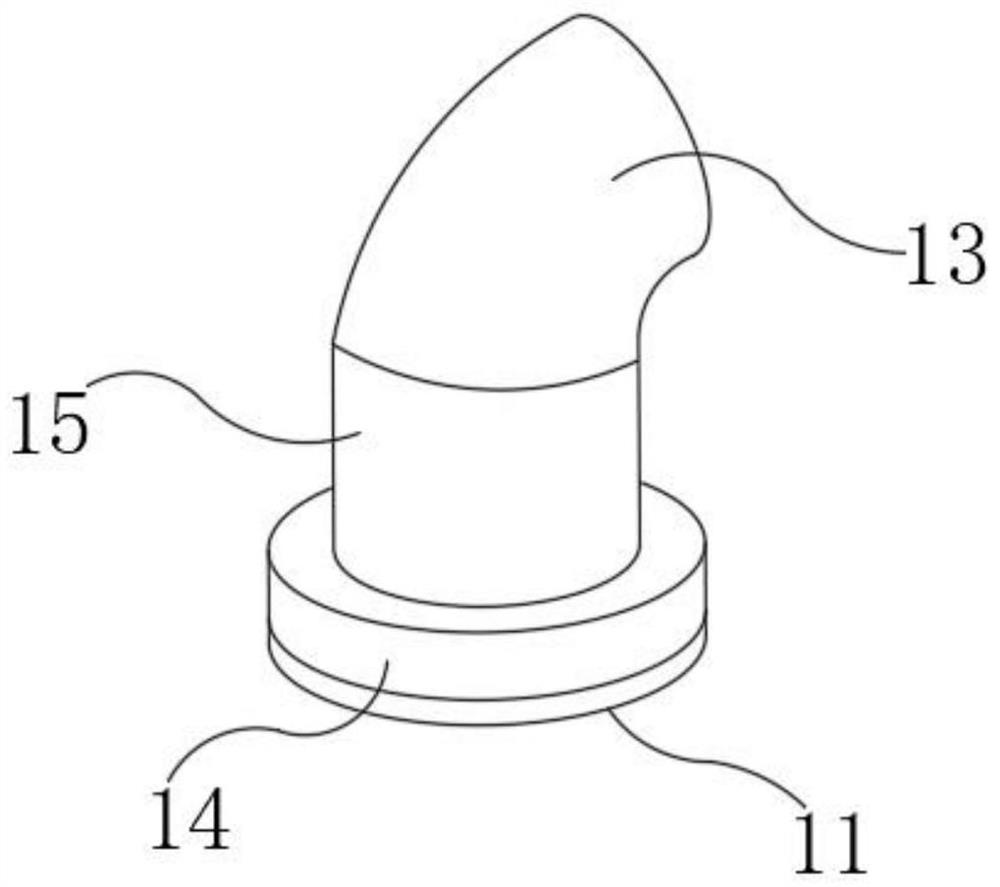

Dental chair with dust hood

InactiveCN103126848AEasy to vacuumReduce volumeOperating chairsDental chairsDental chairInstrument tray

The invention discloses a dental chair with a dust hood and overcomes the defects that a vacuum cleaner is big in size, inconvenient to move and high in noise, and the utilization rate of a high negative pressure absorption pipeline is low. The structure of the dental chair with the dust hood comprises a dental chair body, a side box, an instrument tray and an oral cavity cold light lamp, wherein the side box is provided with the high negative pressure absorption pipeline. The dental chair with the dust hood further comprises the dust hood, and the dust hood is connected with the high negative pressure absorption pipeline through a wind pipe. The reversed side of the dust hood is provided with a clamp holder, and the dust hood can be directly fixed on a treatment platform through the clamp holder. The high negative pressure absorption pipeline is fully used by the dental chair with the dust hood, the dust can be absorbed conveniently, and the vacuum cleaner is small in size, low in noise, convenient to move and obvious in dust absorption effect. The dental chair with the dust hood is suitable for promotion and application in oral clinics.

Owner:SHANDONG UNIV

Nano antibacterial coating impregnation device and method for wooden furniture products

ActiveCN113560120AImprove impregnation efficiencyShorten heating timeSpraying apparatusPretreated surfacesAnti bacteriaMechanical engineering

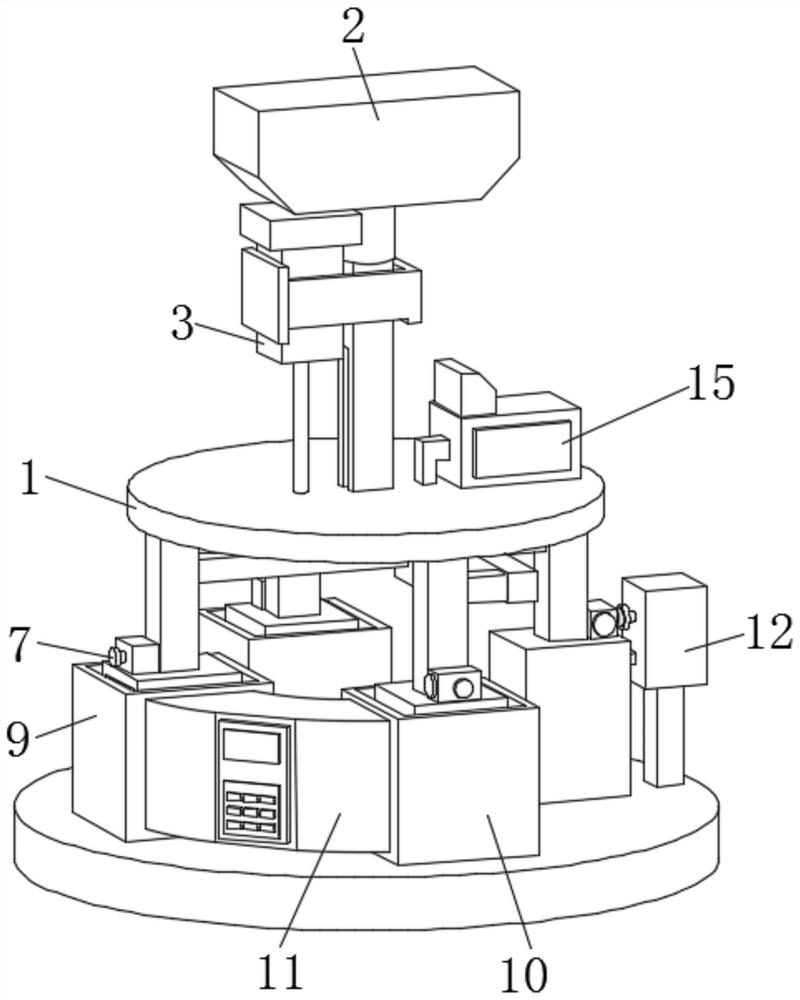

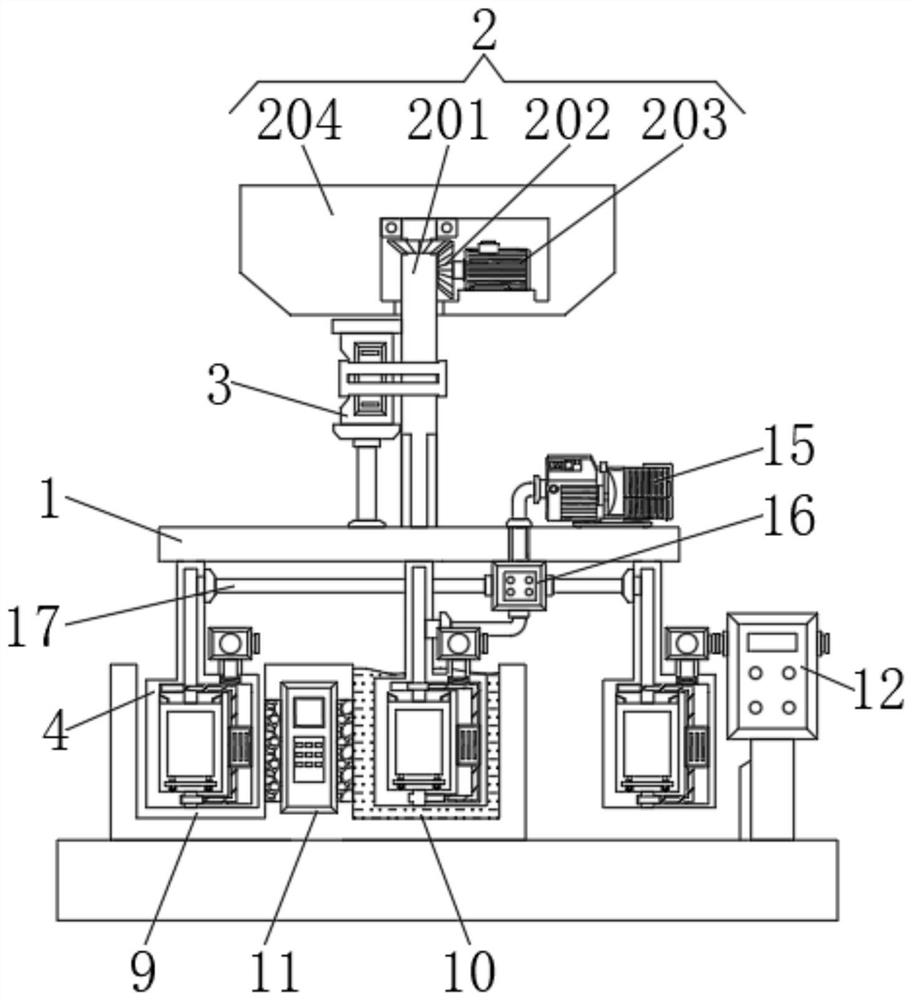

The invention discloses a nano antibacterial coating impregnation device and method for wooden furniture products. The nano antibacterial coating impregnation device comprises a rotary disc, wherein the upper end of the rotary disc is connected with a rotary mechanism; the rotary mechanism comprises a rotary rod; an air inlet of a draught fan is movably connected with an air outlet of a refrigerator in a contact manner; an air connection pipe is mounted at the bottom end of a position, located on the refrigerator, of a placement box; the air connection pipe communicates with a pre-heating groove through an air pipe; and a conveying platform is correspondingly arranged above the pre-heating groove. According to the nano antibacterial coating impregnation device disclosed by the invention, the rotary disc, the rotary mechanism and the placement box are arranged; four sets of placement boxes can be subjected to cyclic division processing, and heating, impregnation, cooling and pre-heating are carried out at the same time, so that the impregnation efficiency of furniture is effectively improved; the air pipe communicates with the pre-heating groove, so that the furniture is pre-heated on one hand and the heating time is further reduced; and on the other hand, waste heat of cooling can be recycled and utilized, so that the impregnation efficiency is improved and the impregnation cost is also reduced.

Owner:福建品家竹品科技有限公司

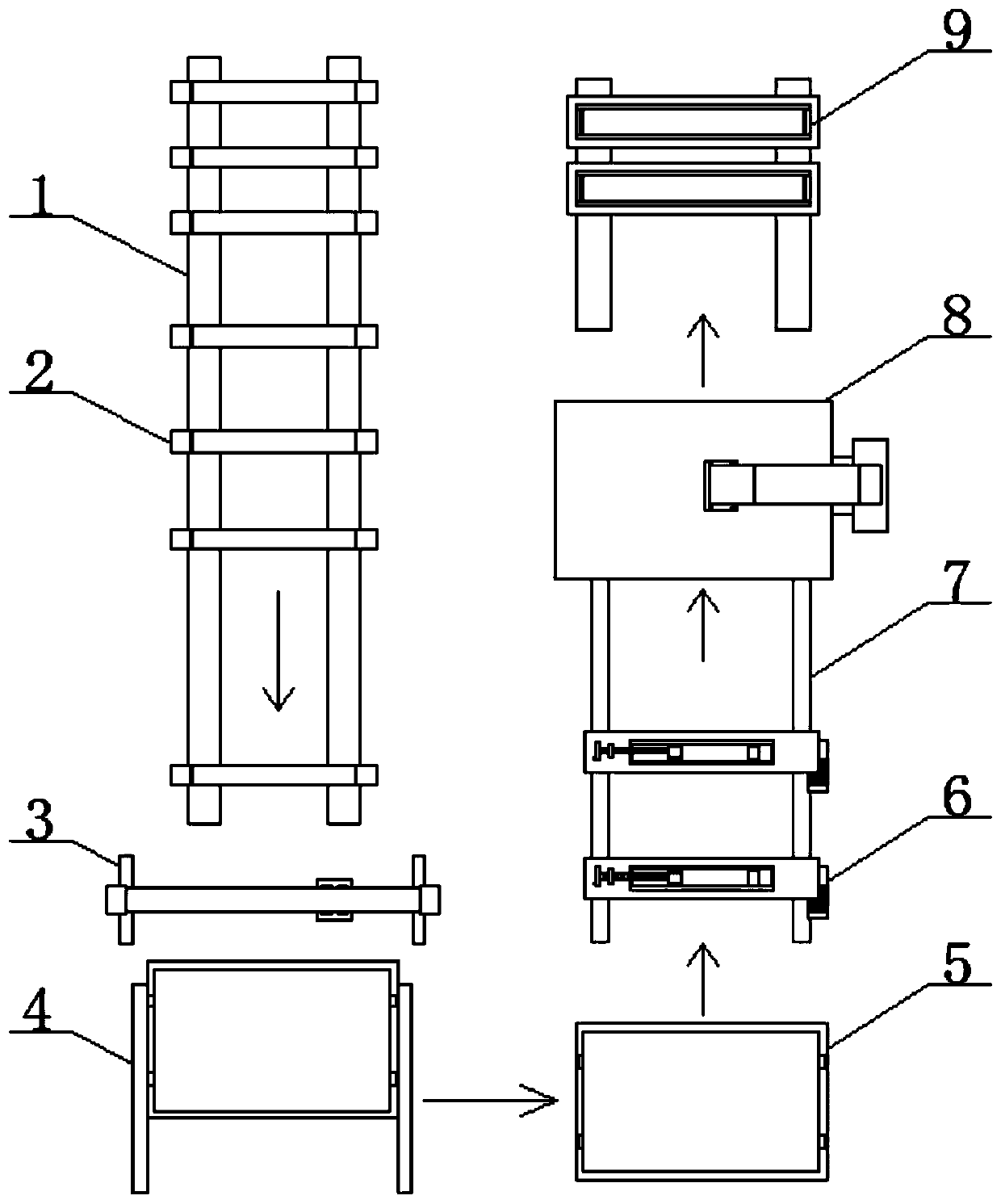

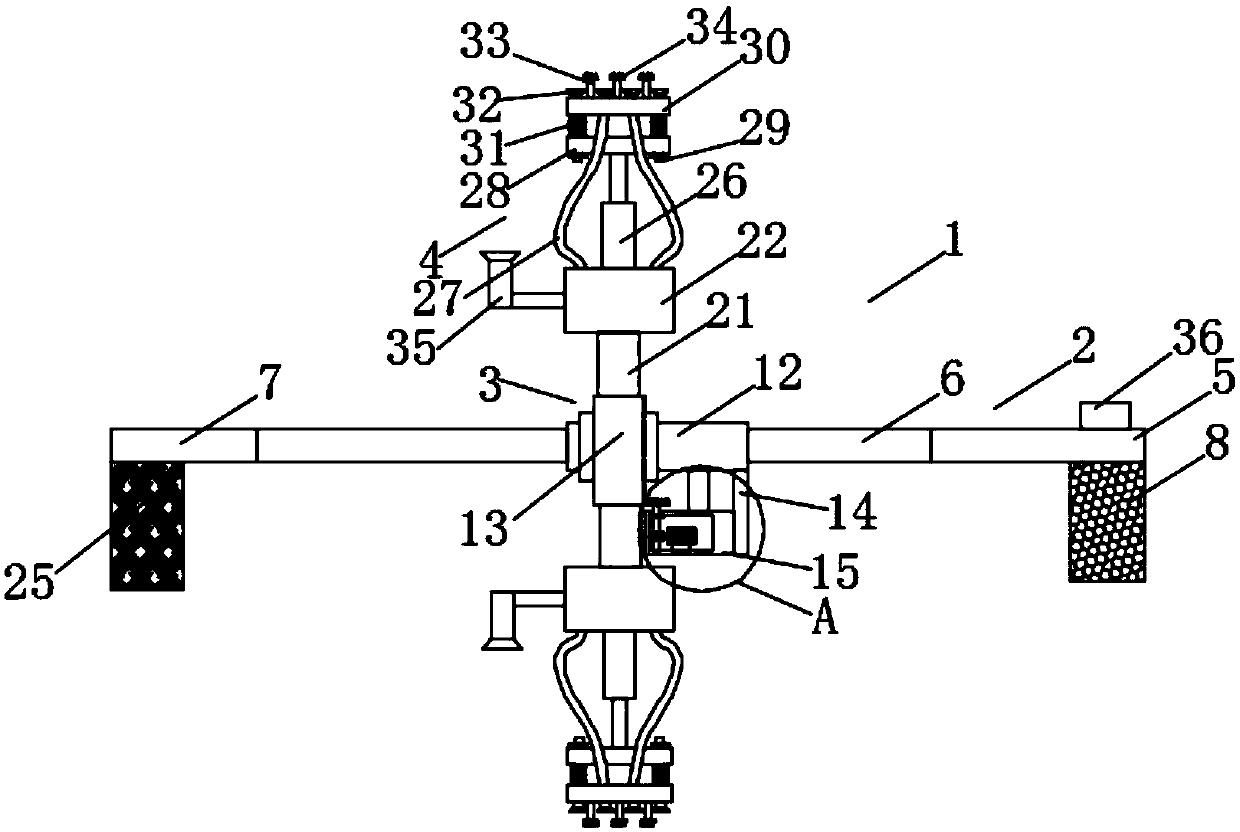

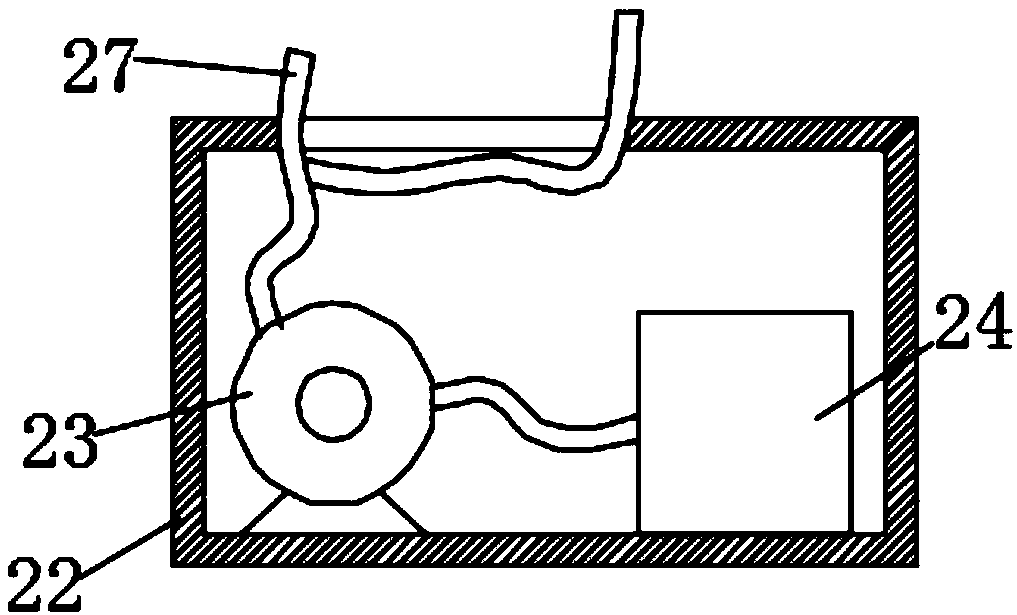

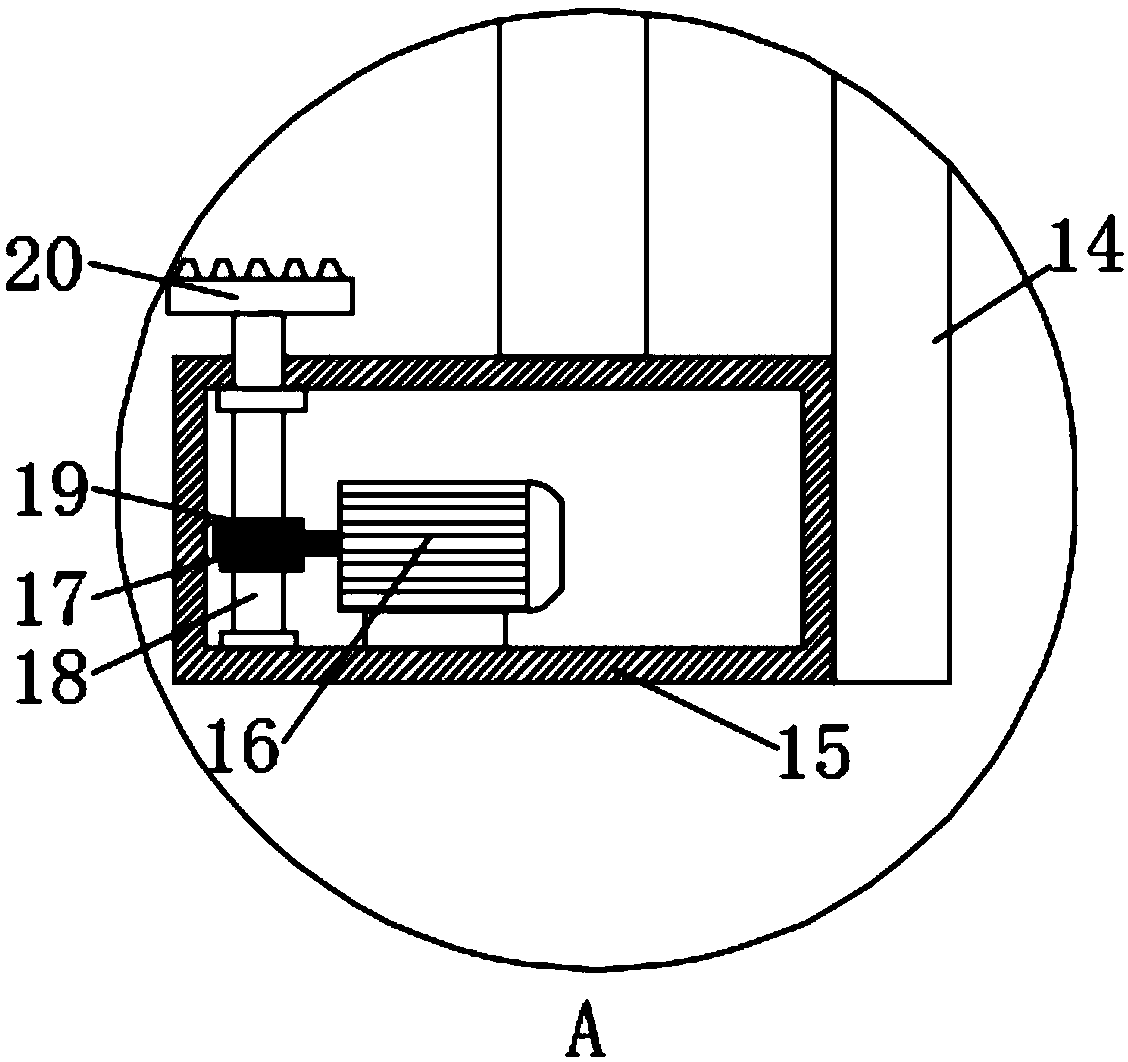

Anti-oxidation treatment production system for anti-oxidation graphite electrode by applying anti-oxidation liquid

InactiveCN110280441AEven heat dissipationEvenly dispersedPretreated surfacesCoatingsGraphite electrodeOxidation resistant

The invention discloses an anti-oxidation treatment production system for an anti-oxidation graphite electrode by applying anti-oxidation liquid. The anti-oxidation treatment production system for the anti-oxidation graphite electrode by applying the anti-oxidation liquid comprises storing tracks and graphite electrode materials, and the graphite electrode materials are fixedly arranged on the storing tracks; and a gantry crane is arranged on the outer sides of the back ends of the storing tracks, a steeping device is arranged on the back side of the gantry crane, a vacuumizing device is arranged on the right side of the steeping device, transporting tracks are arranged on the front side of the vacuumizing device, transporting carts are arranged on the transporting tracks, and then the graphite electrode material anti-oxidation treatment production system is formed through the storing tracks, the gantry crane, the steeping device, the vacuumizing device, the transporting carts, the transporting tracks, a graphite electrode drying room and a finished product packaging area. Therefore, through cooperative work of different machines, the working intensity of personnel is reduced; and in addition, anti-oxidation treatment production is conducted on the regular flowing condition, the production efficiency is improved, and the very good market competitiveness is achieved in treatment production.

Owner:江苏神州万隆节能环保科技有限公司

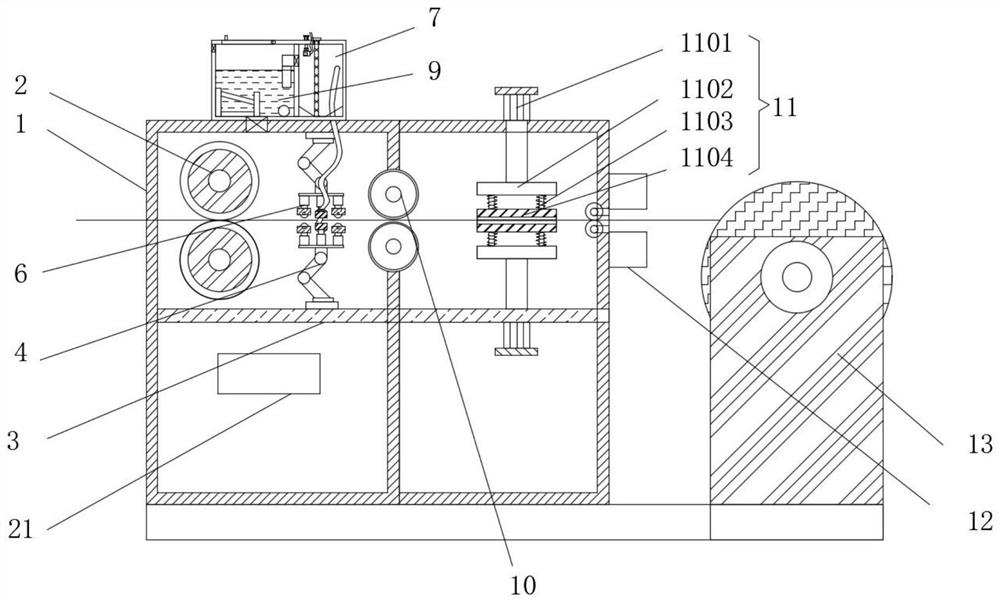

Feeding device for glass production

The invention discloses a feeding device for glass production. The feeding device includes a raw material belt conveyor, the raw material belt conveyor includes a rack and a conveying belt, the raw material belt conveyor includes a stepping motor driving the conveying belt to rotate, a compaction mechanism is disposed above the conveying belt, and the compaction mechanism includes a support frame, a vacuum pumping machine, telescopic parts and a pressing part, the support frame is in fixed connection with the rack, the vacuum pumping machine is fixedly mounted on the support frame, the pressing part is located right above the conveying belt, the pressing part includes a connecting frame and a flexible film, the flexible film is in seal connection with the connecting frame, the telescopic parts are located between the support frame and the connecting frame, and the vacuum pumping machine and the flexible film are connected by a duct. The feeding device for glass production provided by the invention the problem that in the prior art the conveying belt can be easily damaged under a large mechanical pressure, and prolongs the service life of the conveying belt.

Owner:CHONGQING HECHUAN JINXING GLASS PROD CO LTD

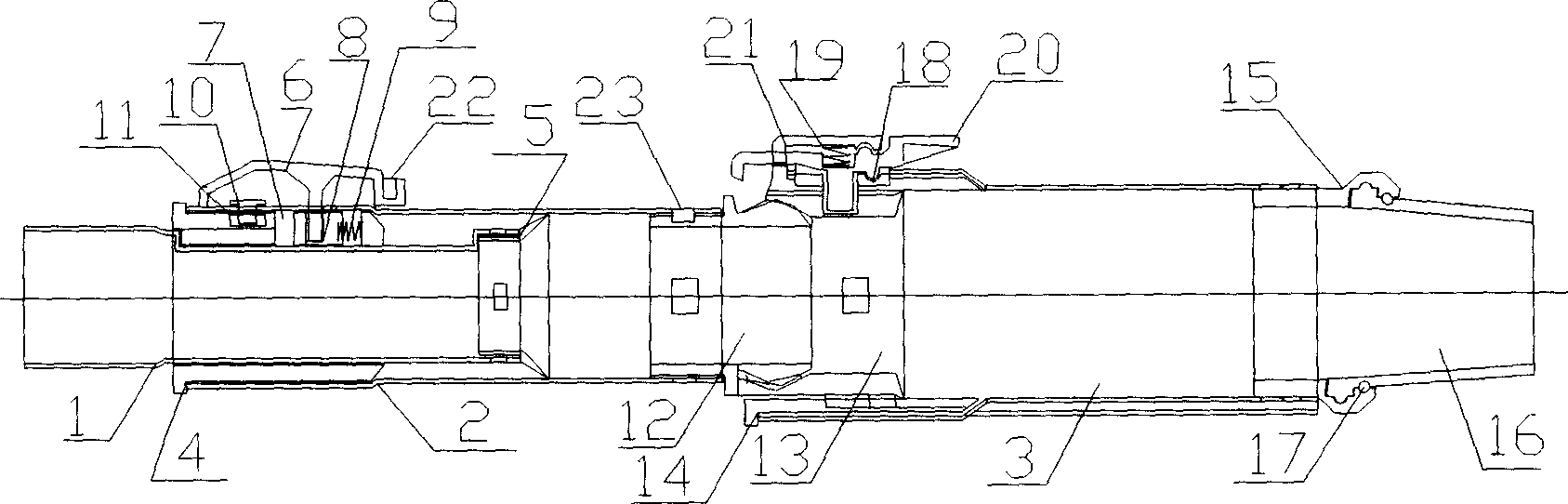

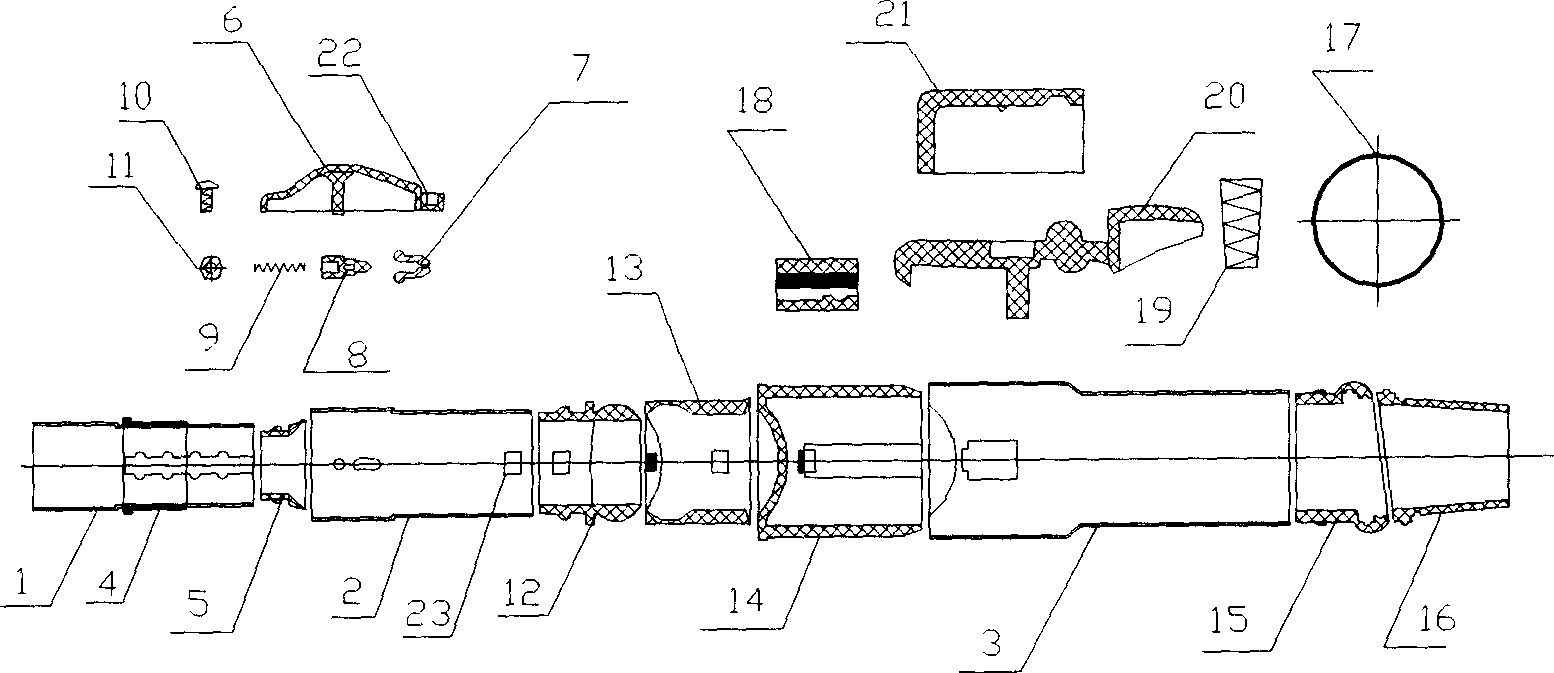

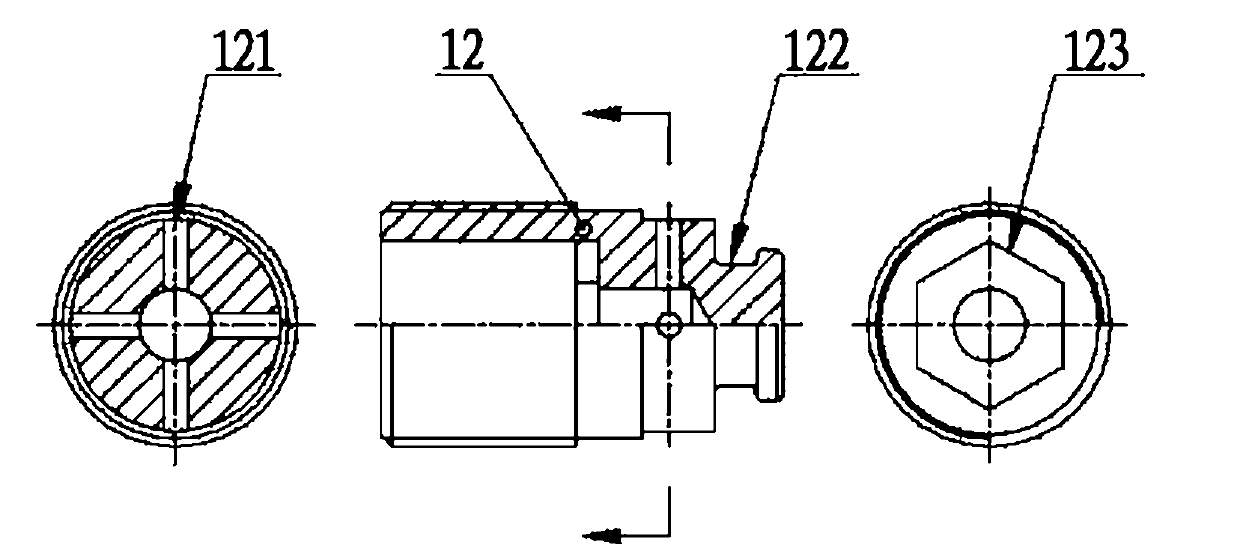

Sealing bayonet device for vacuumizing

The invention discloses a sealing bayonet device for vacuumizing, which consists of an air exhaust tap and an operation wrench, wherein the air exhaust tap is arranged on equipment to be vacuumized and comprises an air exhaust tap seat, a screwed plug and a rubber ring; and the operation wrench comprises an exhaust tube, a magnetic steel shaft, a magnetic steel sleeve, a bearing block, a bearing cap, a bearing, a sealing ring, and the like. The left end of the operation wrench is connected with a vacuum pump; and the right end of the operation wrench is connected with the air exhaust tap by a threaded compressed sealing ring in a sealing manner. The magnetic steel sleeve in the atmosphere environment is turned, the magnet steel shaft inside the exhaust tube is driven by a magnetic force and the screwed plug is driven by a spline at the right end of the magnetic steel shaft to compress a rubber ring so as to seal a bayonet. After sealing, the exhaust tube is reversely turned to loose the threaded connection and separate the operation wrench from the air exhaust tap. The bayonet sealing by means of the device is carried out under a vacuum environment and can be repeatedly used multiple times; and the air exhaust tap can be separated from the operation wrench and has small size and light weight. The sealing bayonet device is especially suitable for realizing vacuumizing and bayonet sealing of space equipment such as control moment gyros, inertia momentum wheels, and the like.

Owner:BEIHANG UNIV

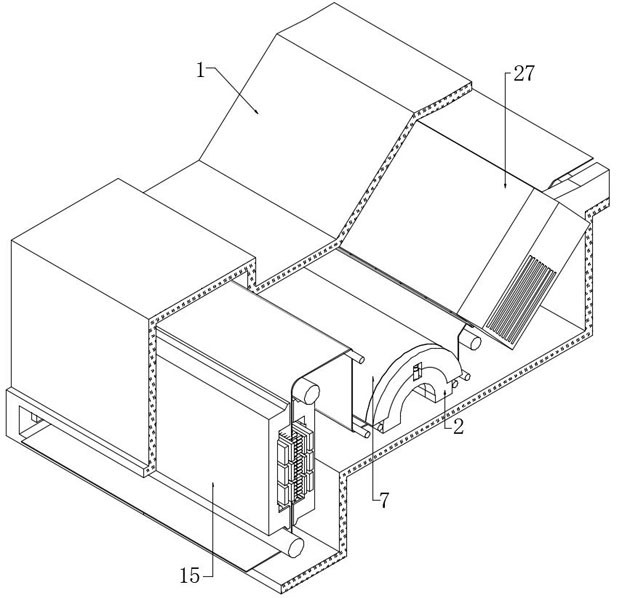

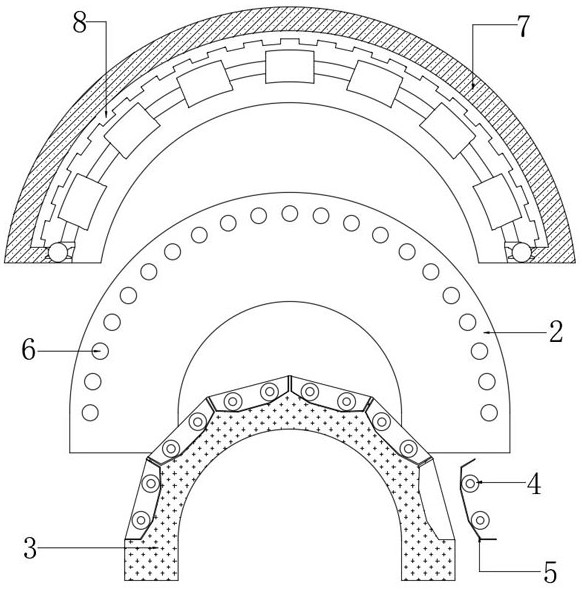

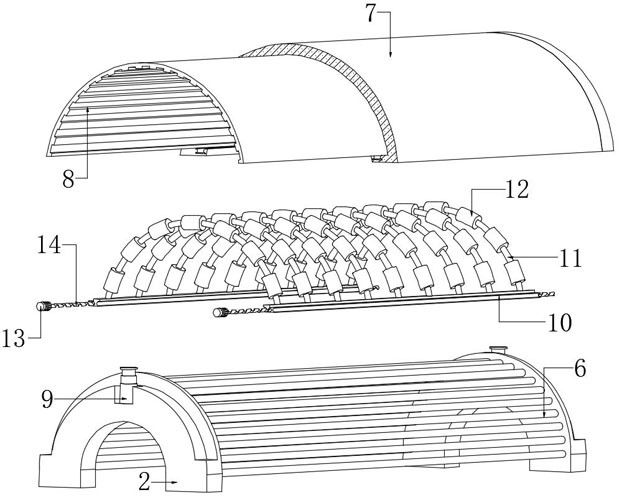

Steam sterilization device for furniture surface cloth production

ActiveCN113521325AIncrease temperatureIncrease humidityMechanical cleaningPressure cleaningInfrared lampProcess engineering

The invention belongs to the technical field of cloth production and processing, particularly relates to a steam sterilization device for furniture surface cloth production, and aims to solve the problems that the humidity of cloth is greatly increased, the follow-up drying process is slow, and the overall treatment efficiency of the cloth is reduced due to the fact that the surface wall temperature of the cloth is relatively low and steam is liquefied when cooled in the steam sterilization process. According to the scheme, the device comprises an outer box, a semicircular base is fixedly connected to the inner wall of the bottom of the outer box, a lamp box is fixedly connected between the inner walls of the two sides of the semicircular base, a plurality of grooves are circumferentially formed in the outer wall of the lamp box at equal intervals, and an infrared lamp tube is fixedly connected between the inner walls of the two sides of each groove. Cloth before steam sterilization is heated through the infrared lamp tubes, the temperature of the cloth is increased, and the situation that in the subsequent steam sterilization process, due to the fact that a large amount of steam is condensed and liquefied due to the low temperature of the surface of the cloth, the humidity of the cloth is greatly increased, the drying time after steam sterilization is prolonged, and the treatment efficiency of the cloth is reduced is avoided.

Owner:JIANGSU ZHONGSHI HOME TECH CO LTD

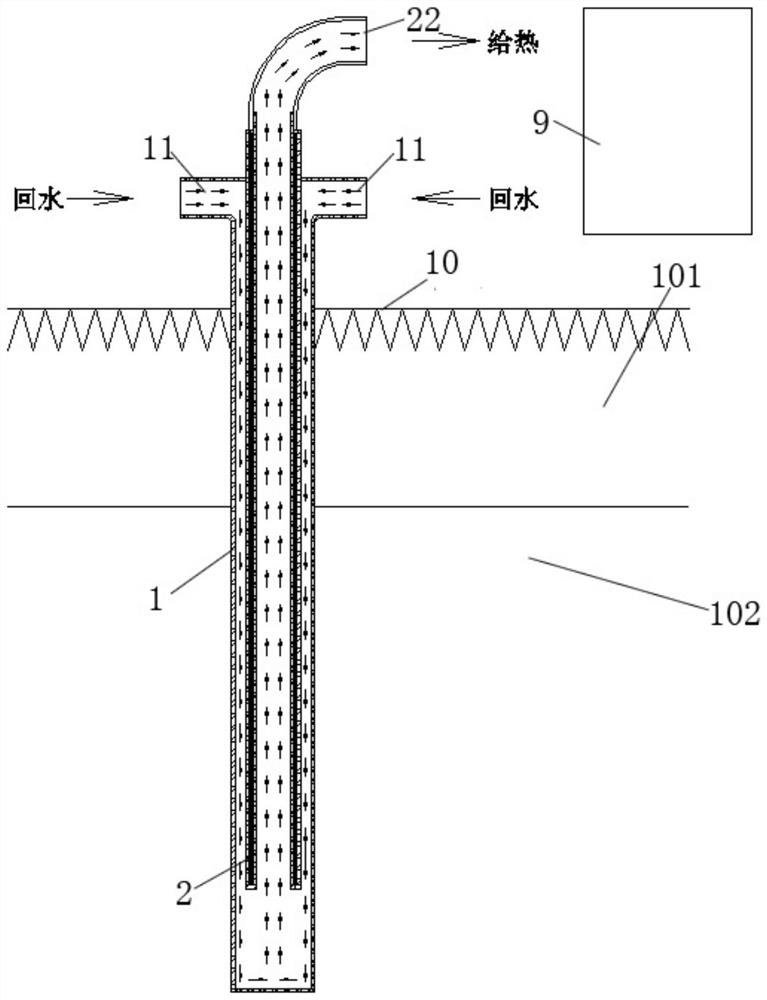

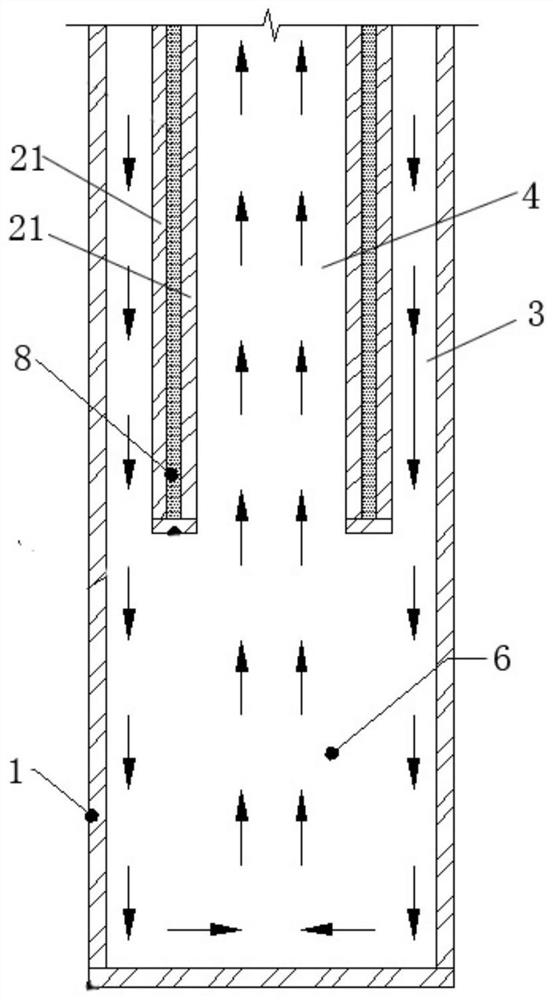

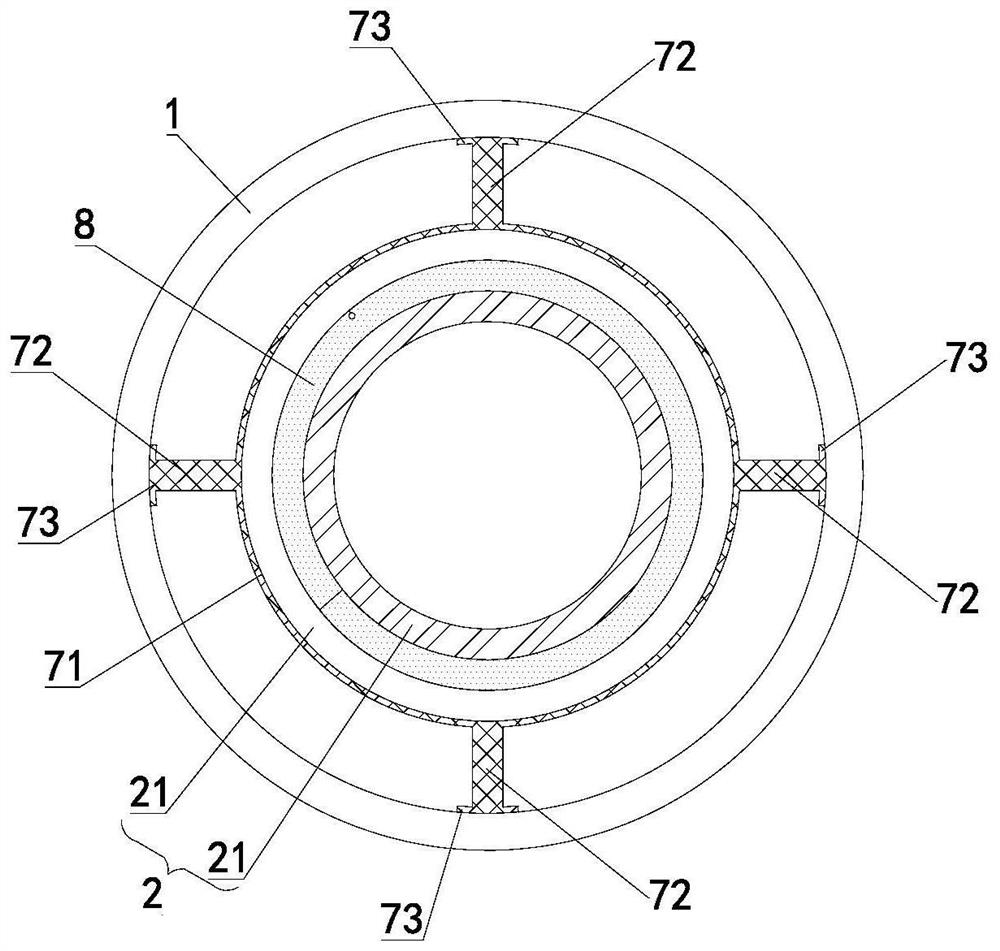

Multi-cavity heat insulation flow guide pipe with heat insulation structure and preparation method thereof

InactiveCN113790316AImprove utilization efficiencyHeating needs are highThermal insulationGeothermal energy generationEcological environmentEngineering

The invention relates to a multi-cavity heat insulation flow guide pipe with a heat insulation structure and a preparation method thereof, and belongs to the related technical field of heat insulation flow guide. The multi-cavity heat insulation flow guide pipe comprises an outer pipe and an inner pipe, the bottom of the outer pipe is of a sealed structure, and the top and the bottom of the inner pipe are of open structures; a first cavity is formed between the inner pipe and the outer pipe, the middle of the inner pipe is provided with an axially-through second cavity, the inner pipe is arranged in the outer pipe in a sleeved mode, a communication area is reserved between the bottom of the inner pipe and the bottom of the outer pipe, and the first cavity is communicated with the second cavity through the communication area; and a third cavity is formed between the inner side wall and the outer side wall of the inner pipe, the third cavity is a vacuum cavity, and a heat preservation material is sealed in the third cavity. The multi-cavity heat insulation flow guide pipe can be used for a medium-deep geothermal energy utilization system, the comprehensive utilization effects of small occupied area, low geothermal energy loss and zero influence on the ecological environment are achieved, the heating requirements of buildings and agriculture can be met without using high-grade energy for heat compensation, and the maximum utilization efficiency of geothermal energy is achieved.

Owner:北京千城集成房屋有限公司

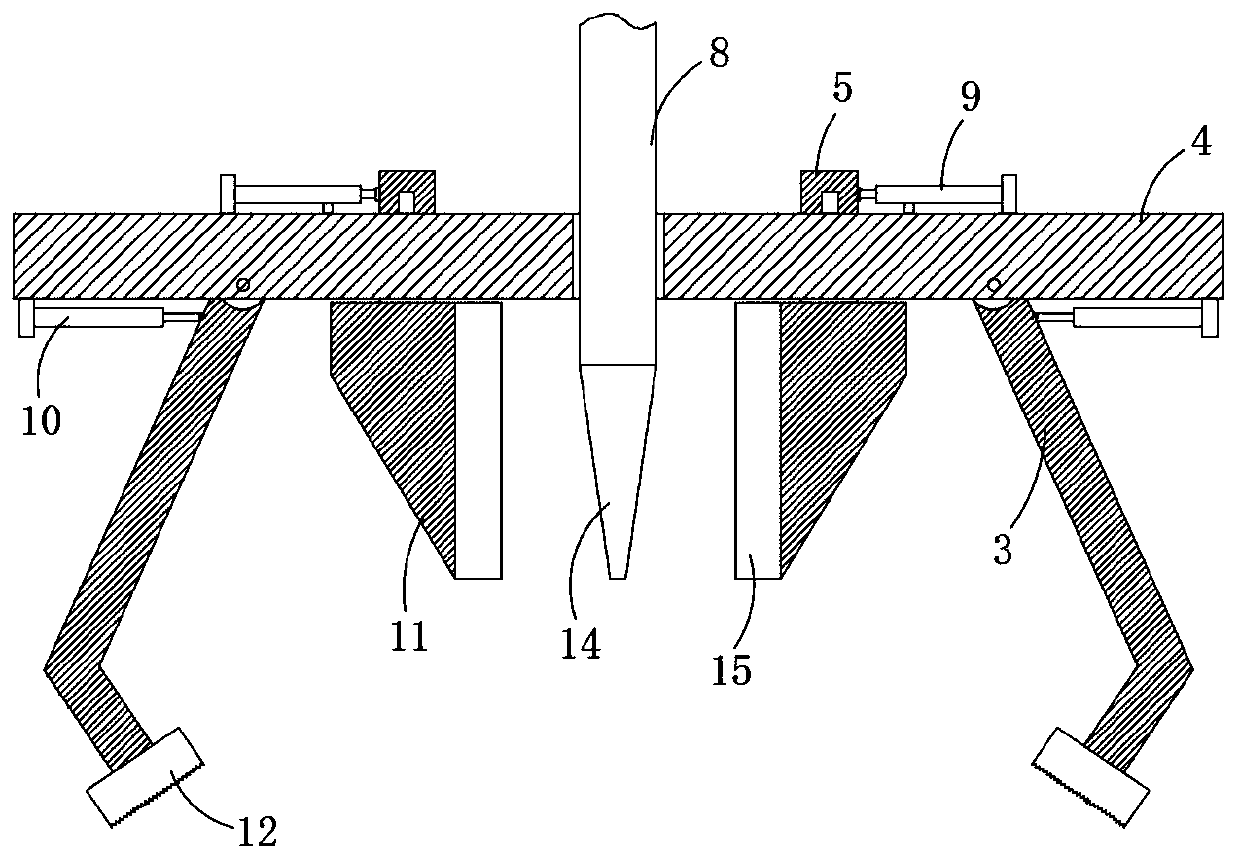

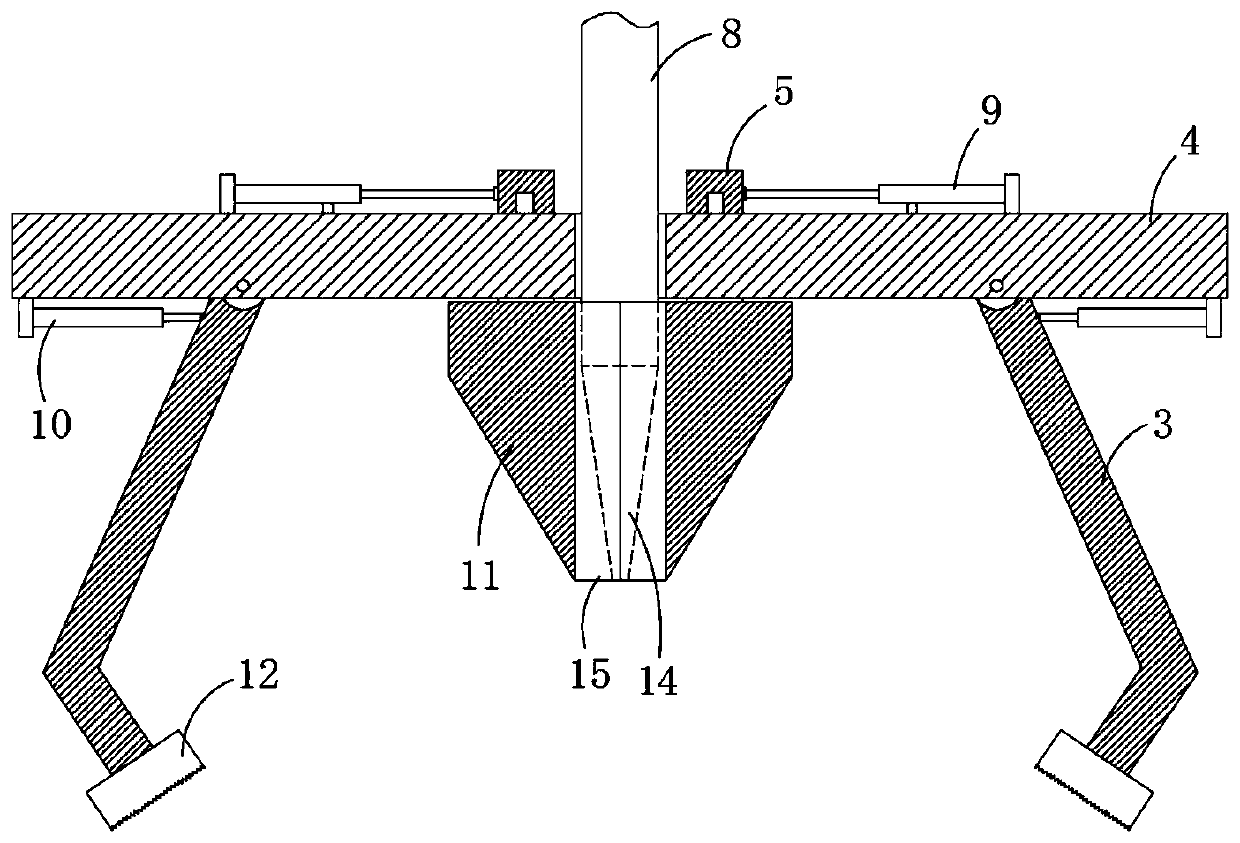

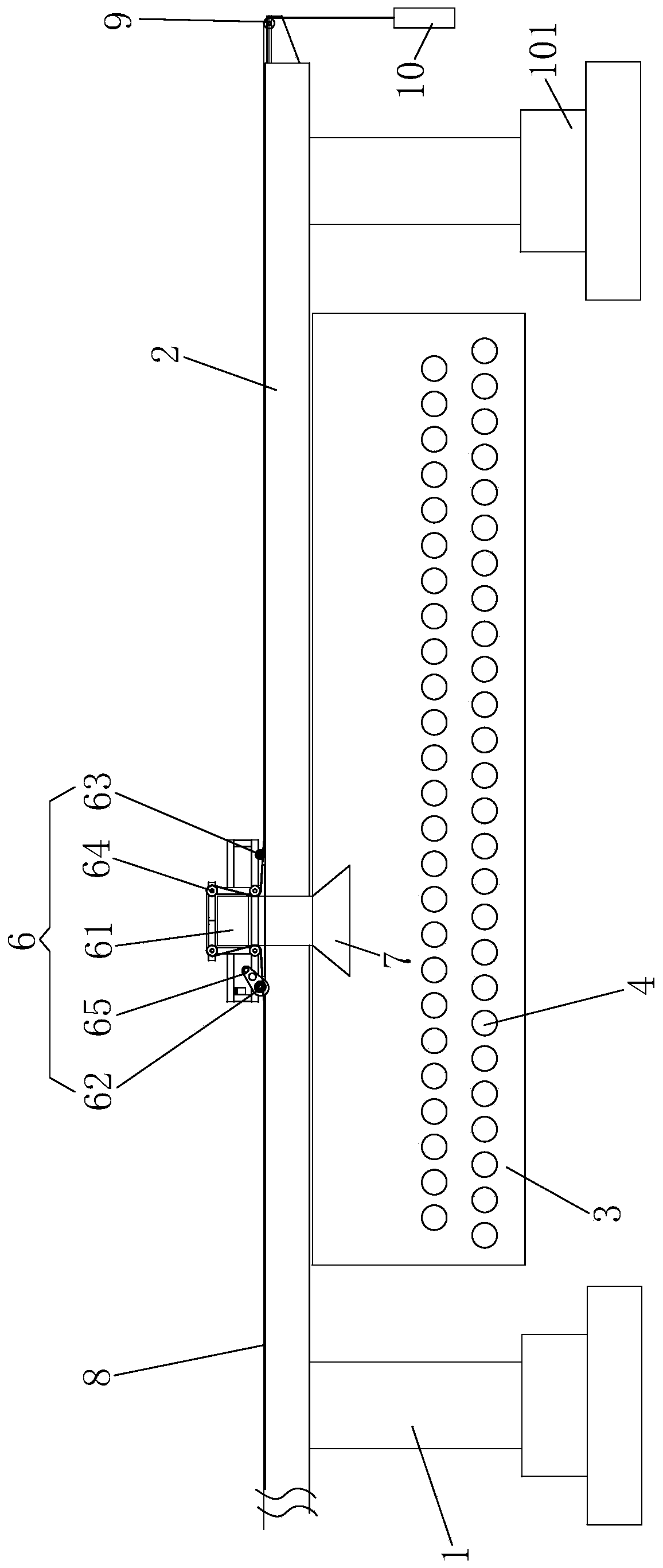

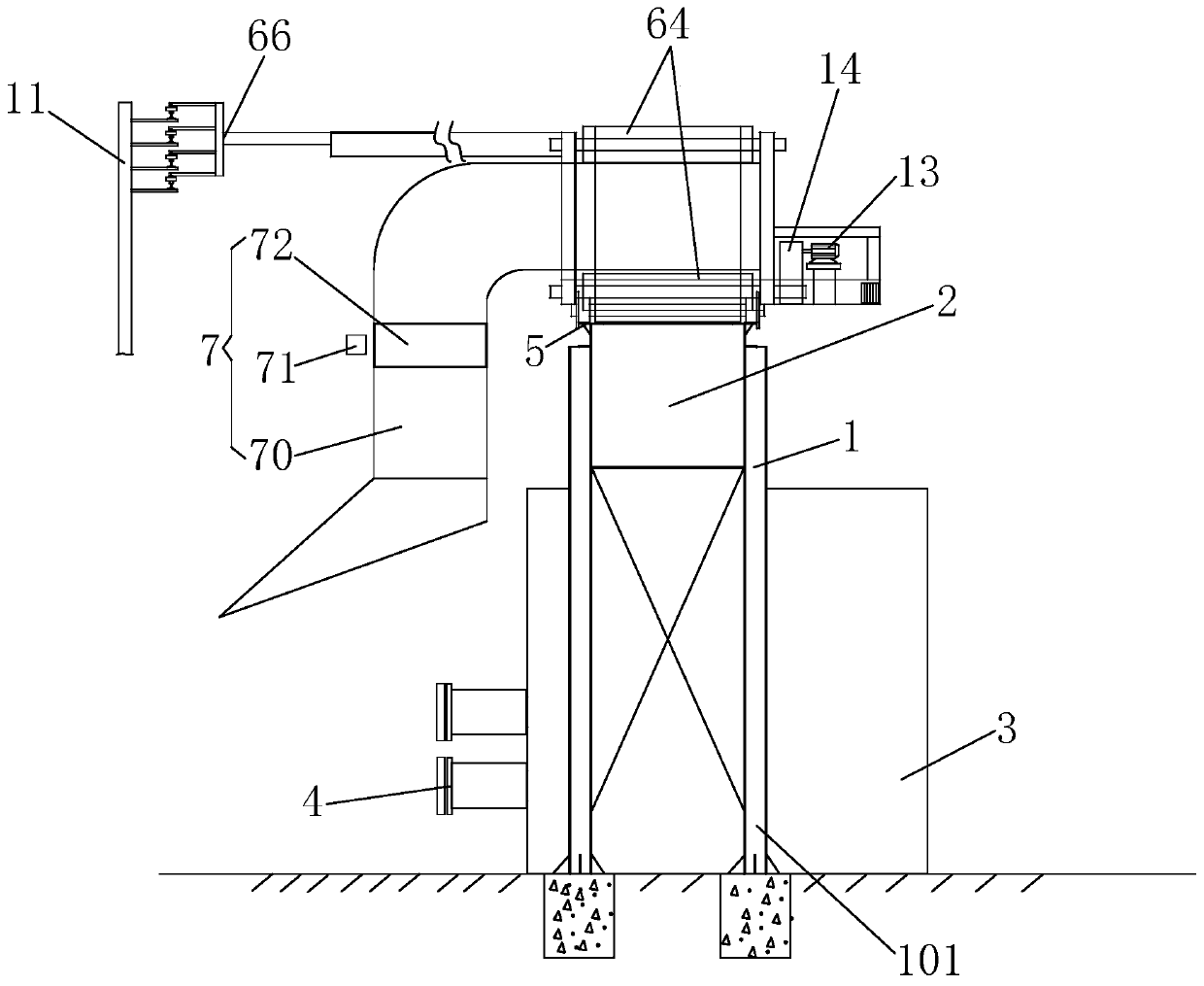

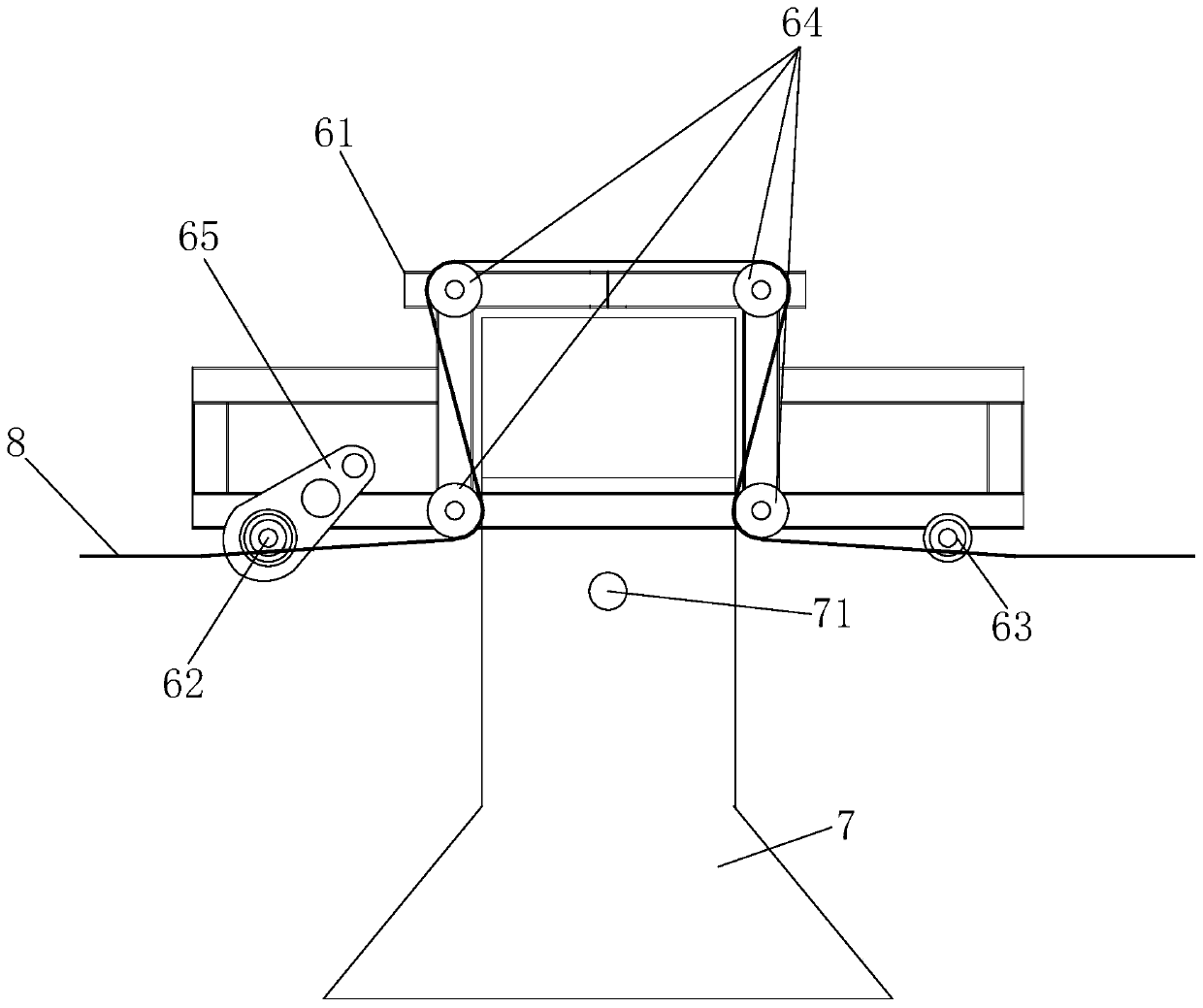

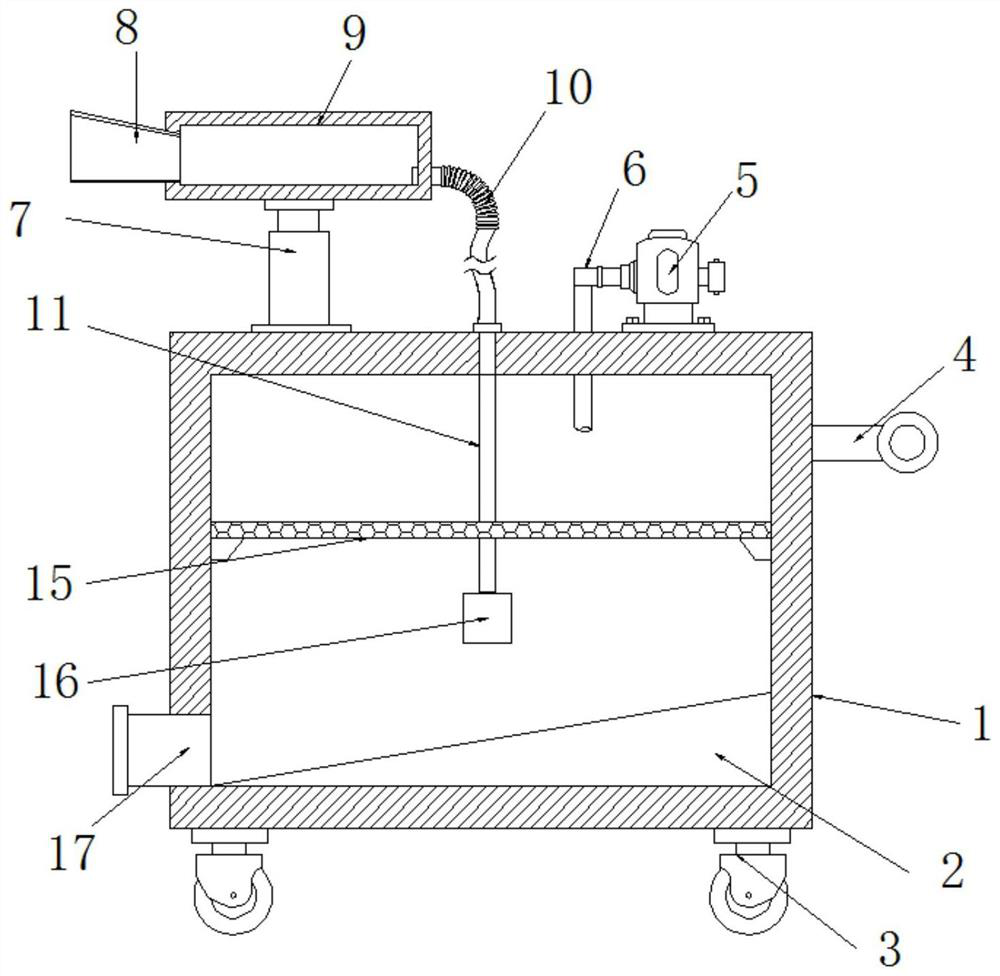

Device and method for collecting dust in front of magnesium ingot smelting reduction furnace

ActiveCN111521030APrevent movementSolve the technical problems of low dust collection efficiency and poor dust collection effectDispersed particle filtrationControl devices for furnacesEnvironmental engineeringMechanical engineering

The invention discloses a device and method for collecting dust in front of a magnesium ingot smelting reduction furnace. The device comprises a support, a smoke guide pipeline, a track, a dust collection trolley, a driving mechanism, a dust collection cover, a detection mechanism and a controller, wherein the smoke guide pipeline is arranged on the support and is positioned above the reduction furnace; a smoke suction window is formed in the top of the smoke guide pipeline; the track is laid on the smoke guide pipeline; the dust collection trolley is mounted on the track; a smoke passage is formed in the dust collection trolley; one end of the smoke passage faces the smoke suction window; one end of the dust collection cover faces inlets and outlets in front of the reduction furnace, andthe other end of the dust collection cover communicates with the smoke passage; the detection mechanism acquires smoke dust state information of each inlet and outlet; and the controller is used for firstly calculating the smoke dust concentrations, then sequencing all the smoke dust concentrations, selecting a dust collection point, finally driving the dust collection trolley to move to be abovethe dust collection point, enabling the dust collection cover to collect smoke dust at the dust collection point, and discharging the smoke dust through the smoke passage, the smoke suction window andthe smoke guide pipeline. By means of the device and method for collecting the dust in front of the magnesium ingot smelting reduction furnace, the smoke dust can be sucked away in time, and the dustcollection efficiency and the dust collection effect on the smoke dust are improved.

Owner:INNER MONGOLIA JINSHI MAGNESIUM IND

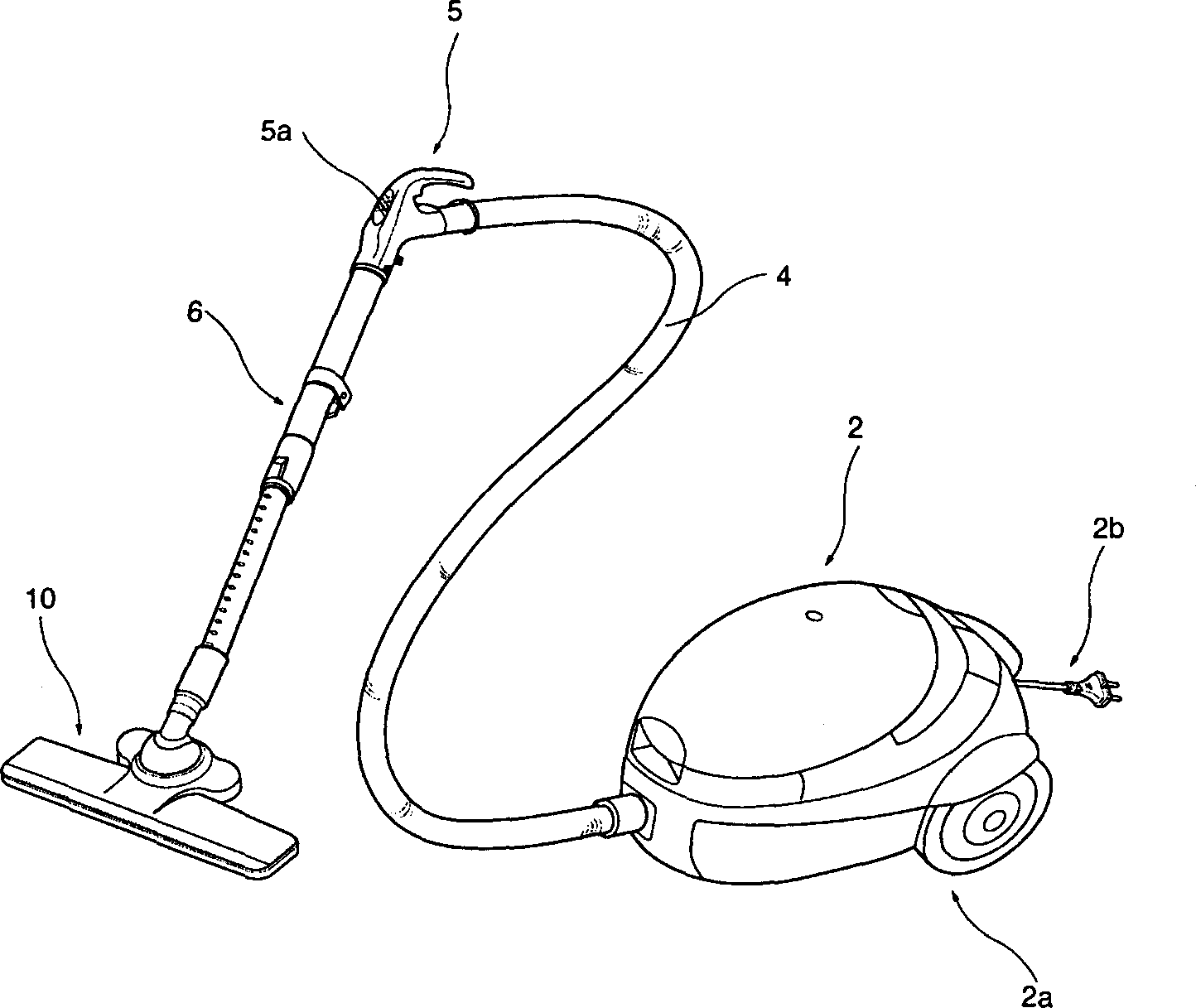

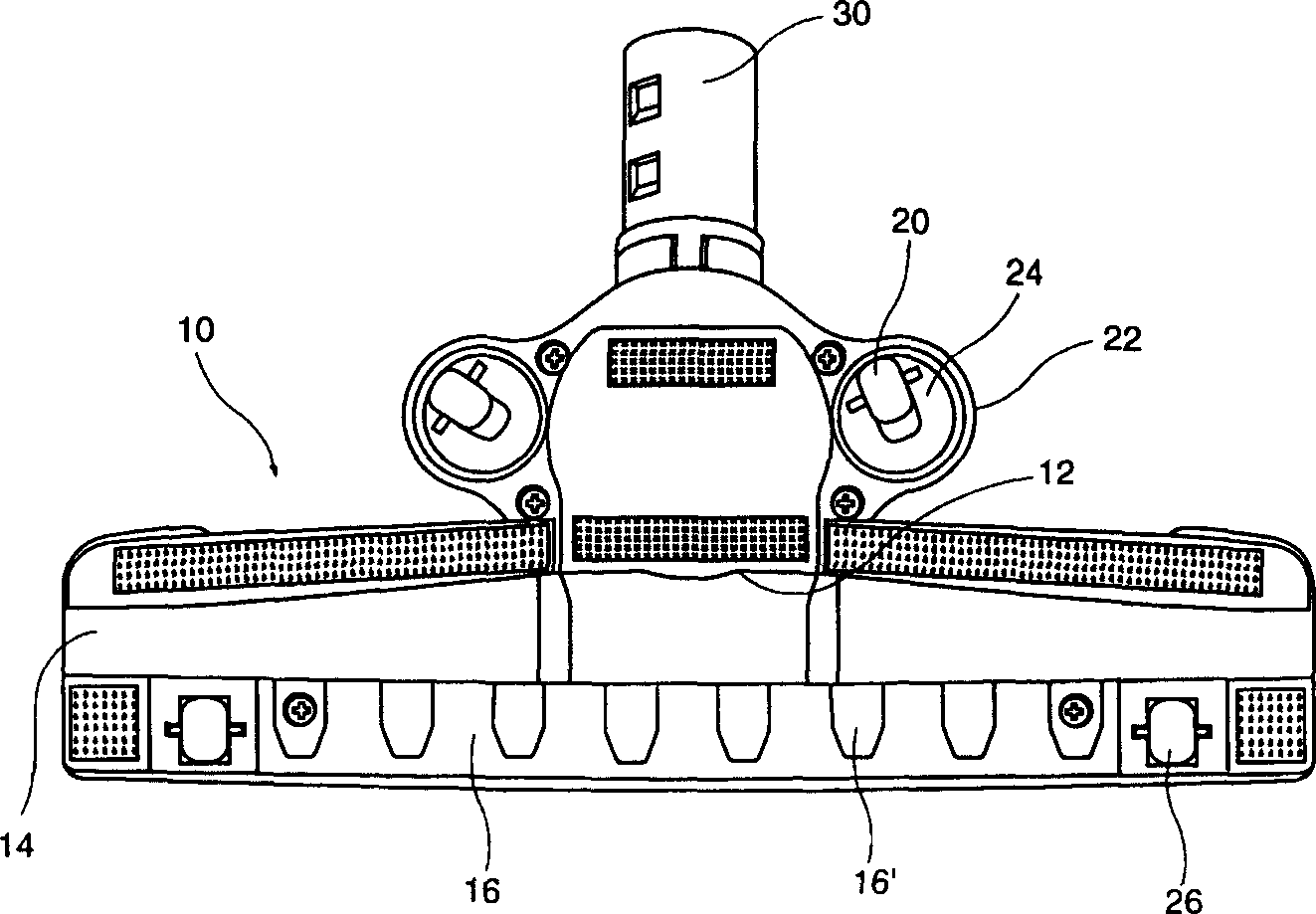

Suction nozzle of vacuum cleaner

A sucking mouth of vacuum cleaner is composed of a lower case to form the bottom surface of sucking mouth, an upper case playing the appearance role, and a sucking pipe connected to the extended pipe of vacuum cleaner.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

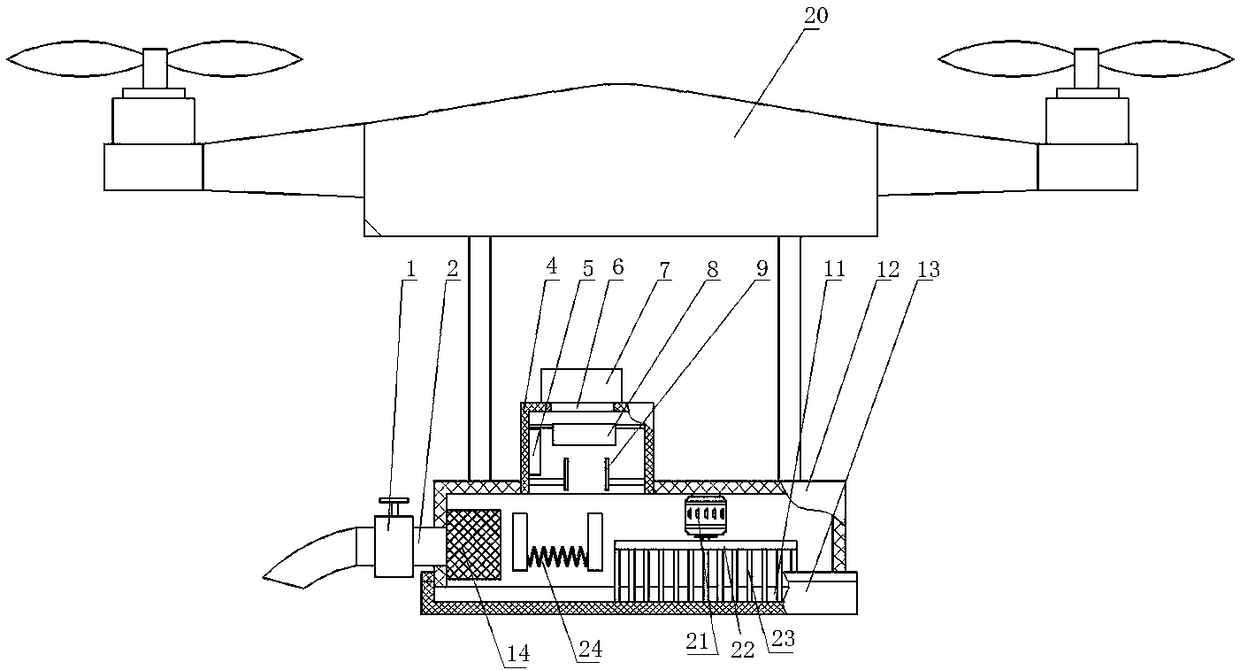

Smart ground cleaning dryer

InactiveCN108175340AReduce contentInhibit bacteriaCarpet cleanersFloor cleanersNitrogen oxidesEnvironmental engineering

The invention discloses a smart ground cleaning dryer. The smart ground cleaning dryer comprises an unmanned aerial vehicle body, the lower portion of the unmanned aerial vehicle body is connected with a sweeping and drying device, the sweeping and drying device comprises a flow-guiding shell, the flow-guiding shell is a cylindrical shell with an opening in the lower portion, and an ozone generation shell is installed on the upper portion of the flow-guiding shell. The unmanned aerial vehicle and the sweeping and drying device are combined, and in this way, the smart ground cleaning dryer automatically reaches the region needing to be swept through the unmanned aerial vehicle to sweep and sterilize the ground without handholding of a user. A rotary efficient sweeping device is combined with the ozone generation device, the smart ground cleaning dryer performs disinfection and sterilization operation on ozone and nitrogen oxide while sweeping and drying the target region, in this way, the content of bacterial microorganisms on the swept ground region is greatly lowered, and the risk that staff living indoors are infected with bacteria and microorganisms is effectively avoided. The smart ground cleaning dryer is suitable for cleaning and drying the ground.

Owner:崔少曦

Novel holder assembly machine of automobile sliding rail semi-automatic assembly line

PendingCN111531346AEasy to fixEasy to installCleaning using gasesMetal working apparatusSemi automaticControl engineering

The invention discloses a novel holder assembly machine of an automobile sliding rail semi-automatic assembly line. The novel holder assembly machine comprises a rack, supporting legs, a control switch, stand columns, a machine base, a control case, a control machine, a control panel, a gear motor, a rotating table, mounting holes, a telescopic adjusting rod, a holder adjustable fixed mounting support structure, a movable assembly sliding rod structure and a bendable telescopic adjusting type dust removal suction nozzle structure. The supporting legs are in longitudinal bolted connection to the positions of the four corners of the bottom of the rack. Through the arrangement of a moving support, connecting seats, fixed nuts, locating sensors, adjusting screws, rotating handles and holder clamp heads, holders of different types can be fixedly mounted easily, and mounting work can be done conveniently; and through the arrangement of a rotating screw, a moving motor, a moving nut, an inverted-U-shaped moving frame, a moving sliding block, a linear sliding rail and limiting switches, the positions of the holders can be moved and adjusted easily, and mounting operation can be carried outconveniently.

Owner:ZHANGJIAGANG HONGBO MACHINERY

Preservation device of galvanized copper bar

PendingCN108687733ASolve the problem that the preservation effect is not good enoughConducive to preservationGas treatmentDispersed particle separationEngineeringCopper

The invention discloses a preservation device of a galvanized copper bar. The preservation device comprises a box body. A storage plate is arranged in an inner cavity of the box body, a copper bar body is arranged on the top of the storage plate, the two sides of the top of the storage plate are both fixedly connected with connecting frames, the two sides of the inner wall of the box body are bothfixedly connected with heating devices, the portions, located at the front ends of the heating devices, of the two sides of the inner wall of the box body are both fixedly connected with supporting rods, fans are arranged at the ends, away from the inner wall of the box body, of the supporting rods, and the top of the inner cavity of the box body is fixedly connected with a fixing plate. Throughthe arrangement of the heating devices, the fans, electric telescopic rods, movable rods, check blocks, sealing gaskets, a supporting plate and an air exhauster, the inner cavity of the box body can be dehumidified and further vacuumized, meanwhile, the problem that the preservation effect of a traditional preservation device is not good enough is solved, and the preservation device of the galvanized copper bar has the beneficial effect of being good in preservation effect and is worthy of being popularized.

Owner:NANTONG ZHUOER ELECTROMECHANICAL CO LTD

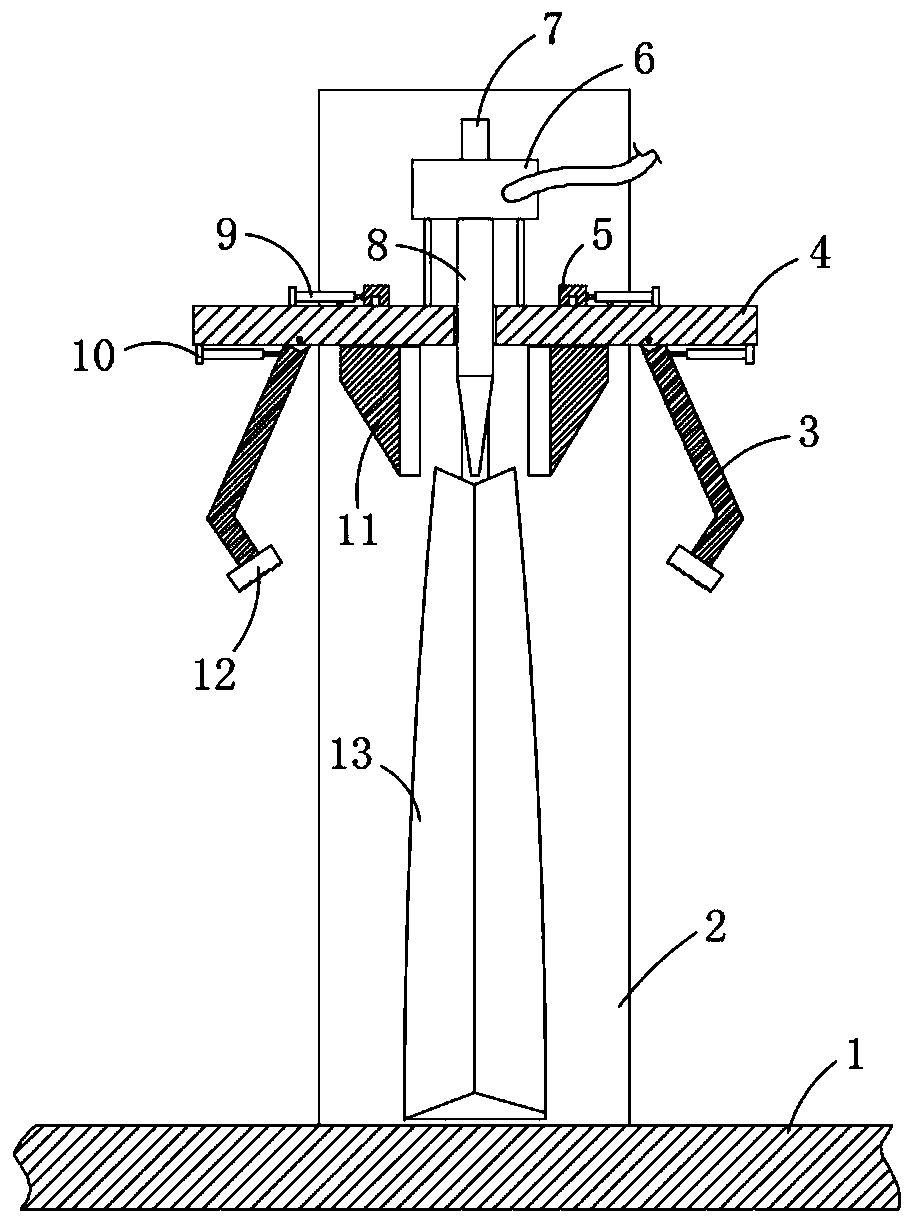

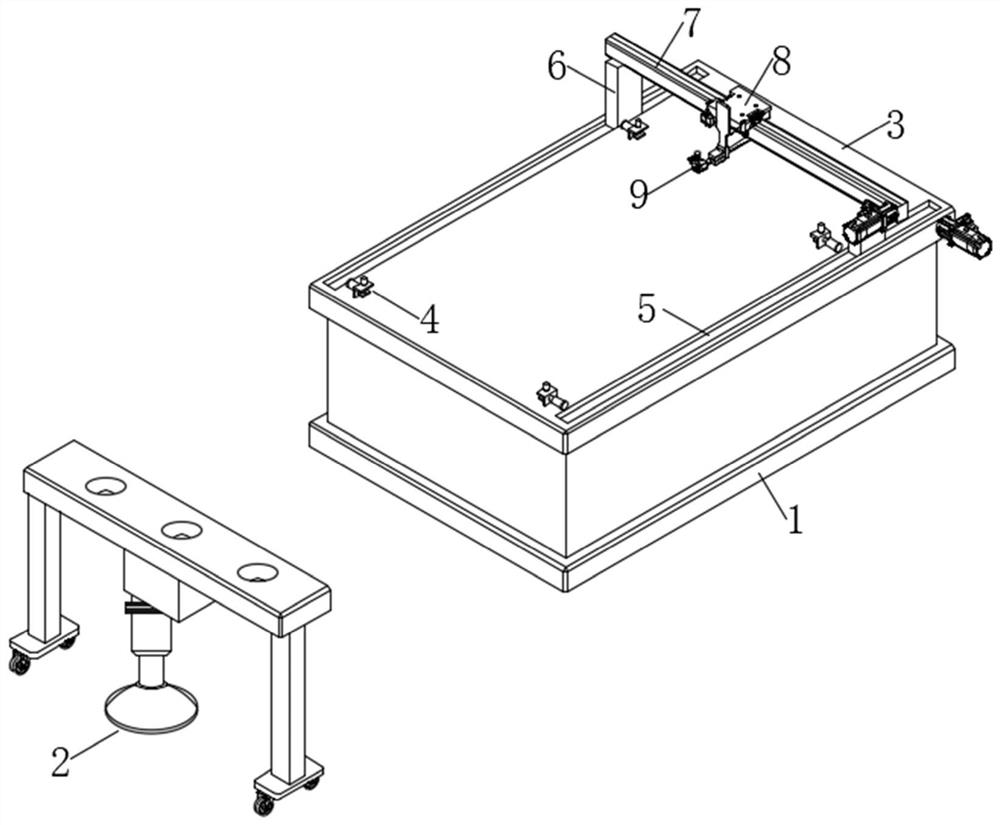

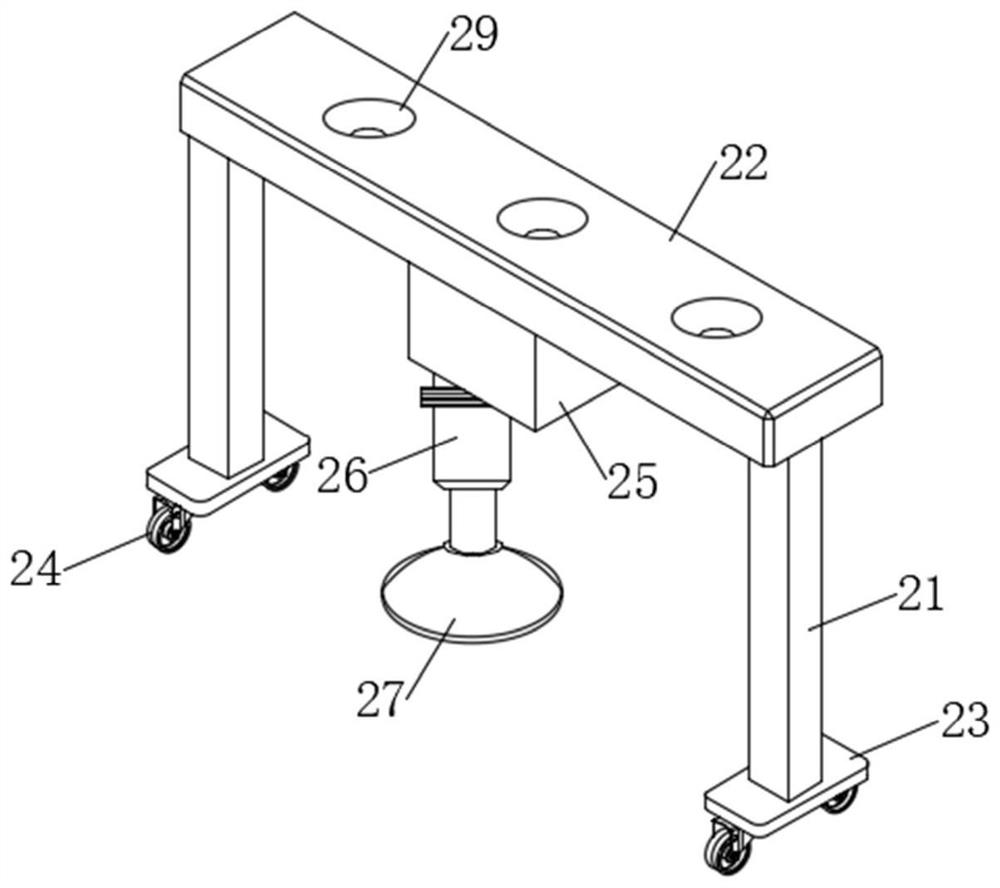

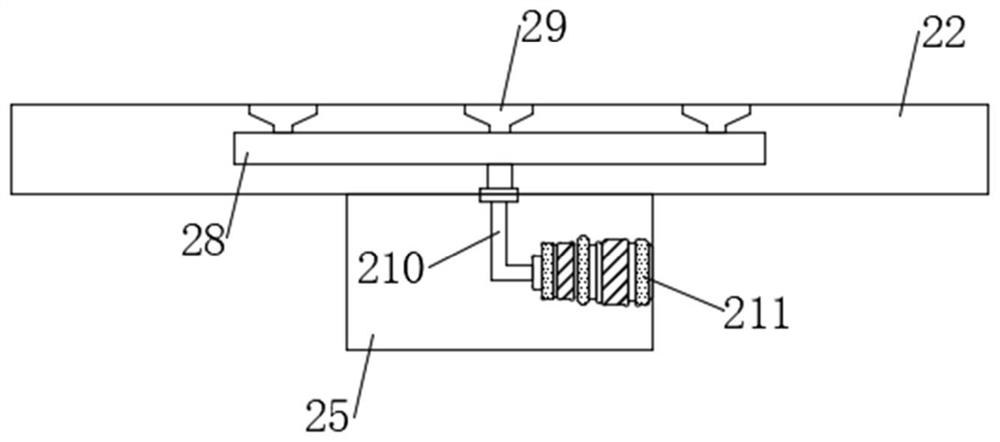

Stabilizing device and method for steel plate laser cutting

PendingCN112222632AAvoid sloping bendsAvoid and the steel plate is easy to shake and shift during the cutting processWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringLaser cutting

The invention discloses a stabilizing device for steel plate laser cutting. The device comprises a cutting machine base and a movable supporting table. The movable supporting table is arranged on oneside of the cutting machine base, a fixed cutting table is fixedly installed on the top of the cutting machine base, a workpiece deviation prevention mechanism is arranged on the fixed cutting table,first guide rails are installed on the edges of the two opposite sides of the top of the fixed cutting table, first moving bases of the same structure are installed on the two first guide rails, second guide rails are fixedly installed on the tops of the two first moving bases, second moving bases are installed on the second guide rails, and laser cutting heads are fixedly installed on the sides,close to the movable supporting table, of the second moving bases through supports. The stabilizing device for steel plate laser cutting steel has the beneficial effects that the movable supporting table supports a steel plate in a non-cutting area and prevents the steel plate from downwards inclining, bending and deforming, the movable supporting table is fixed by a positioning assembly so that stable support can be guaranteed, a fixing assembly on the movable supporting table is used in cooperation with the workpiece deviation prevention mechanism on the fixed cutting table, the steel plateduring cutting is guaranteed to be stable, and the steel plate cutting precision is improved.

Owner:合肥恒泰工程机械有限公司

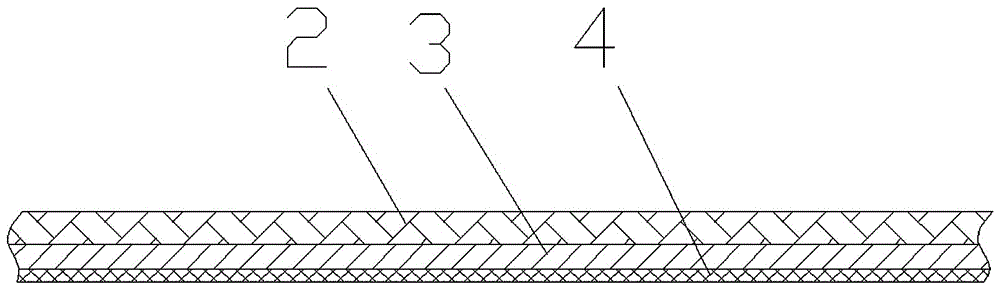

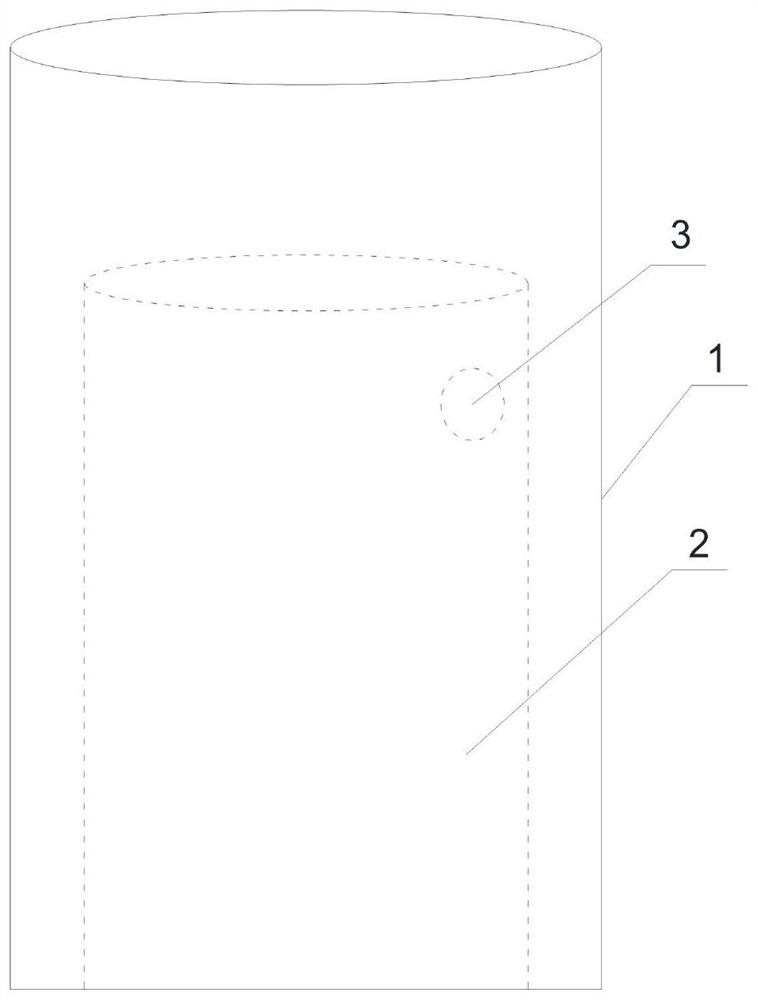

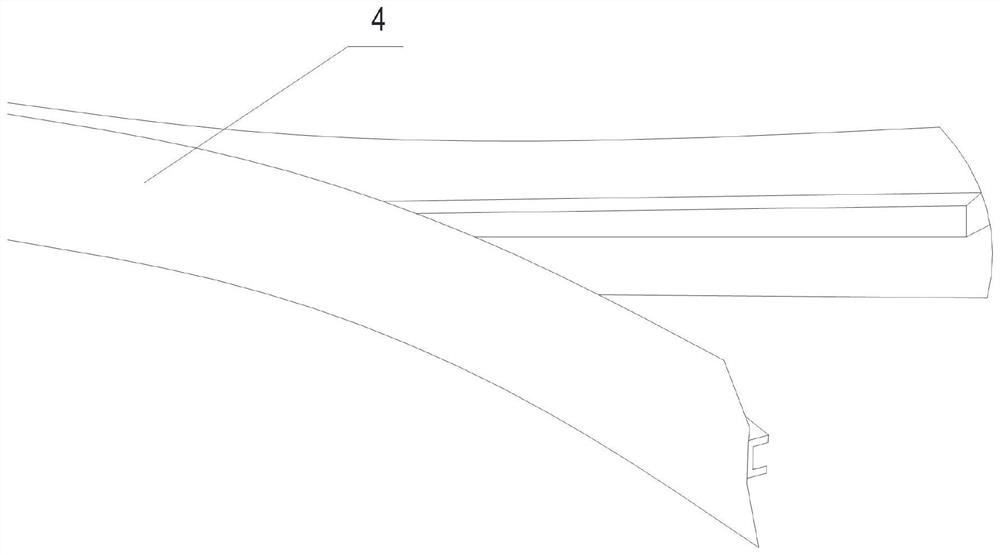

Blocking bag for vacuum heat insulation board

InactiveCN106193350AExtended service lifeGuaranteed vacuumClimate change adaptationSynthetic resin layered productsAluminum foilMaterials science

The invention discloses a blocking bag for a vacuum heat insulation board. The blocking bag (1) is of a baggy structure with one side open. The blocking bag comprises a composite blocking film layer (2), an aluminum foil layer (3) and a macromolecular heat isolation bonding layer (4) with the low fusion point, and the composite blocking film layer (2), the aluminum foil layer (3) and the macromolecular heat isolation bonding layer (4) are sequentially composited from outside to inside. The blocking bag has the advantages that the blocking bag for the vacuum heat insulation board is of the baggy structure, after an opening of the blocking bag is closed, the gas tightness of the blocking bag is ensured, vacuumizing operation is facilitated, and the vacuum degree of the vacuum heat insulation board can be maintained for a long time; and meanwhile, the blocking bag has the dual heat insulation effects, the heat insulation and heat preservation effects are good, the sealing matching performance of the blocking bag with a core plate is good, and the service life of the vacuum heat insulation board is prolonged.

Owner:安徽百特新材料科技有限公司

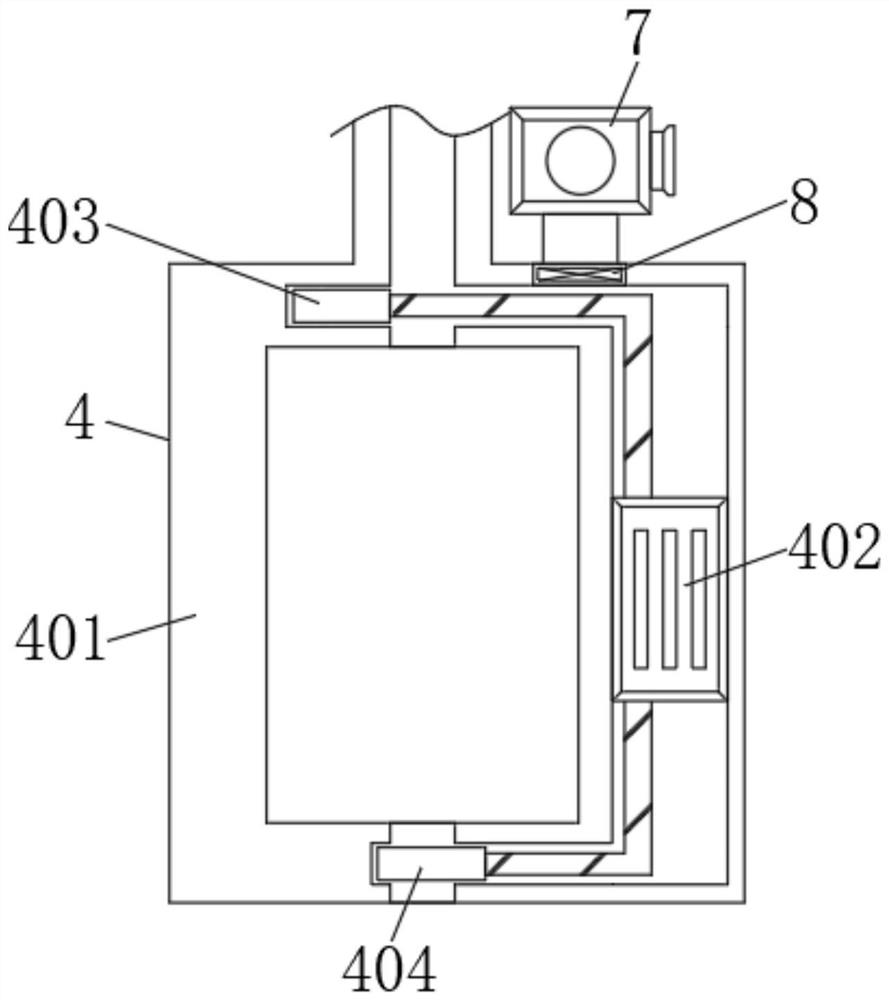

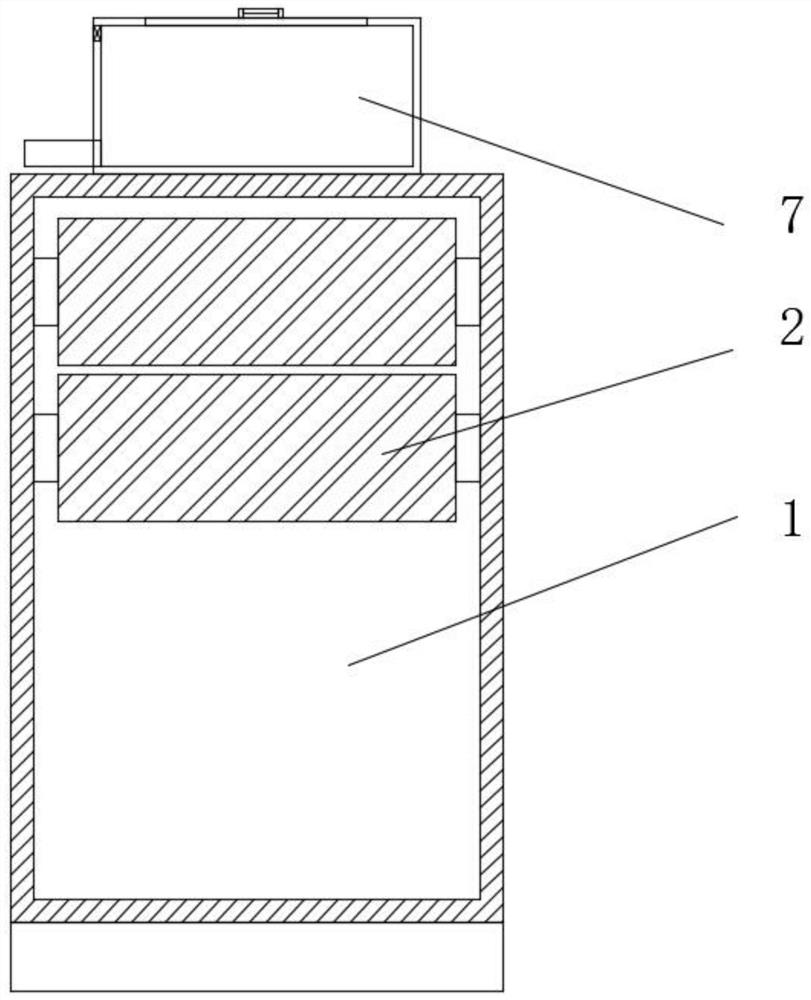

Factory vacuum pressing frame electronic product detection jig

InactiveCN112798824AImprove sealingEasy to vacuumMeasurement instrument housingEngineeringPumping vacuum

The invention discloses a factory vacuum pressing frame electronic product detection jig, and relates to the technical field of electronic product detection devices. The factory vacuum pressing frame electronic product detection jig comprises an operation base, the upper surface of the operation base is fixedly connected with an operation box and a detection box, and the surface of the operation box is fixedly connected with the surface of the detection box; the inner wall of the top end of the operation box is slidably connected with two lifting rods, and the upper ends of the two lifting rods are jointly and fixedly connected with a sealing cover plate. According to the invention, through mutual cooperation of the above structures, an electronic product is automatically and effectively fixed in the detection process, the device is assisted in sealing operation, normal operation of a vacuumizing step is ensured, manual operation of an operator is not needed, and the labor intensity of the operator is greatly reduced. The problems that a traditional electronic product detection device is low in automation degree and poor in sealing performance, and certain inconvenience is caused in the actual use process are solved.

Owner:滁州安飞信电子科技有限公司

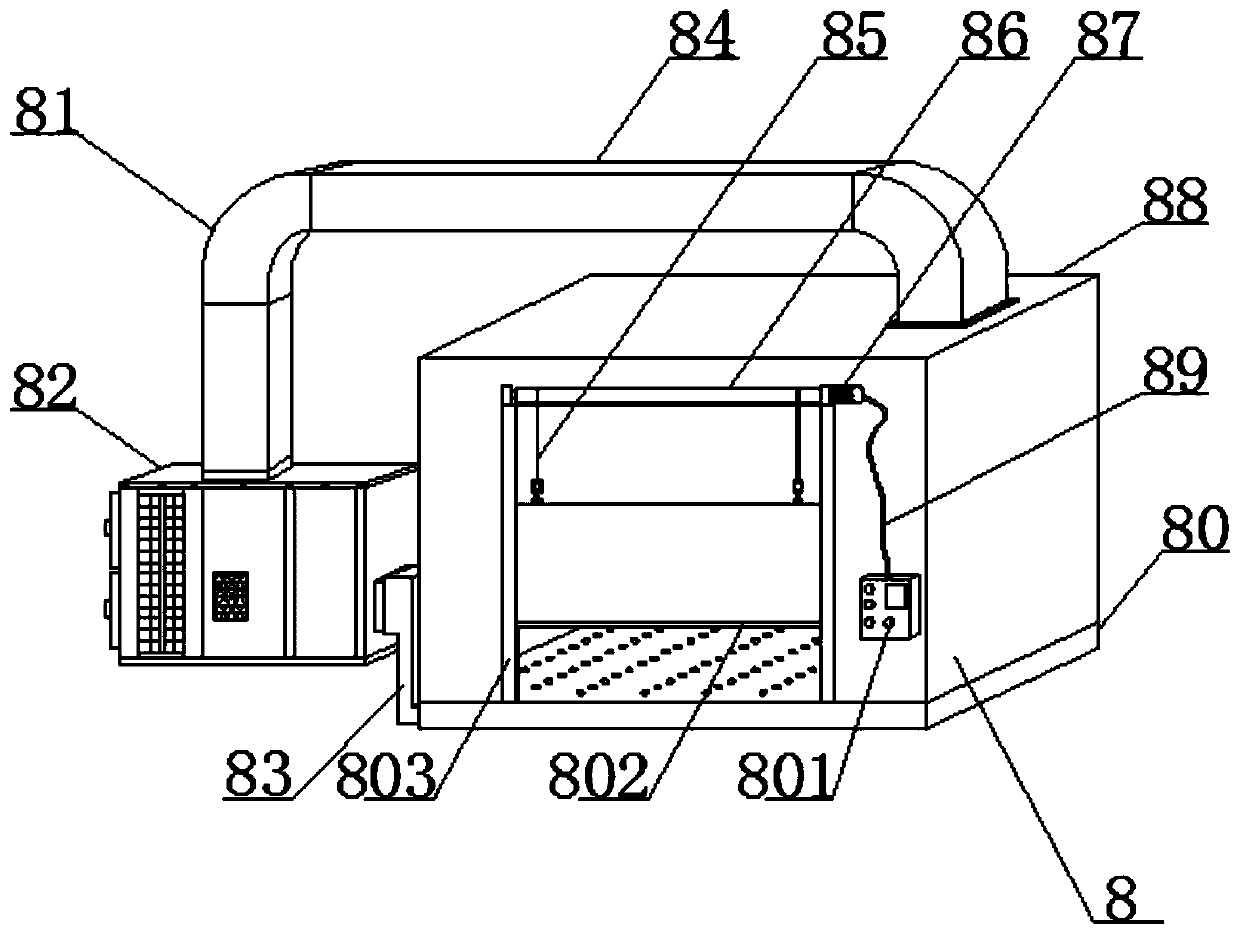

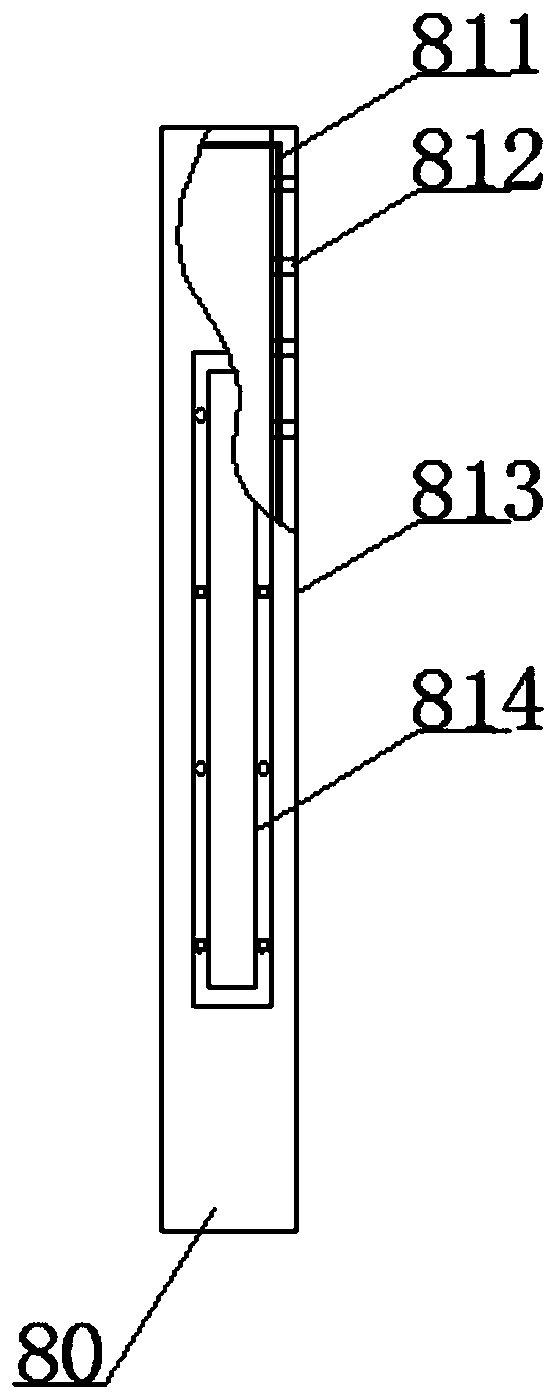

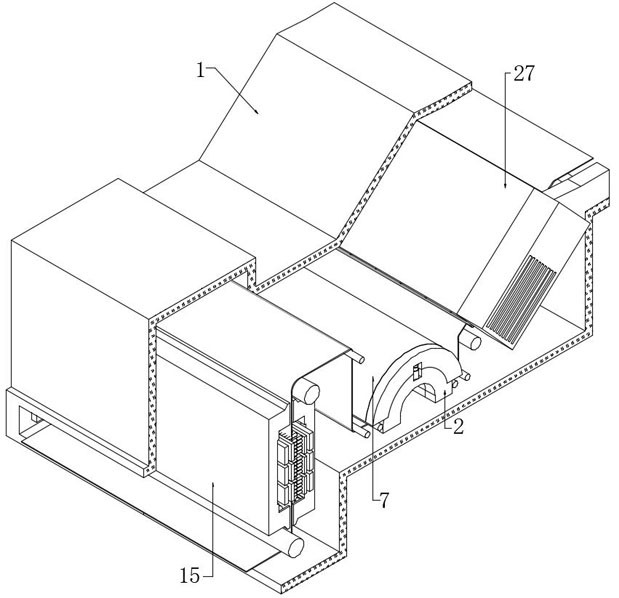

Robot welding fume purifying and collecting device and treatment method thereof

PendingCN113731108AEasy to collectEasy to handleDispersed particle separationDirt cleaningProcess engineeringManufacturing engineering

The invention discloses a robot welding fume purifying and collecting device and a treatment method thereof.The robot welding fume purifying and collecting device comprises a fume collecting box, the fume collecting box is connected with a third connecting air pipe, one end of the third connecting air pipe is connected with a fume purifying box, and one end of the fume purifying box is connected with a second connecting air pipe; one end of the second connecting air pipe is connected with a fan box, one end of the fan box is connected with a first connecting air pipe, and one end of the first connecting air pipe is connected with a discharge chimney. According to the robot welding fume purifying and collecting device and the treatment method thereof, a rotary dust collection mechanism, an adsorption and purification mechanism and a smoke dust content detection mechanism are arranged, smoke dust can be conveniently and better subjected to dust collection operation, collection is simpler, adsorption and purification operation can be conveniently and better carried out, smoke dust treatment is facilitated, the toxic content of the smoke dust can be conveniently detected, the purification strength is regulated and controlled, and the effect is more excellent.

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD

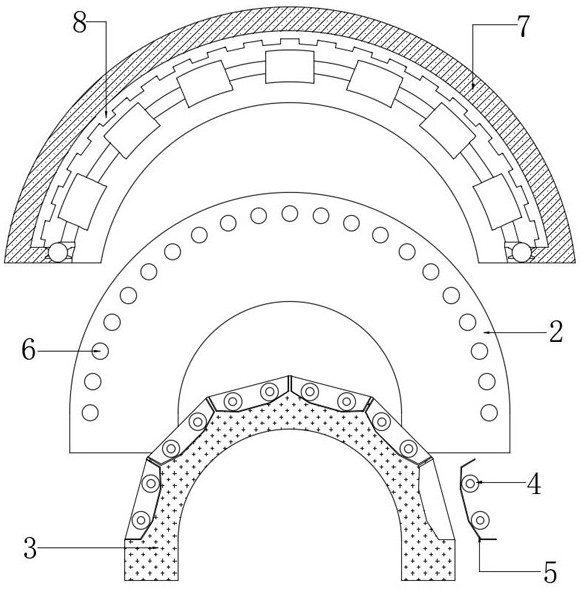

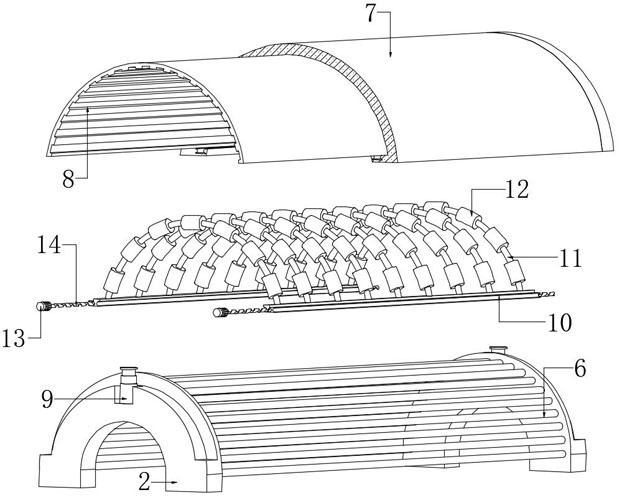

A steam sterilization device for furniture surface fabric production

ActiveCN113521325BIncrease temperatureIncrease humidityMechanical cleaningPressure cleaningProcess engineeringMechanical engineering

The invention belongs to the technical field of fabric production and processing, in particular to a steam sterilization device for furniture surface fabric production, aiming at the fact that the surface wall temperature of the fabric is low, and the steam will liquefy when it is cold during the steam sterilization process, resulting in a substantial increase in the humidity of the fabric , the follow-up drying process is slow, reducing the overall processing efficiency of the cloth. The following scheme is now proposed, including the outer box, the bottom inner wall of the outer box is fixedly connected with a semicircular seat, and a light box is fixedly connected between the inner walls of both sides of the semicircular seat. The outer wall of the light box is provided with a plurality of grooves equidistant from the circumference, and infrared lamp tubes are fixedly connected between the inner walls of both sides of the plurality of grooves. The present invention heats the cloth before steam sterilization by means of an infrared lamp tube, increases the temperature of the cloth, and avoids a large amount of steam condensing and liquefying due to the low temperature on the surface of the cloth during the subsequent steam sterilization process, thereby greatly increasing the humidity of the cloth and increasing steam sterilization The final drying time will reduce the processing efficiency of the cloth.

Owner:JIANGSU ZHONGSHI HOME TECH CO LTD

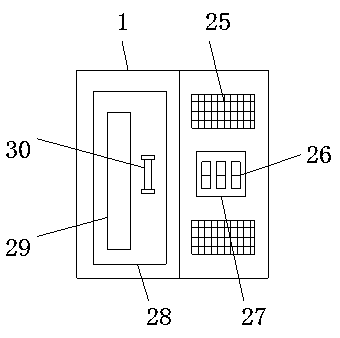

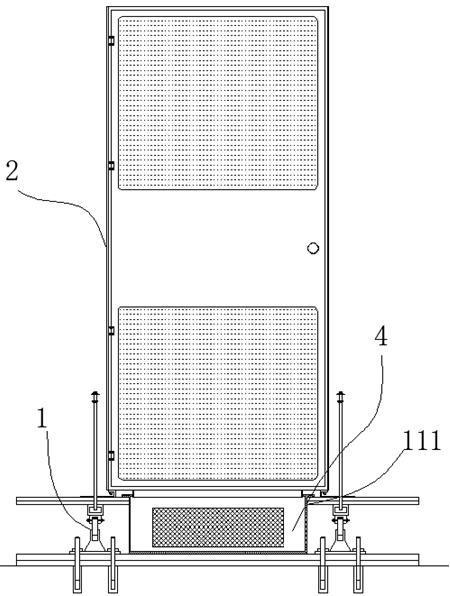

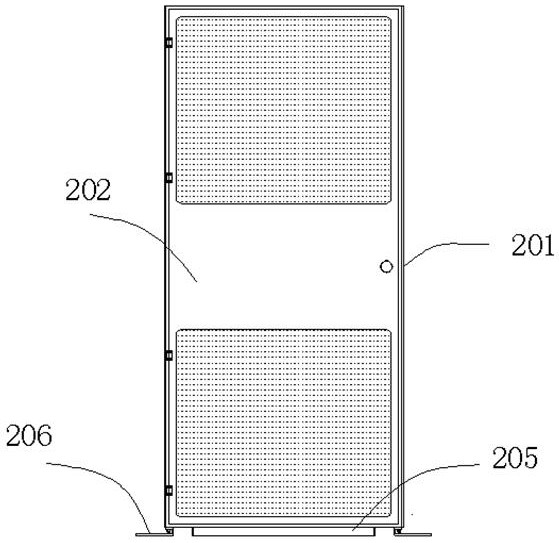

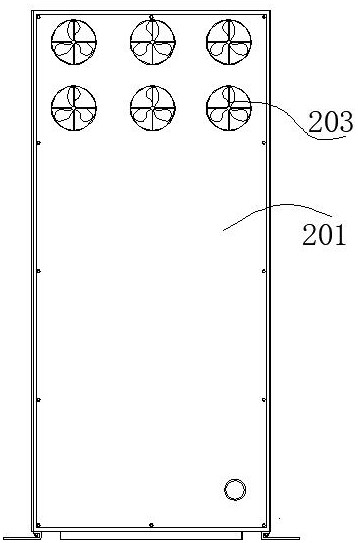

Power distribution cabinet capable of supplying air from bottom and heat dissipation method

PendingCN113315006ASmall branch spaceRealize heat dissipationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsCold airKeel

The invention discloses a power distribution cabinet capable of supplying air from the bottom and a heat dissipation method. The power distribution cabinet comprises a base structure laid in a machine room and a cabinet body structure installed at the top of the base structure. The base structure comprises keels laid on the ground, and the keels are longitudinally arranged. The keels are mainly used for bearing load, and the keels are light steel keels which are light in weight and sufficient in supporting capacity. A plurality of height adjusting mechanisms are mounted at the bottoms of the keels; through the height adjusting mechanisms, horizontal supporting of the keels on the uneven ground can be achieved; vertical rods are welded at the upper ends of the keels; and heat insulation cotton is laid between the adjacent keels in the transverse direction. The device can reduce the cold air distribution loss, and enables the cold air to effectively act on each power distribution cabinet.

Owner:邵慧艳

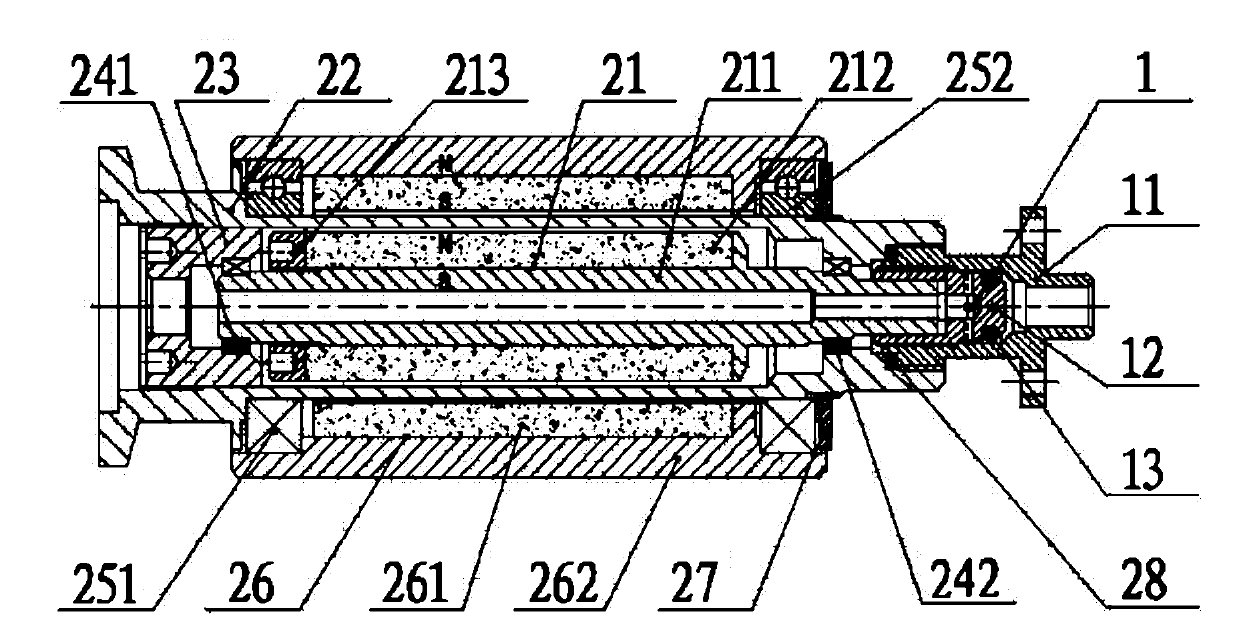

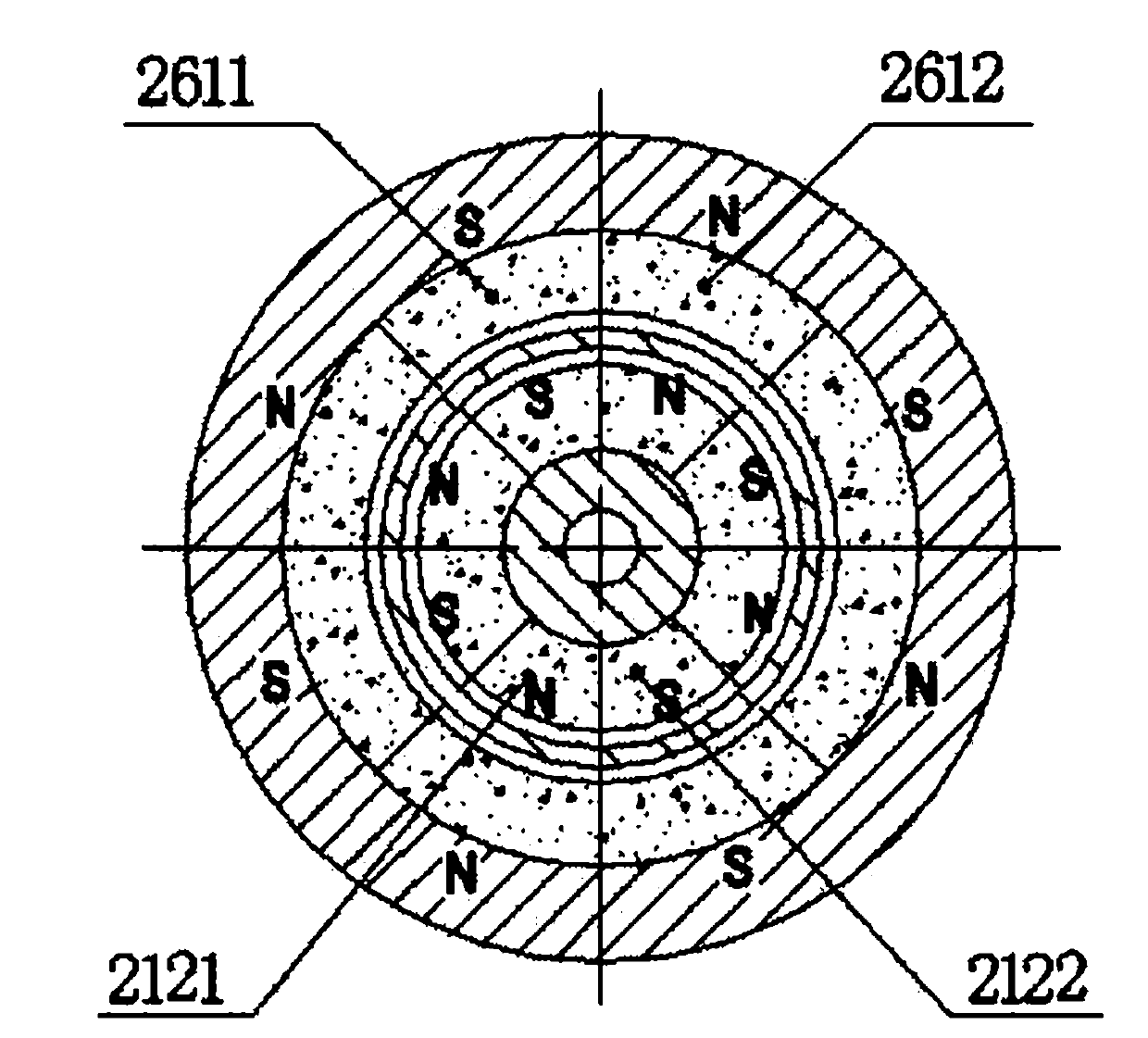

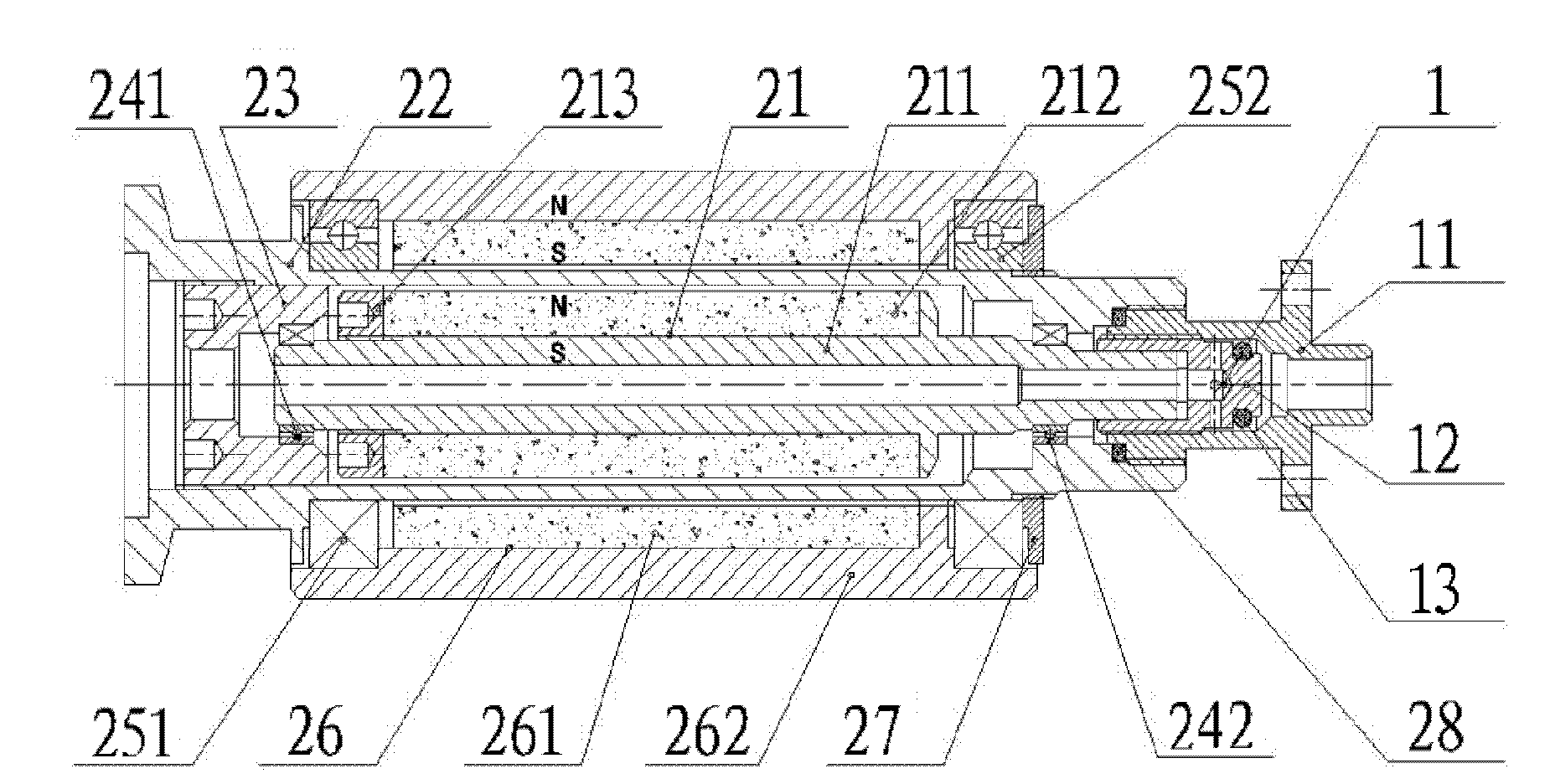

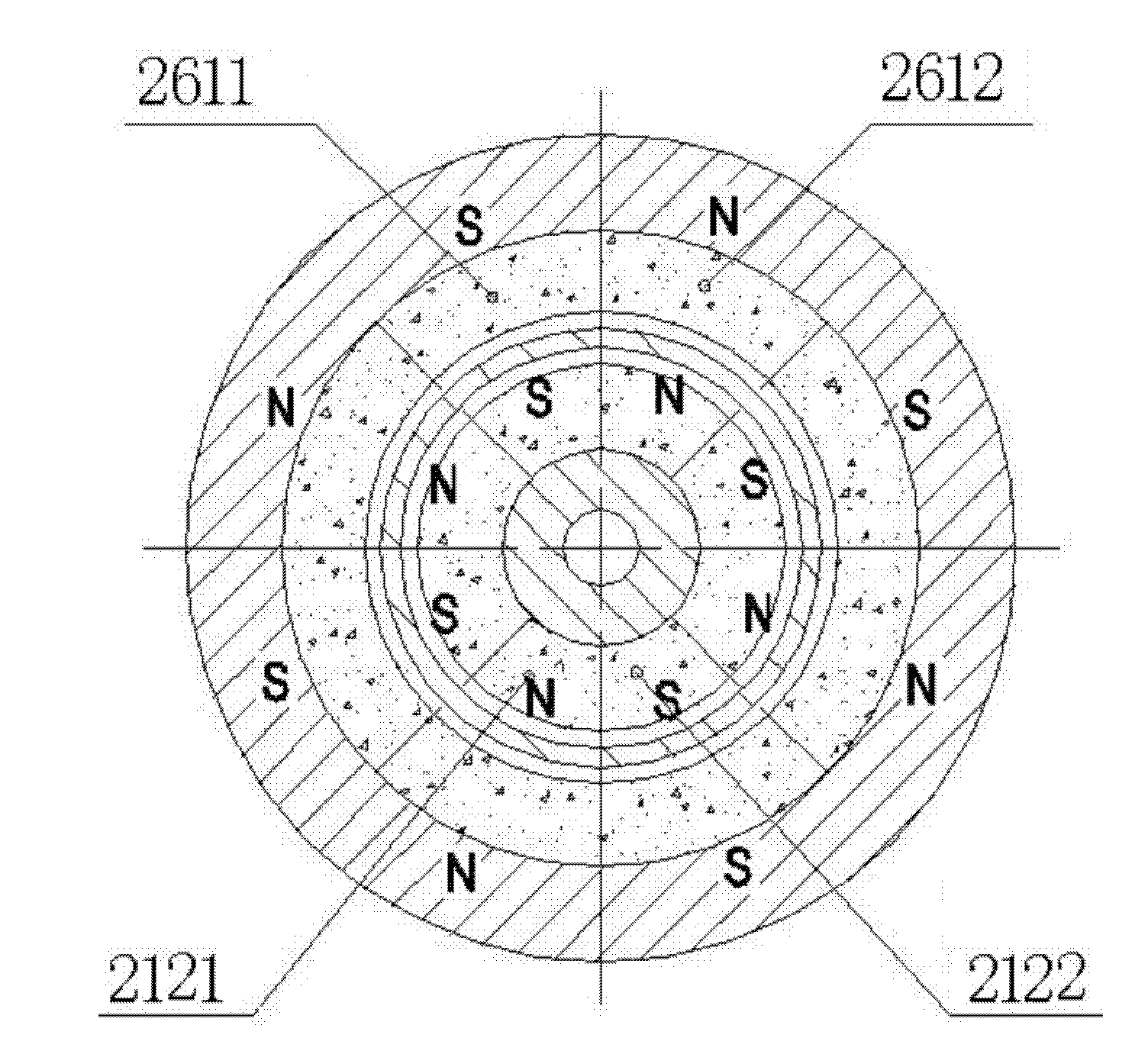

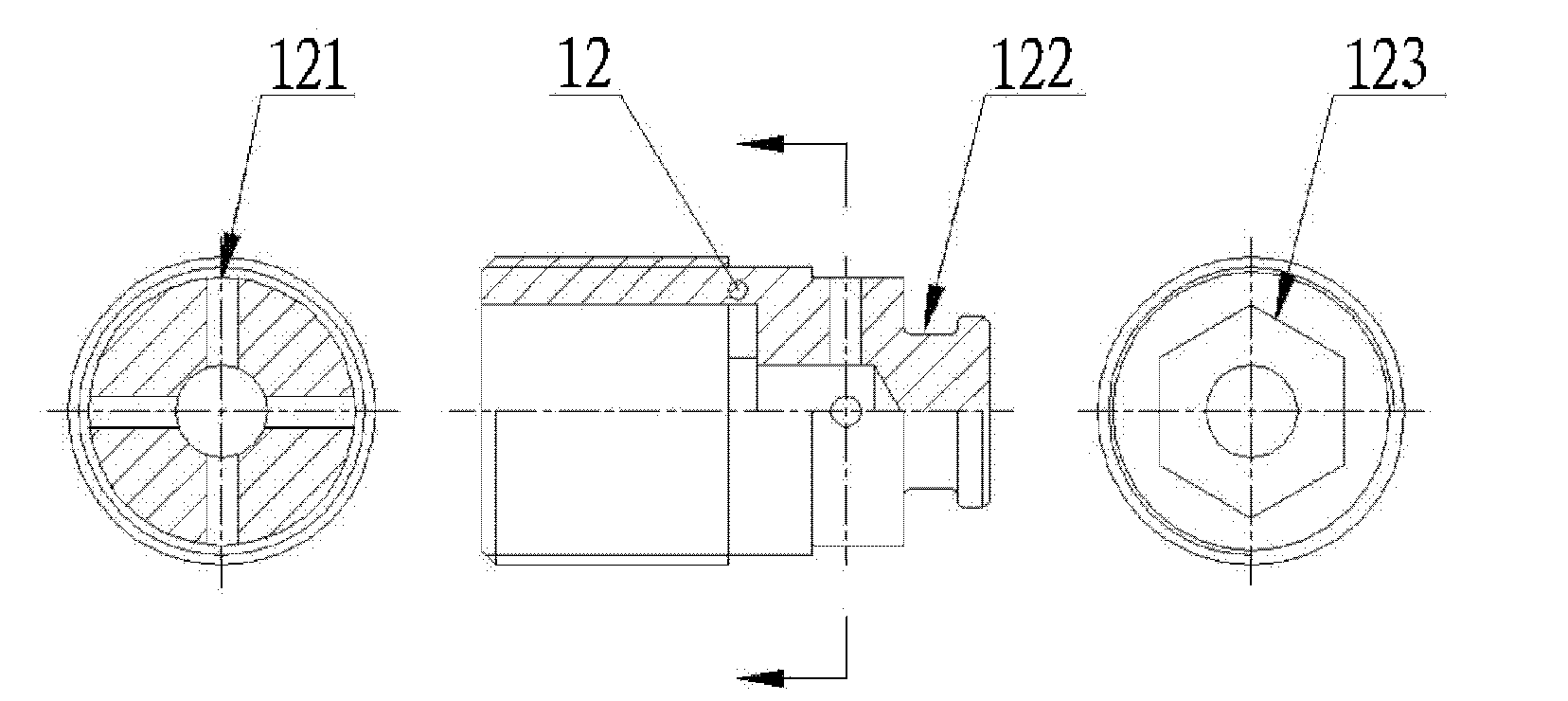

Sealing bayonet device for vacuumizing

The invention discloses a sealing bayonet device for vacuumizing, which consists of an air exhaust tap and an operation wrench, wherein the air exhaust tap is arranged on equipment to be vacuumized and comprises an air exhaust tap seat, a screwed plug and a rubber ring; and the operation wrench comprises an exhaust tube, a magnetic steel shaft, a magnetic steel sleeve, a bearing block, a bearing cap, a bearing, a sealing ring, and the like. The left end of the operation wrench is connected with a vacuum pump; and the right end of the operation wrench is connected with the air exhaust tap by a threaded compressed sealing ring in a sealing manner. The magnetic steel sleeve in the atmosphere environment is turned, the magnet steel shaft inside the exhaust tube is driven by a magnetic force and the screwed plug is driven by a spline at the right end of the magnetic steel shaft to compress a rubber ring so as to seal a bayonet. After sealing, the exhaust tube is reversely turned to loose the threaded connection and separate the operation wrench from the air exhaust tap. The bayonet sealing by means of the device is carried out under a vacuum environment and can be repeatedly used multiple times; and the air exhaust tap can be separated from the operation wrench and has small size and light weight. The sealing bayonet device is especially suitable for realizing vacuumizing and bayonet sealing of space equipment such as control moment gyros, inertia momentum wheels, and the like.

Owner:BEIHANG UNIV

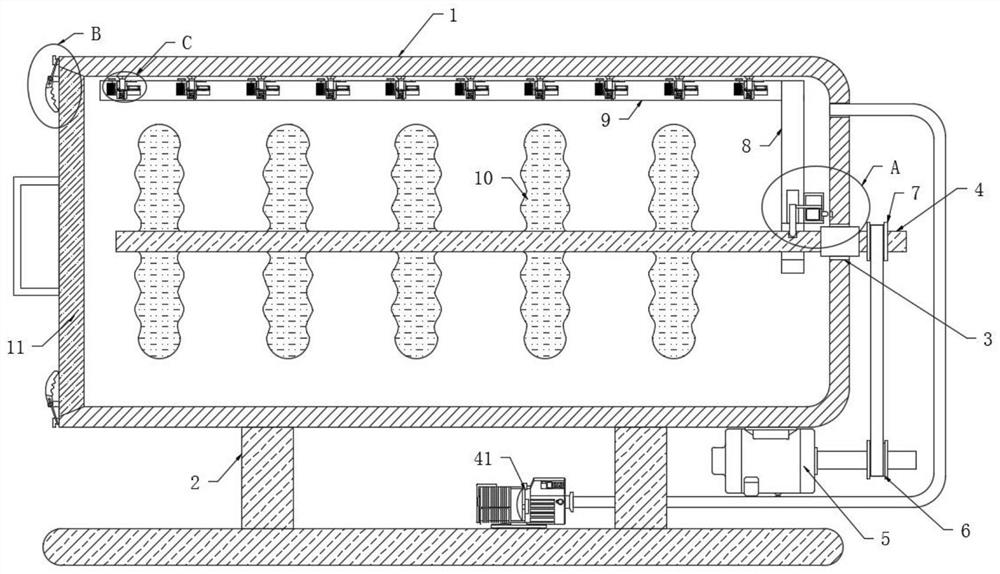

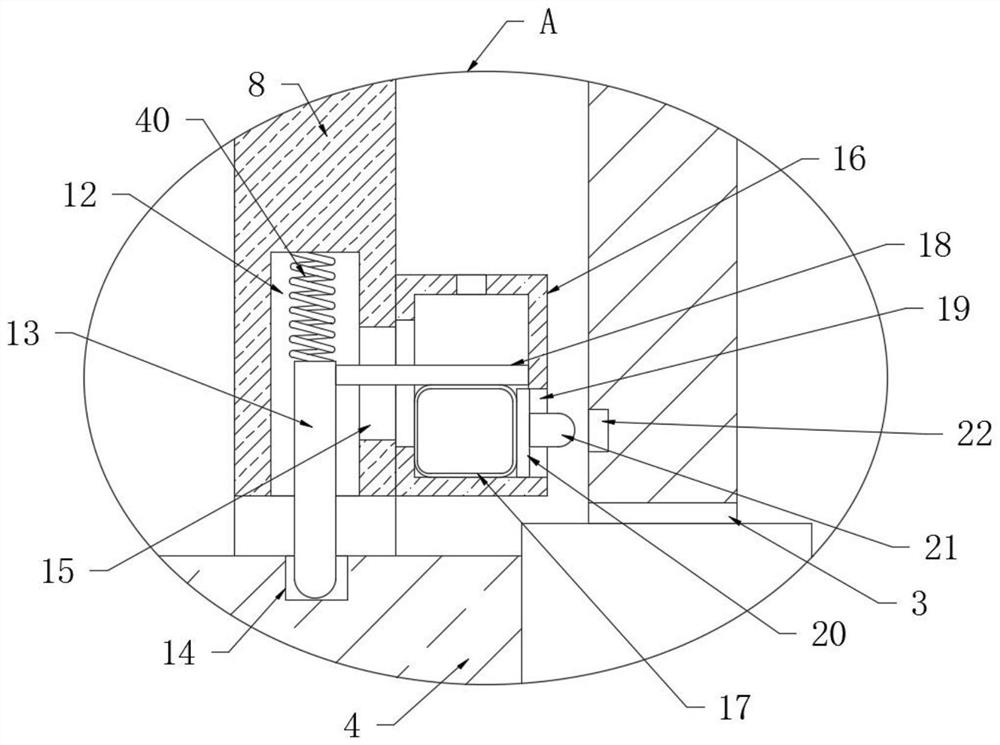

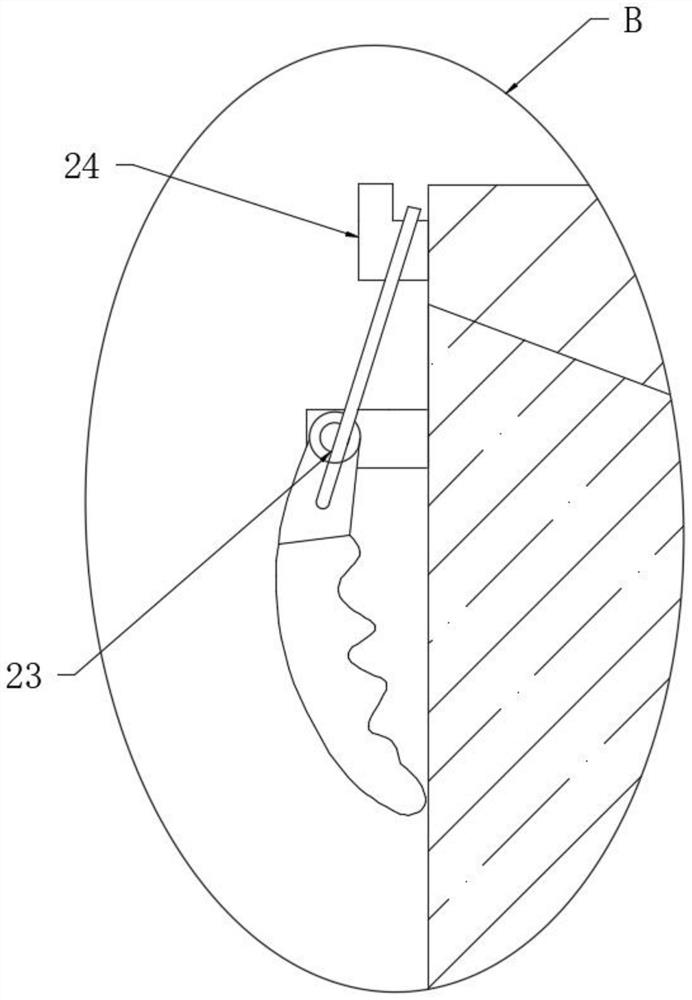

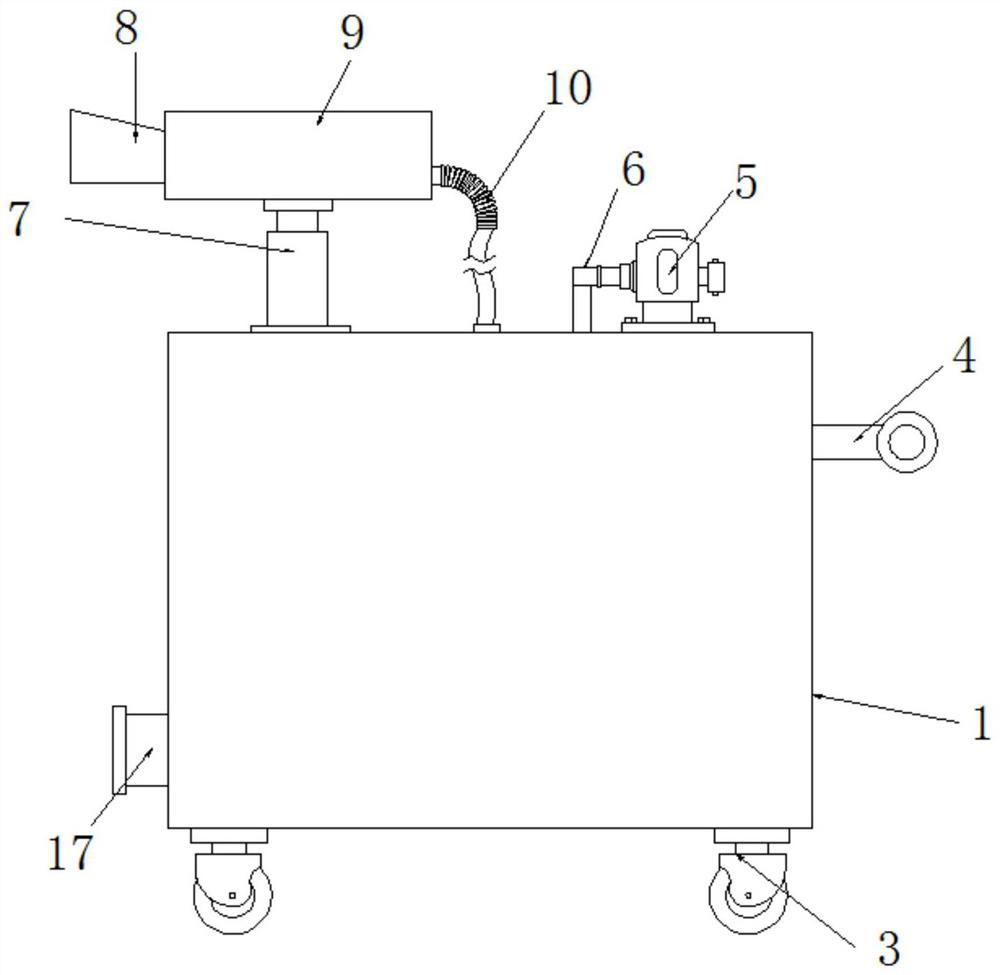

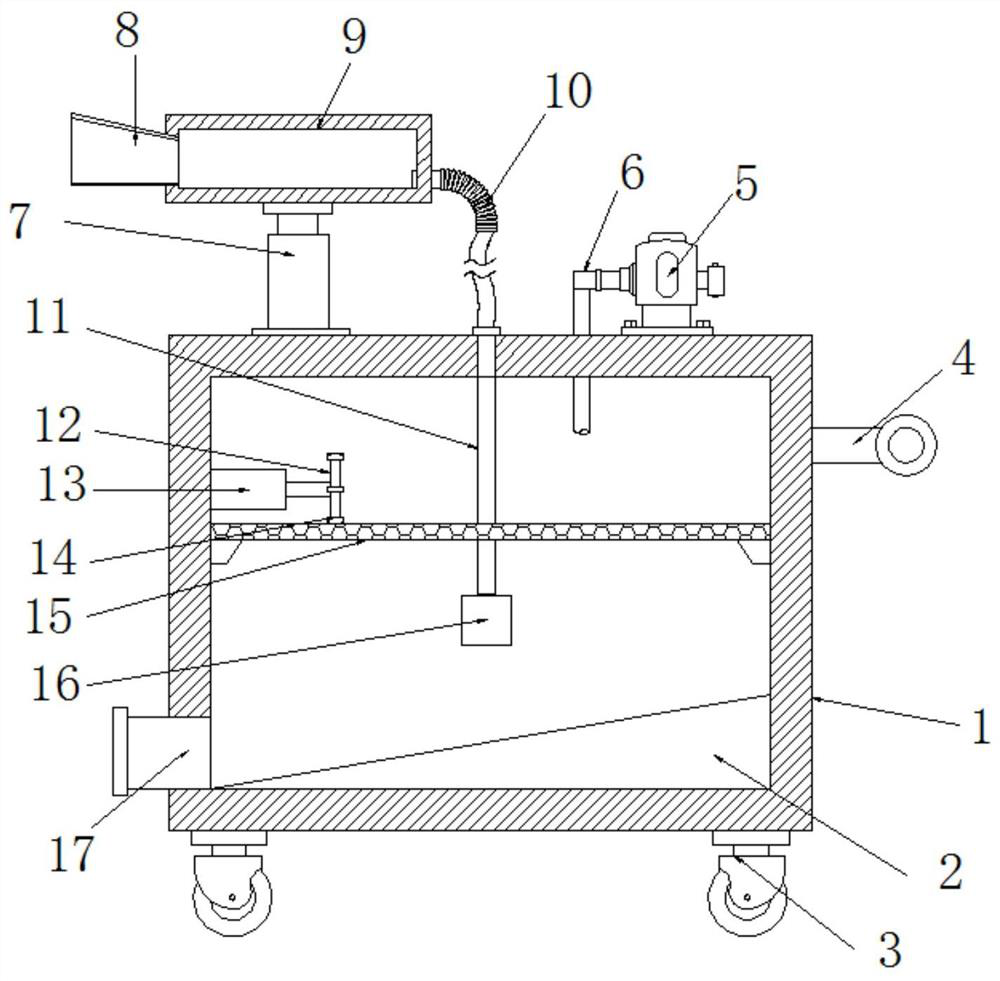

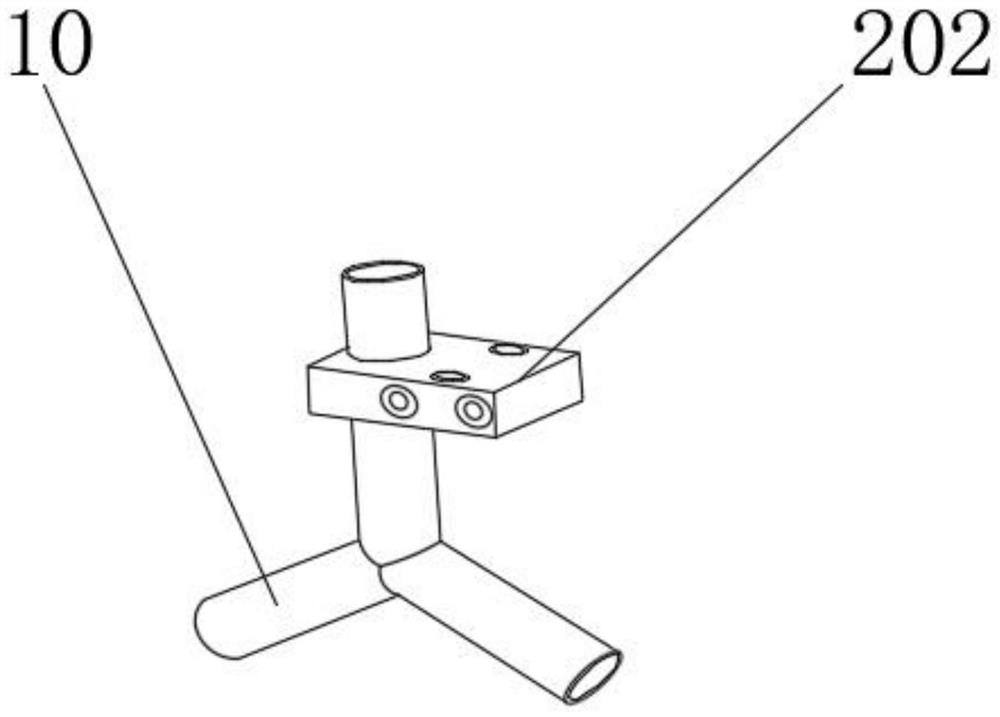

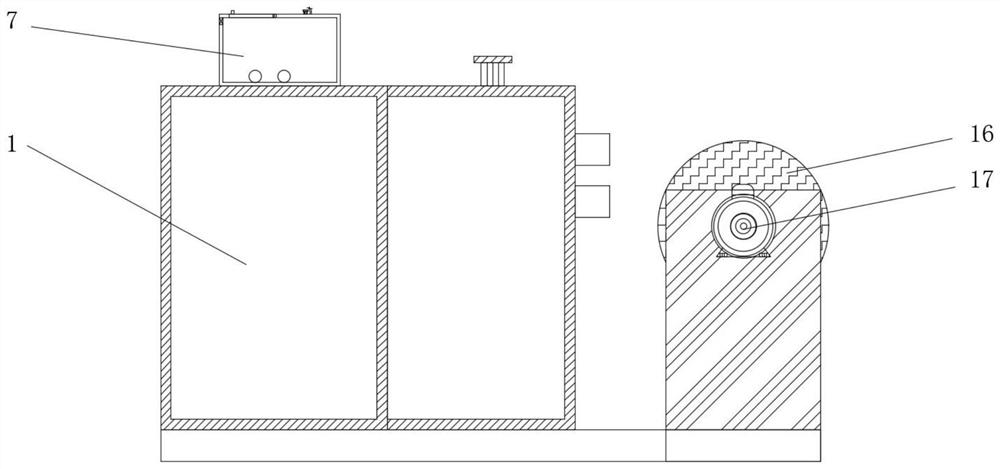

Vacuum tumbling machine for food processing

ActiveCN113040202AAchieve fixationAchieve sealingEngine sealsHollow article cleaningElectric machineryEngineering

The invention discloses a vacuum tumbling machine for food processing. The vacuumtumbling machine comprises a tumbling cylinder and a sealing plate, wherein the outer side wall of the tumbling cylinder is fixedly connected with a supporting base, the outer side wall of the supporting base is fixedly connected with a vacuum pump, the tail end of an air inlet pipe of the vacuum pump is fixedly connected with the outer side wall of the tumbling cylinder, a motor is fixedly connected to the outer side wall of the tumbling cylinder, a connecting groove is formed in the outer side wall of the tumbling cylinder, a stirring rod is rotationally connected to the inner side wall of the connecting groove, a second rotating wheel is fixedly connected to the outer side wall of the stirring rod, a plurality of stirring blades are fixedly connected to the outer side wall of the stirring rod, the stirring rod drives a cleaning rod to rotate through the transmission rod, as the tail end of abrush abuts against the inner side wall of the tumbling cylinder, cleaning of the inner side wall of the tumbling cylinder is achieved, in the rotating process of the cleaning rod, a cleaning liquid in a containing box is thrown out of a discharging groove, and then grease in the tumbling cylinder can be effectively cleaned.

Owner:山东德善食品有限公司

Dust removal device of pharmaceutical tablet press

InactiveCN112873983AEasy to vacuumImprove filtering effectDispersed particle filtrationTransportation and packagingDust controlStructural engineering

The invention discloses a dust removal device of a pharmaceutical tablet press. The dust removal device of the pharmaceutical tablet press comprises a box body, wherein a negative pressure mechanism and a dust collection mechanism are fixed to one side of the outer wall of the top of the box body, a filter screen is fixed in the box body, a hose is fixed to the air outlet end of the dust collection mechanism, a material guide pipe is fixed to one end of the hose, and the bottom end of the material guide pipe penetrates through the inner wall of the top of the box body to be inserted to the position below the filter screen. An air guide hopper is fixed to the bottom end of the material guide pipe, a discharging mechanism is fixed to the bottom end of the outer wall of one side of the box body, moving wheels are fixed to the four corners of the outer wall of the bottom of the box body, and a push handle is fixed to the outer wall of one side of the box body. The dust removal device of the pharmaceutical tablet press can utilize the negative pressure mechanism and the dust collection mechanism to carry out dust collection work on the tablet press, and dust collection treatment can be conveniently carried out on tablet press pressing mechanisms with different heights.

Owner:湖北科田药业有限公司

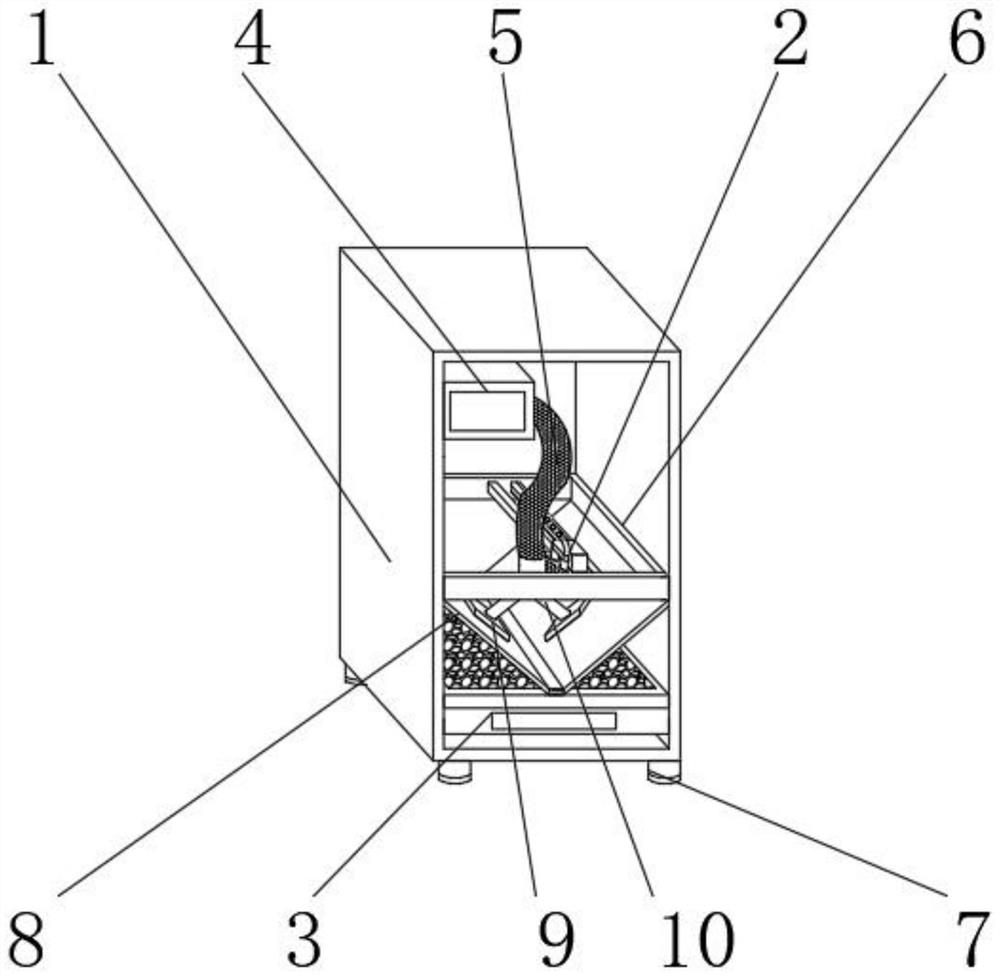

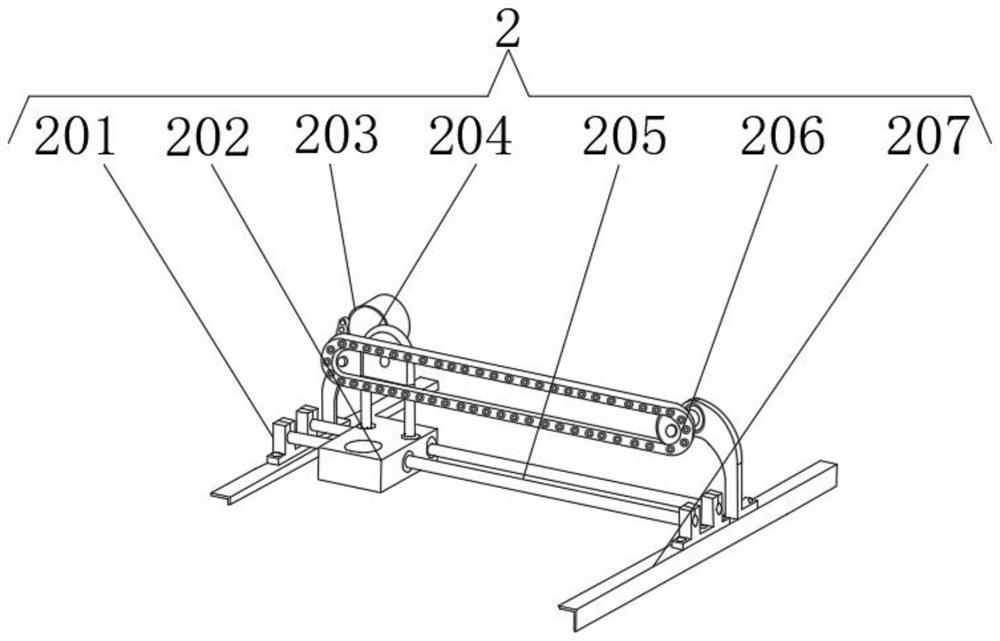

Large-length reciprocating transmission mechanism

PendingCN112452071AImprove adsorption capacityEasy to vacuumPipe supportsDispersed particle filtrationStructural engineeringMechanical engineering

The invention discloses a large-length reciprocating transmission mechanism which comprises a device box body, a dust collector bin is arranged in the device box body, a hose is arranged on the outersurface of one side of the dust collector bin, a three-way air pipe is arranged on the outer surface of the lower end of the hose, and a reciprocating transmission mechanism is arranged on the outer surface of one side of the three-way air pipe; a fixed side plate is arranged on the outer surface of one side of the reciprocating transmission mechanism, a dust suction plate and a filter screen arearranged on the outer surface of the lower end of the three-way air pipe, the dust suction plate is located on one side of the filter screen, and a fixed support is arranged on the outer surface of the lower end of the device box body. The large-length reciprocating transmission mechanism is simple and compact in structure, easy to manufacture, reliable in work, large in transmission length, reliable in work, stable and adjustable in speed, stable in transmission, free of noise, small in overall dimension, small in complex end point outer side space requirement, convenient to maintain and capable of bringing better use prospects.

Owner:合肥库仑电气科技有限责任公司

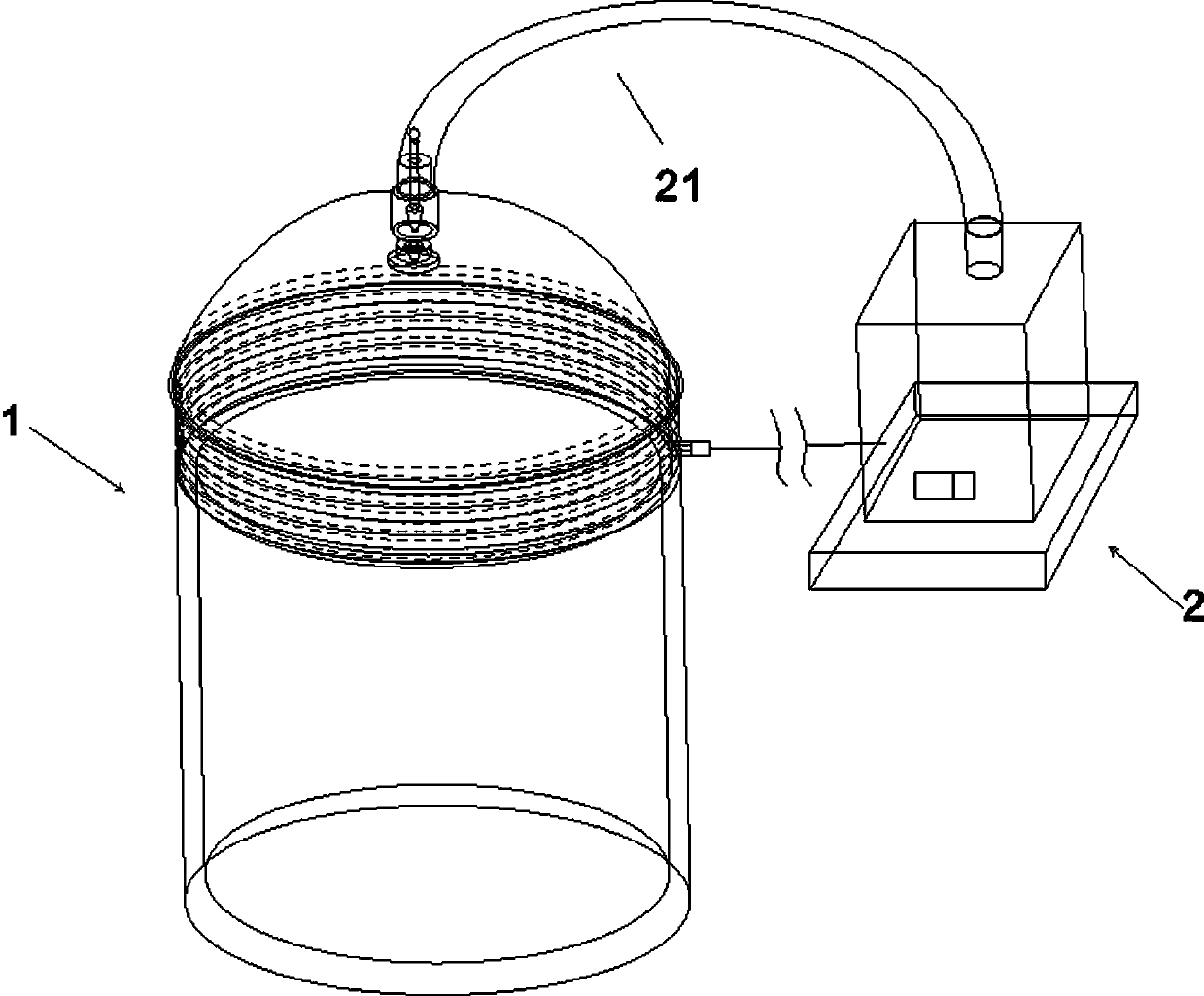

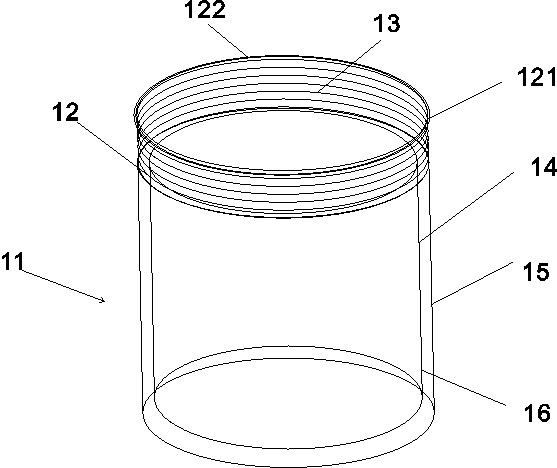

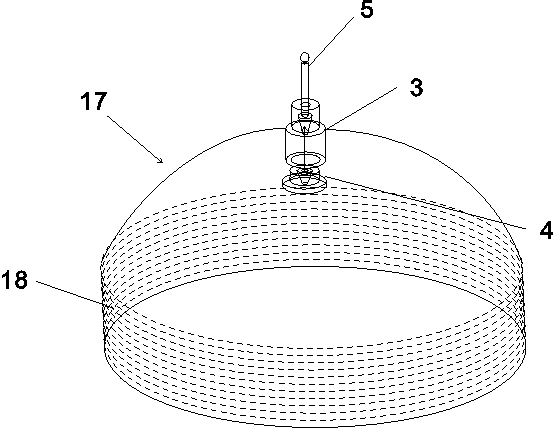

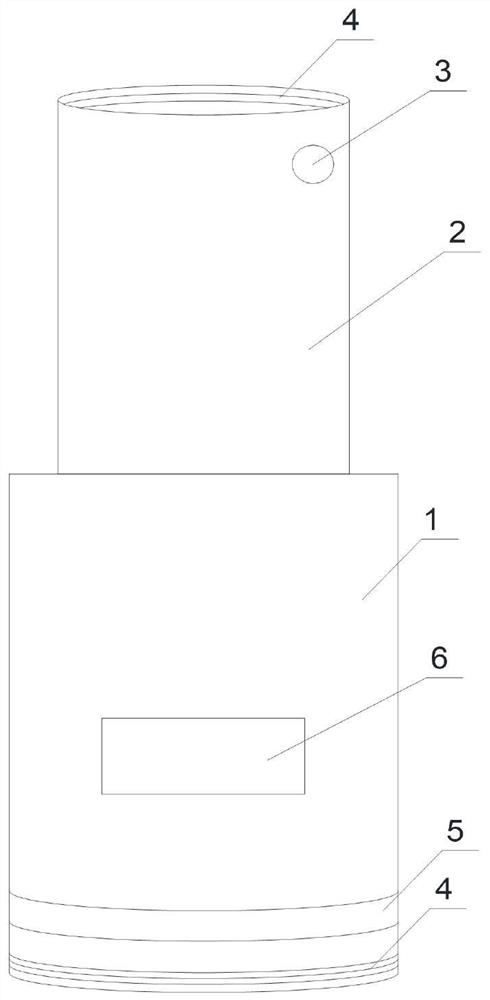

Negative pressure vacuum honeying tank

InactiveCN110839807APrevent air leakageEasy to vacuumFood preservationEngineeringMechanical engineering

The invention relates to a negative-pressure vacuum honeying tank, which comprises a honeying tank and an air extraction electric pump; the air extraction electric pump is provided with a switch and apower cord, the power cord is provided with a power plug, the air extraction electric pump is provided with an air extraction pipe, and a hose is arranged on the air extraction pipe in sleeving manner. The negative-pressure vacuum honeying tank is characterized in that the honeying tank comprises a tank body and a cover which is screwed on the tank body, the tank body comprises an inner layer andan outer layer, a vacuum layer is arranged between the inner layer and the outer layer, an opening part which is extended is arranged in the top surface of the tank body, the outside of the opening part is provided with an external thread along the circumference of the opening part, the top surface of the cover is of a semicircular structure, an internal thread which is screwed on the external thread is on the inside of the cover along the circumference of the cover, and when the cover covers the tank body, the internal thread is in threaded connection with the external thread for fitting. The honeying tank is connected with a flexible pipe through the air extraction electric pump to extract the interior of the tank body through the cover, so that a vacuum state is formed in the tank body, and preserved fruits placed in the tank body can be conveniently stored.

Owner:九江鸿立食品有限公司

Ball grinding machine dust suction device for ceramic tile machining

ActiveCN108672030AEasy to vacuumCompact structureHollow article cleaningDirt cleaningBall millMachining

The invention discloses a ball grinding machine dust suction device for ceramic tile machining. The ball grinding machine dust suction device comprises a dust suction device body. The dust suction device body is composed of a supporting mechanism, a rotation mechanism and a dust suction mechanism. The supporting mechanism is composed of a first fixing plate, a grafting sliding rod, a second fixingplate, a first fixing electromagnet, a first electric telescopic rod, a connecting plate, a distance adjusting push rod and a movable sliding column. The ball grinding machine dust suction device iscompact in structure, and is conveniently used for ball grinding machine dust suction; through the arrangement of the supporting mechanism and the grafting sliding rod, the stroke of the dust suctionmechanism can be adjusted according to the length of a ball grinding machine during usage, the ball grinding machine dust suction device can conduct dust suction for ball grinding machines different in type and specification, and using practicability is improved; and through the arrangement of the rotation mechanism and a second electric telescopic rod, the distance between a dust suction port andthe inner wall of a ball grinding machine can be adjusted through the ball grinding machine dust suction device, a cleaning brush can be closely attached to the inner wall of the ball grinding machine, the dust suction efficiency and convenience are improved, and the ball grinding machine dust suction device is flexible and adjustable in structure and convenient and fast to use.

Owner:周昱行

Textile winding machine capable of achieving treatment to fabric scraps

InactiveCN113428701AEasy to vacuumPlay an auxiliary supporting roleMechanical cleaningPressure cleaningWinding machineIndustrial engineering

The invention discloses a textile winding machine capable of achieving treatment to fabric scraps. The textile winding machine comprises a bracket, a second feeding roller, a base and a control box, wherein a first feeding roller is rotatably connected to the inner wall of the bracket; a first supporting plate is fixed to the inner wall of the lower side of the bracket, and meanwhile a manipulator is fixed to the first supporting plate and the inner wall of the bracket; a second supporting plate is fixed to the manipulator, and an auxiliary supporting assembly and a scrap removing assembly are fixed to the upper side of the second supporting plate; a spray washing assembly is fixed to the upper side of the scrap removing assembly, and the second feeding roller is rotatably connected to the inner wall of the bracket; a cutting mechanism is located on the left side of a bracket dismounting assembly, and a limiting groove is formed in a limiting roller; and a moving mechanism is fixed to the base. The textile winding machine capable of achieving treatment to the fabric scraps has the advantages that the fabric scraps can be removed, the auxiliary supporting effect can be achieved during scrap removal, the cloth can be ironed, and a cloth roller can be automatically detached.

Owner:江苏雅高纺织科技有限公司

Sealing device and method for anaerobic fermentation

PendingCN112522069AImprove sealingEasy to vacuumBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryFood packaging

The invention discloses a sealing device and method for anaerobic fermentation. The sealing device comprises an outer sealing bag and an inner sealing bag, wherein the inner sealing bag is located inthe outer sealing bag. The sealing method comprises the following step of performing sealing storage on fermentation raw materials by adopting a double-layer sealing structure. According to the invention, the sealing device with the double-layer structure is designed, and the inner-layer structure can be sealed through the outer sealing structure, so that the sealing performance of the whole device is improved; and the double-layer sealing structure solves the problem that in the prior art, a simple food packaging bag is adopted for packaging the fermentation raw materials, so that the sealingperformance is poor.

Owner:倪国帮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com