Robot welding fume purifying and collecting device and treatment method thereof

A technology for robotic welding and fume purification, applied in chemical instruments and methods, fume removal, separation methods, etc., can solve problems such as inability to adjust the collection position, inability to purify fume, and troublesome fume collection, and achieve a simple and convenient structure. The effect of processing and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

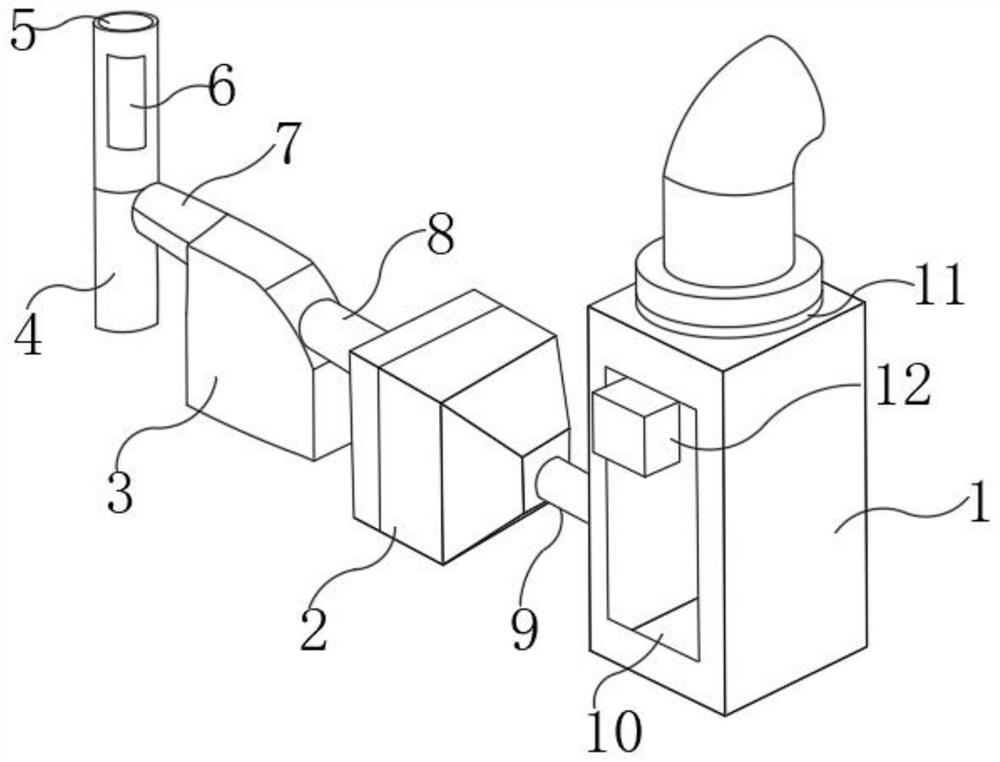

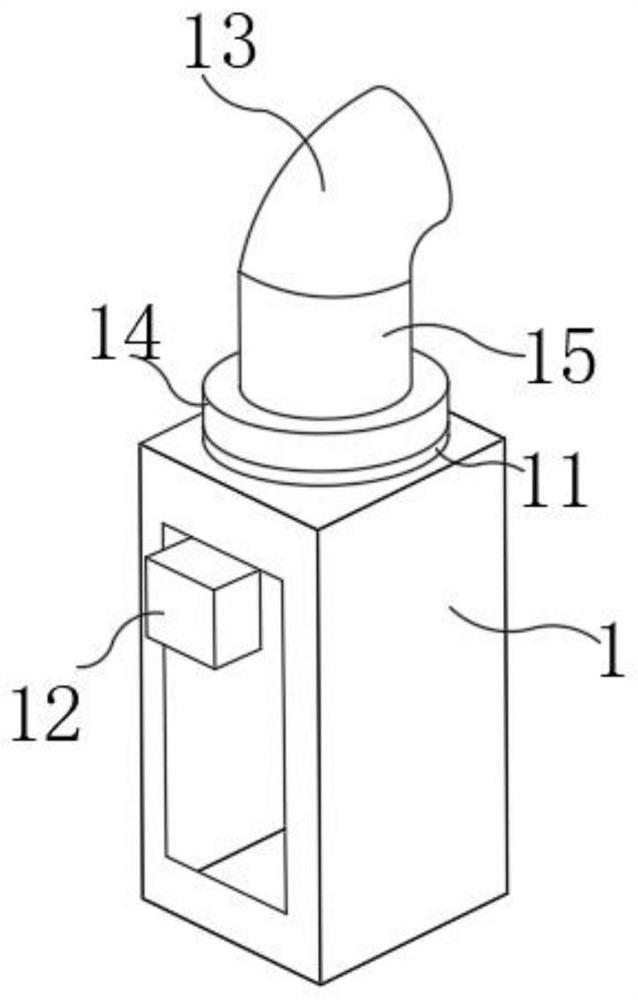

[0030] Such as Figure 1-5 As shown, a robot welding fume purification and collection device includes a dust collection box 1, the dust collection box 1 is connected with a No. One end is connected with No. 2 connecting air pipe 8, one end of No. 2 connecting air pipe 8 is connected with fan box 3, one end of fan box 3 is connected with No. 1 connecting air duct 7, and one end of No. 1 connecting air duct 7 is connected with discharge chimney 4 , the outer wall of the discharge chimney 4 is fixedly connected with an outlet detection mechanism 6 , and the upper end of the discharge chimney 4 is provided with a discharge port 5 .

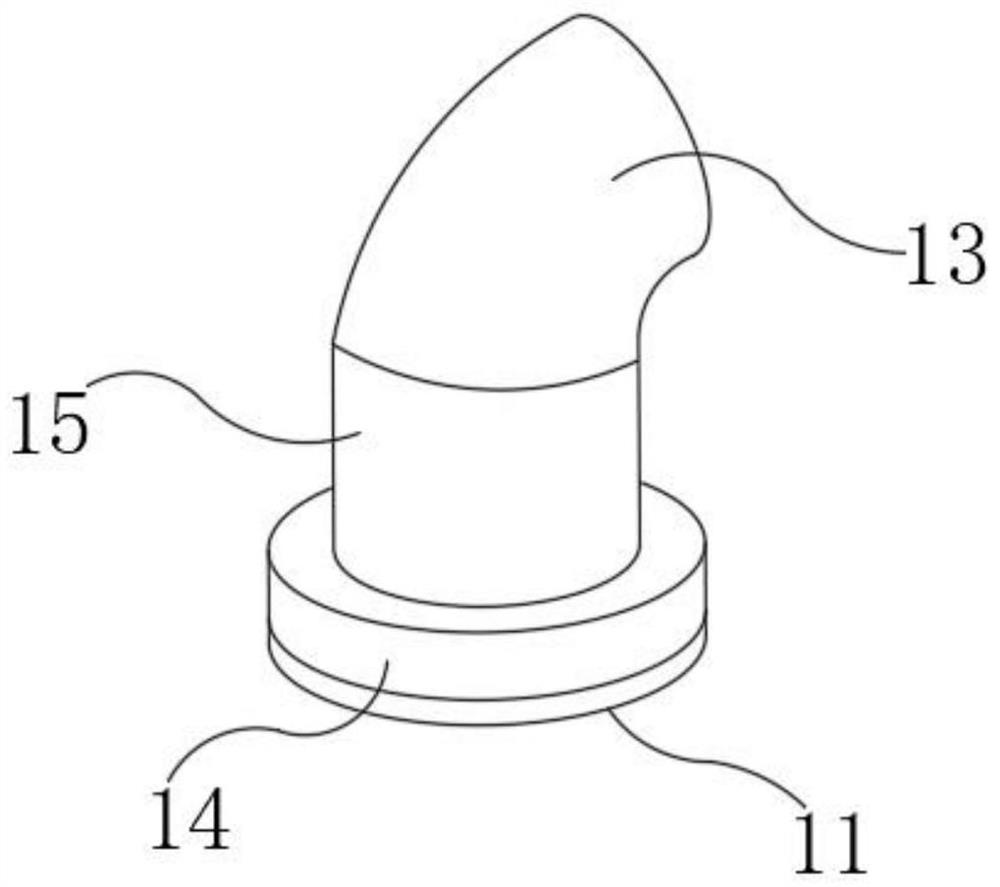

[0031] The front end of the dust collection box 1 is equipped with an observation window 10, the outside of the dust collection box 1 is equipped with an air intake detection mechanism 12, the upper end of the dust collection box 1 is movably installed with a rotating seat 11, and the upper end of the rotating seat 11 is installed with a dust suction ...

Embodiment 2

[0038] On the basis of Embodiment 1, a processing method for a robot welding fume purification and collection device includes the following steps:

[0039] S1: Move the dust collection box 1 to the position near the welding station of the robot, move the position of the dust suction fan 14 through the rotating seat 11, align the dust suction pipe 13 with the position of the welding station, turn on the dust suction fan 14, and The dust pipe 13 performs the dust suction operation;

[0040] S2: The collected smoke and dust enters the inside of the smoke and dust collection box 1, and the observation window 10 is installed at the front end for observation. The air intake detection mechanism 12 can observe the internal smoke and dust content, and the smoke and dust enter the inside of the smoke and dust purification box 2 for purification through the No. 3 connecting air duct 9 Operation, adsorption is carried out by purifier 17, and purifying feeding port 18 is put into purifying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com