Device and method for collecting dust in front of magnesium ingot smelting reduction furnace

A technology of dust collection device and reduction furnace, which is applied in the fields of dust collection device, dust collection before magnesium ingot smelting and reduction furnace, and dust collection device before magnesium ingot smelting and reduction furnace, which can solve the problem of poor dust collection effect and low dust collection efficiency, etc. problem, achieve the effect of saving time and labor, high dust collection efficiency and good dust collection effect in the dust collection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

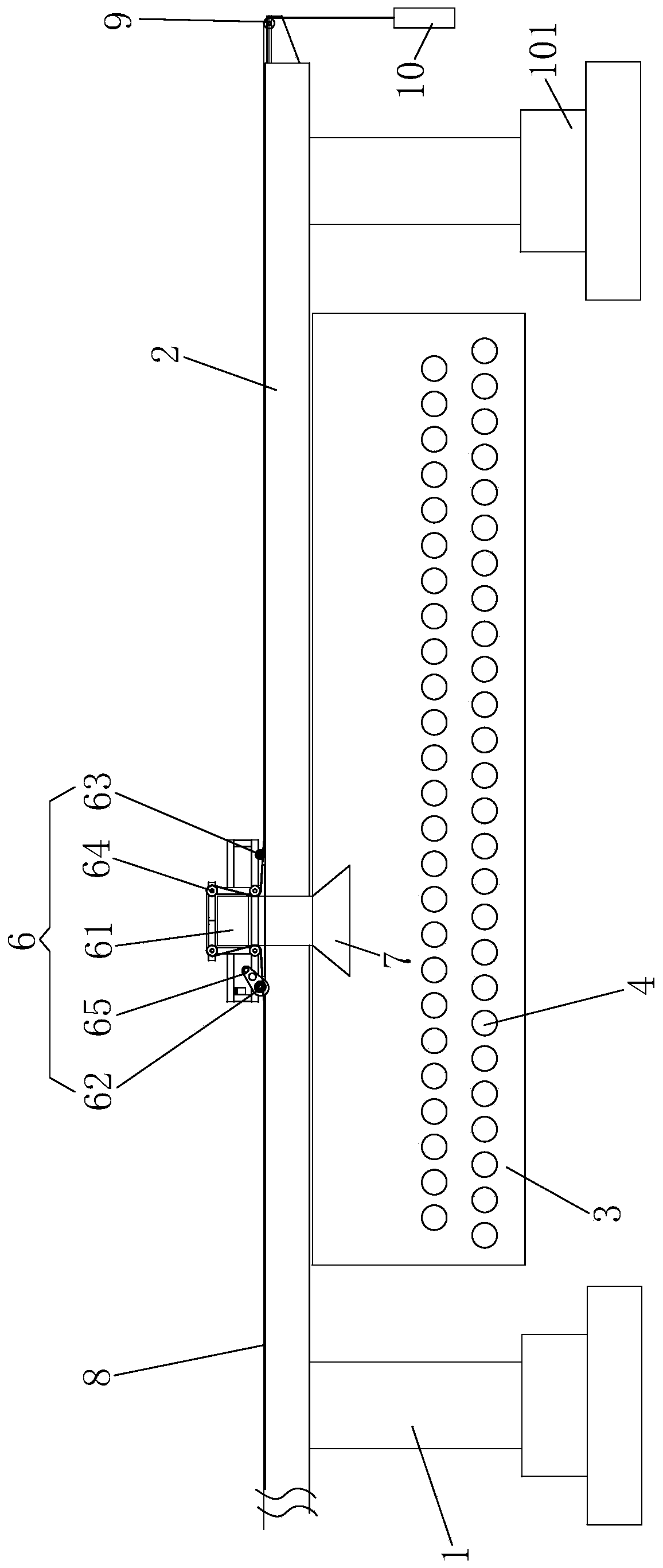

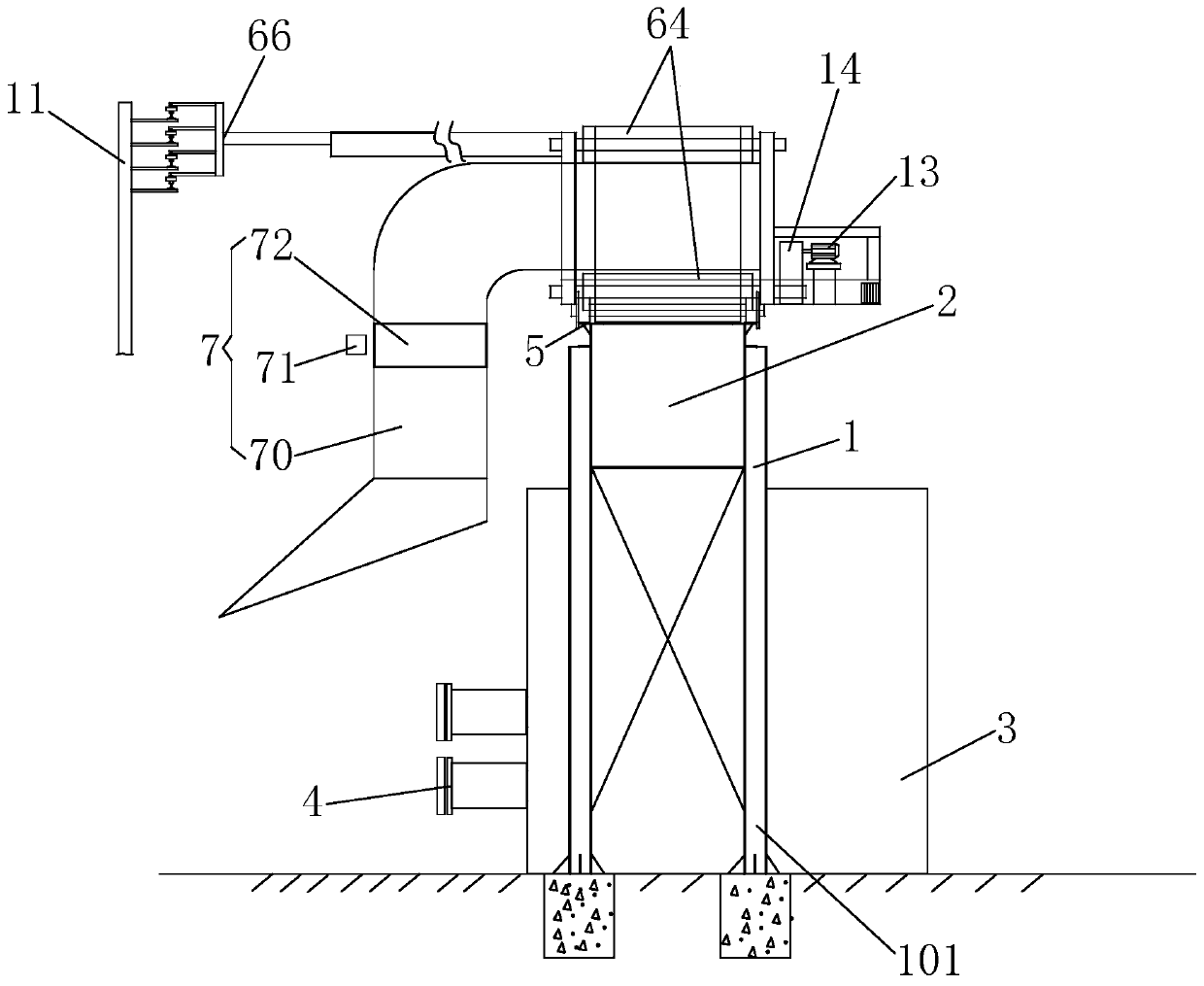

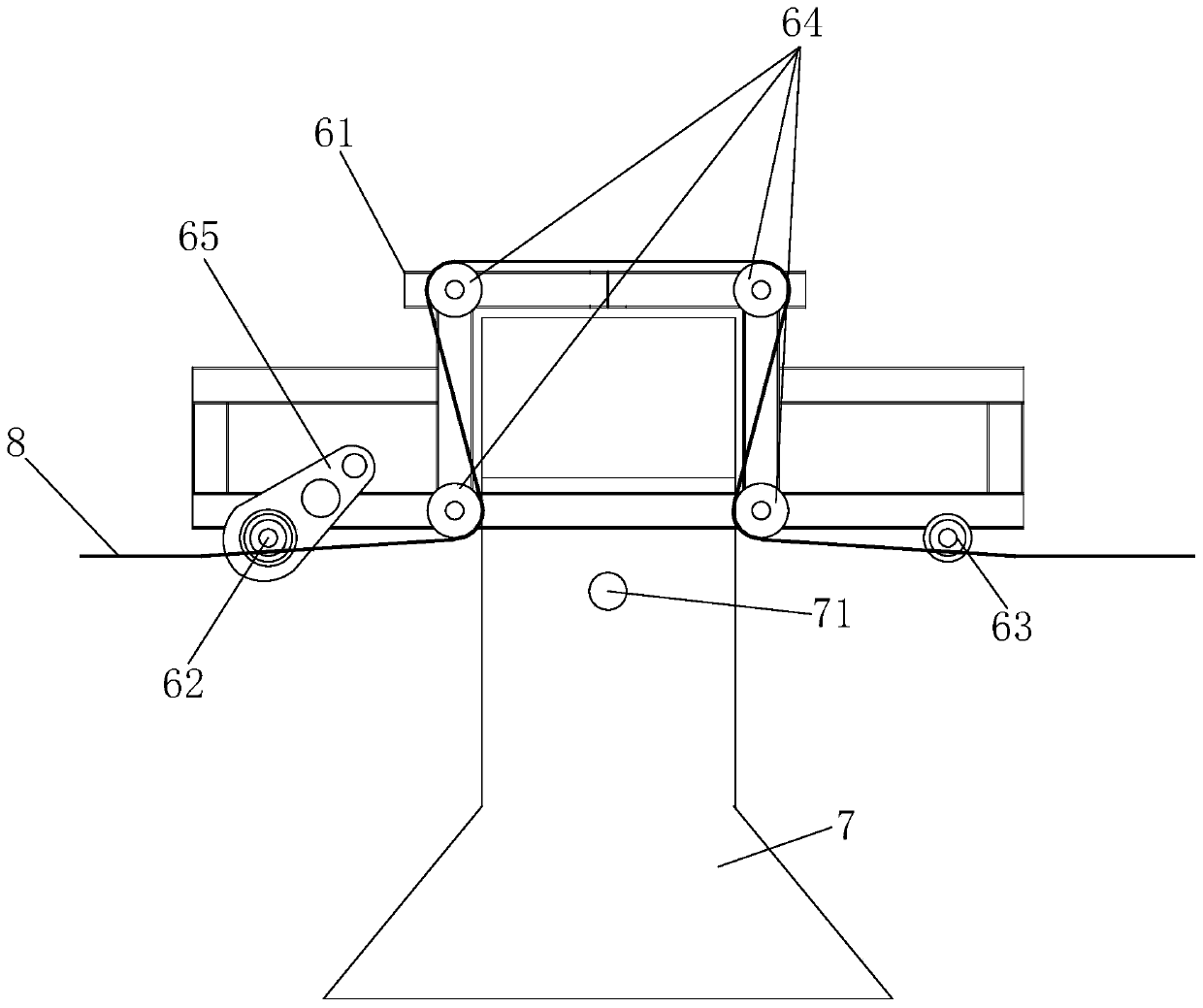

[0061] see figure 1 , figure 2 as well as image 3 , This embodiment provides a dust collecting device in front of the magnesium ingot smelting reduction furnace. The dust collection device is used to collect the smoke and dust in front of the reduction furnace during the production of crude magnesium, and discharge the smoke and dust after treatment. The dust collection device includes a support 1, a smoke guide pipe 2, a track 5, a dust collection vehicle 6, a drive mechanism, a dust collection cover 7, a detection mechanism and a controller, and may also include a belt and a tension mechanism. Wherein, a plurality of reduction tanks 4 are arranged in the reduction furnace 3, and their arrangement and quantity are determined according to actual needs. The reduction furnace 3 is provided with multiple inlets and outlets, through which the reduction tank 4 can be operated, and other structures in the reduction furnace 3 can also be operated.

[0062] see Figure 4 , the ...

Embodiment 2

[0078] This embodiment provides a dust collection device in front of the magnesium ingot smelting reduction furnace, which adds a bag filter 15 and an induced draft fan 16 on the basis of the first embodiment. The bag filter 15 communicates with the smoke guide pipe 2, and it can collect the dust in the smoke from the smoke guide pipe 2. The induced draft fan 16 communicates with the bag filter 15 and absorbs the smoke and dust in the smoke guide pipe 2 through the bag filter 15 . The smoke and dust coming from the smoke guide pipe 2 will be sent into the chimney 12 and discharged after passing through the bag filter 15 and the induced draft fan 16 . In this way, the induced draft fan 16 can suck away the dust in the smoke guide pipe 2 through the bag filter 15, so that a negative pressure is generated in the smoke guide pipe 2 to ensure that the smoke in the smoke guide pipe 2 is processed in time without overflowing from the smoking window. At the same time, the bag filter ...

Embodiment 3

[0080] This embodiment provides a dust collecting device in front of the magnesium ingot smelting and reducing furnace, which is similar to the dust collecting device in front of the magnesium ingot smelting and reducing furnace in embodiment 1, the difference is that the trolley wire power supply integration 11 is added in this embodiment, At the same time, the dust collection vehicle 6 also includes a collector 66 . One end of the current collector 66 is fixed on the vehicle body 61, and the other end can follow the movement of the vehicle body 61, and the trajectory of the movement is a horizontal line. The trolley line power supply integration 11 is arranged on one side of the track 5 and overlapped with the other end of the collector 66 , and supplies power to the dust collecting vehicle 6 through the collector 66 . The cooperation mode of collector 66 and trolley line power supply integration 11 is similar to the existing trolley power supply mode, one of which is in mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com