Sealing bayonet device for vacuumizing

A sealing card and vacuuming technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of non-reusability, easy air leakage, failure of bayonet sealing operation, etc., to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

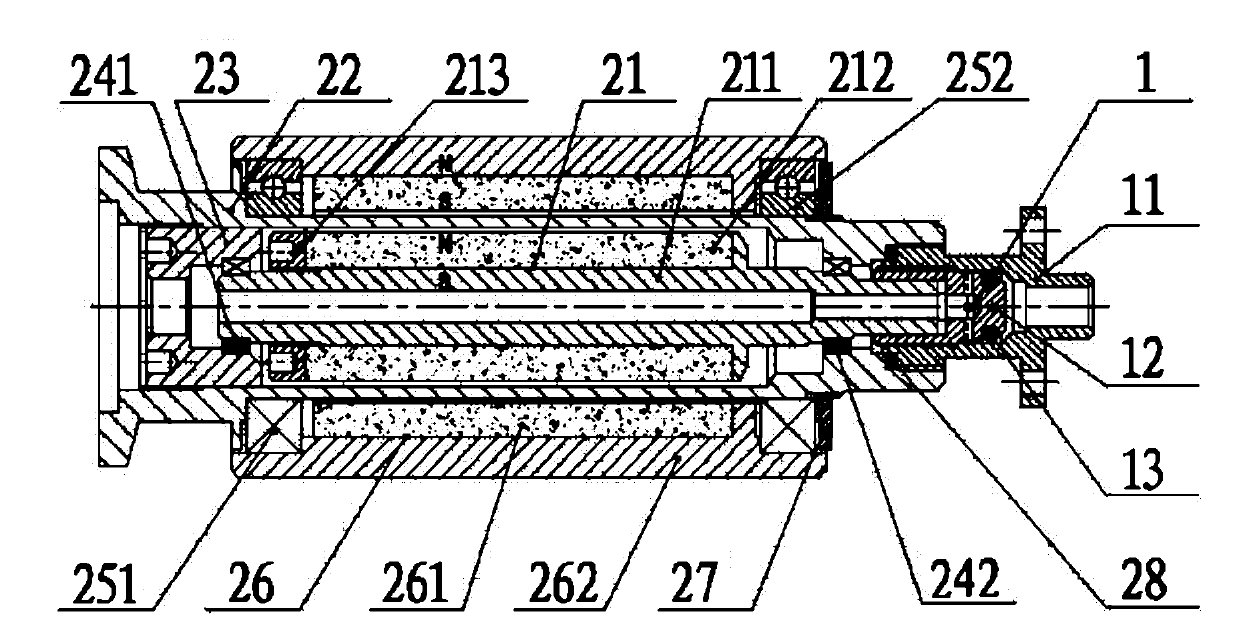

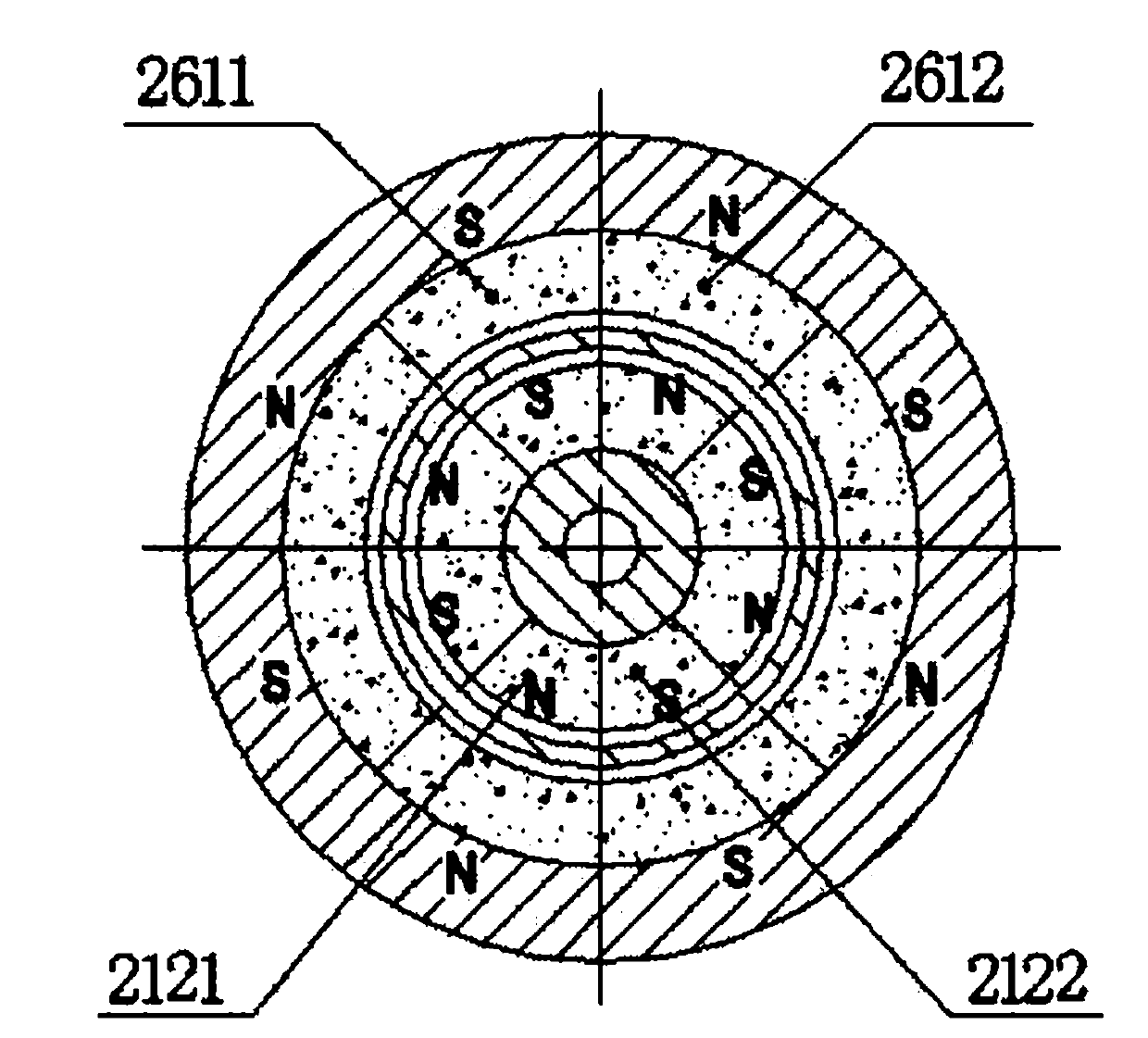

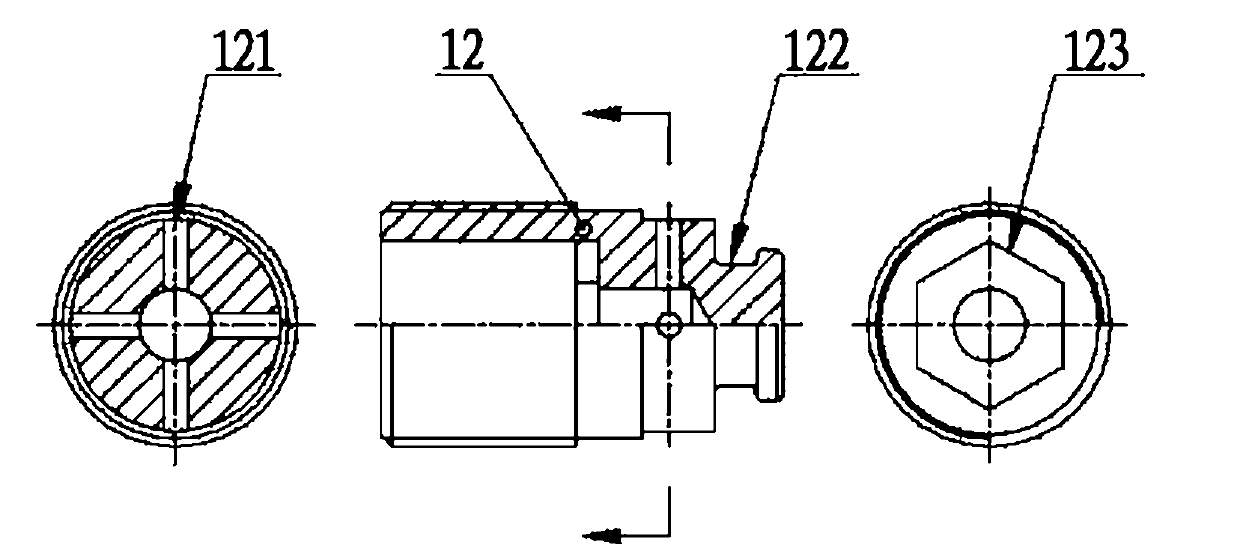

[0013] like figure 1 As shown, the present invention is composed of two parts, the air extraction nozzle 1 and the operation wrench 2; the air extraction nozzle 1 is composed of an air extraction nozzle seat 11, a threaded plug 12 and a rubber ring 13; the rubber ring 13 is installed in the ring groove at the right end of the threaded plug 12 122 (see image 3 ), the polygonal hole 123 at the left end of the screw plug 12 (see image 3 ) and the radial hole 121 on it (see image 3 ) are interlinked; the threaded plug 12 is installed in the internal thread hole of the air extraction nozzle seat 11 through threads; Bearing 251, the 4th bearing 252, magnetic steel cover 26, bearing cover 27 and sealing ring 28 are made up; Magnetic steel shaft 21 is made of tile-shaped first inner ring magnetic steel 2121 and the second inner ring magnetic steel 2121 and the second inner ring with the same shape and opposite radial magnetization directions. The ring magnetic steel 2122 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com