Dust removal device of pharmaceutical tablet press

A dust removal device, tablet press technology, applied in the direction of presses, material molding presses, manufacturing tools, etc., can solve the problems of dust pollution, drug powder overflow, etc., to achieve the effect of improving filtration capacity and increasing adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

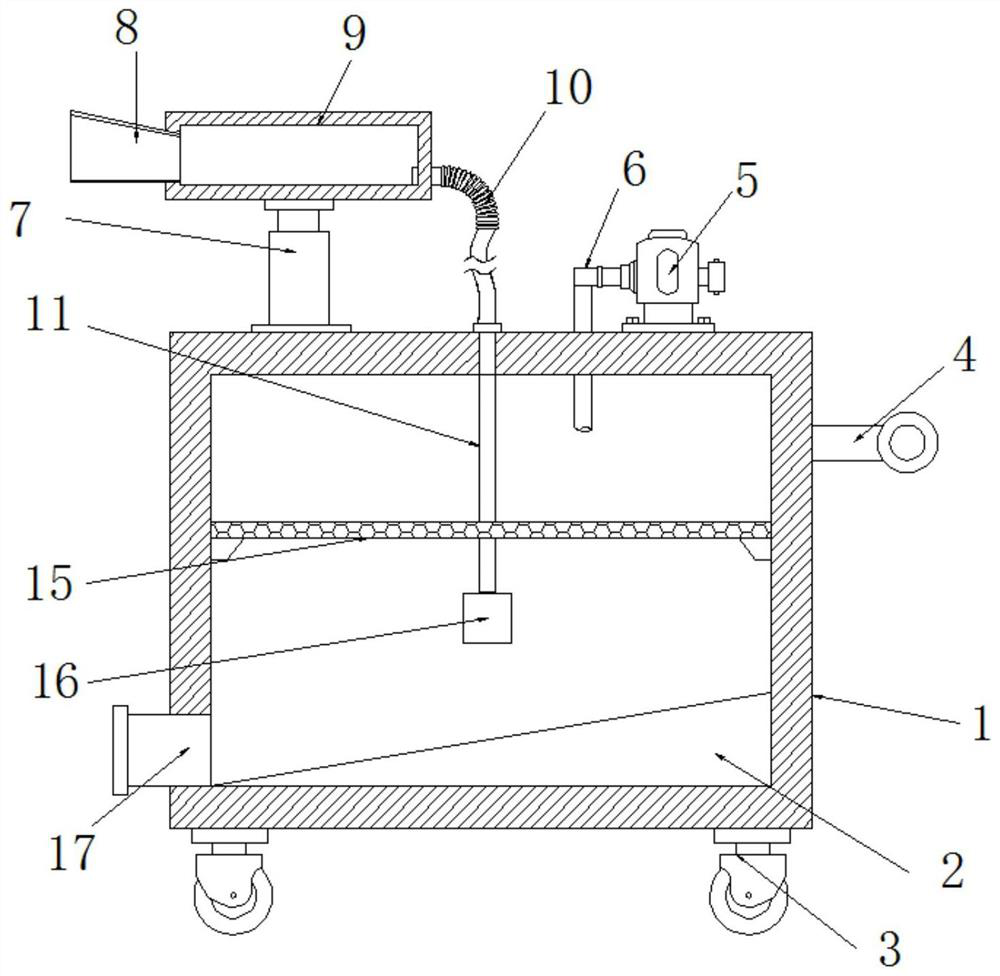

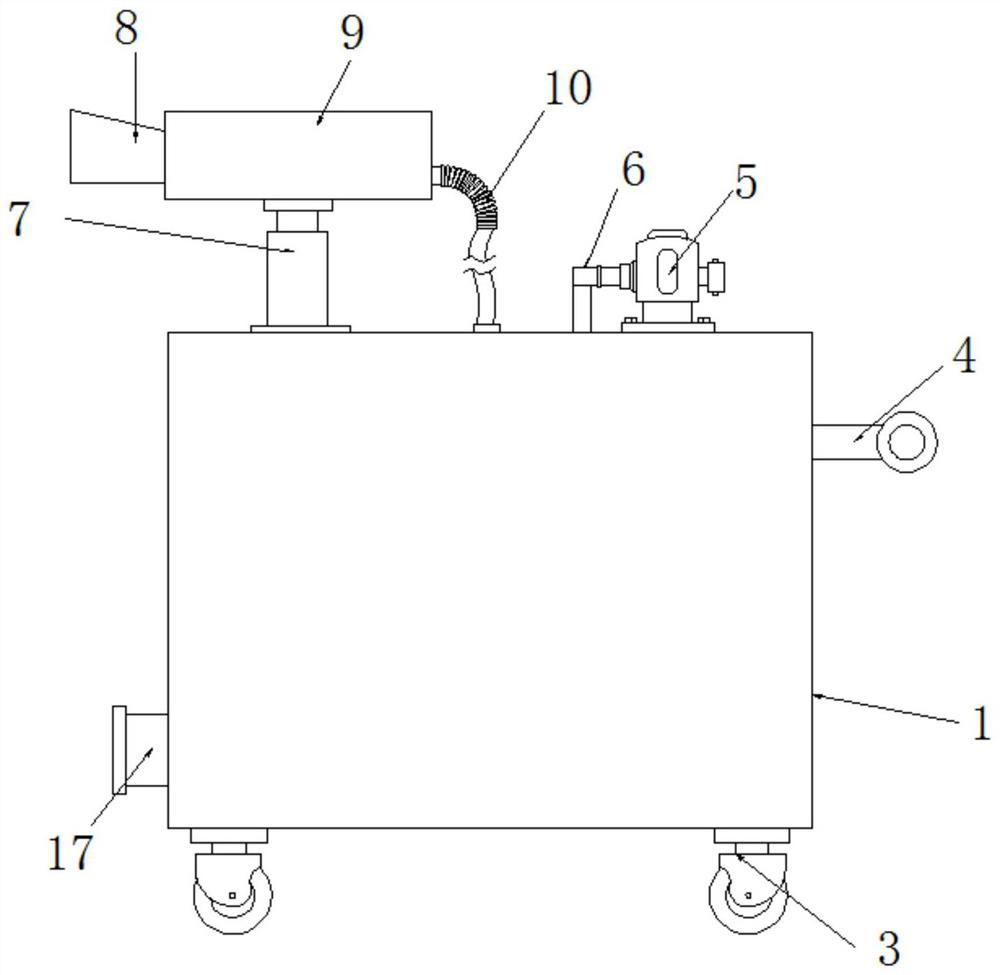

[0023] refer to figure 1 with figure 2 , a dust removal device for a pharmaceutical tablet press, comprising a box body 1, a negative pressure mechanism and a dust suction mechanism are fixed on one side of the top outer wall of the box body 1, and a filter screen 15 is fixed inside the box body 1, and the air outlet end of the dust suction mechanism A hose 10 is fixed, one end of the hose 10 is fixed with a guide tube 11, the bottom end of the guide tube 11 passes through the top inner wall of the box body 1 and is inserted under the filter screen 15, and the bottom end of the guide tube 11 is fixed with an air guide bucket 16 A discharge mechanism is fixed at the bottom of the outer wall on one side of the box body 1, and moving wheels 3 are fixed at four corners of the outer wall at the bottom of the box body 1, and a push handle 4 is fixed on the outer wall on one side of the box body 1.

[0024] The dust collection mechanism includes a material guide box 9, a suction no...

Embodiment 2

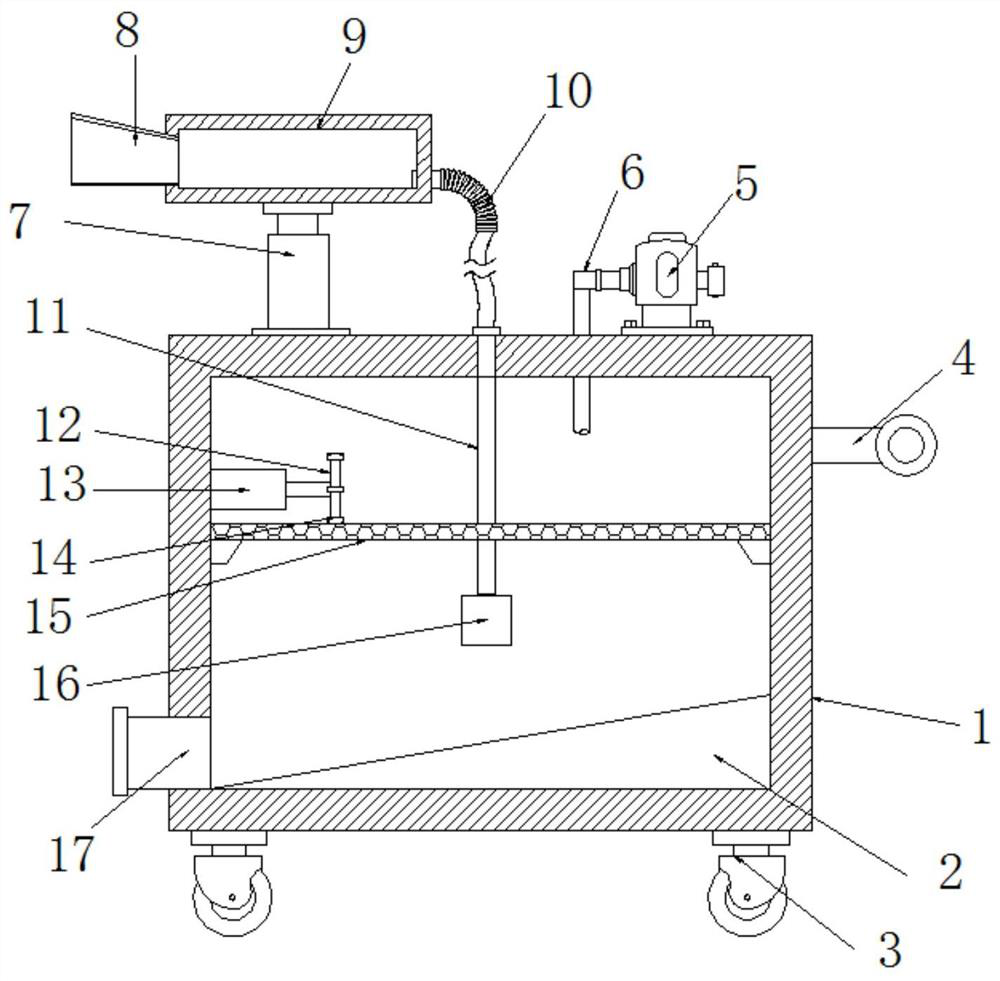

[0027] refer to image 3 , a dust removal device for a pharmaceutical tablet press. The difference between this embodiment and Embodiment 1 is that a motor 13 is fixed on the inner wall of one side of the box body 1, the output shaft of the motor 13 is fixed with a turntable 12, and the outer circumference of the turntable 12 is fixed with a A plurality of rubber bumps 14 are distributed equidistantly, and the rubber bumps 14 are in contact with the upper surface of the filter screen 15 .

[0028] The working principle of this embodiment: the turntable 12 can rotate under the drive of the motor 13, and the rubber bump 14 beats the filter screen 15 during the rotation process, so that the dust adsorbed on the bottom of the filter screen 15 is shaken off, improving the filtering capacity of the filter screen 15, increasing Dust adsorption effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com