Stabilizing device and method for steel plate laser cutting

A laser cutting and stabilizing device technology, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of limited area of laser cutting table, downward bending and deformation of steel plate, easy shaking and offset of steel plate, etc., to achieve Vacuum adsorption is convenient for fixing, improving product precision and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

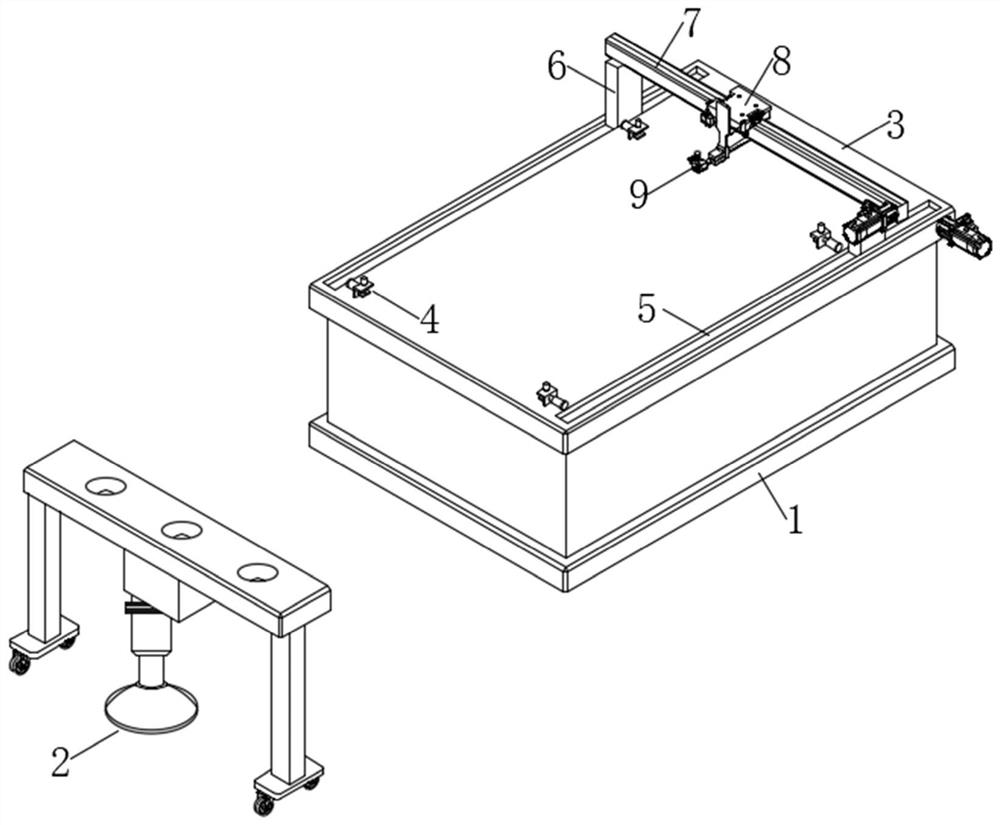

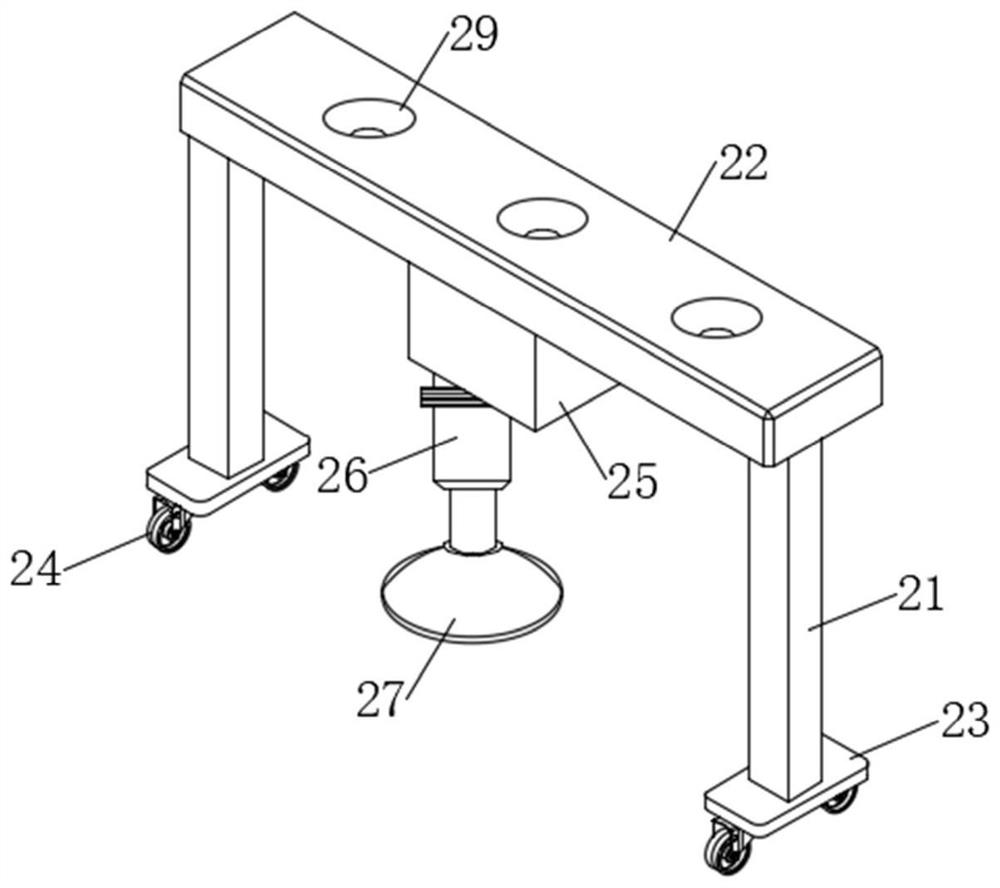

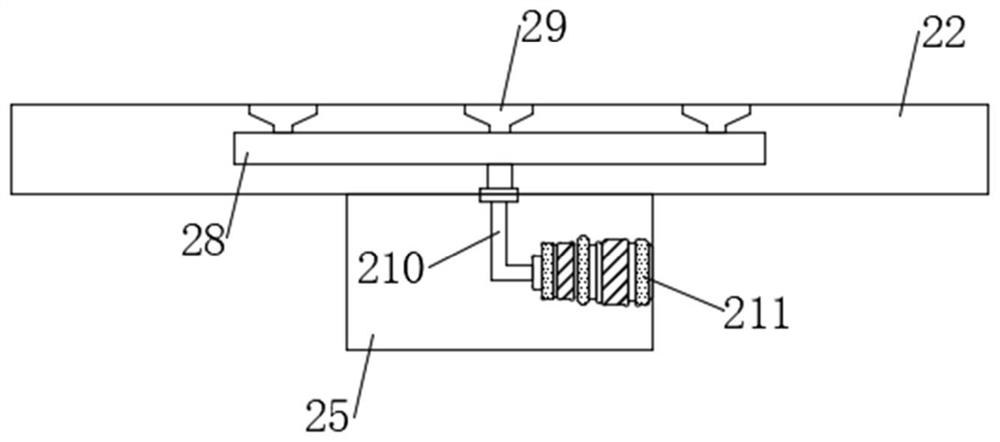

[0025]Such asFigure 1-4As shown, this specific embodiment adopts the following technical solutions: a stabilizing device for laser cutting of steel plates, including a cutting machine base 1 and a movable support table 2, and a movable support table 2 is provided on one side of the cutting machine base 1, and The top of the cutting machine base 1 is fixedly installed with a fixed cutting table 3, the fixed cutting table 3 is provided with a workpiece anti-deflection mechanism 4, and the opposite sides of the top of the fixed cutting table 3 are installed with a guide rail 5, two The No. 1 moving seat 6 of the same structure is installed on the No. 1 guide rail 5, the No. 2 guide rail 7 is fixedly installed on the tops of the two No. 1 moving seats 6, and the No. 2 moving seat is installed on the No. 2 guide rail 7 Base 8, the side of the No. 2 moving base 8 close to the movable support table 2 is fixedly mounted with a laser cutting head 9 through a bracket, and a controller is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com