Novel holder assembly machine of automobile sliding rail semi-automatic assembly line

A cage, semi-automatic technology, applied in the cleaning method using gas flow, metal processing, metal processing equipment, etc., can solve the problem of unable to fix the cage, unable to move to adjust the assembly effect, without the function of vacuuming, etc. Operation convenience, avoid dust influence, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

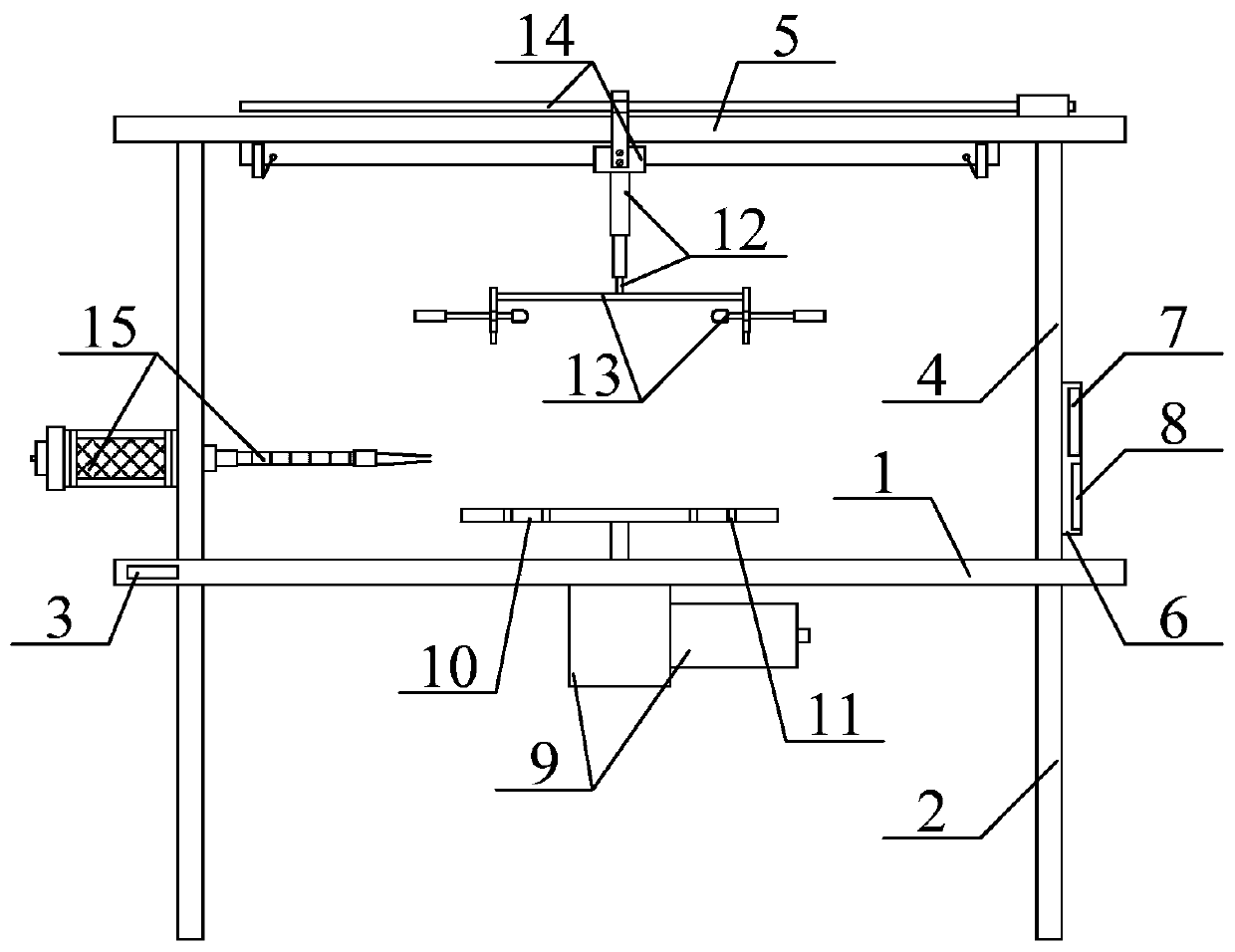

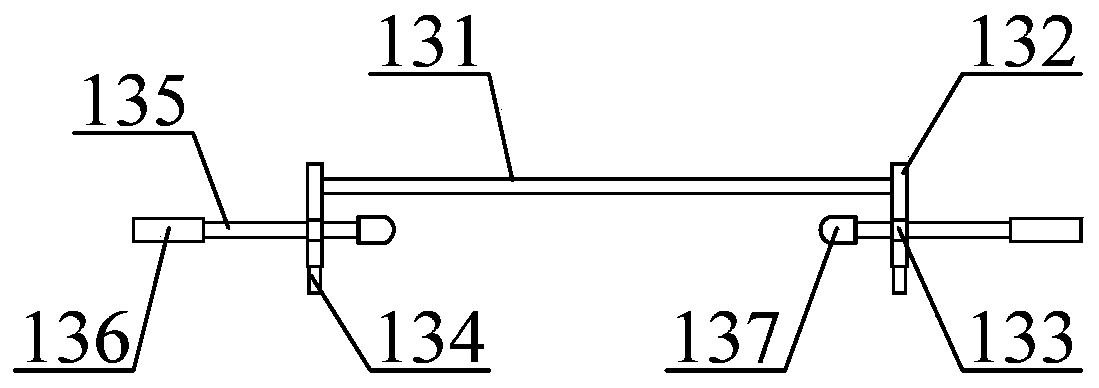

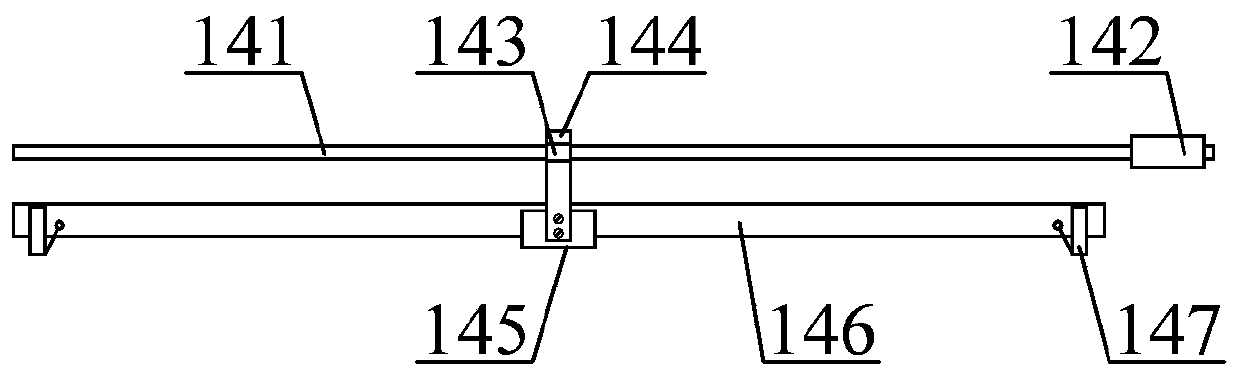

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

[0034] as attached figure 1 And attached figure 2 As shown, a novel cage assembly machine of a semi-automatic assembly line for automobile slide rails according to the present invention includes a frame 1, a support leg 2, a control switch 3, a column 4, a machine base 5, a control box 6, and a control machine 7 , control panel 8, deceleration motor 9, rotary table 10, mounting hole 11, telescopic adjustment rod 12, adjustable and fixed mounting bracket structure 13 of the cage, self-movable assembly slide rod structure 14 and bendable and telescopic adjustable dust cleaning Suction nozzle structure 15, the four corners of the bottom of the frame 1 are respectively connected with supporting legs 2 by longitudinal bolts; the front left side of the frame 1 is connected with a control switch 3 by screws; the upper part of the frame 1 The four corners are respectively longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com