Rail guided control method and optic disc machine

A control method and a technology of an optical disc drive, applied in optical recording/reproduction, data recording, instruments, etc., can solve the problem of inability to correctly judge the burning/reading power and track error of the alternate point of concave track and convex track Problems such as difficult to read or identify signals or physical marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The tracking control method and the optical disk drive according to the preferred embodiments of the present invention will be described below with reference to related drawings.

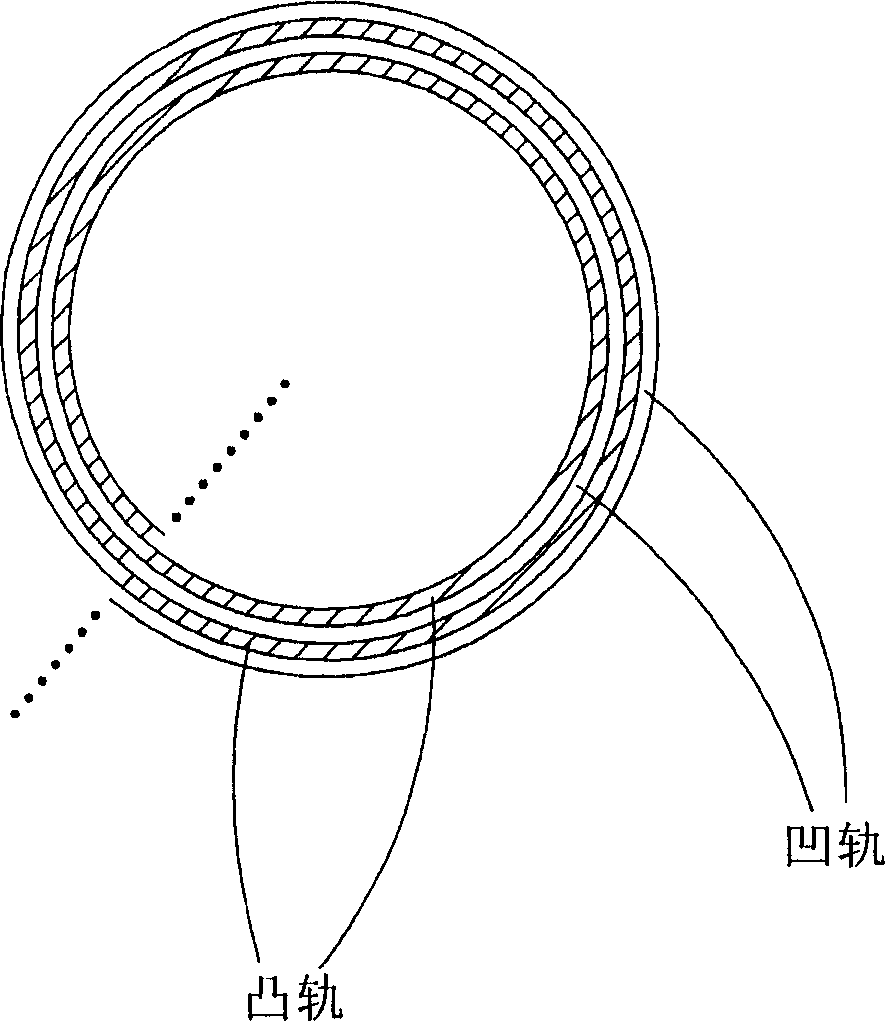

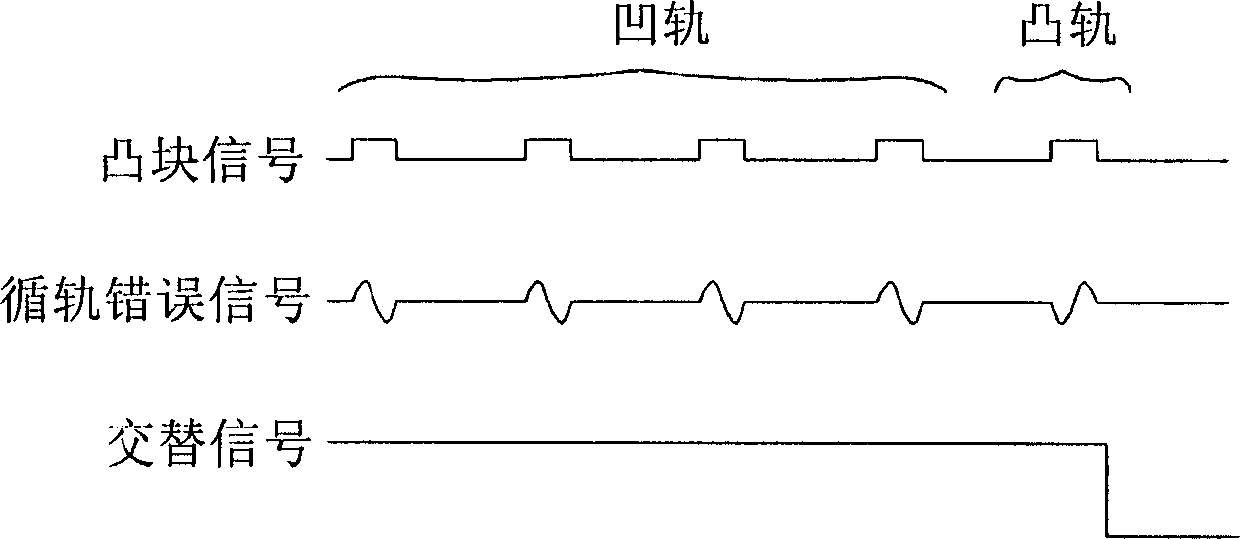

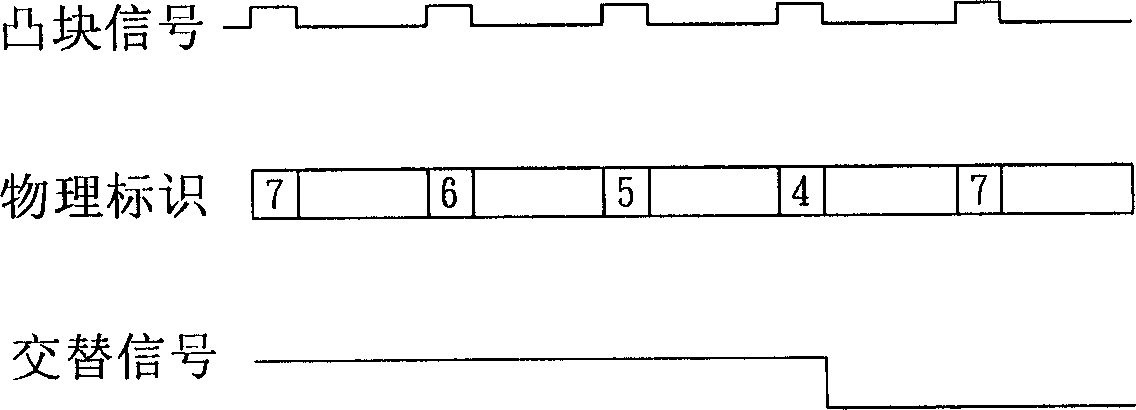

[0034] The track tracking control method according to the preferred embodiment of the present invention controls an optical disc drive to read an optical disc, wherein the optical disc has a plurality of tracks, and the tracks include a plurality of concave tracks and a plurality of convex tracks, and the concave tracks and the convex tracks are alternately connected in series. catch. The tracking control method includes the steps of: detecting a track position read or written by the optical disc drive on the optical disc, then predicting at least one distance count value according to the track position, and generating an alternate signal according to the distance count value to use different Write / read power to write / read grooves and bumps. The track position is a current track in the track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com