Micro reactor

A technology of micro-reactors and reactors, which is applied in chemical/physical/physical-chemical reactors, laboratory equipment, fluid controllers, etc., and can solve the problems of inability to increase the integration rate and poor productivity

Inactive Publication Date: 2006-08-23

NGK INSULATORS LTD

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, when integrating multiple infusion mechanisms into a microreactor, since the infusion mechanisms are installe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

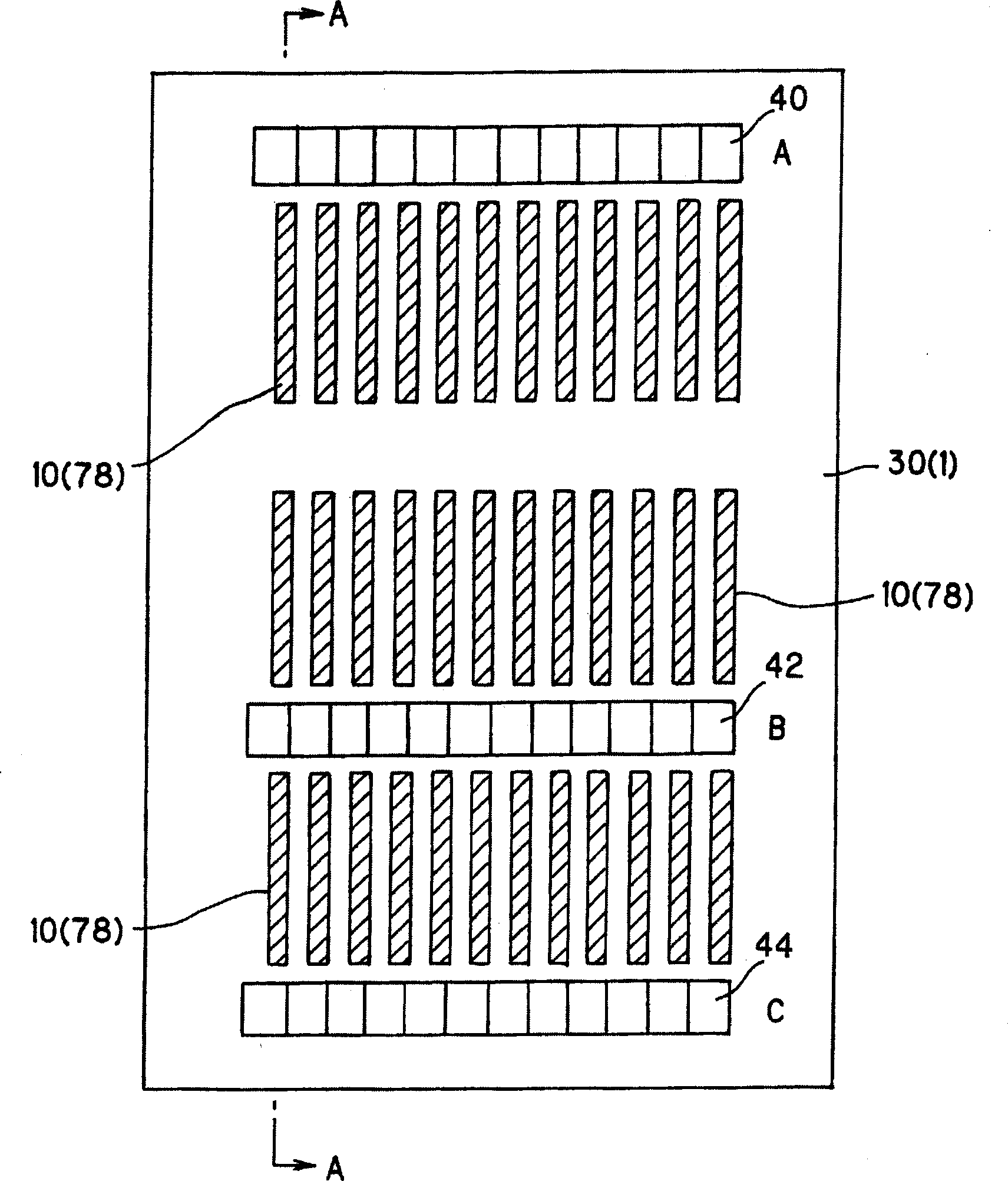

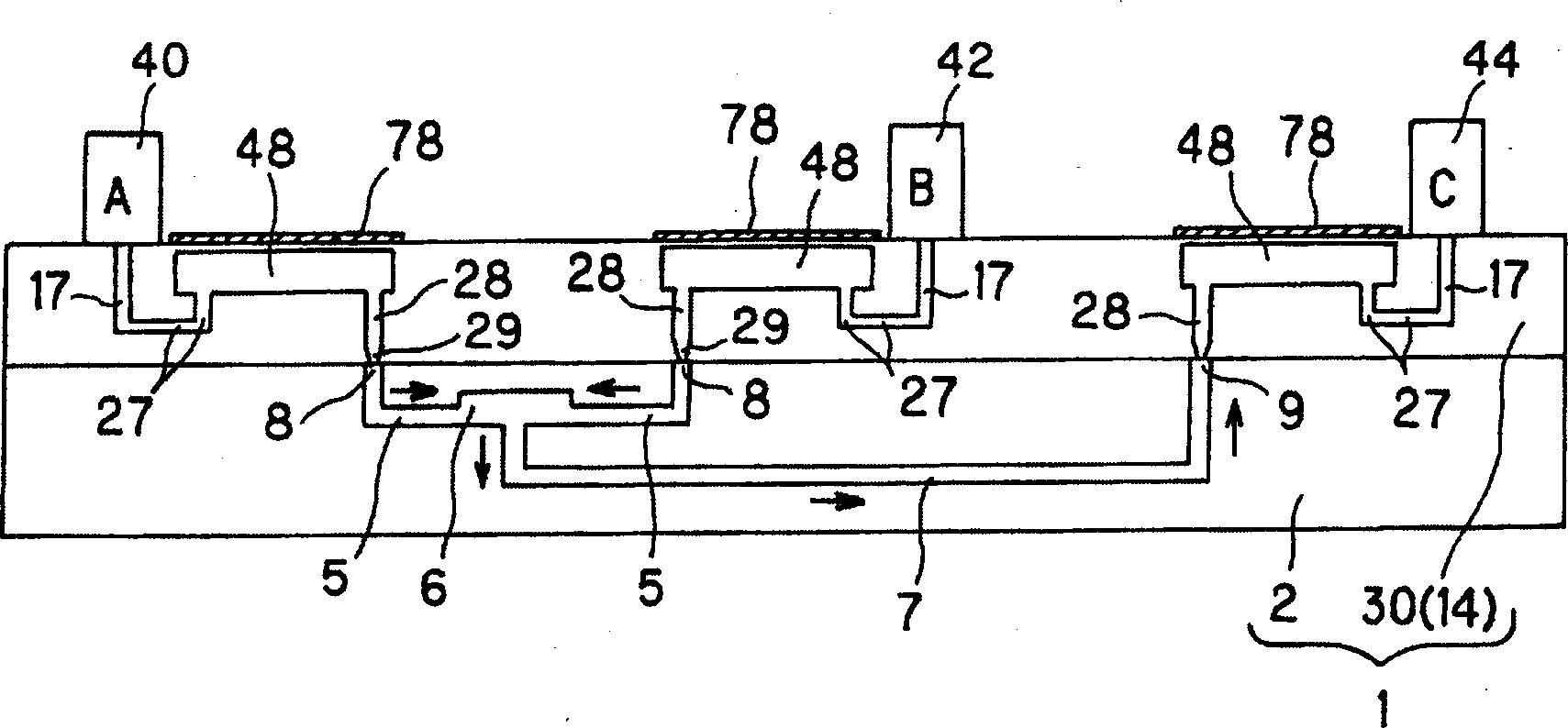

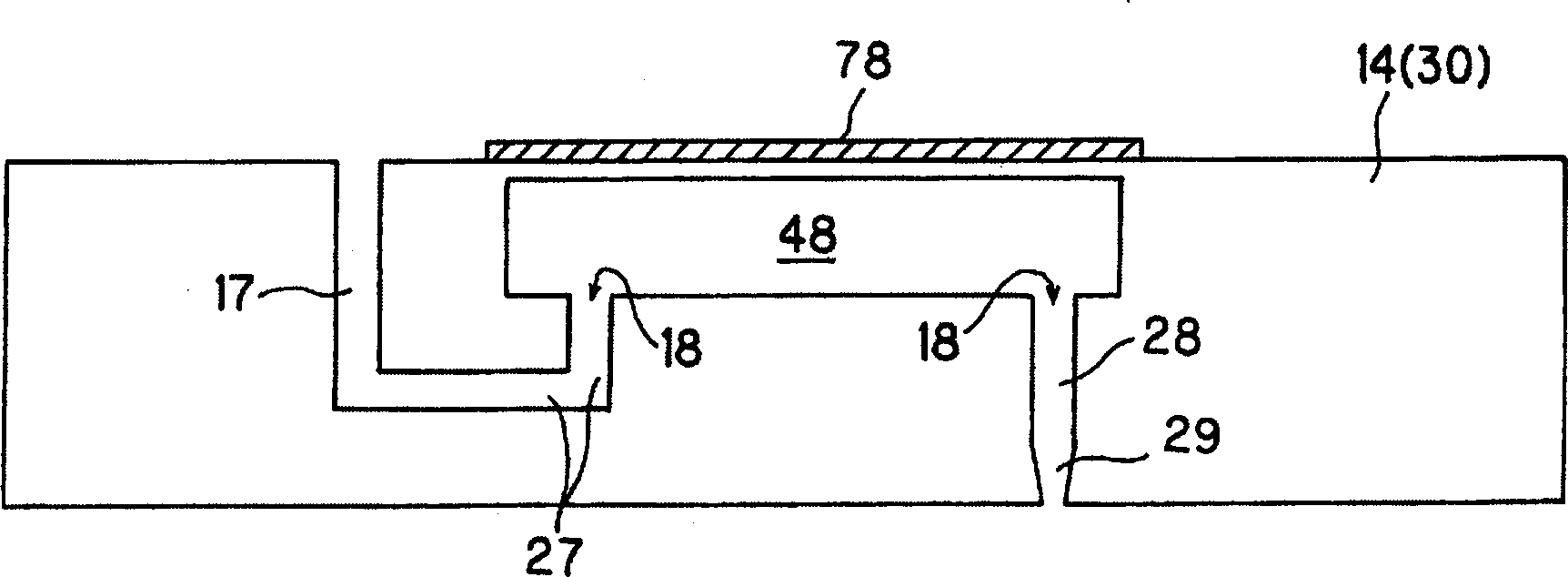

A micro reactor comprising: a first substrate comprising a predetermined number each of micro channels, reactors connected to micro channels at respective connection points, injection ports for feeding/receiving a sample solution, and discharge ports for recovering a sample solution after reaction from respective reactors; and a second substrate in which at least one micro pump is disposed so as to be faced to the injection ports and the discharge ports, the at least one micro pump being provided with a substrate including a cavity made of a ceramic in the inner surface thereof; a piezoelectric/ electrostrictive operation section formed on the outer surface of the substrate, and at least two connection ports for feeding/receiving a sample solution in the cavity; and the micro reactor being formed integrally by laminating the first substrate and the second substrate.

Description

technical field [0001] The present invention relates to microreactors used in microfluidic device systems. Background technique [0002] At present, microreactors, chemical chips, biochips, Lab-on-a-chip (lab-on-a-chip), nanochips, etc., use very small amounts of solutions for reaction, separation, and analysis technologies are extremely popular. In particular, a technique using microreactors has been proposed in order to simultaneously perform multiple biochemical reactions (see JP-A-10-337173). The microreactor is used for chemical reaction experiments in the microscopic field, drug development, artificial organ development, gene and DNA analysis tools, and basic analysis tools for microfluidic engineering. [0003] For chemical reactions using microreactors, for example, the overall size of the device is small. If a microreactor is used for a reaction that requires temperature control with extremely high thermal efficiency, there is an advantage that temperature control ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J19/00B01L3/00B01L3/02F04B43/04

CPCF04B43/046B01L3/0241B01L3/50273B01J19/0093B01L2400/0442B01L2400/0439B01J2219/00164B01L2300/0887B01L3/502715B01J2219/00162

Inventor 别所裕树武内幸久

Owner NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com