Production method of transfer printing film for rubber product and its product

A production method and technology of rubber products, applied in the direction of copying/marking method, process for producing decorative surface effects, printing, etc., can solve the problems of slow printing speed, low production efficiency, poor product stability, etc., and achieve printing speed and Increased production efficiency, high degree of automation, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

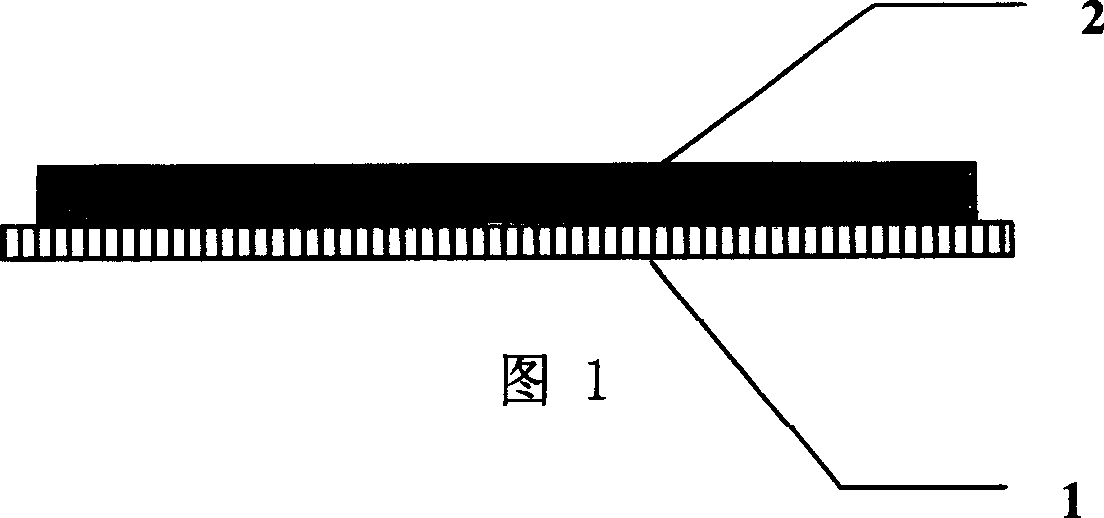

[0034] As shown in Figure 1, the transfer film is composed of a release film layer 1 and a printed graphic ink layer 2, corresponding to the surface of rubber products such as rubber rain boots, rubber tires, V-belts, balloons, etc. The production method is: 1) ask a professional gravure printing company to make a set of gravure rolls in advance according to the customer's printing drawings and manuscripts; 2) install the set of gravure rolls on the corresponding printing station on the gravure printing machine, Pour the gravure rubber resin system ink into the ink tray of the corresponding printing station, and let the release film pass through each corresponding printing station on the printing machine until it reaches the winding position, and the release surface is the printing surface; (3) Start the printing machine , let the release film run at a certain speed, and after debugging, let the film pass through each corresponding printing station for printing or overprinting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com