Bearing lubricated by hydrophobic and magnetic grease, and preparation of hydrophobic and magnetic lubricating grease

A lubricating grease and hydrophobic technology, which is applied to bearing components, shafts and bearings, and lubricating compositions, can solve the problems of lack of lubrication, deterioration, and loss of bearings, and achieve the effects of prolonging service life, low cost, and ensuring lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

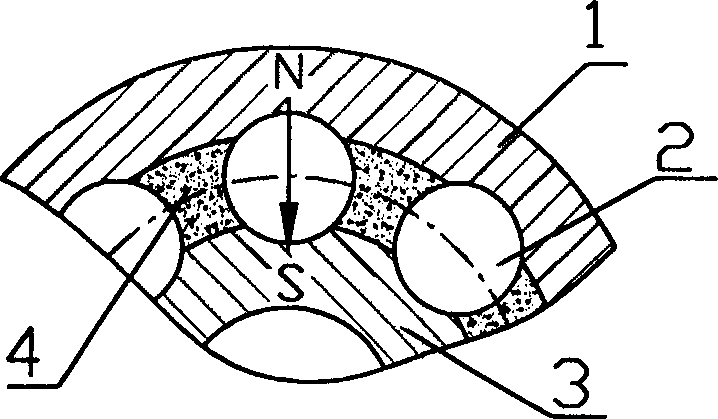

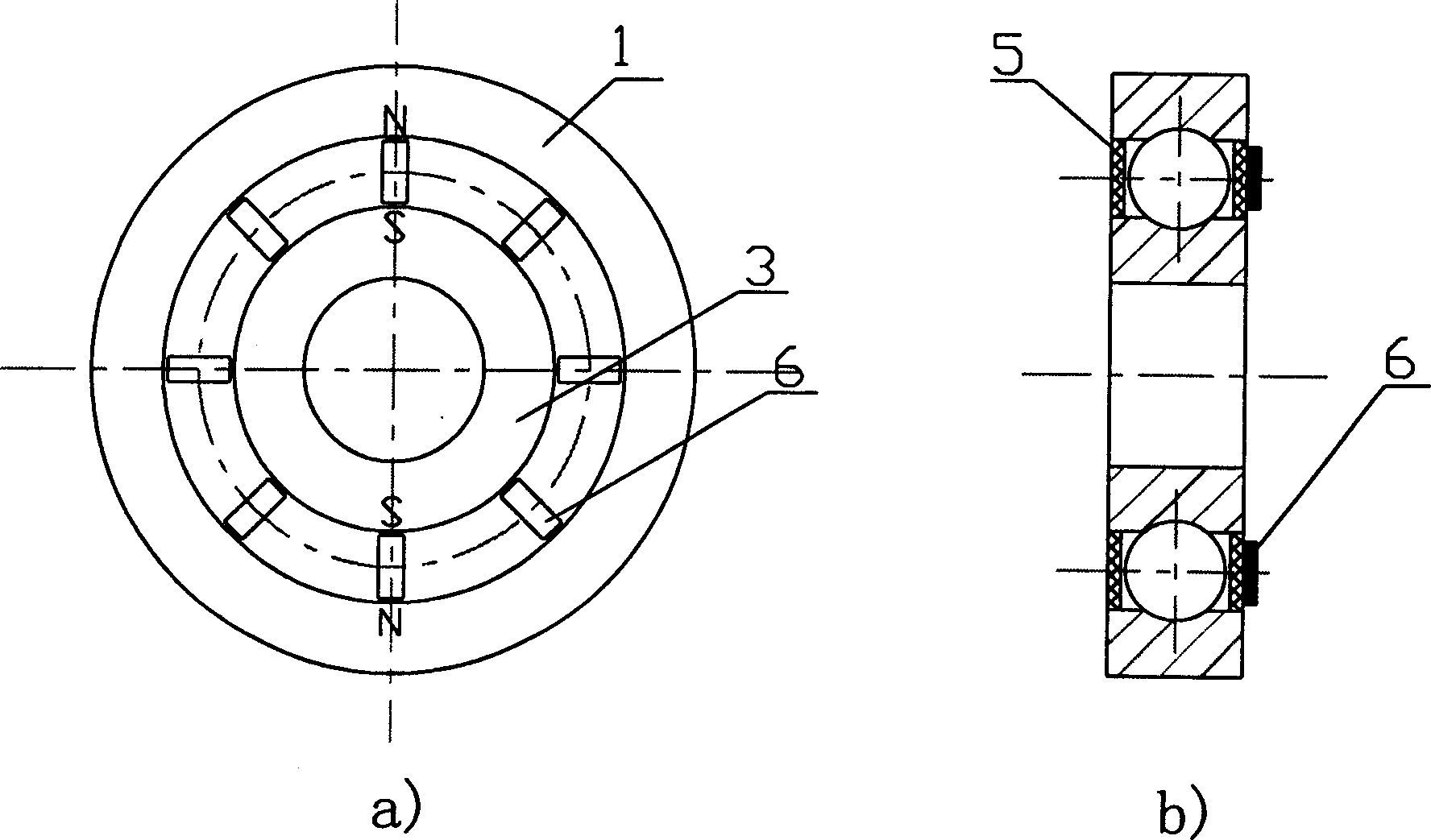

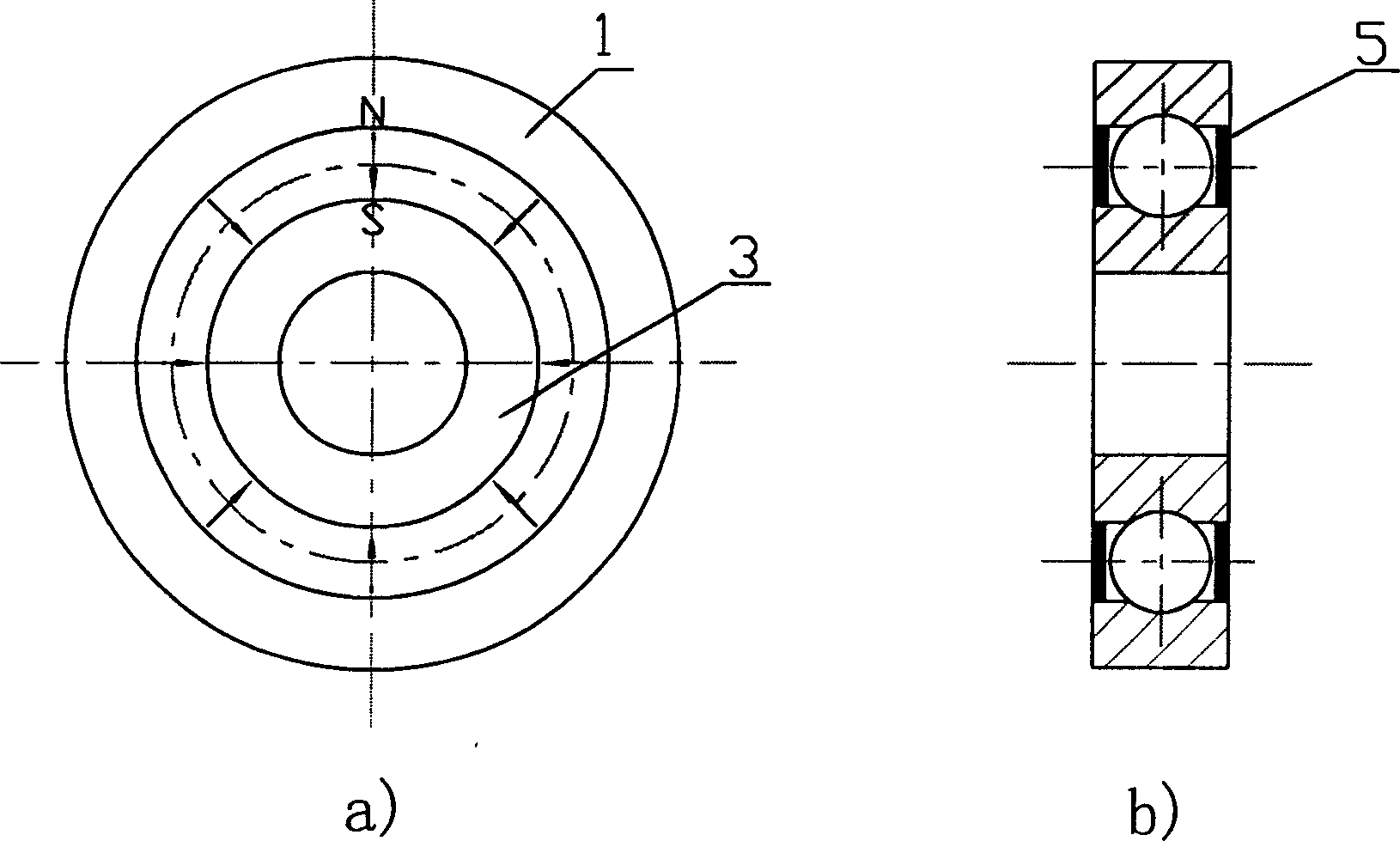

[0017] The hydrophobic and magnetically lubricated bearing of the present invention is composed of a bearing outer ring 1, bearing balls or rollers 2, a column bearing inner ring 3 and a bearing cover 5 arranged between the bearing inner and outer rings, and the bearing outer ring 1 or bearing inner ring 3 or The material of the bearing cover 5 is set as a permanent magnet, so that a closed magnetic circuit in the direction of N and S poles is always formed between the inner and outer rings of the bearing, and the hydrophobic magnetic grease 4 is set in the inner cavity of the bearing, and the hydrophobic magnetic grease 4 is always in the bearing Among the magnetic fields of the closed magnetic circuit established above. The permanent magnet bearing cover 5 can be set to one side or both sides as required. On the basis of not changing the performance o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap