Rolling friction sine mechanism

A rolling friction and sinusoidal mechanism technology, which is applied in friction transmission devices, mechanical equipment, transmission devices, etc., can solve the problems of short service life of the mechanism and low mechanical efficiency of the sinusoidal mechanism, and achieve extended service life, small friction coefficient and high mechanical efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

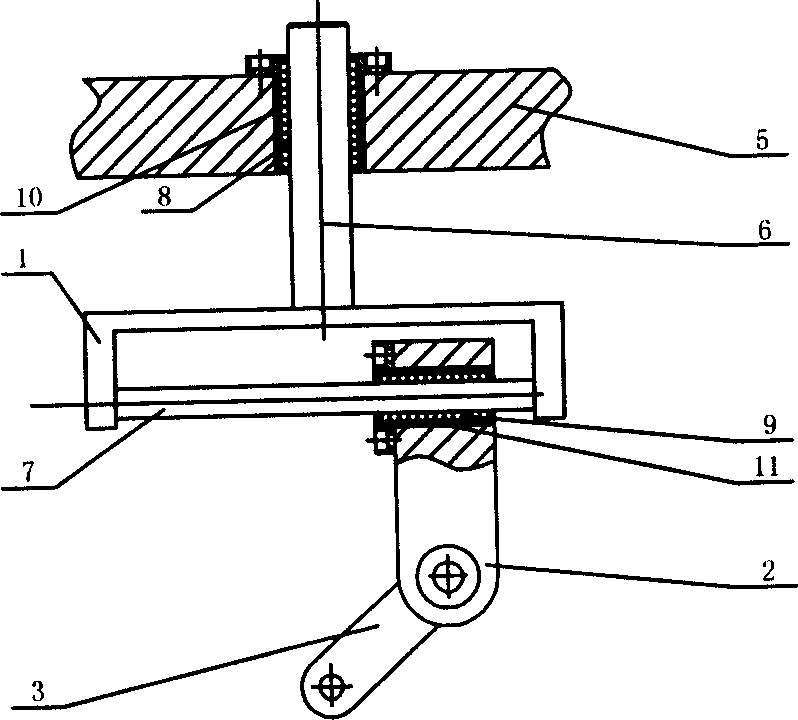

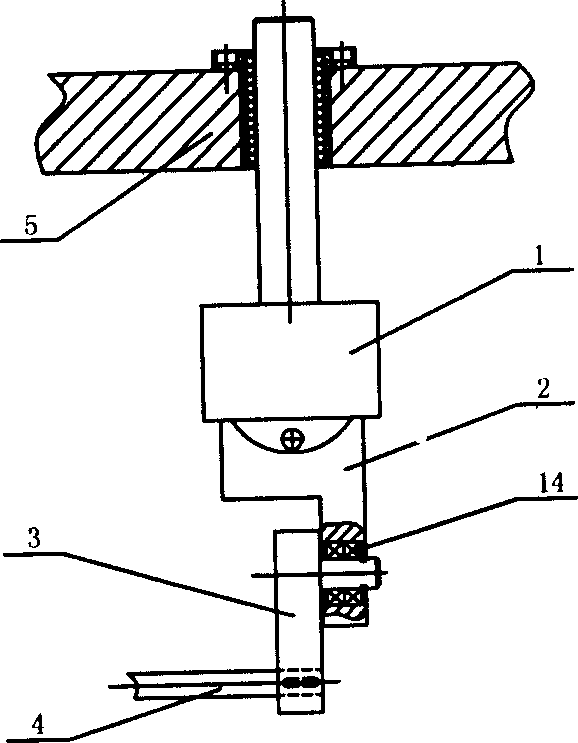

[0017] refer to figure 1 , 2 , a rolling friction sinusoidal mechanism, including a first motion mechanism and a second motion mechanism, the first motion mechanism includes a reciprocating member 1, a first linear guide rail assembly, a slider 2, a rotating member 3 and a rotating input shaft 4 , the slider 2 is slidingly connected to the reciprocating part 1 through the first linear guide rail assembly; the second motion mechanism includes the reciprocating part 1, the second linear guide rail assembly and the body 5, and the reciprocating part 1 and the body 5 pass through the second linear guide rail The components are slidingly connected; the movement direction of the reciprocating member 1 generated by the first movement mechanism relative to the slider 2 is perpendicular to the movement direction of the reciprocating member 1 generated by the second movement mechanism relative to the body 5; the slider 2 passes through the bearing 14 Connected with the rotating member ...

Embodiment 2

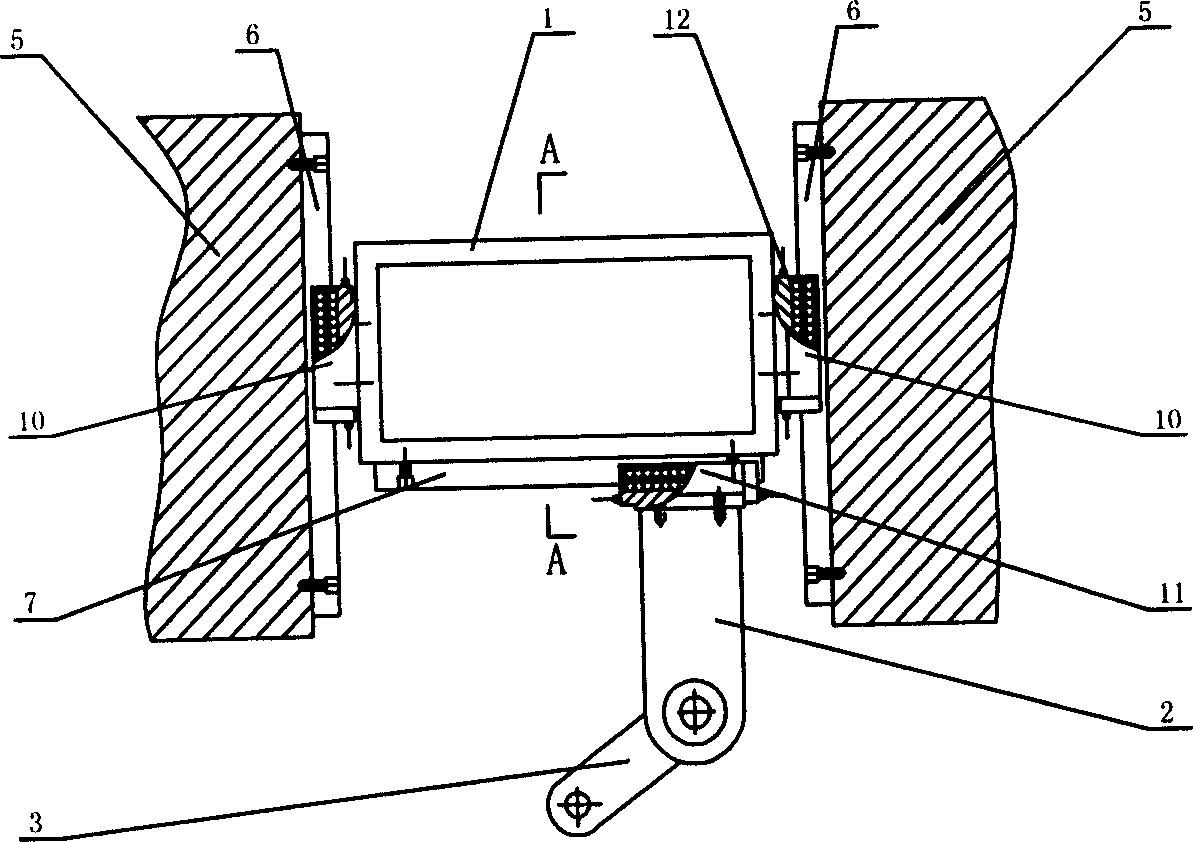

[0020] refer to Figure 3-5 , the connection mode of the first movement mechanism is: the first guide rail column 7 is fixedly connected to the first reciprocating member 1, and the first guide rail block 11 is fixedly connected to the slider 2. The connection mode of the second movement mechanism is as follows: the second guide rail block 10 is fixedly connected to the reciprocating member 1 , and the second guide rail column 6 is fixedly connected to the machine body 5 . Others are the same as embodiment one.

[0021] The rotary motion provided by the power source drives the rotary shaft 3 to rotate by turning the input shaft 4, and the rotary shaft 3 drives the slider 2 to drive the reciprocating component 1 along the second linear guide component through the first linear guide assembly on the reciprocating component 1. Sine regular reciprocating motion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com