U-shape anti-seepage channel grooving technology and its equipment

A U-shaped, trough-forming technology, applied in water conservancy projects, artificial waterways, buildings, etc., can solve problems affecting uniform irrigation of farmland, uneven draft of crops, affecting yield and quality, etc., to improve field appearance, reduce soil erosion, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

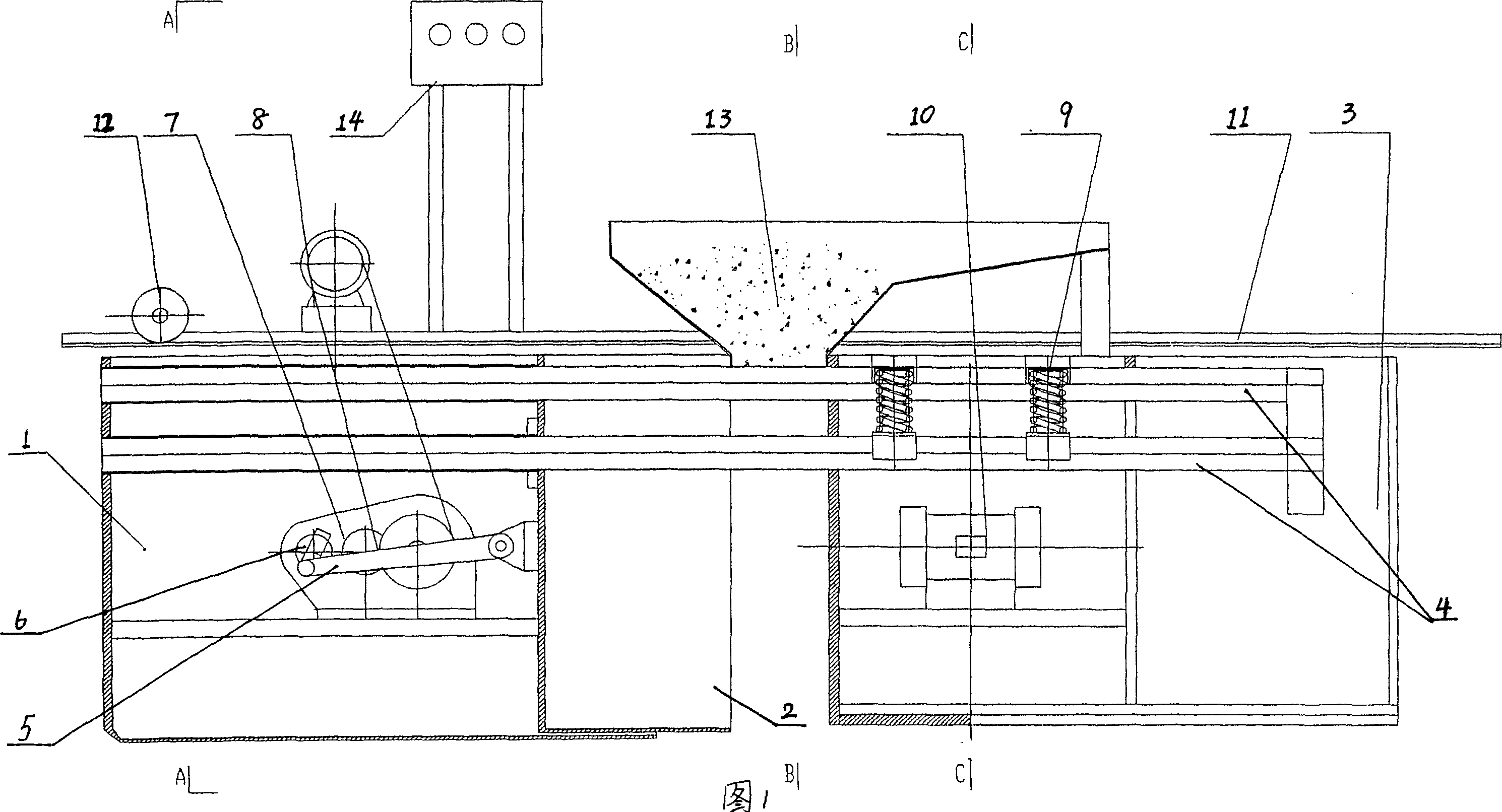

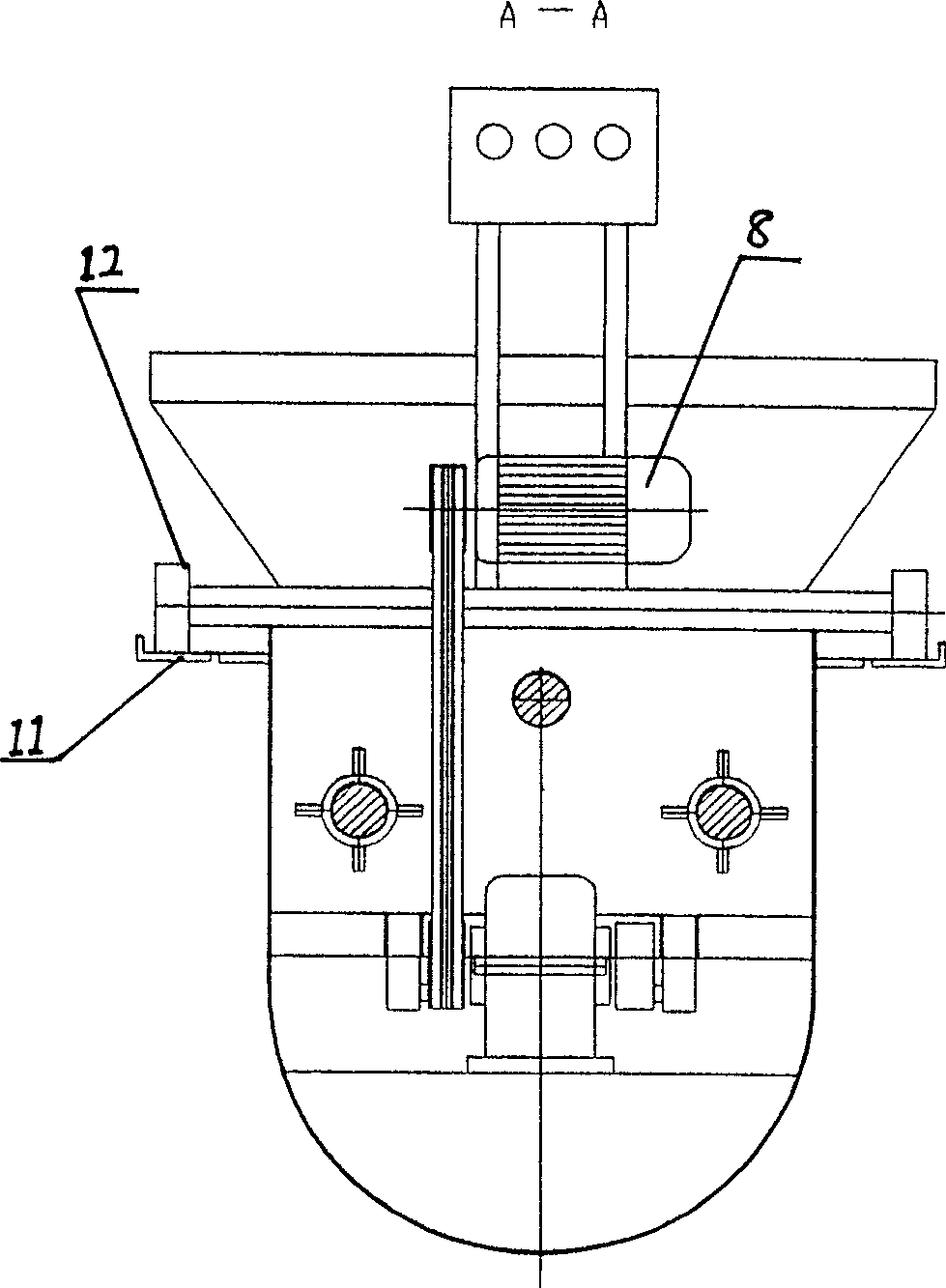

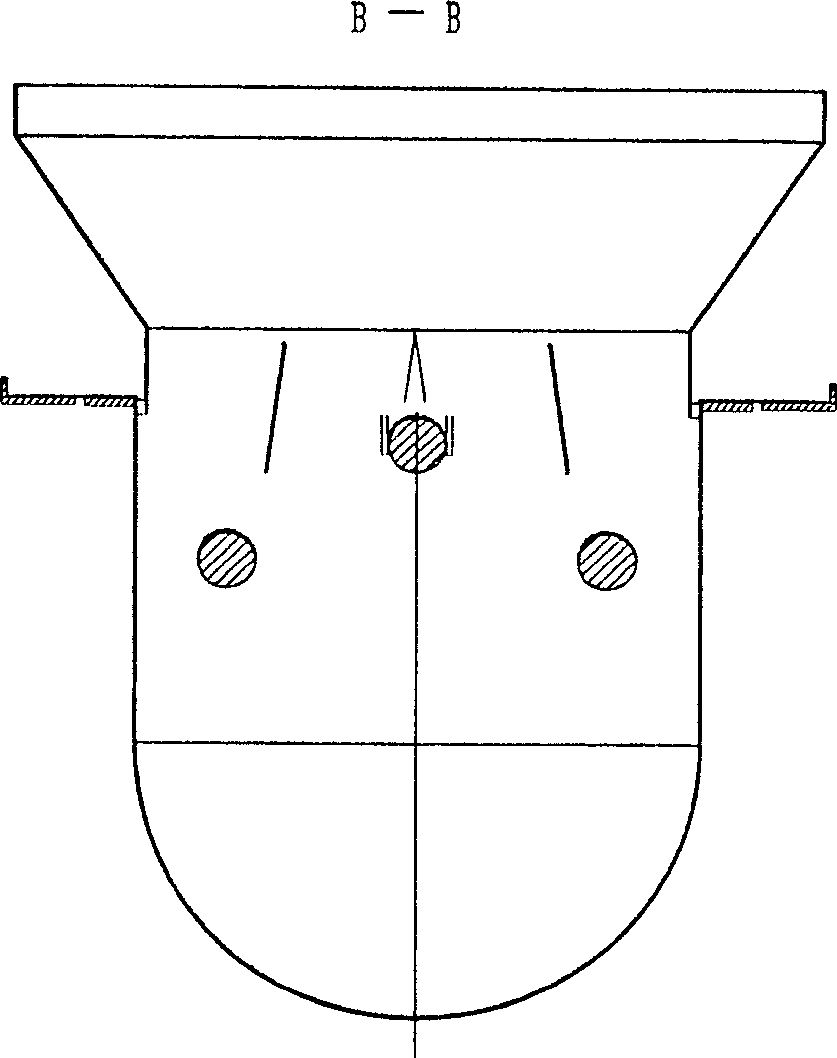

[0019] The U-shaped anti-seepage channel trough forming equipment is mainly composed of a traveling device 1 that controls the advancement of the equipment, a feeding device 2 and a shaping device 3. The feeding device 2 is arranged between the walking device 1 and the shaping device 3. The feeding device 1 and the shaping device The casing of the device 3 is fixedly connected by the connecting shaft 4, the unloading device 2 is slidably connected to the connecting shaft 4, a push rod 5 is hinged at the front end of the unloading device 2, and the other end of the push rod 5 is hinged on the eccentric wheel 6 The axis of the eccentric wheel 6 is connected to the inner wall of the traveling device 1 , and the eccentric wheel 6 is connected to the motor 8 through the reduction mechanism 6 .

[0020] The upper end of the casing of the running device 1 is connected to a horizontal shaft, and road wheels 12 are respectively arranged on both sides of the shaft.

[0021] The profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com