Installing method of portal crane

A technology of a gantry crane and an installation method, which is applied to the cranes, trolleys, transportation and packaging, etc., can solve the problems of difficult adjustment of rigid legs, safety, etc., and achieves accurate cable wind force, reduced cable wind adjustment, and convenient adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

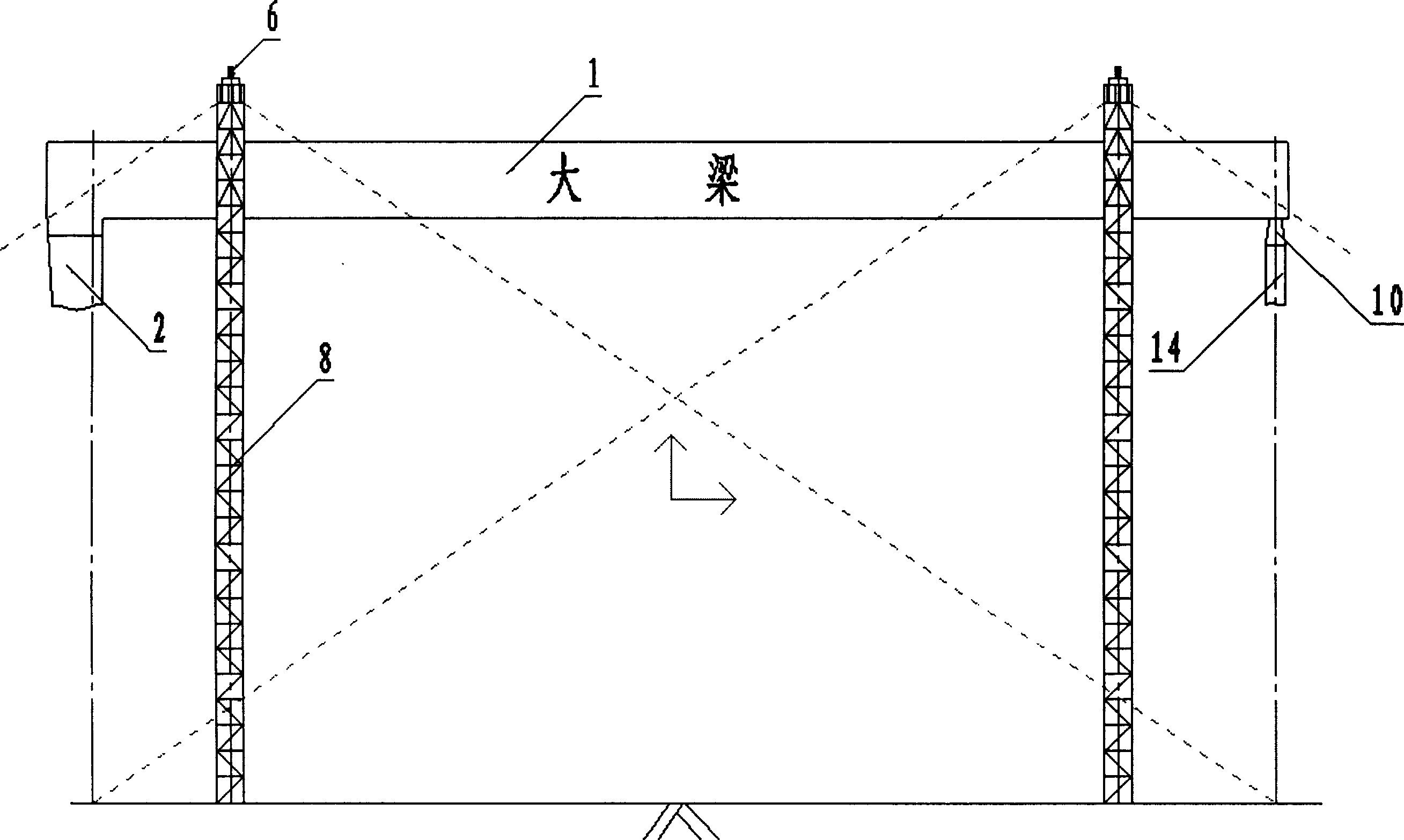

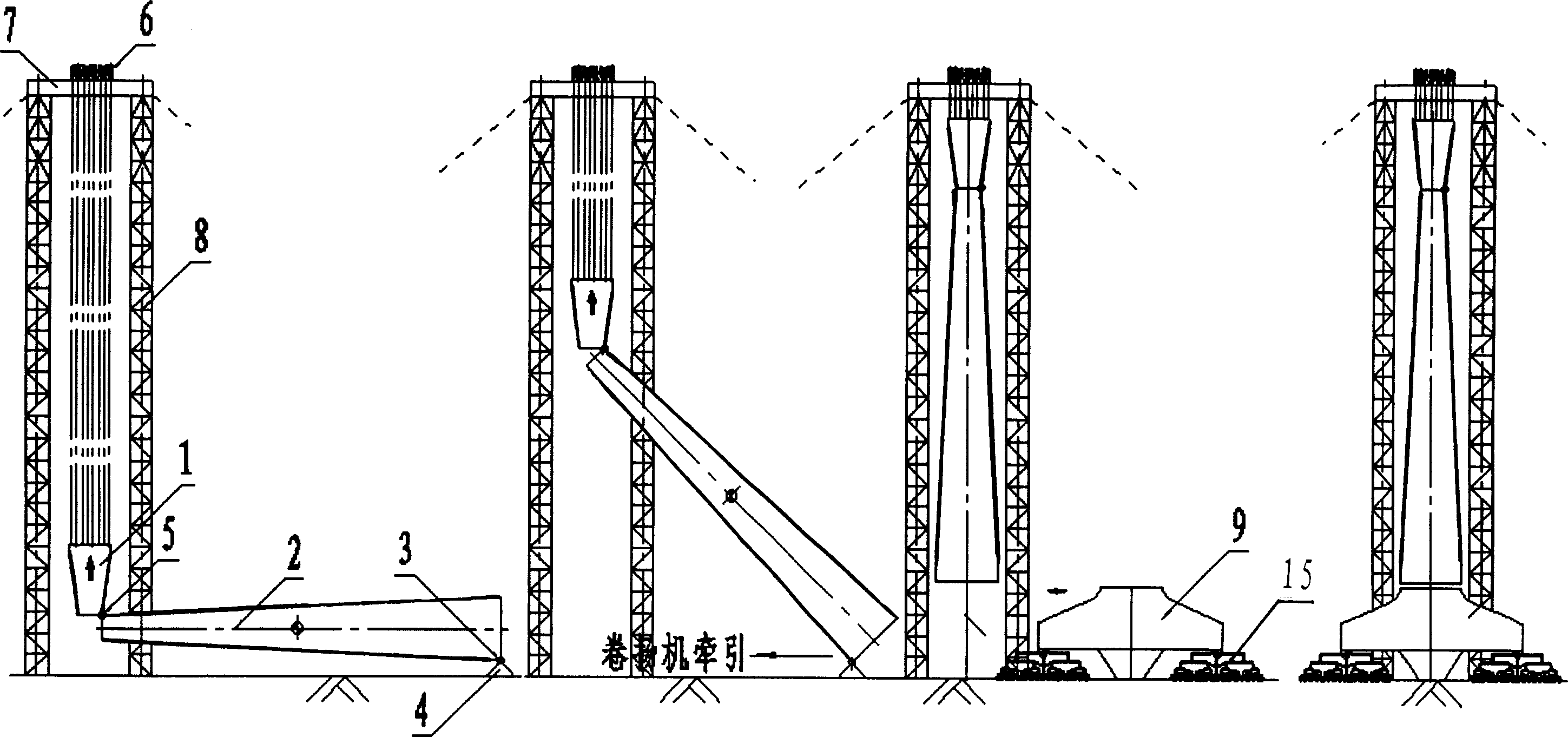

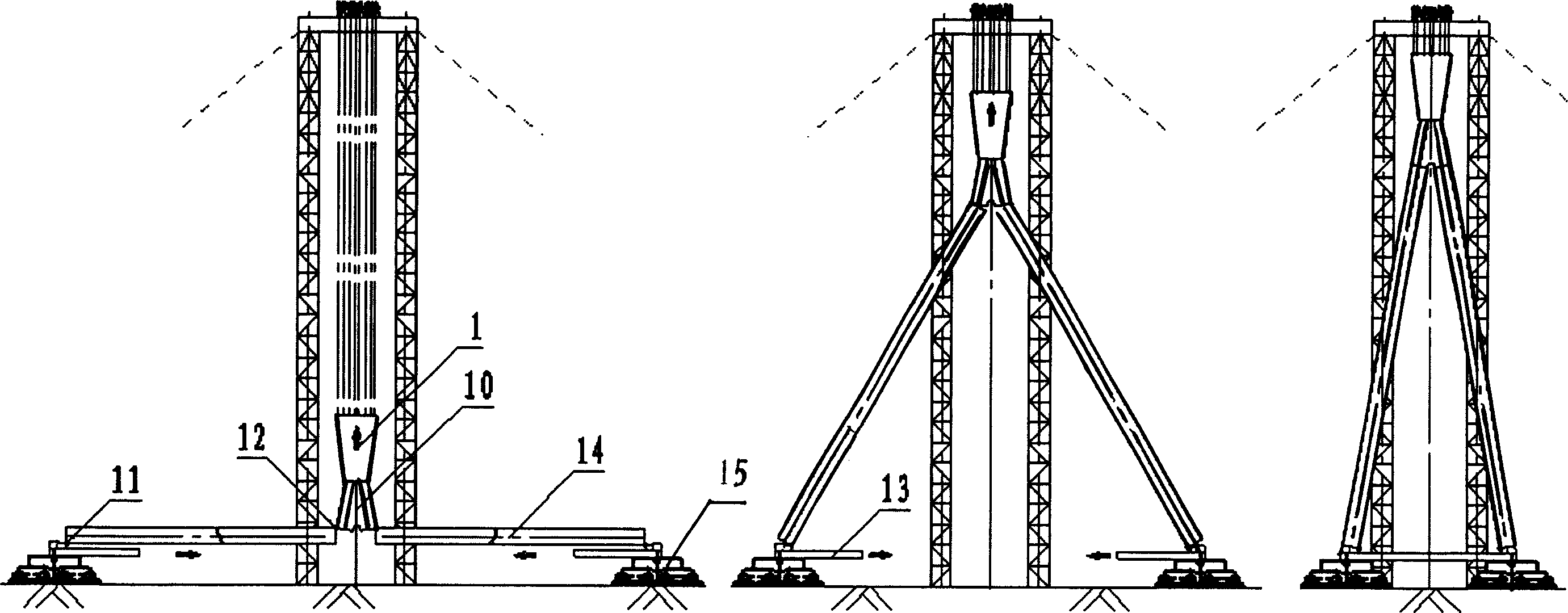

[0009] The present invention will be further described in conjunction with the accompanying drawings. See figure 1 , 2 , 3, the present invention consists of girder 1, rigid leg 2, hinge point JX 3, slide block 4, hinge point JS 5, lifting cylinder 6, tower top gantry beam 7, tower frame 8, traveling mechanism 9, A prefix 10. Hinge point JB 11, hinge point JA 12, flexible leg lower beam 13, flexible leg 14 and sliding trolley 15 etc.

[0010] installation method:

[0011] 1. Installation of the tower frame and the gantry beam on the top of the tower

[0012] The present invention uses two pairs of towers 8 as lifting towers. The effective height of the towers 8 varies according to the specific gantry cranes. Generally, it can be as high as more than 100 meters, with a section of 4 meters. The steel pipe lattice structure, the tower The bottom of the frame 8 is connected with the ground foundation using bolts. The gantry beam 7 on the top of the tower is a box structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com