Moulding equipment with electric claming frame and synchronous climbing control method thereof

A climbing frame and mold-reversing technology, applied in mechanical control devices, control/adjustment systems, devices to prevent/limit/restore the movement of parts of the control mechanism, etc. The needs of safety and operation technology, the overall safety and stability are good, and the equipment cost and construction cost are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

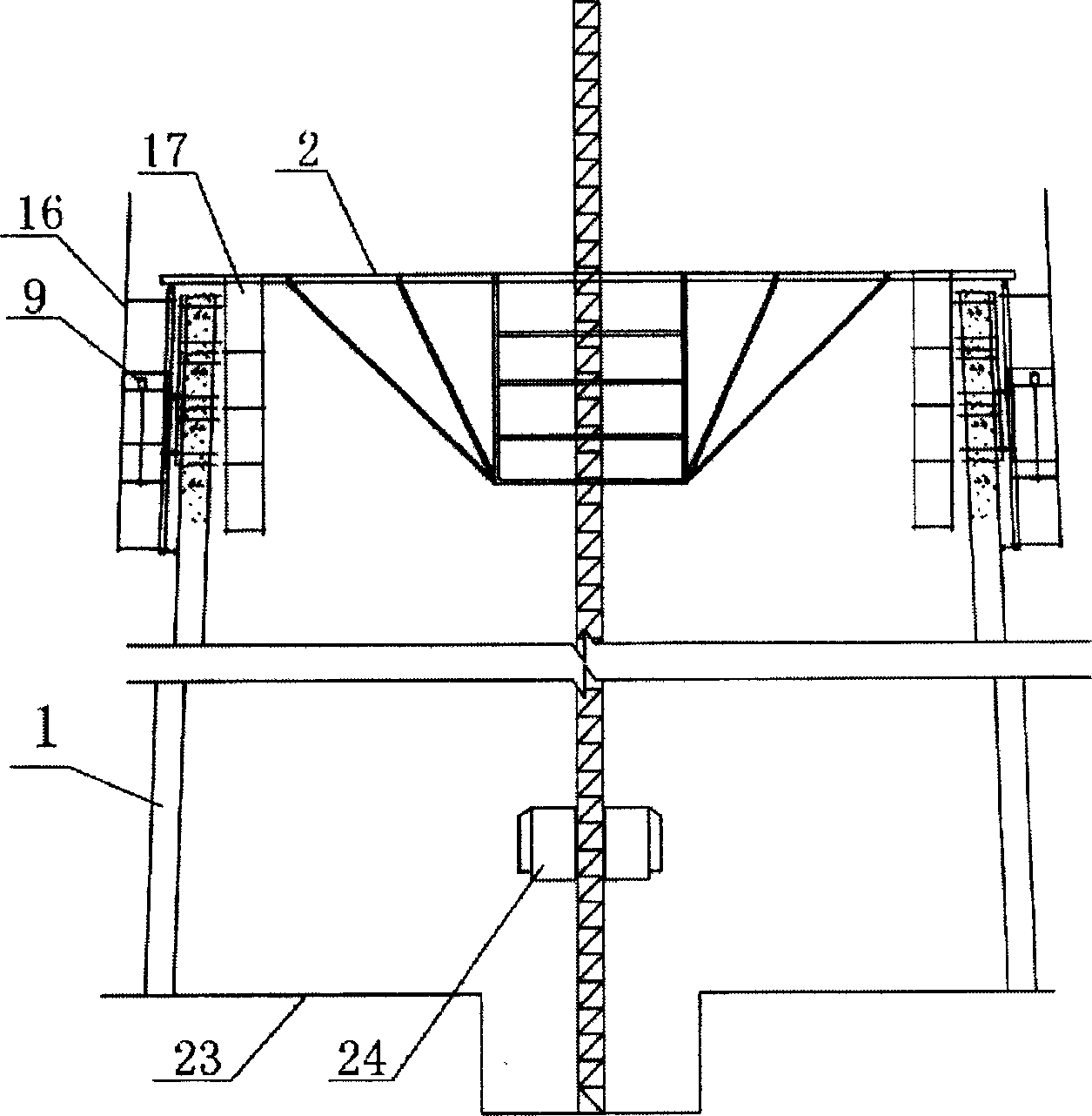

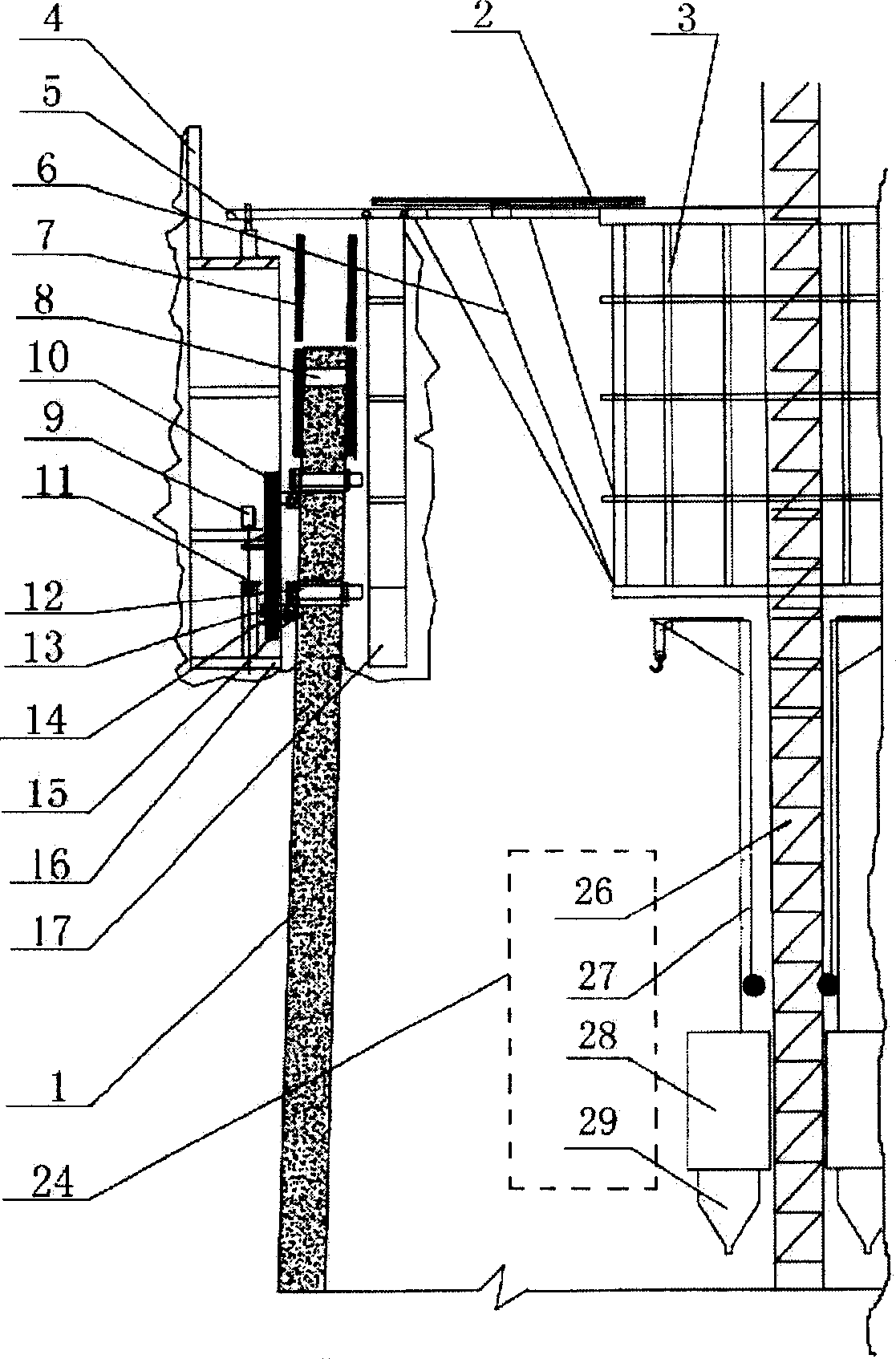

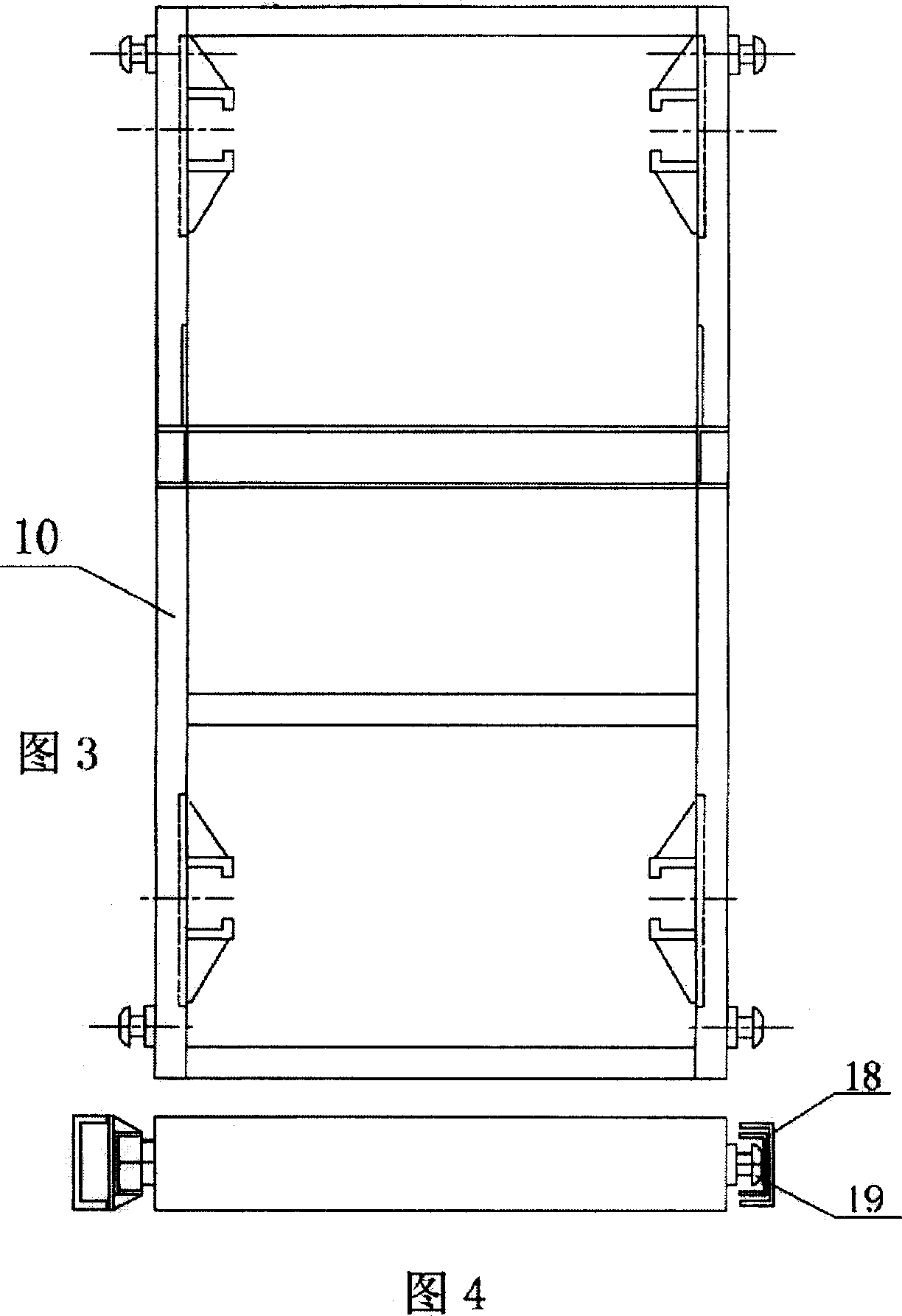

[0040] see figure 1 , 2 , 5. The concrete cylinder wall 1 under construction stands on the foundation 23, and the concrete is poured in the formwork 7. The electric climbing frame inverting equipment of the present invention includes a circle of operating frames attached to the inside and outside of the concrete cylinder wall 1 and a lifter 24 connected to the concrete cylinder core and a lifting platform 2. The lifting platform 2 mainly includes a central drum ring 3, Railings 4 and diagonal stays 6 are horizontally connected to a circle of radiating beams 5 on the rising platform 2, and the radiating beams are fixedly connected to the operating frame. Each section of operating frame mainly includes an inner operating frame 17, an outer operating frame 16 and a climbing frame 10. Referring to Fig. 3, 4, vertical slideway 18 is arranged on the outer operating frame, and the climbing frame is provided with the slide block 19 that cooperates with above-mentioned slideway and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com