Mold structure

A mold and mold base technology, applied in the field of mold structure that can reduce the coaxiality error, can solve the problems of inconvenient mold manufacturing and assembly, cumbersome methods, not on the same straight line, etc., and achieve the effect of reducing the coaxiality error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

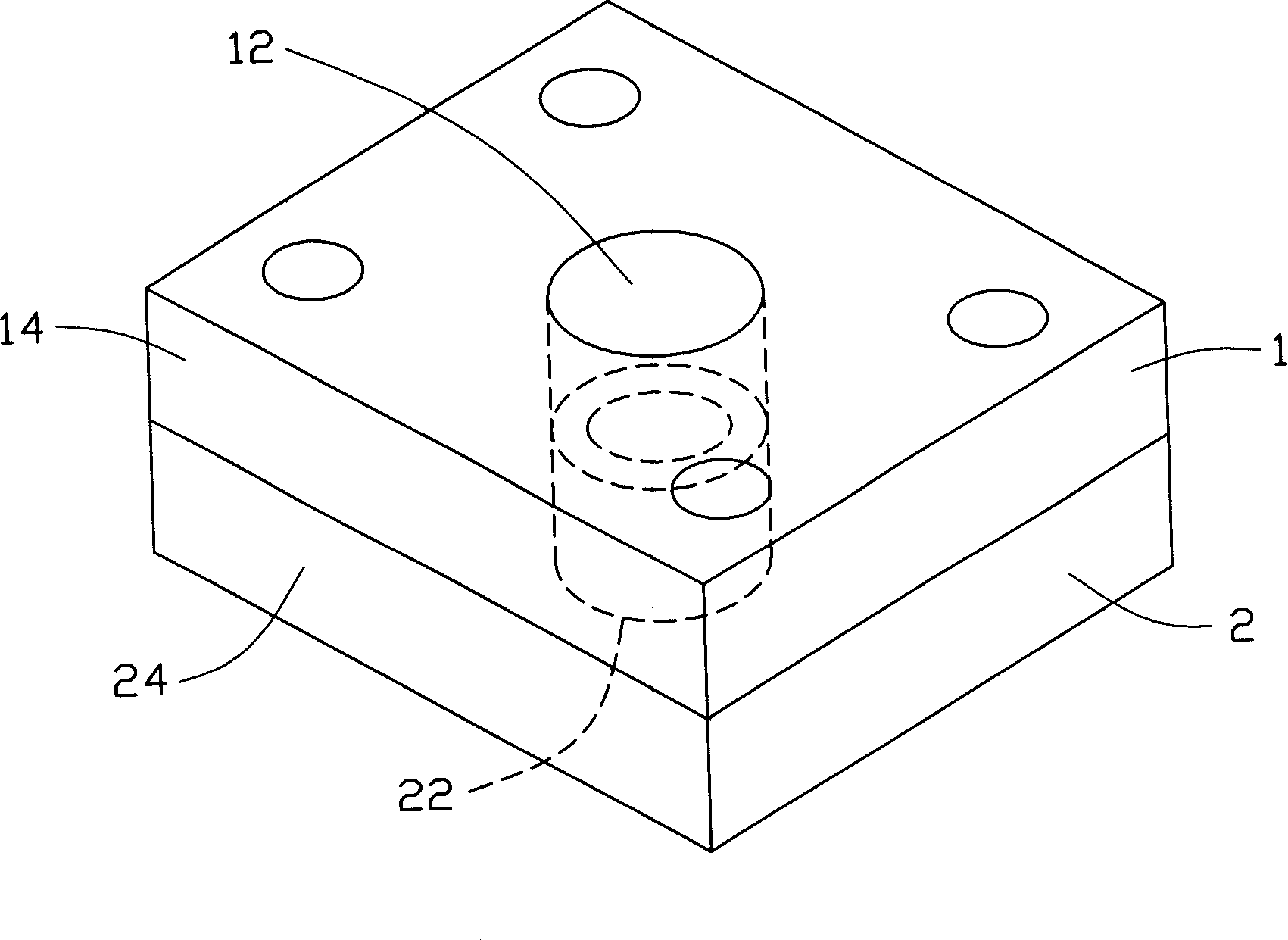

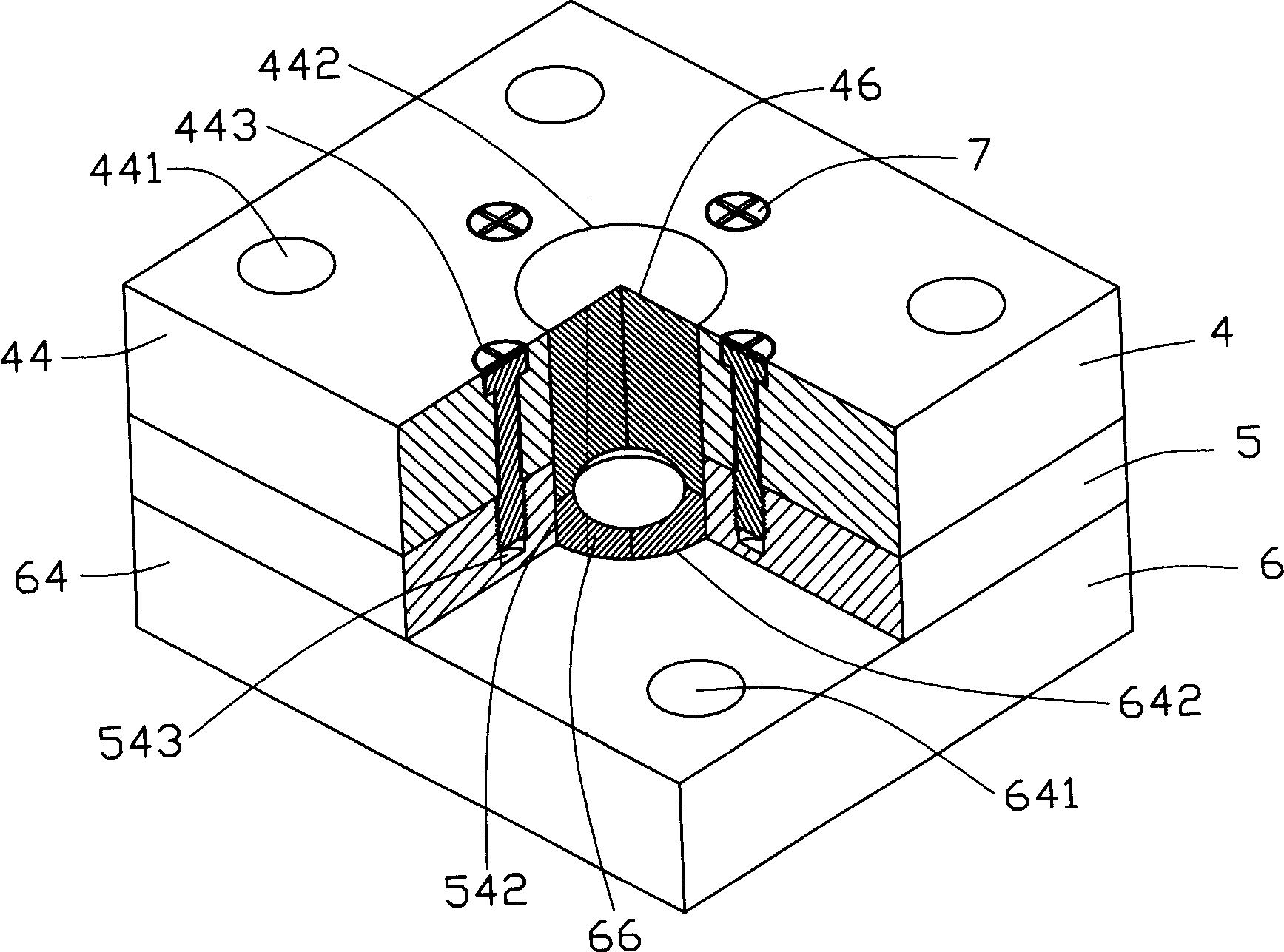

[0011] see figure 2 , The preferred embodiment of the mold structure of the present invention takes the injection molding plastic mold as an example.

[0012] The mold structure includes an upper mold 4, a buffer layer 5, a lower mold 6 and several screws 7.

[0013] Upper mold 4 is divided into two parts, comprises upper mold base 44 and upper mold kernel 46. An opening 442 is opened in the middle of the upper mold base 44 . The upper die core 46 is columnar, and one end surface matches a surface of the processed object. Four corners of the upper die base 44 are respectively provided with pin holes 441 , and the pin holes 441 pass through the upper die base 44 . On the upper mold base 44 and around the opening 442 , four adjustment holes 443 are provided, and the four adjustment holes 443 pass through the upper mold base 44 and can be matched with the screws 7 .

[0014] The buffer layer 5 is disposed between the upper mold 4 and the lower mold 6 , and the buffer layer 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com