Centering cabling structure for principal shaft of electromagnetic enzyme deactivation machine

A greening machine and wire structure technology, applied in tea processing before extraction, etc., can solve the problems of easy electric sparks, equipment failure, poor contact between moving contacts and static contacts, etc., to prevent poor contact and reduce electric sparks , improve the effect of normal contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

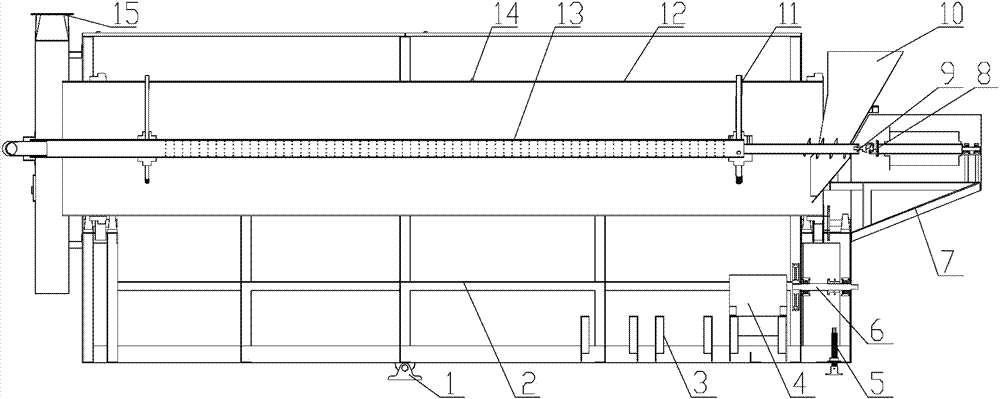

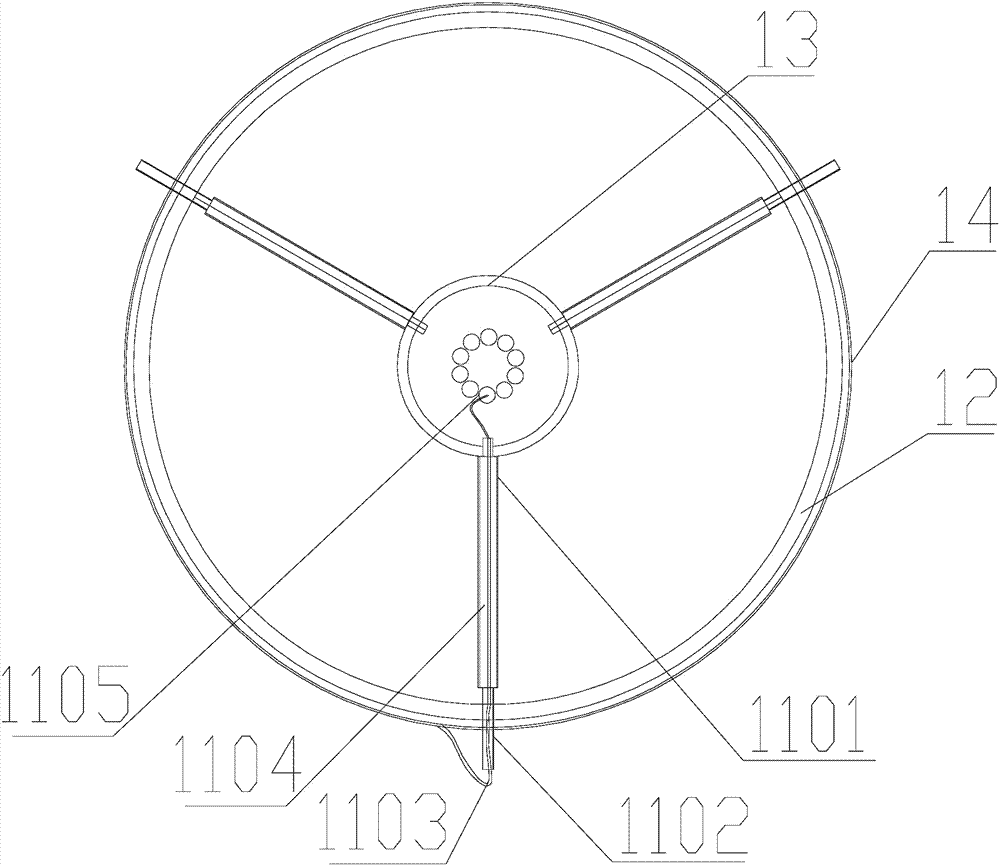

[0018] join Figure 1-2 , a central alignment structure of the main shaft of an electromagnetic greening machine, which includes a frame 2, a fixed foot 1 is installed at the bottom of the frame 2, and screw adjustment supports 5 are installed at the four corners of the frame 2, and the bottom of the frame 2 is installed with Electromagnetic generating device 4, electromagnetic generating device 4 is fixed on the support 3, and the right side of frame 2 is equipped with drive shaft 6, and drive shaft 6 drives drum body 12 to rotate on frame 2 through chain drive, and the inside of drum body 12 A main shaft 13 is provided by multiple sets of alignment devices 11, and a coil 14 is wound on the outside of the drum body 12. The right end of the main shaft 13 is connected with a moving contact 9, and the moving contact 9 is in phase with the static contact 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com