Method and apparatus for attaching a transmission filter to a pump

A technology for filters and filter assemblies, applied in transmissions, fluid transmissions, transmission parts, etc., to solve problems such as unpleasant noise, improper connection of filters and pumps, loose fasteners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

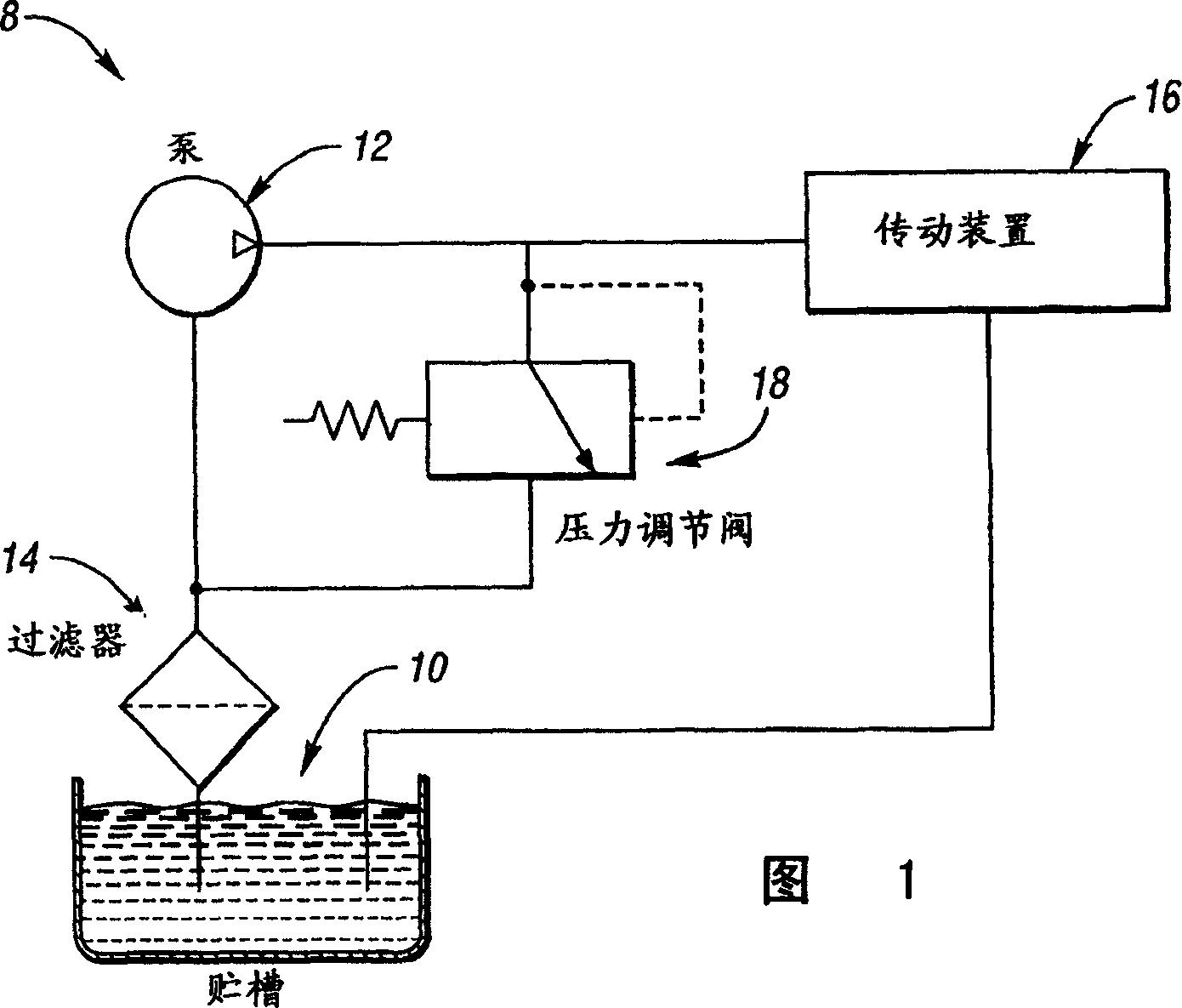

[0013] Referring to the drawings, in which like numerals designate like or corresponding parts throughout, there is shown in FIG. 1 a schematic representation of a transmission fluid distribution system 8 including a sump or container 10 preferably containing hydraulic fluid. . Transmission pump 12 draws hydraulic fluid from container 10 through filter 14 . The pump 12 outputs the pressurized hydraulic fluid to the transmission 16 . The maximum pressure at the pump output port is determined by pressure regulating valve 18, which delivers excess pump flow to filter 14. According to a preferred embodiment of the present invention, the above hydraulic fluid first meets the pressure demand of the transmission, then the pressure demand of the torque converter, and then provides a portion of lubrication and cooling, after which the excess fluid is returned to the filter 14 .

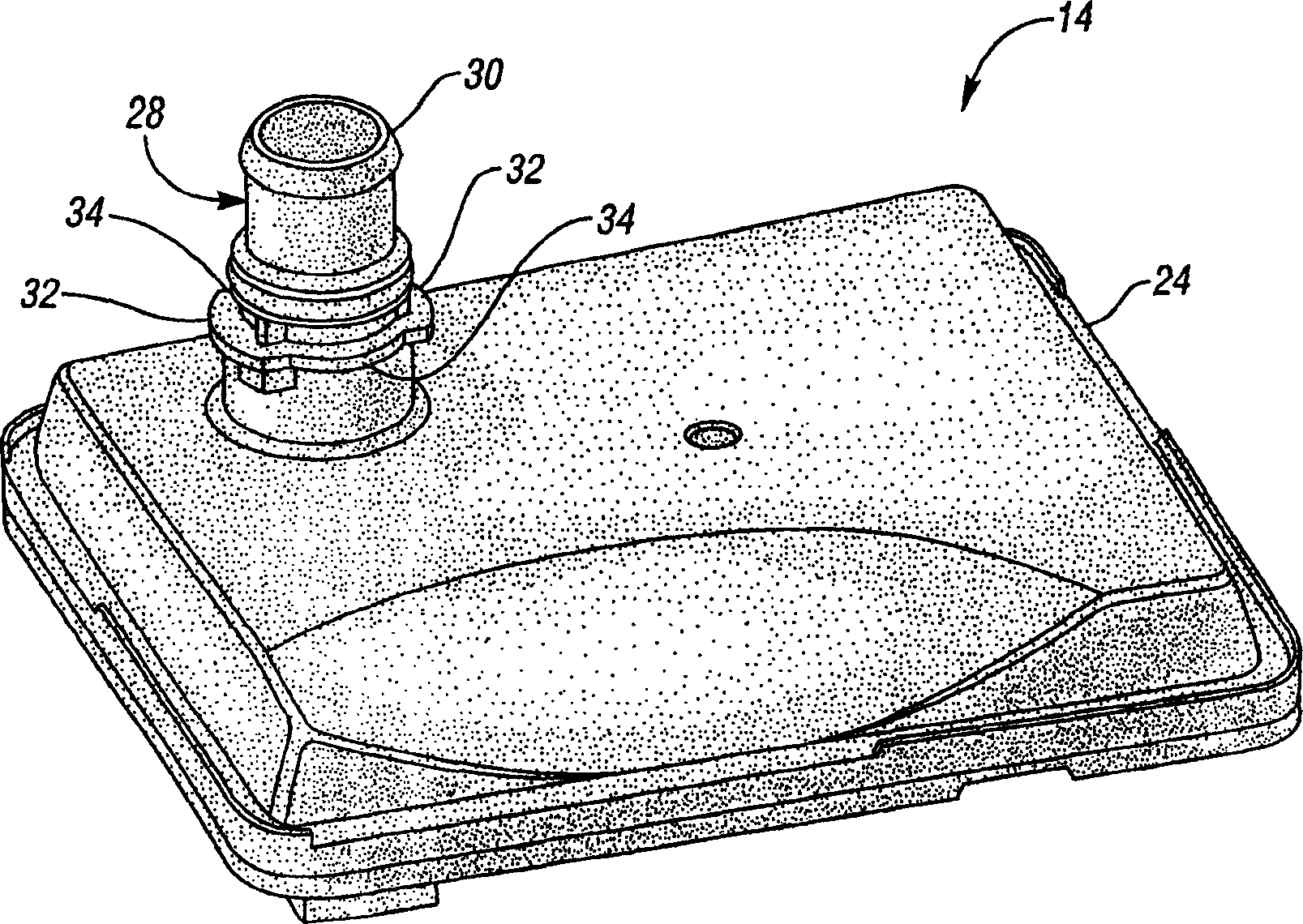

[0014] refer to figure 2 , the filter assembly 14 includes a housing 24 with a filter element (not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com