Attachment of holder strip applying device

A technology for installing devices and snap-fit sheets, which is applied in the direction of identification devices, stamps, instruments, etc., can solve the problems of hindering the operator's operation, cumbersome and complicated operation, card jamming, etc., and achieve the effect of improving operation efficiency and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

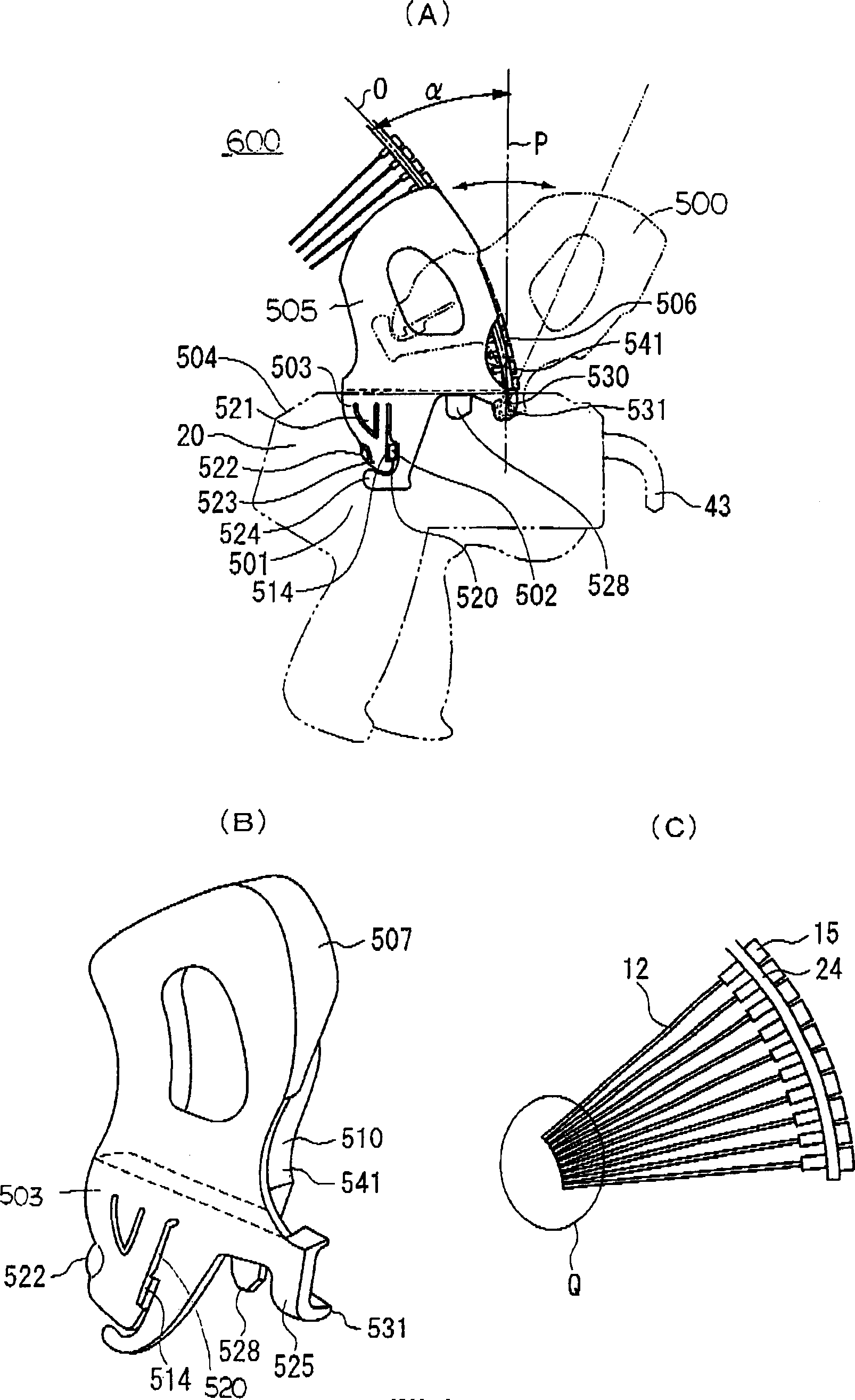

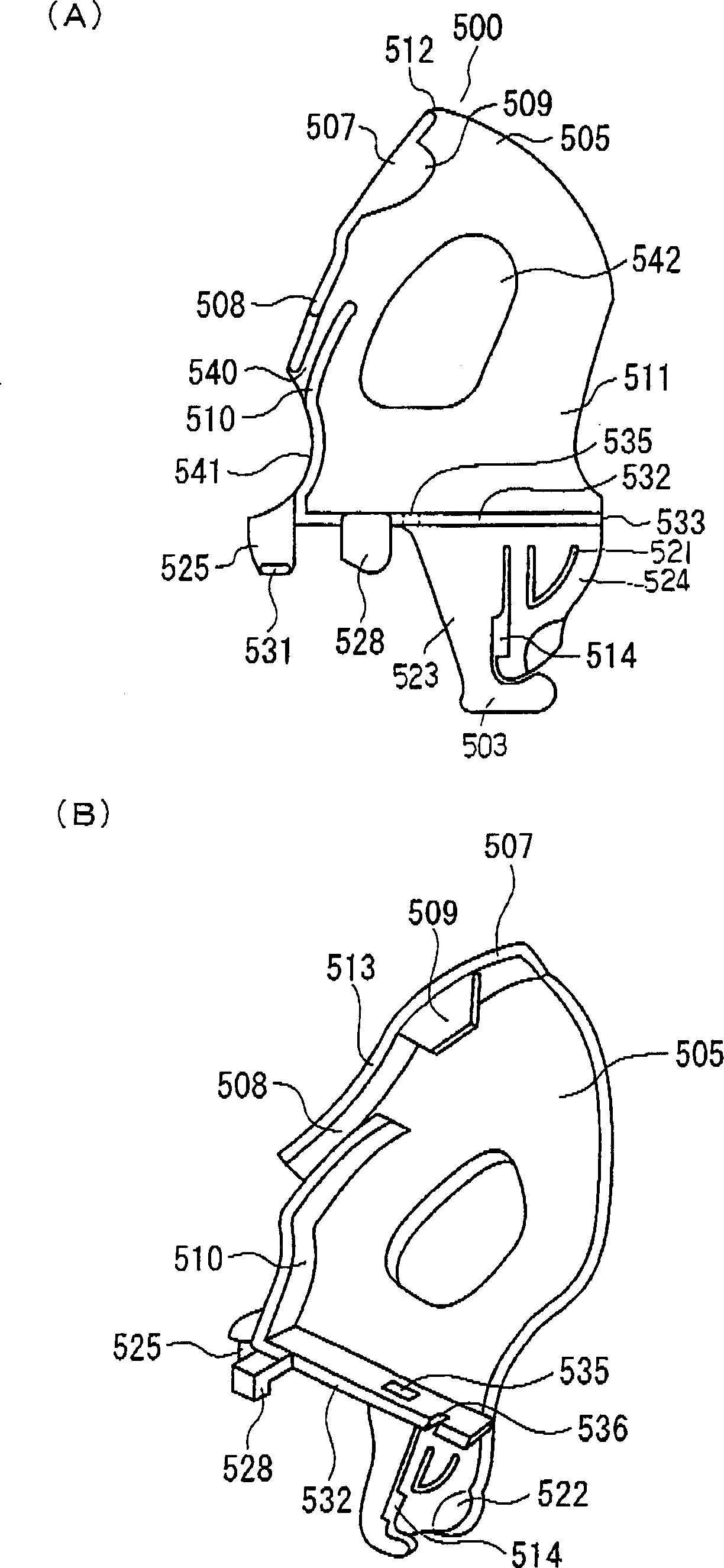

[0065] Next, the configuration of a specific example of the attachment of the engaging piece mounting device of the present invention will be described in detail with reference to the drawings.

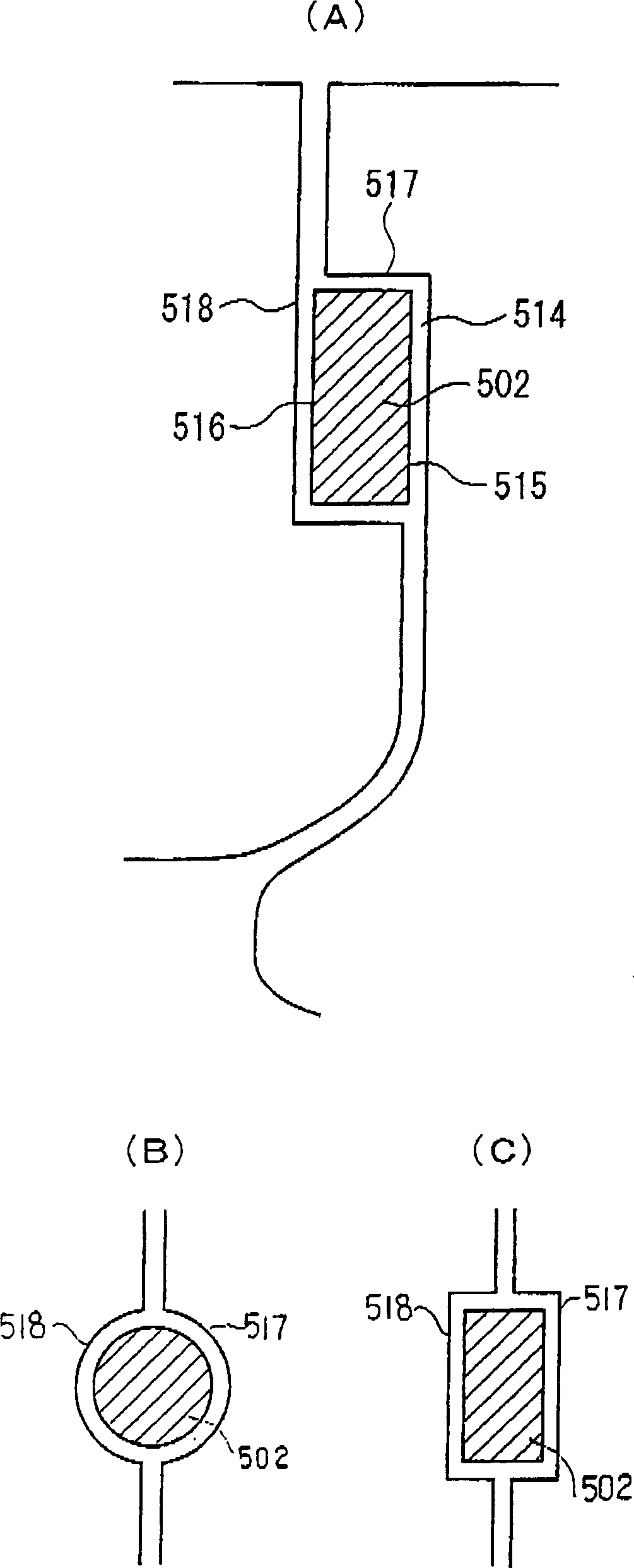

[0066] which is, figure 1 A schematic view showing the configuration of a specific example of an attachment detachably attached to the engaging piece mounting device according to the present invention, and the figure shows the attachment used in the engaging piece mounting device 20 using the engaging piece thin plate 600 500, if reference 7 and Figure 9, it can be seen that the insertion portion 2 or 13 and the holding portion 3 or the socket portion 15 are inserted into the insertion portion 2 or 13 of the engaging piece 1 or 10 provided at both ends of the long line portion 4 or 10. In the hollow needle 21, the insertion portion 2 or 13 is pushed out from the hollow needle 21 by a predetermined extrusion device (not shown), thereby fixing the insertion portion 2 or 13 together w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com