Mechanism for producing end edge guide angle of golden finger on circuit board

A gold finger and circuit board technology, applied in printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve the problems of cutting out, uneven length of gold finger surface, and flat pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

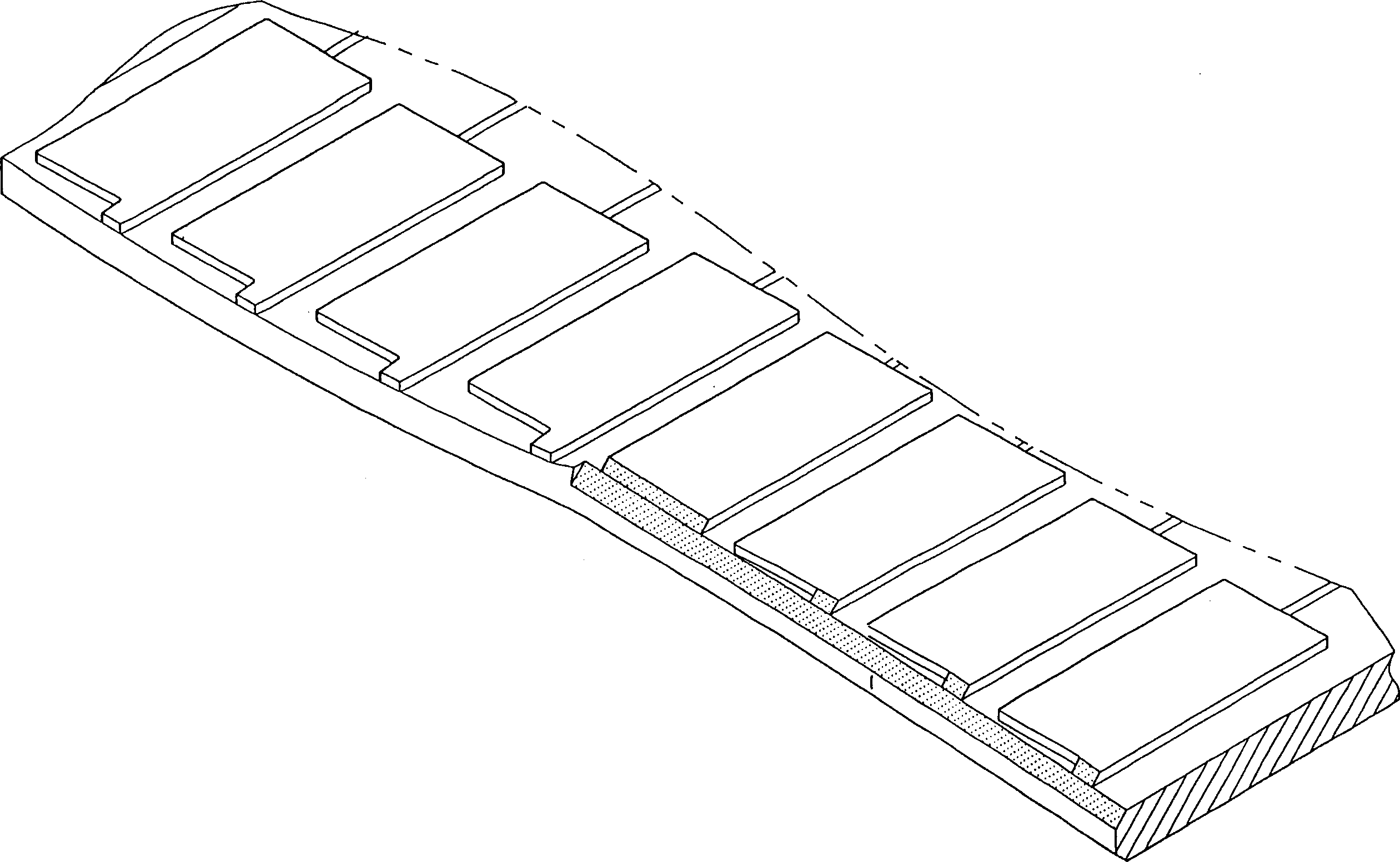

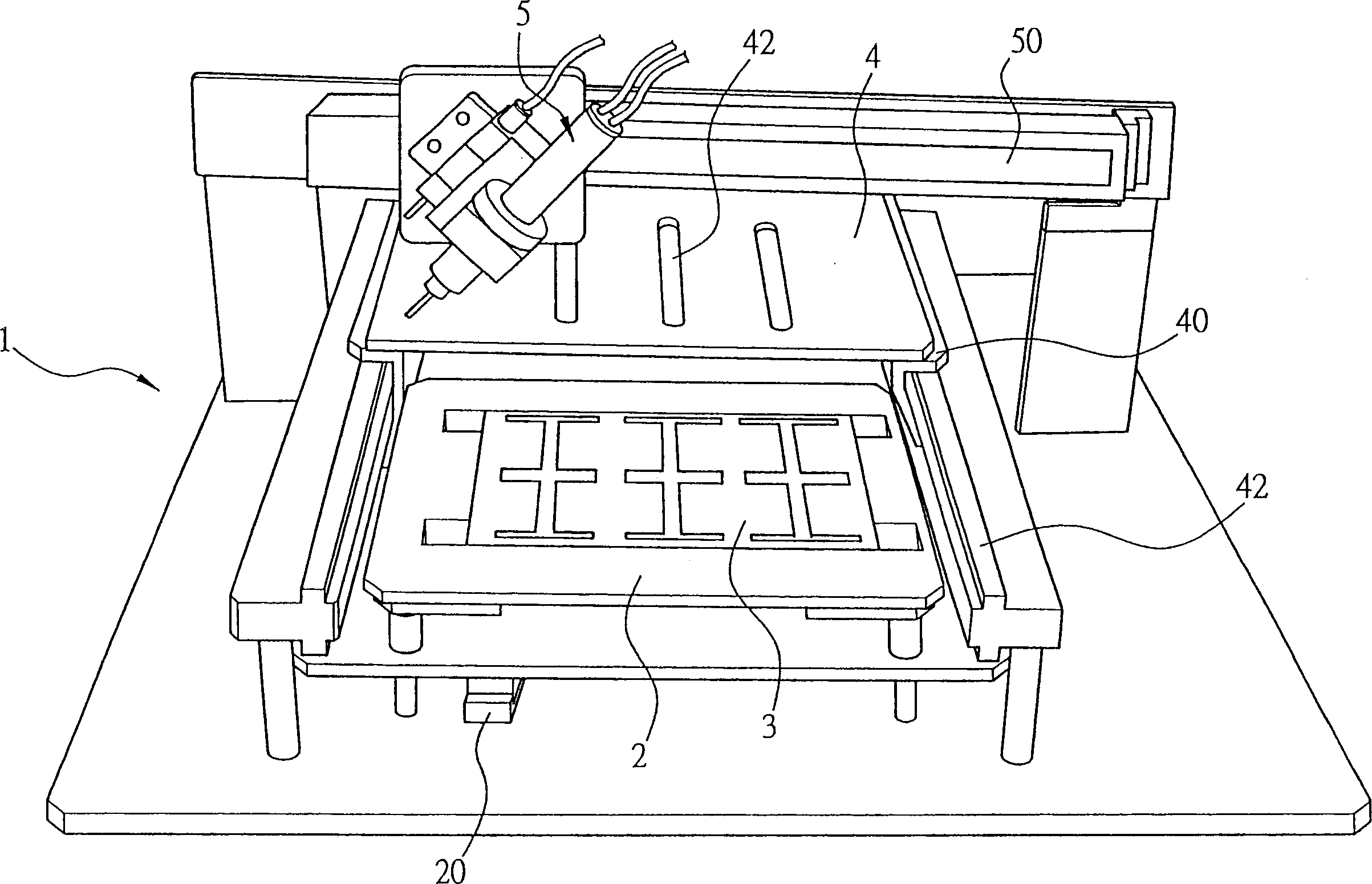

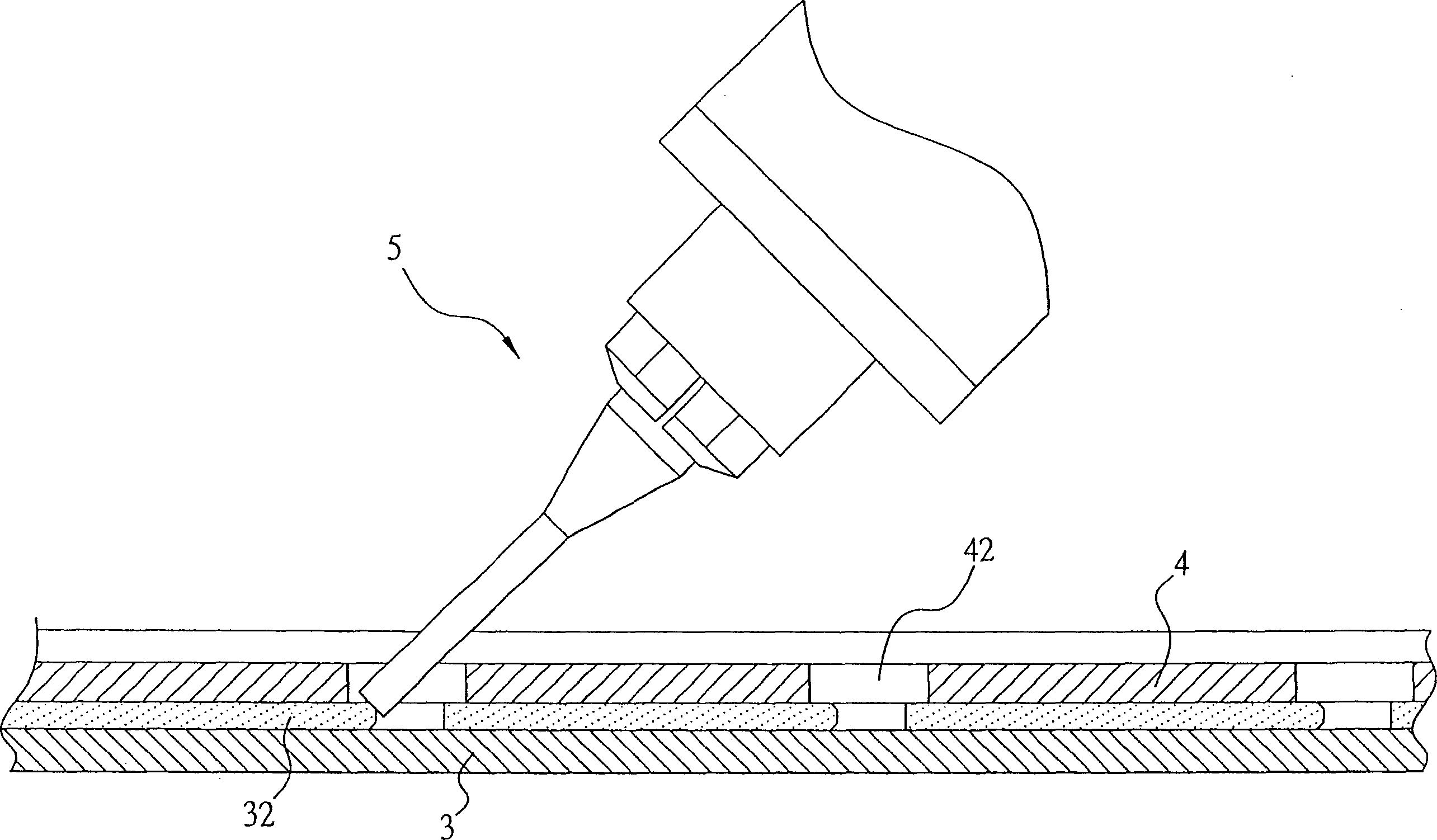

[0021] like figure 2 , 3 , 4, the present invention is a mechanism for making the edge chamfering of the golden fingers on the circuit board, the mechanism is provided with a machine 1, the machine 1 is provided with a movable on the machine 1 Platform 2, a circuit board 3 can be fixed on one side of the platform 2, the machine 1 is provided with a fixture 4 above the platform 2 that can move on the machine 1, the fixture 4 is provided with several openings 42 , the platform 2 and the fixture 4 can be flatly attached to the two sides of the circuit board 3 respectively, and the openings 42 can just correspond to the gold fingers 32 set on the circuit board 3, so that the circuit can be eliminated. The tolerance of the board 3 enables the circuit board 3 to have better flatness at the gold fingers 32. The machine 1 is provided with a tool 5 that can move on the machine 1 adjacent to the fixture 4. When the tool 5 moves to the opening 42, the tool 5 and the processing surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com