Automatic identification system and method for printer recording medium

An automatic identification and printer technology, applied in printing devices, printing, object supply, etc., can solve the problems of high manufacturing difficulty, inability to guarantee printing quality, and inability to judge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

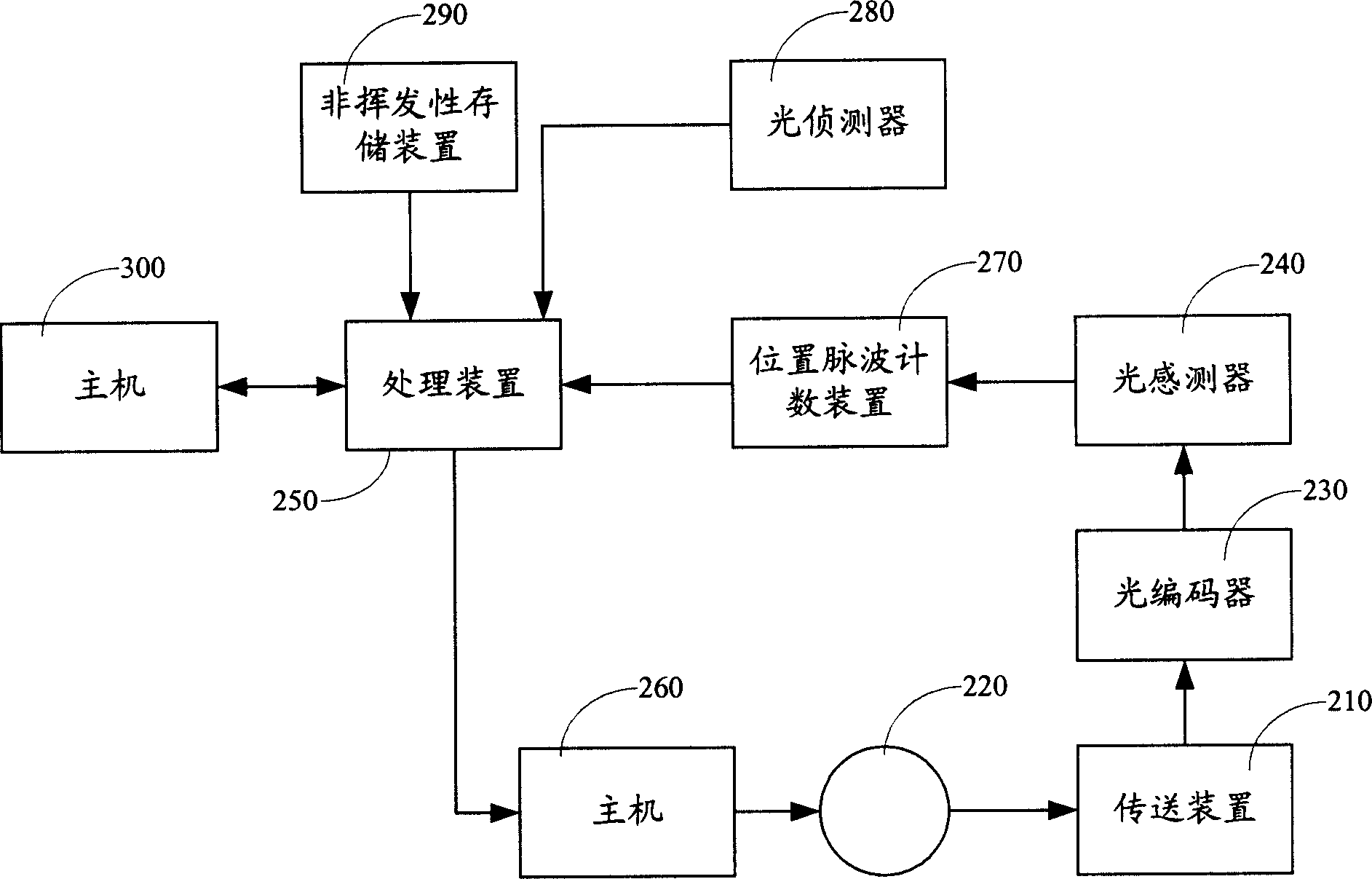

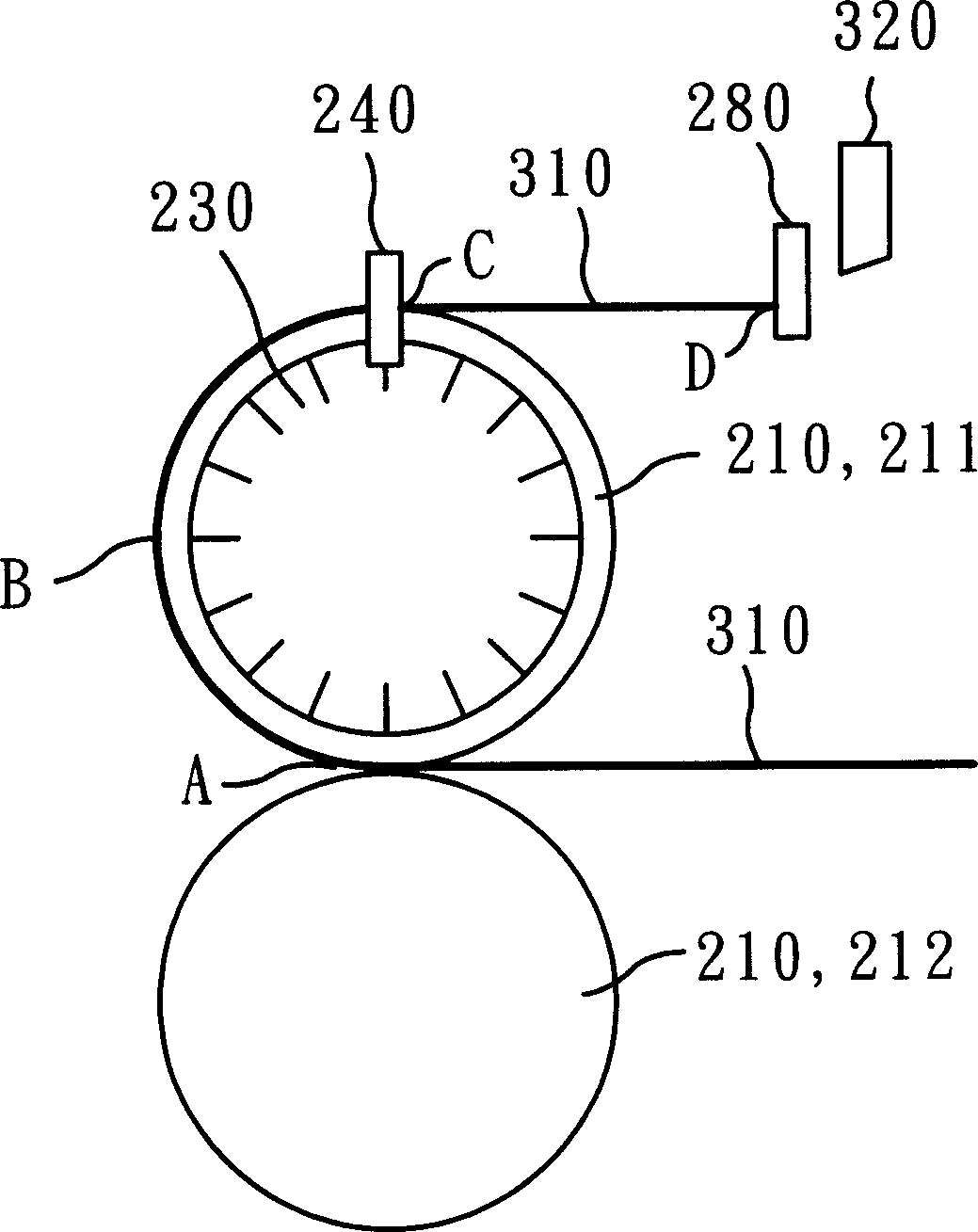

[0024] figure 2 It is a block diagram of the automatic identification system for printer recording media of the present invention, which is used to detect at least two different recording media when a printer is printing, and the at least two different recording media have different load characteristics. The system includes a transmission device 210, a driving device 220, an optical encoder 230, an optical sensor 240, a processing device 250, an amplifying device 260, a position pulse counter 270, an optical detector 280 and a non- Volatile memory device 290.

[0025] The transmitting device 210 is used for transmitting at least two different recording media. The driving device 220 is coupled to the conveying device 210 for driving the conveying device 210 , and the driving device 220 may be a motor.

[0026] The optical encoder 230 is disposed on the transmission device 210. When the transmission device 210 transmits at least two different recording media, the optical enco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com