A three-dimensional zero-gravity simulation device combining knife-type cam constant force spring and air-floating thrust bearing

A constant force spring and thrust bearing technology, applied in the field of three-dimensional zero-gravity simulation devices, can solve the problems of high aircraft handling and maintenance costs, affecting the accuracy of aircraft microgravity simulation, etc., and achieve simple structure, easy maintenance, and reduced maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

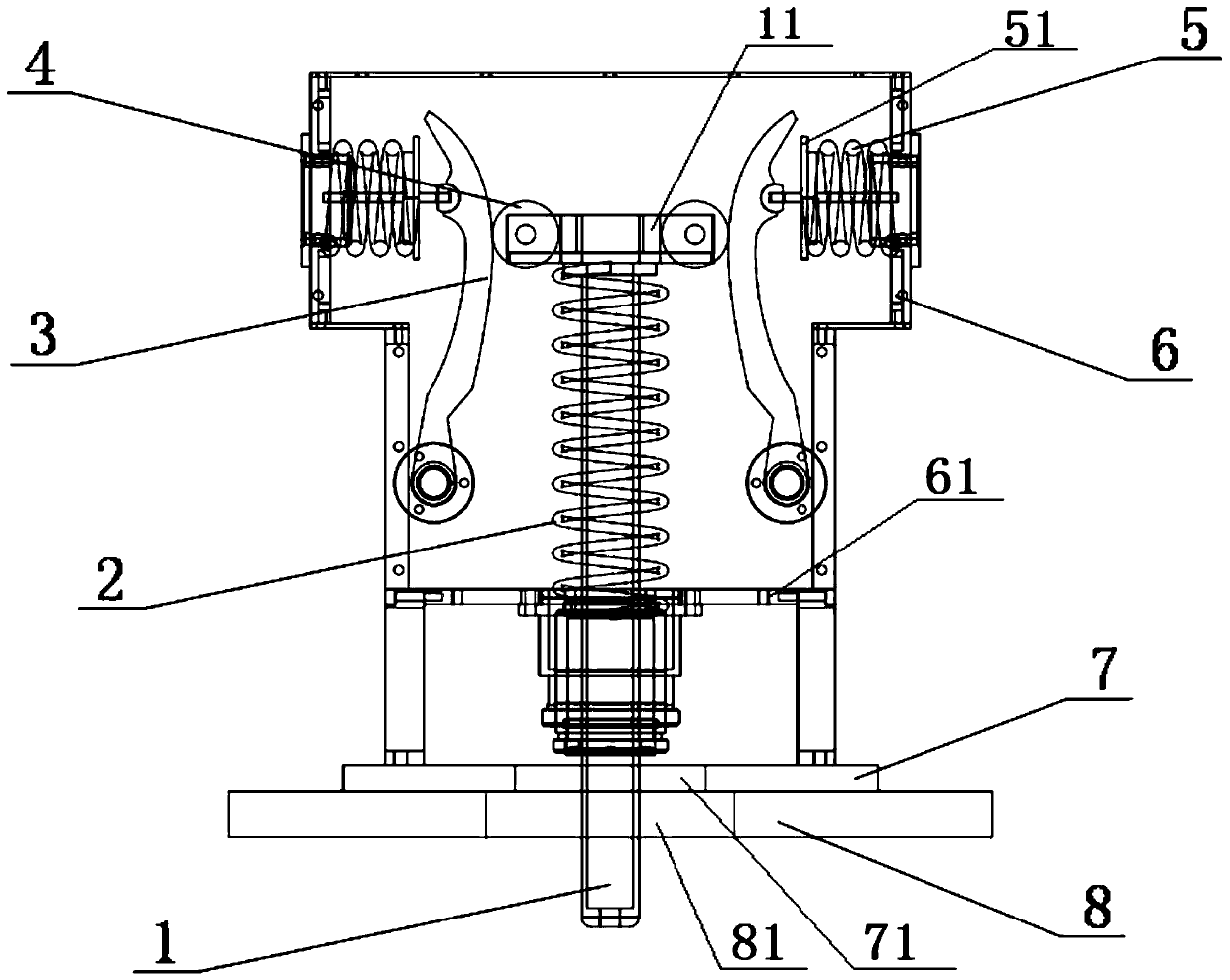

[0020] A three-dimensional zero-gravity simulation device combined with a knife-type cam constant force spring and an air-floating thrust bearing, including: a positive and negative rigidity combined spring assembly, an inverted plane air foot 7 and an air-floating support plate 8;

[0021] The center of the plane air foot 7 is provided with an air foot plate through hole 71, and the center of the air flotation supporting plate 8 is provided with a supporting plate through hole 81; the plane air foot 7 is provided with several throttle holes, and the plane air foot 7 is provided with an air cavity, after the air supply, the compressed gas flows out from the orifice, forming a high-rigidity air film between the plane air foot and the air flotation support plate, and the plane air foot 7 and the air flotation support plate 8 work together to realize the plane air foot 7 Ultra-low-friction air suspension lubrication between the air bearing plate 8 and two-dimensional zero-gravity ...

specific Embodiment approach 2

[0032] In this embodiment, the plane air foot 7 is provided with 8 throttle holes.

[0033] Other structures and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0035] The diameter of the orifice in this embodiment is 0.2mm.

[0036] Other structures and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com