Cap for wiper connector

A connector and wiper technology, which is applied to vehicle cleaning, heating methods, lighting and heating equipment, etc., can solve the problems of unsightly appearance of the wiper connector and reduce the wiping performance of the wiper, so as to achieve a beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, best embodiments of the present invention will be described based on the drawings.

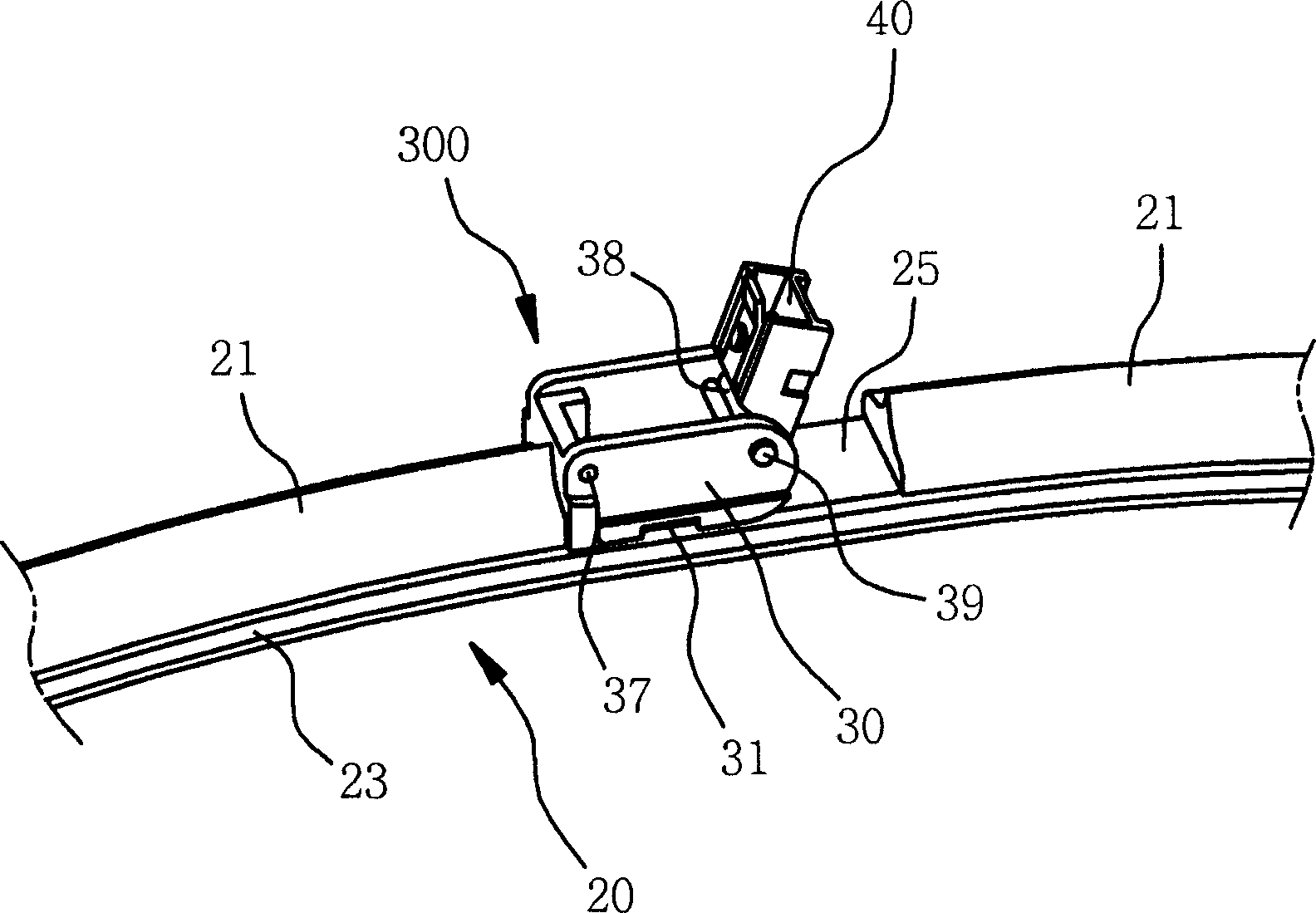

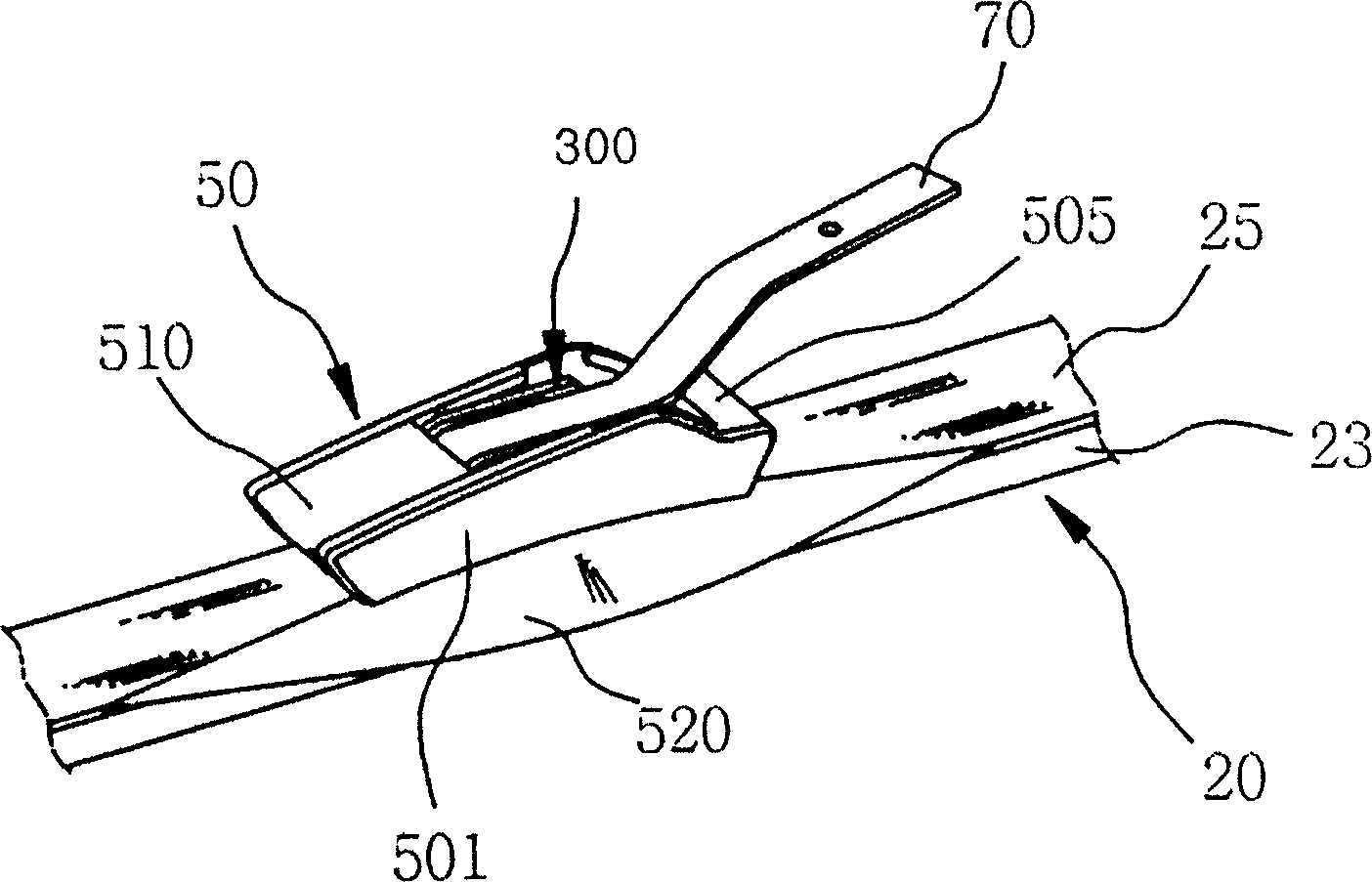

[0043] figure 2 It is a perspective view showing the state where the wiper connector cover of the present invention is fastened to the wiper connector. below, refer to figure 2 , illustrating the state that the wiper connector cover of the present invention is fastened to the wiper connector.

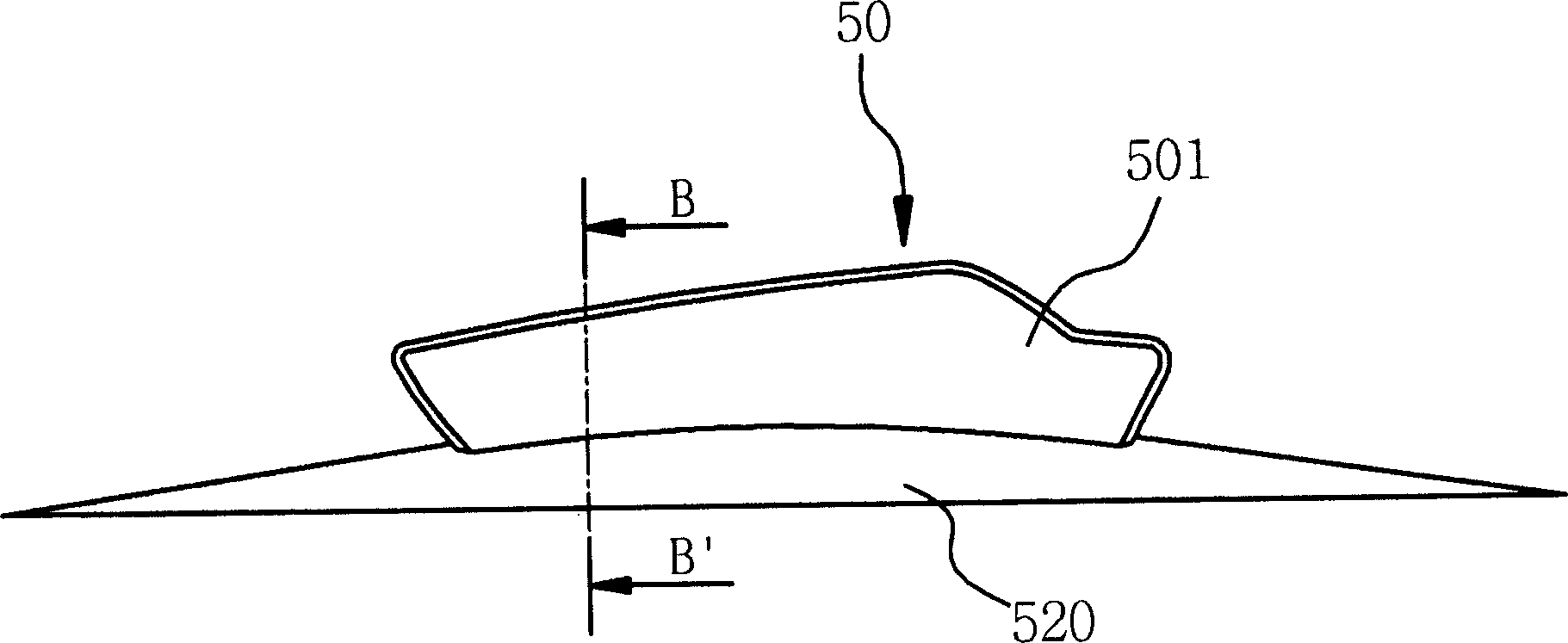

[0044] refer to figure 2 , the wiper connector cover 50 of the present invention can be freely attached to the wiper connector 300, the wiper connector 300 is arranged in the approximate center of the length direction of the elastic support member 25, the above elastic support The member 25 is a member for supporting the flexible sheet 23 which is in direct contact with the windshield of the vehicle, and has elasticity. The wiper rocker arm 70 is connected to the connector part 40 of the wiper connector 300 and transmits the wiping drive force transmitted from the drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com