Longitudinal and transverse moving device for switch and rail row

A technology of rail row and turnout, which is applied in the field of special equipment for railway engineering, can solve the problems of unstable construction safety, laborious construction cost, and high construction risk, and achieve the effects of saving manpower and time, good safety, and reducing traffic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

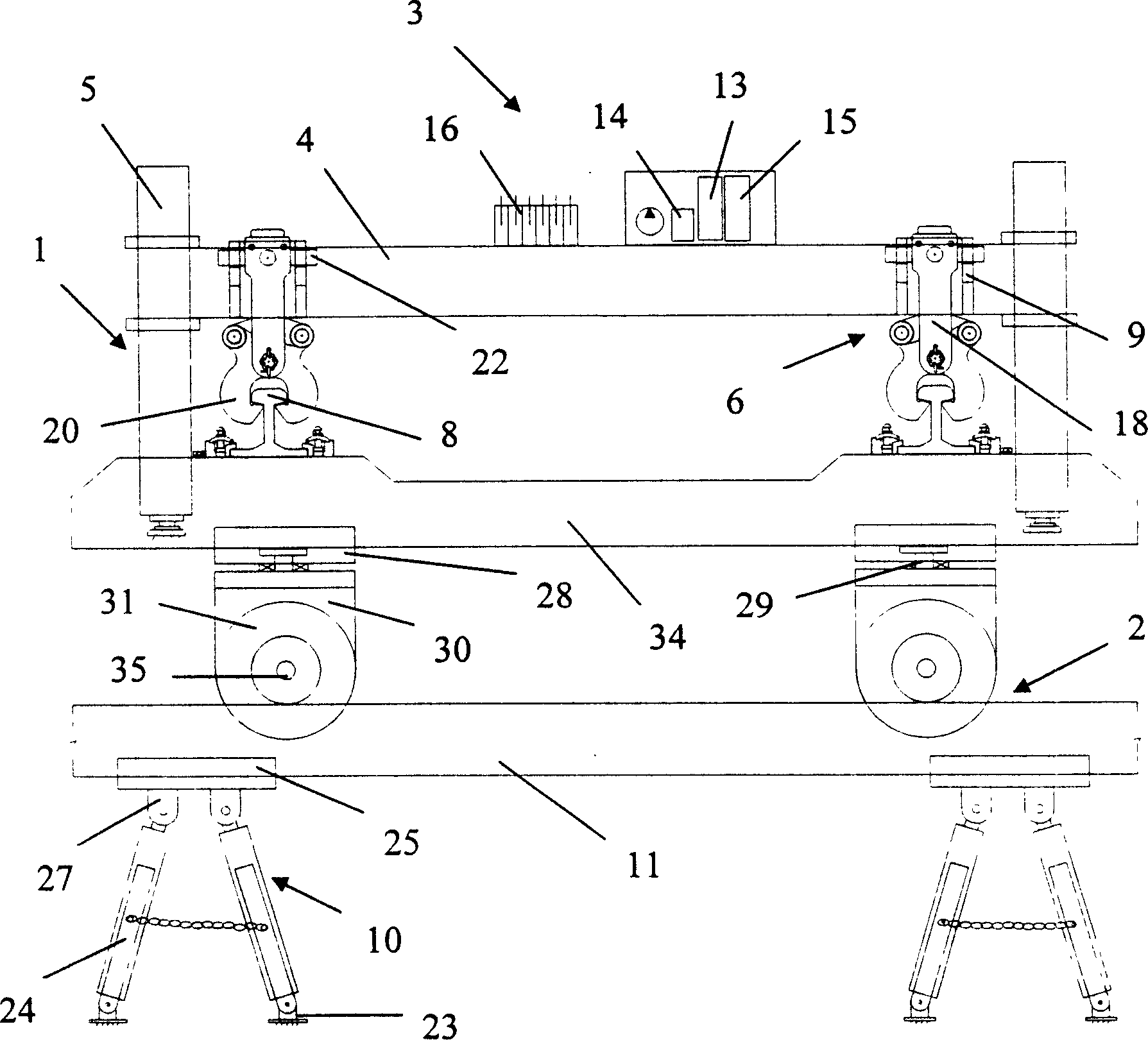

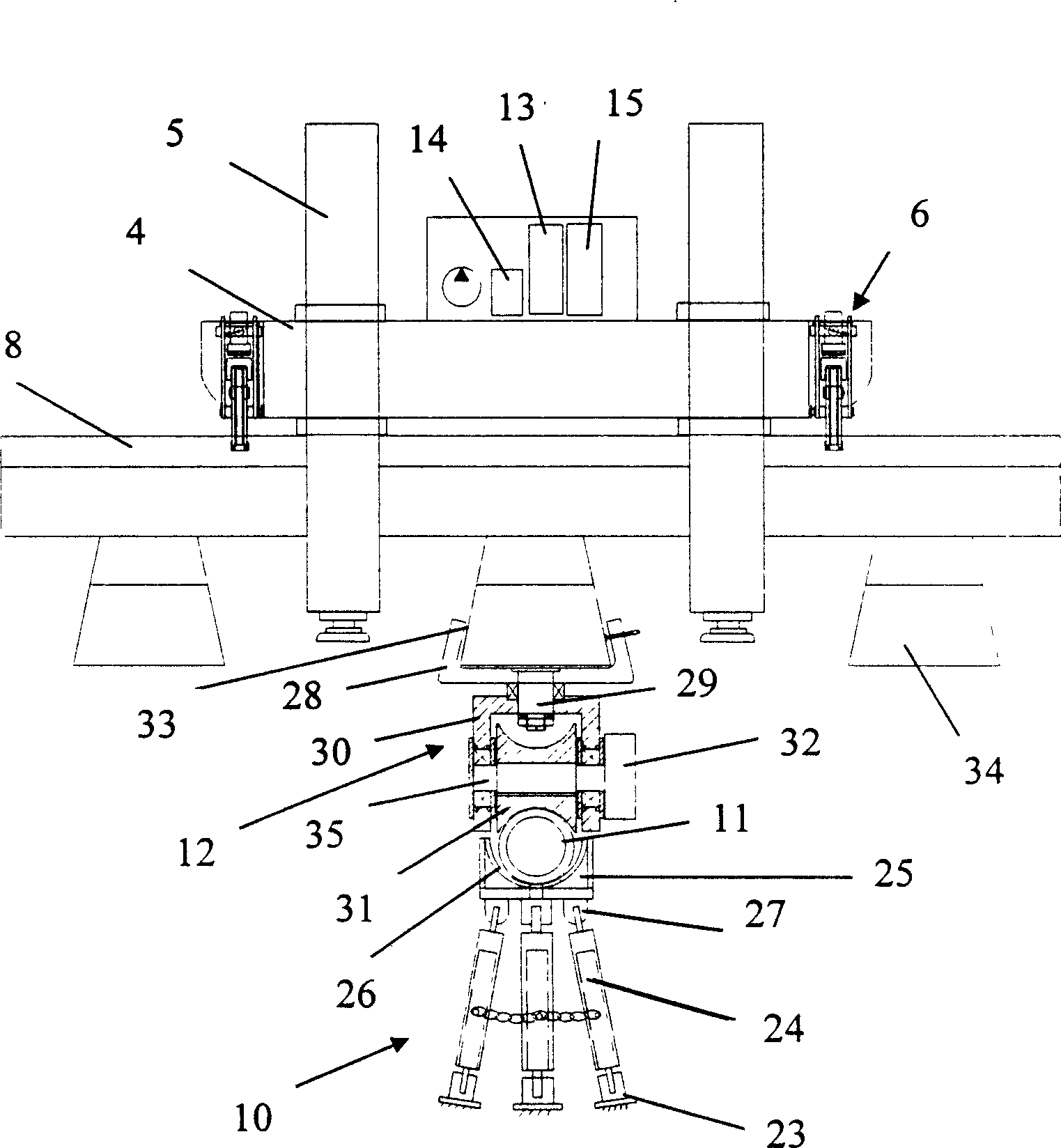

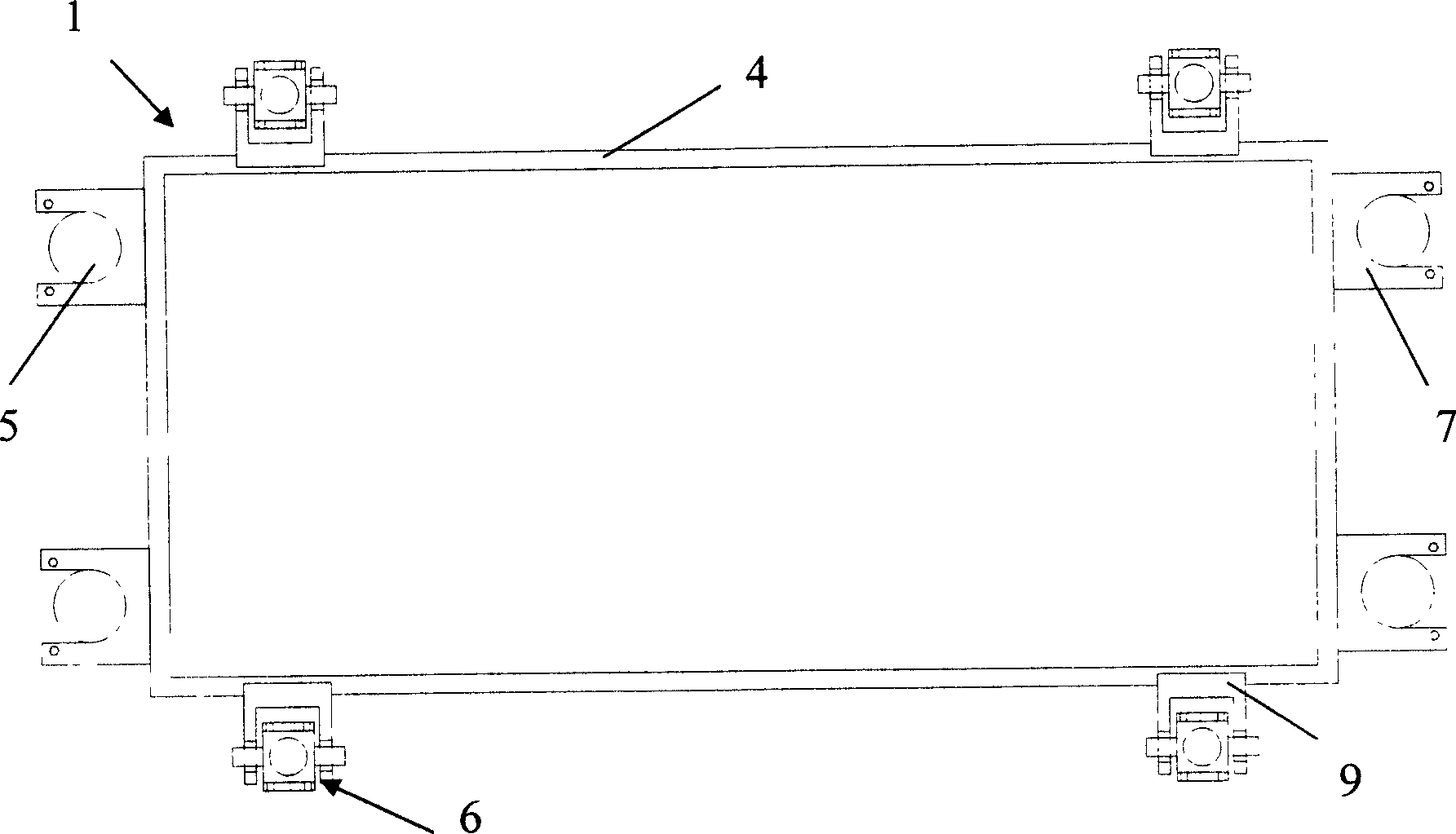

[0034] Such as Figure 1 to Figure 5 As shown, the turnout and rail row longitudinal and lateral movement equipment include a lifting system 1, a traveling system 2 and a hydraulic power control system 3; wherein the lifting system 1 is composed of a combined steel frame 4, 4 jacking cylinders 5 and 4 The main body of the combined steel frame 4 is a rectangular frame arranged horizontally, and the outer two ends of each short side protrude outward to form 2 jacking cylinder hangers 7, and each long side The two ends of the outer side protrude outward to form two rail grab hangers 9 with the same distance as the distance between the two steel rails 8; the four jacking cylinders 5 connected with the hydraulic power control system 3 are detachable. Vertically installed on the 4 jacking cylinder hangers 7 of the combined steel frame 4; the 4 rail grabbers 6 are respectively detachably arranged on each rail grabber hanger 9 of the combined steel frame 4; The running system 2 consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com