Indicator lamp

A display lamp and lens technology, applied in the field of display lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

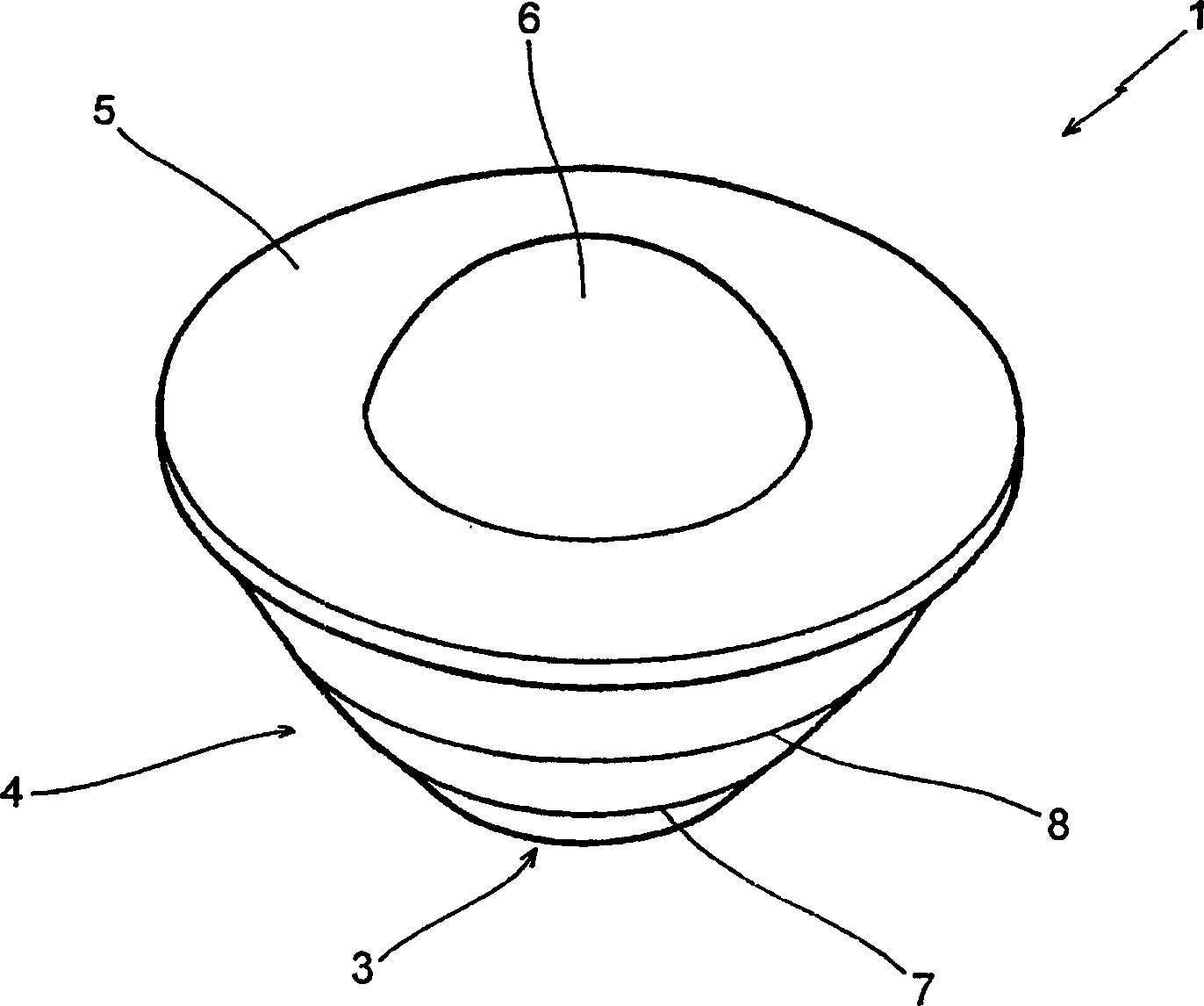

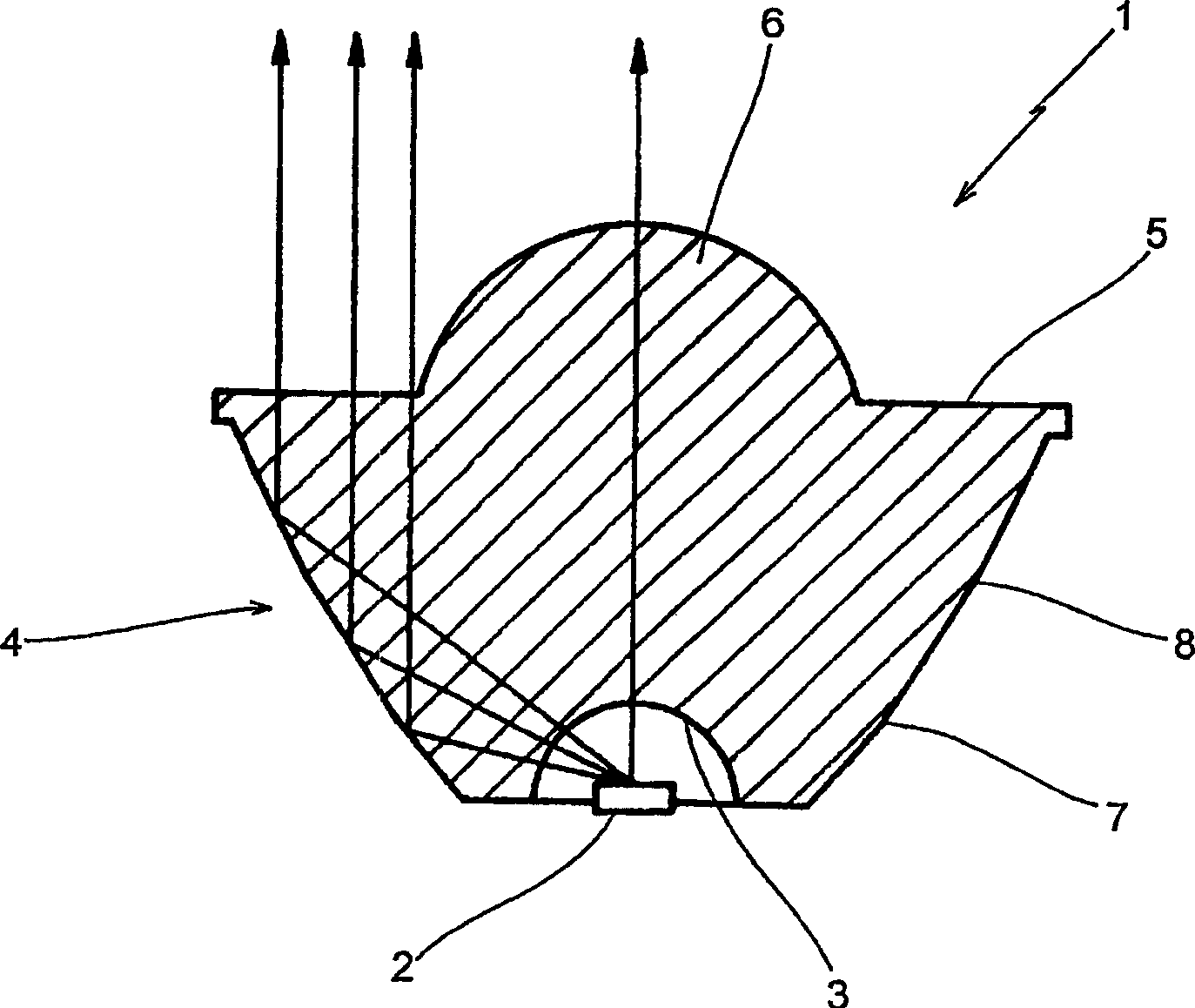

[0027] figure 1 , figure 2 In the display lamp showing the first embodiment of the present invention, the lens 1 for a light-emitting element obtained by forming a transparent synthetic resin material into an approximately truncated cone shape has a light-emitting element mounting portion 3 for arranging a light-emitting element 2 such as an LED at the bottom thereof. , the peripheral wall 4 is inclined so that the angle with the central axis of the lens gradually decreases in three stages from the bottom to the front of the lens. Furthermore, the lens front surface 5 is made flat, and a convex lens portion 6 (R5.78) having a diameter smaller than the width of the lens front surface 5 and having a convex front shape is formed protrudingly from the central portion thereof. The front surface of the lens 5 has a shape in which the outer peripheral edge protrudes slightly in the shape of a flange and expands. The angles between the three-stage slopes of the peripheral wall 4 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com