Circuit board inspection device

A technology for testing devices and circuit boards, applied in printed circuits, measuring devices, electronic circuit testing, etc., can solve problems such as difficulty in stably connecting circuit boards, low potential difference absorption performance, and small degree of elastic deformation, and achieve long-term use. Longevity, high reliability inspection, effect of stable electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

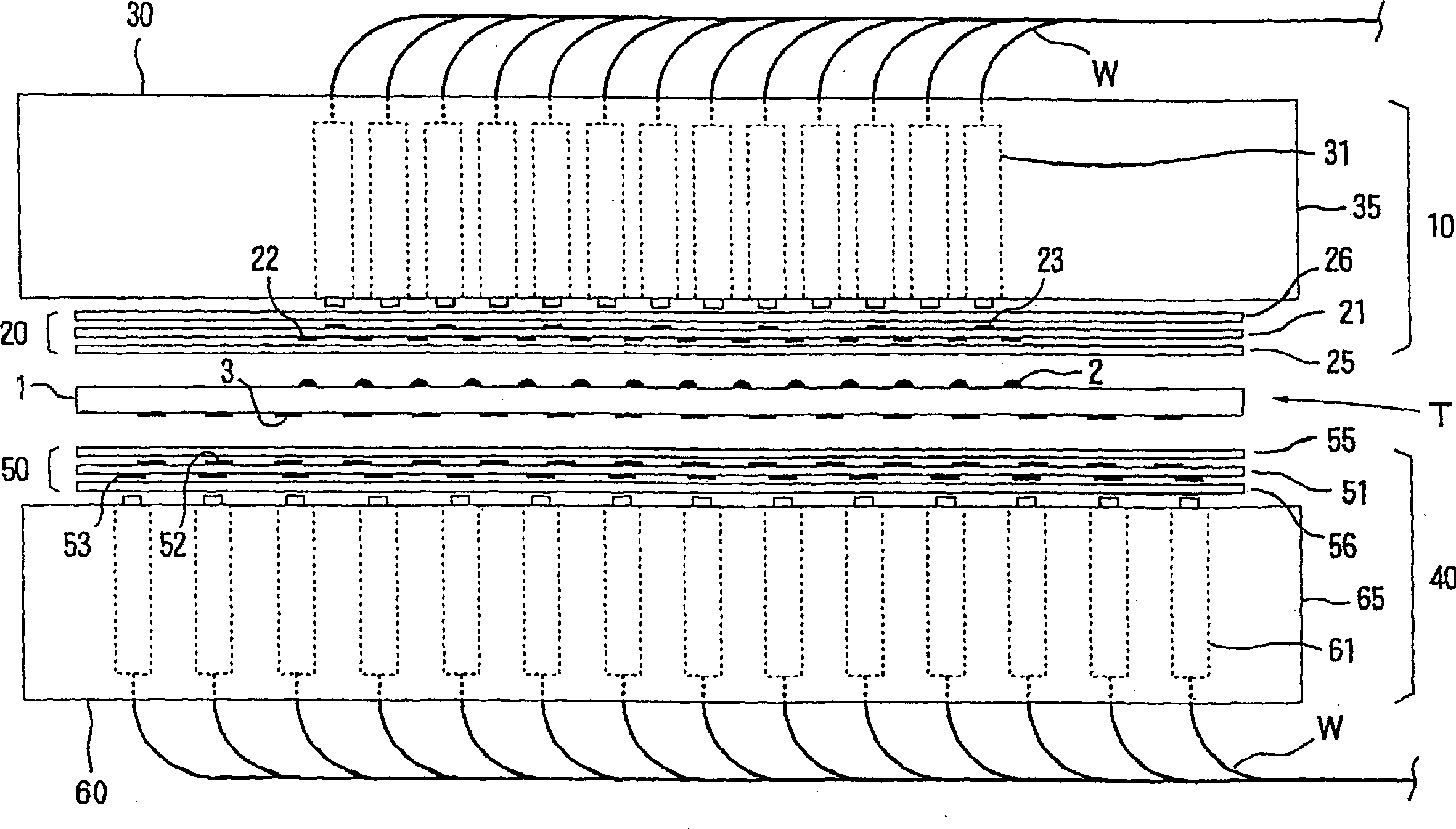

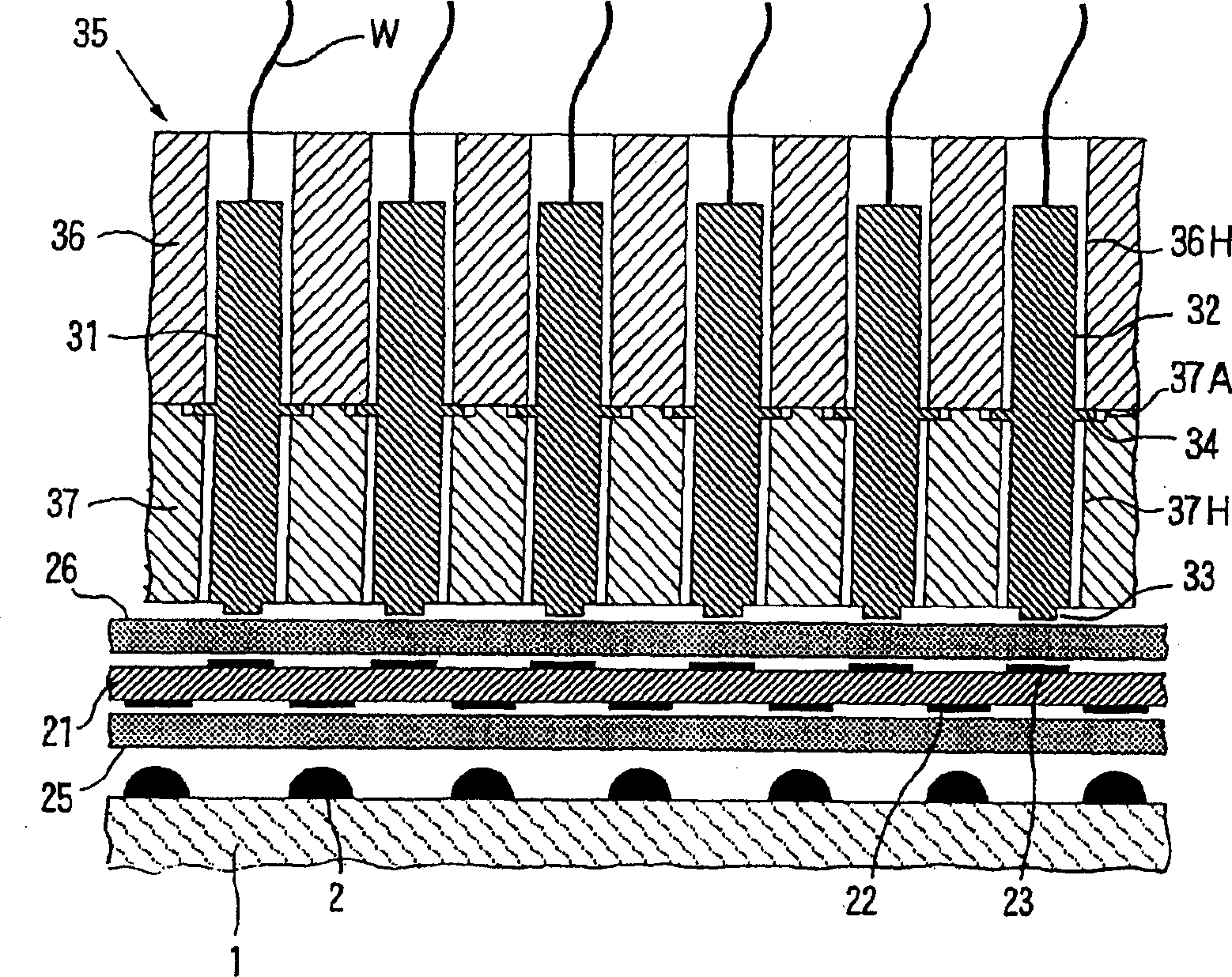

[0233] The circuit board inspection device described below is based on Figures 1 to 3 The structure shown was fabricated.

[0234] [upper adapter (20)]

[0235] The base material of the wiring board (21) is glass fiber reinforced epoxy resin with a thickness of 200 μm, which has 596 circular connecting electrodes (22) and 596 circular terminal electrodes (23), and the minimum diameter of the connecting electrodes (22) The minimum distance between connecting electrodes (22) is 200 μm, the minimum diameter of terminal electrodes (23) is 100 μm, and the minimum distance between terminal electrodes (33) is 200 μm. The terminal electrodes (23) are arranged so that when the wiring board (21) is viewed through the thickness direction, one terminal electrode (23) is located at the center of the specific electrode region (R1), and the terminal electrodes (23) are arranged so as not to cover the connecting electrodes (22) (see Figure 5).

[0236] The first anisotropic conductive ela...

example 2

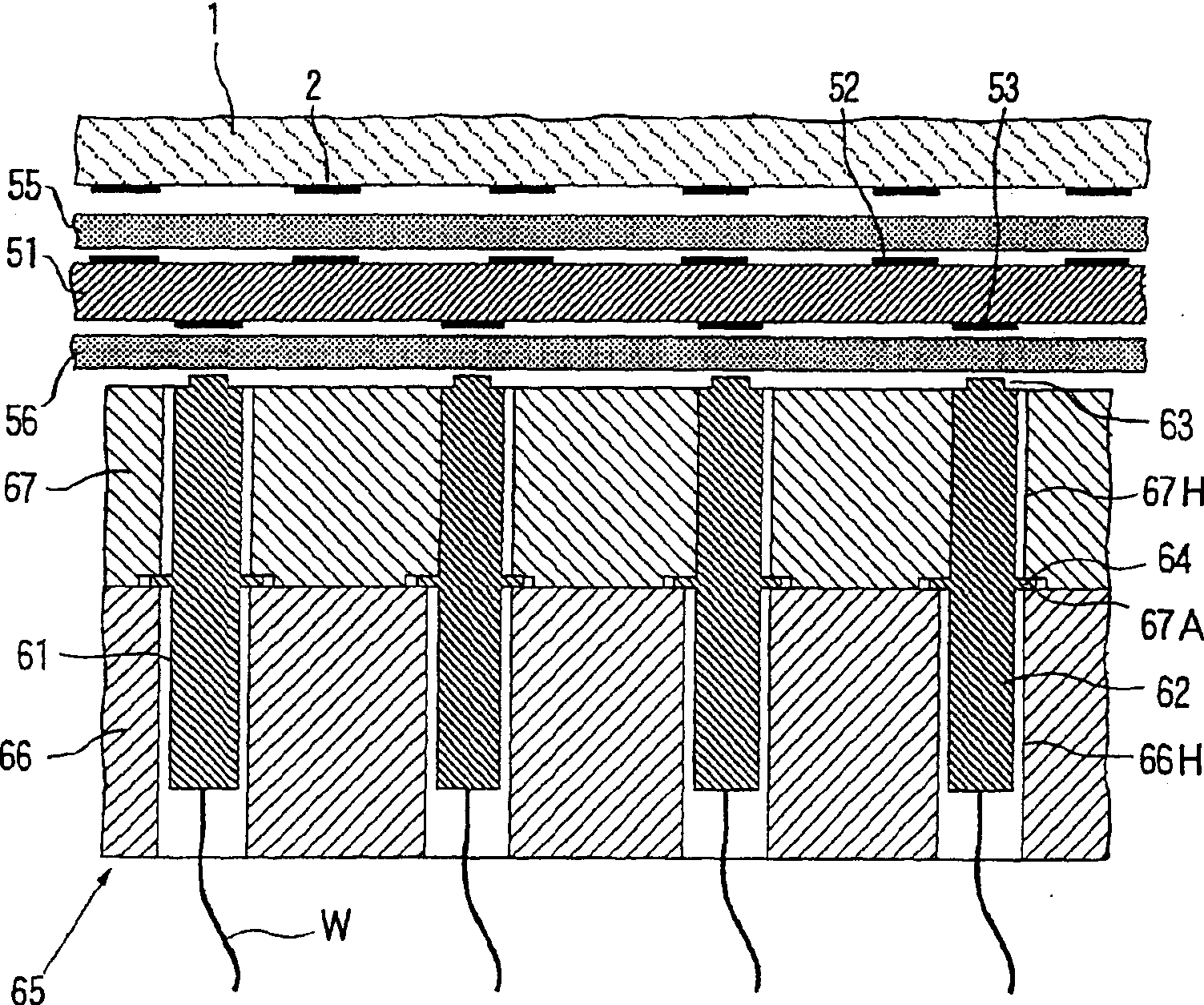

[0267] The circuit board inspection device described below is based on Figures 8 to 10 The structure shown was fabricated.

[0268] [upper adapter (20)]

[0269] The base material of the wiring board (21) is glass fiber reinforced epoxy resin with a thickness of 200 μm. It has 596 pairs of rectangular connection electrodes (22c), which are respectively composed of a connection electrode (22a) for power supply and a connection electrode (22a) for voltage measurement. Consisting of connecting electrodes (22b), and 1192 circular terminal electrodes (23), the minimum size of connecting electrodes (22a) for power supply and connecting electrodes (22b) for voltage measurement is 30 μm*60 μm, for power supply The gap between the connection electrode (22a) and the connection electrode (22b) for voltage measurement is 30 μm, the minimum distance between the connection electrode pair (22c) is 200 μm, and the diameter of the terminal electrode (23) is 60 μm. The terminal electrodes (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com