Waterproof fitting for preventing water leakage of pipeline

A technology for pipes and accessories, applied in the field of waterproof accessories, can solve the problems of poor waterproof effect, complex waterproof construction process around pipes, and ineffective waterproof durability, etc., achieving obvious effects and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

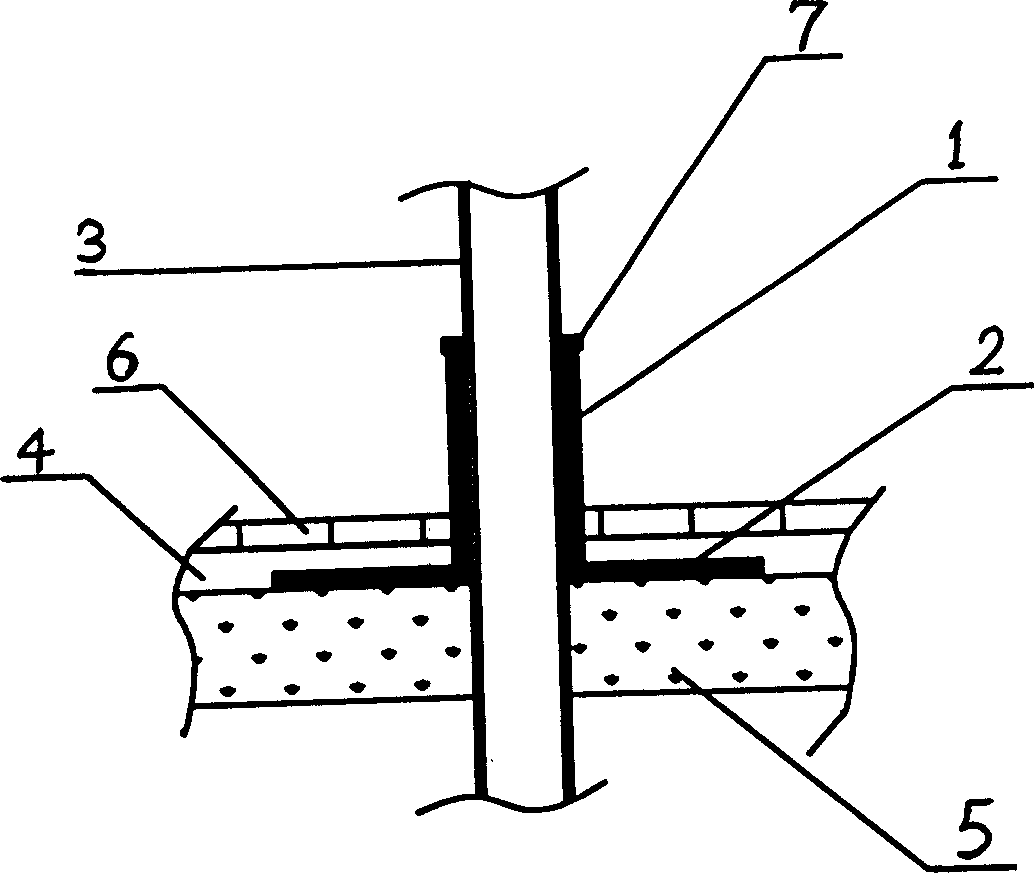

[0010] Below in conjunction with accompanying drawing and embodiment the present invention is further described

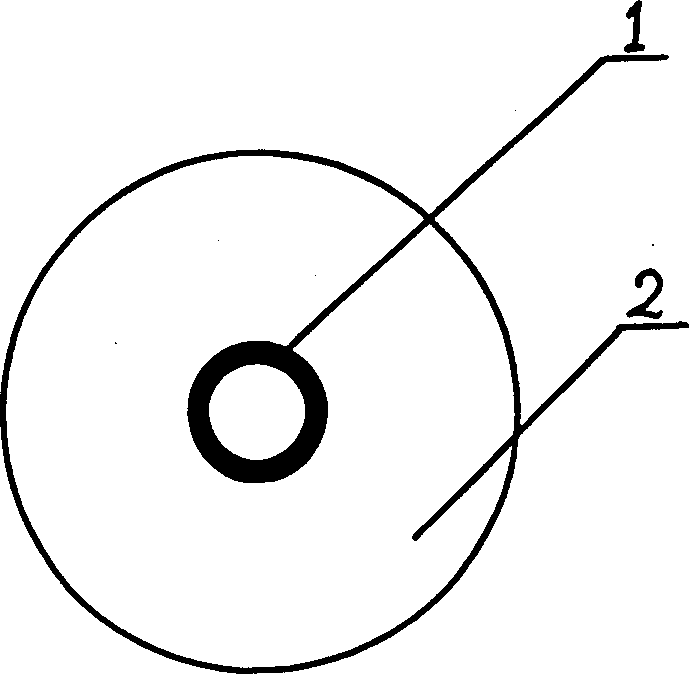

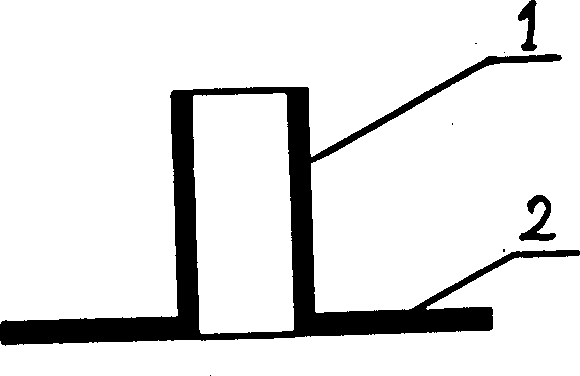

[0011] like figure 1 , 2 As shown, a waterproof sleeve (1) is made of an elastomer waterproof membrane, and a ring-shaped waterproof flange (2) is connected to the lower end of the waterproof sleeve (1). The waterproof sleeve (1) is perpendicular to the waterproof The plane where the flange (2) is located, the waterproof sleeve (1) and the waterproof flange (2) are built at one time.

[0012] like image 3 As shown, the waterproof sleeve (1) is nested on the vertical pipe (3), and the upper end of the waterproof sleeve (1) is clamped and sealed with a pipe collar (7). The waterproof flange (2) is installed between the floor structure layer (5) and the floor surface layer (3), and the waterproof flange (2) is used to connect with the floor surface waterproof material (4) to ensure the sealing lap length, In this way, an integral waterproof node will be formed ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com