Plug-in connection for pipe and hose lines with a reinforced material cross-section

A plug connection, cross-section technology, applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, coupling, etc., to achieve the effect of superior strength and high tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

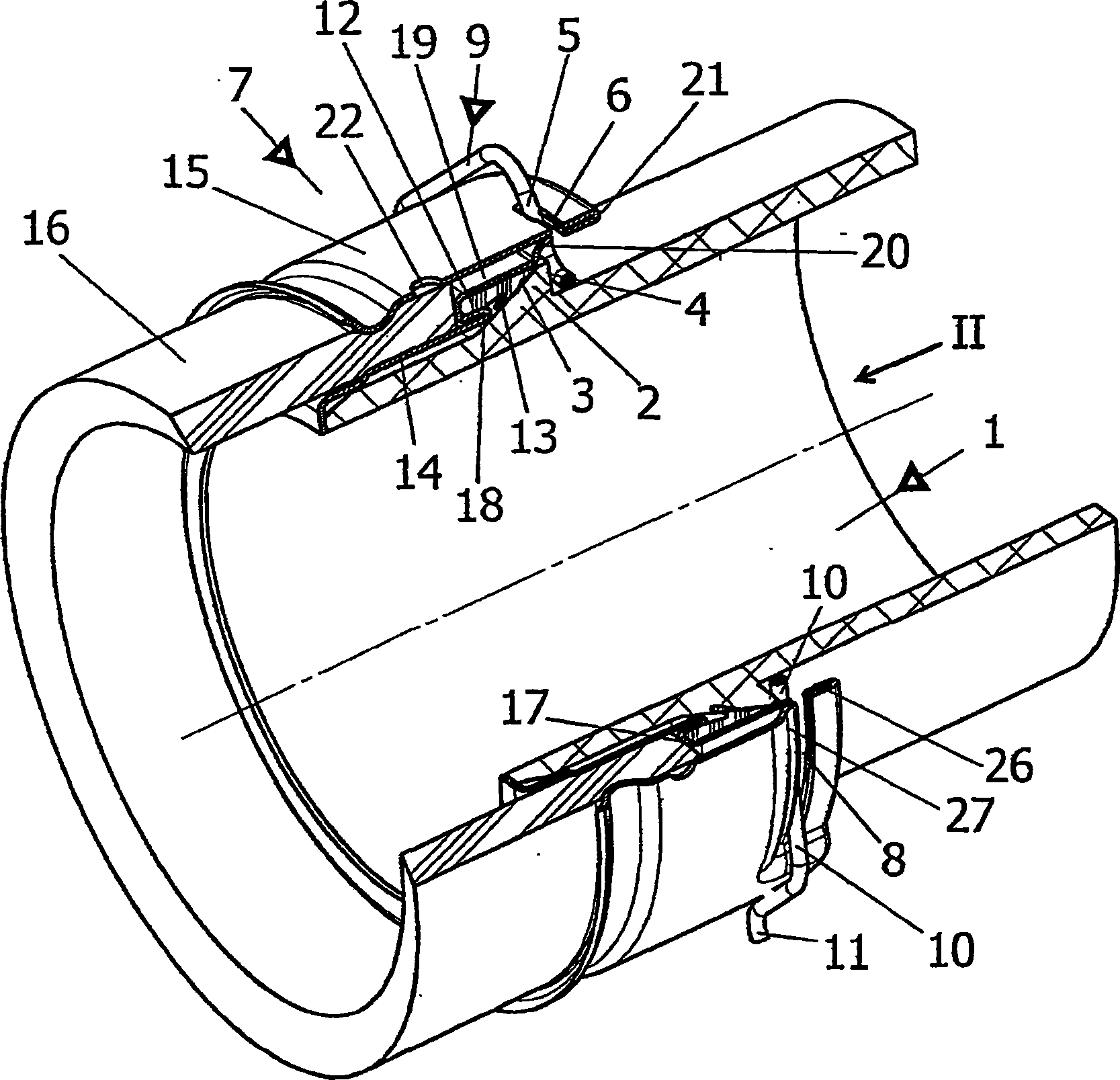

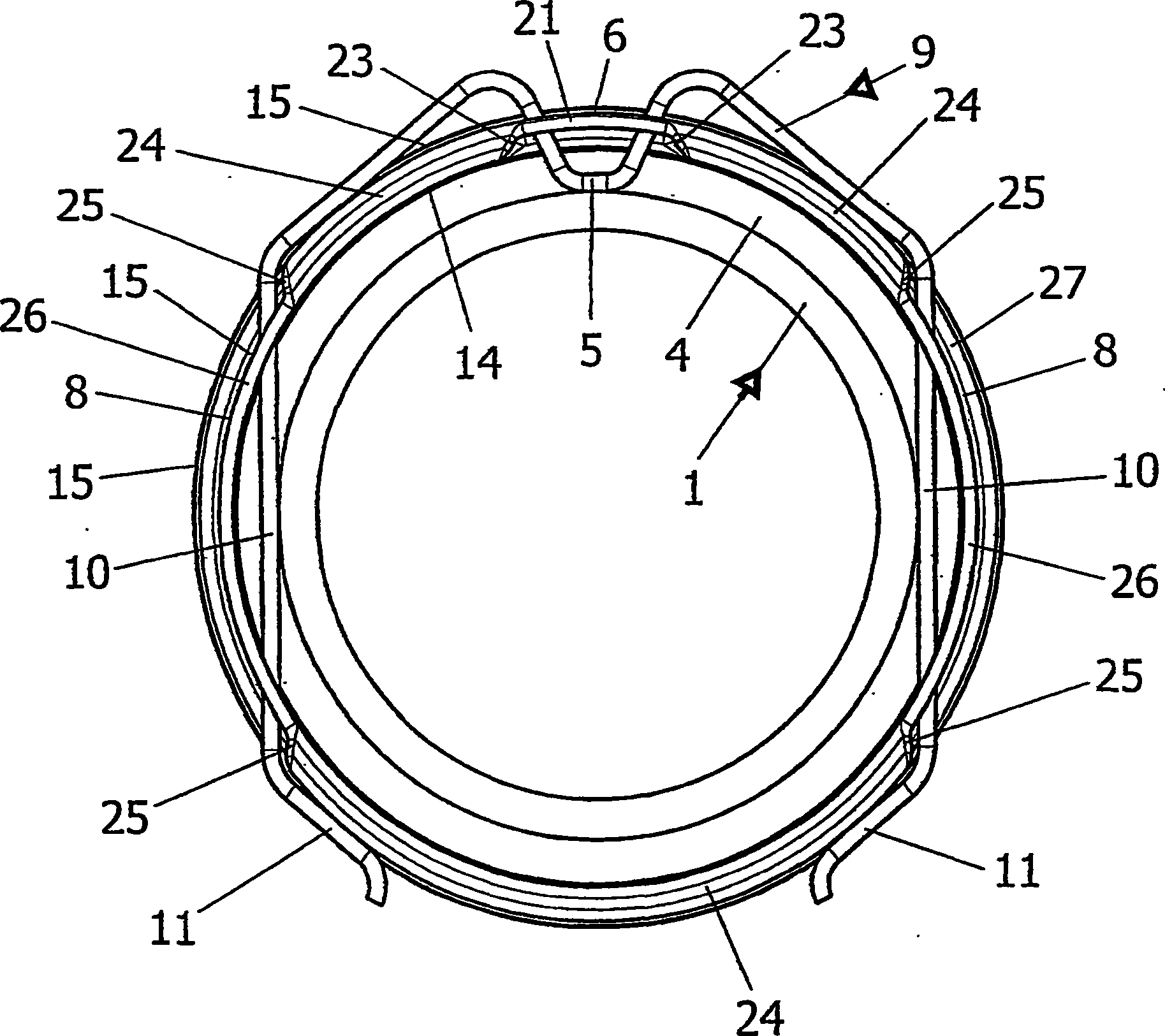

[0025] according to figure 1 A socket 1 , for example made of metal or plastic material, is inserted into a plug 7 and latched there.

[0026] The connecting piece 1 essentially consists of a cylindrical sleeve, on the outer circumference of which a locking shoulder 2 is formed. The latching shoulder 2 forms a front bevel 3 in the direction of the plug, which transitions to the rear into a latching surface 4 .

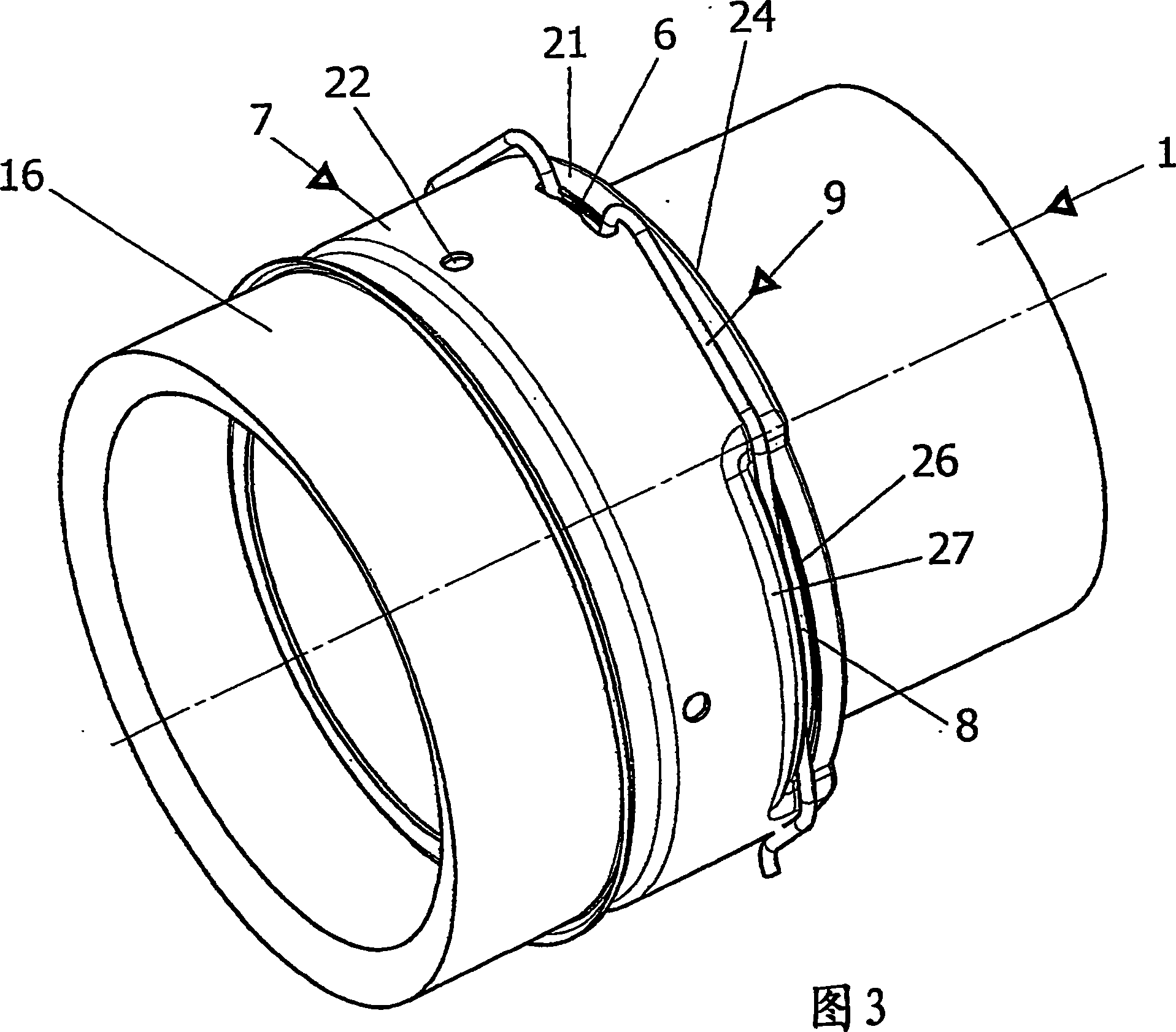

[0027] The latching with the plug 7 is effected in that the plug 7 is connected to an approximately U-shaped latching spring 9 which overall forms three different latching locations.

[0028] Two mutually opposite latches are formed by the latching arms 10 of the U-shaped latching spring 9 arranged parallel to one another.

[0029] The locking arms 10 of the locking spring 9 engage through mutually parallel locking spring passage holes 8 on the plug connector 7 . On the free front ends of the detent arms 10 , outwardly bent spring ends 11 are formed in each case.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com