Drop-out line unit in drawbench

A wire drawing machine and equipment technology, which is applied in the field of wire drawing machine arranging devices, can solve the problems of easy damage to the double-ended screw stroke of the air valve, unstable air source, reduced production efficiency, etc. Improve the performance of the cable, the effect of uniform and stable cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

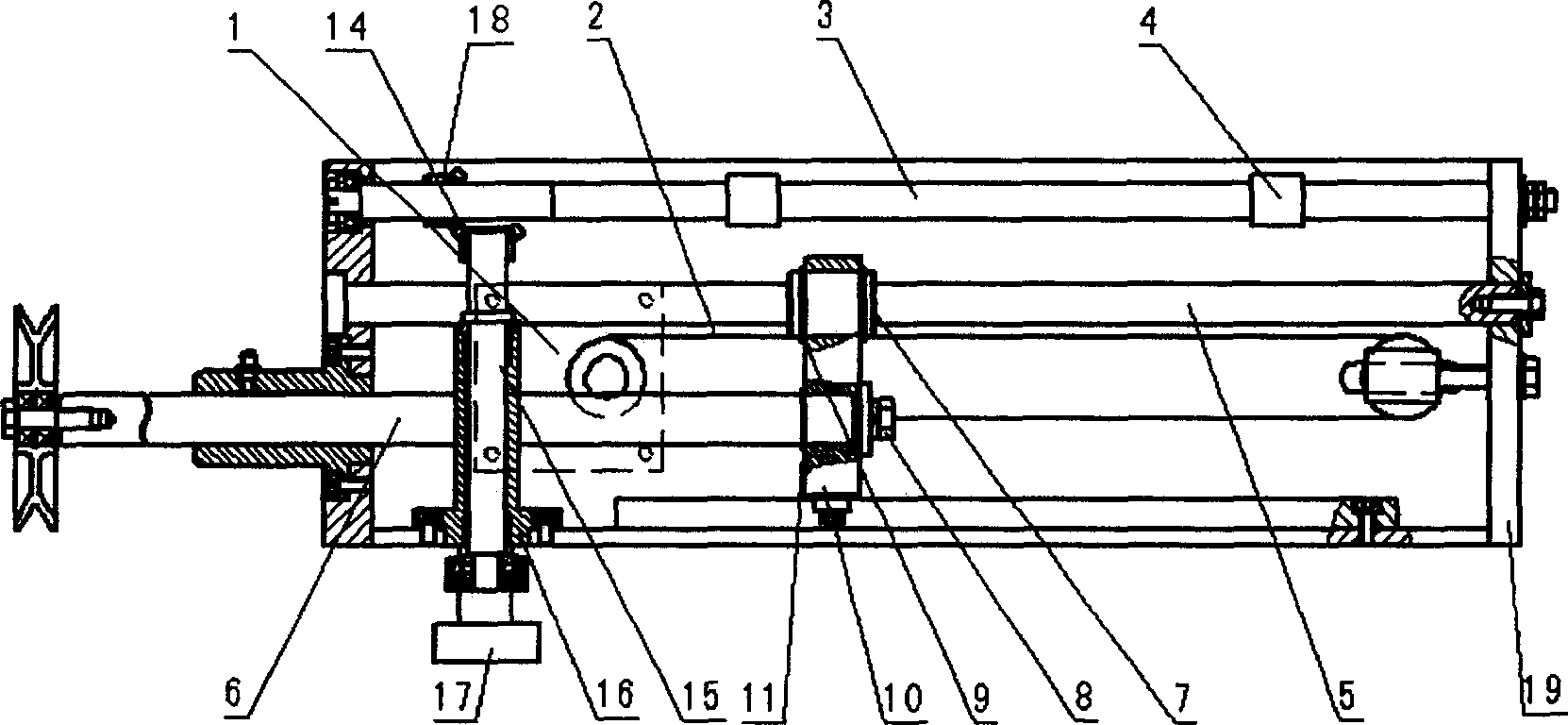

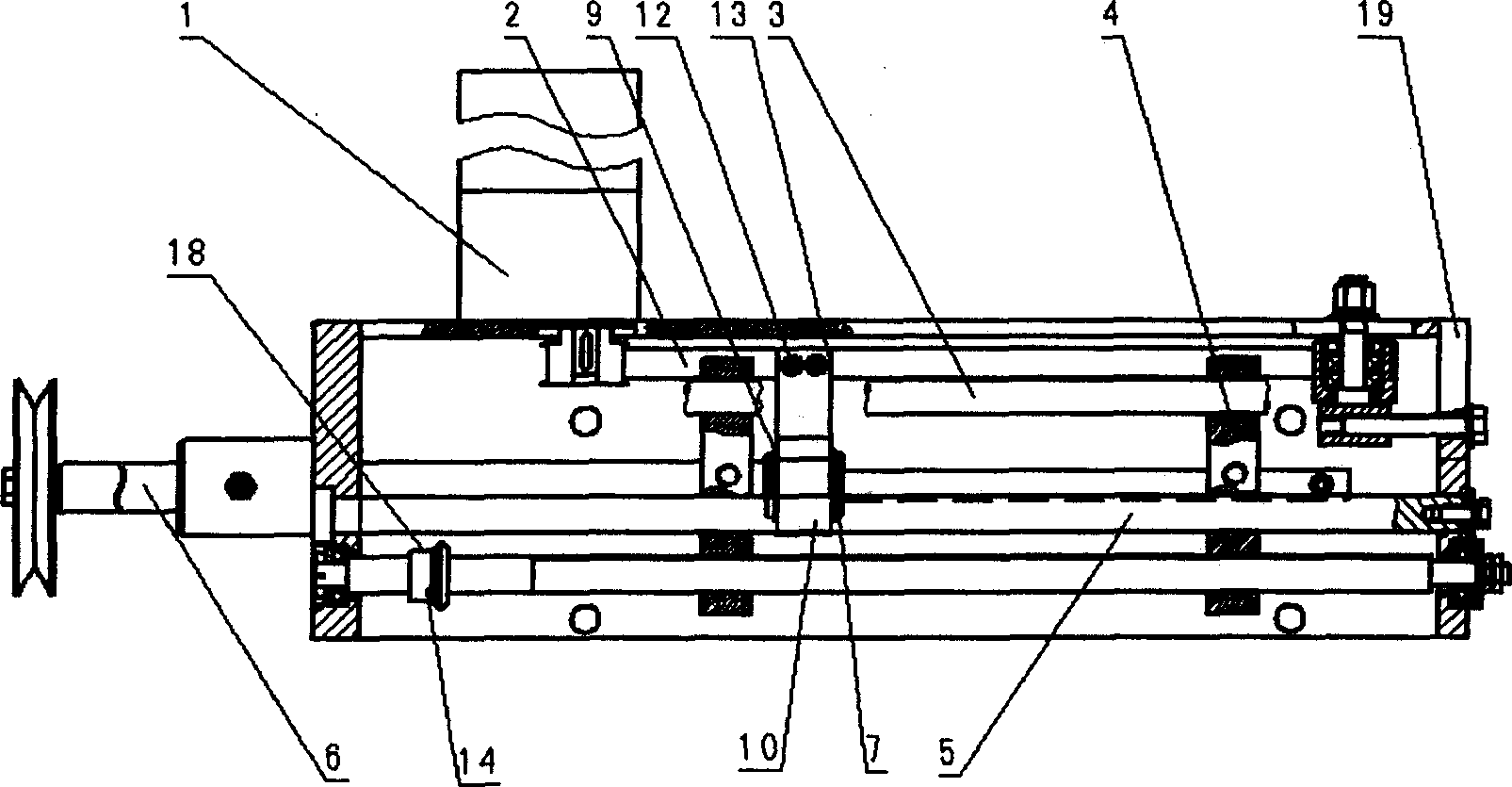

[0014] The frequency converter controls the positive and negative rotation of the deceleration motor to realize the frequent reversing of the cable mechanism. The transmission type is synchronous belt drive; the width of the synchronous belt is 15mm, the modulus is 5M, and the tension of the synchronous belt has an adjustment mechanism. Adjusted to achieve. The frequency converter controls the deceleration motor, and the deceleration motor drives the cable rod in forward and reverse directions. The back and forth movement of the cable rod is realized by the deceleration motor driving the synchronous belt. The stroke size of the cable is controlled by the screw and the stopper. . Both the cable rod and the guide rod are made of GCr15 material through surface treatment, and they are required to be very flexible and reliable during the working process.

[0015] The device consists of a reduction motor 1, a synchronous belt 2, a screw 3, a block 4, a guide rod 5, a cable rod 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com