Granulated member continuous subpackage method and device with counting function

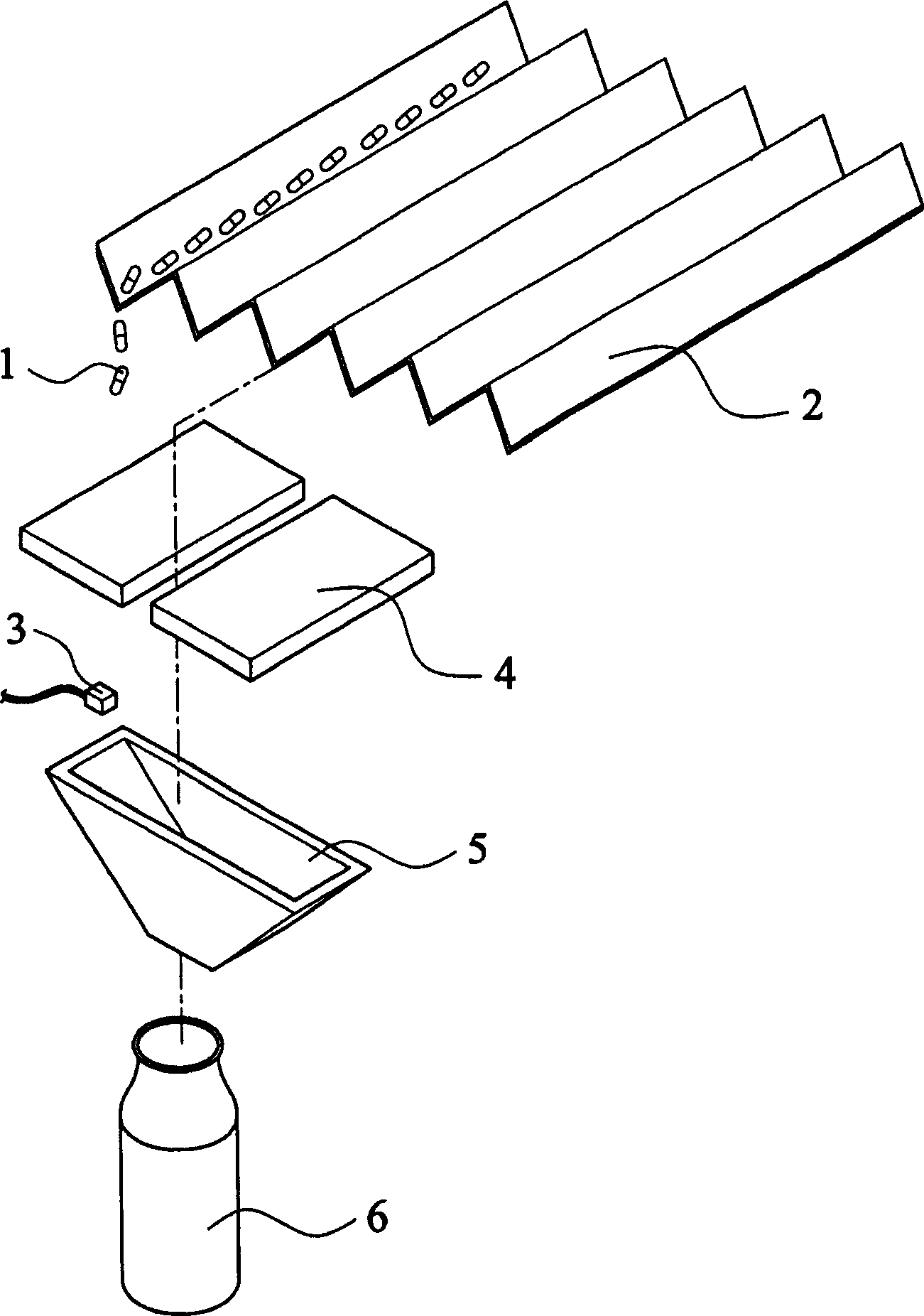

An object and particle technology, which is applied in the field of continuous sub-packaging of particle object counting and its device, can solve the problems of high labor cost and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

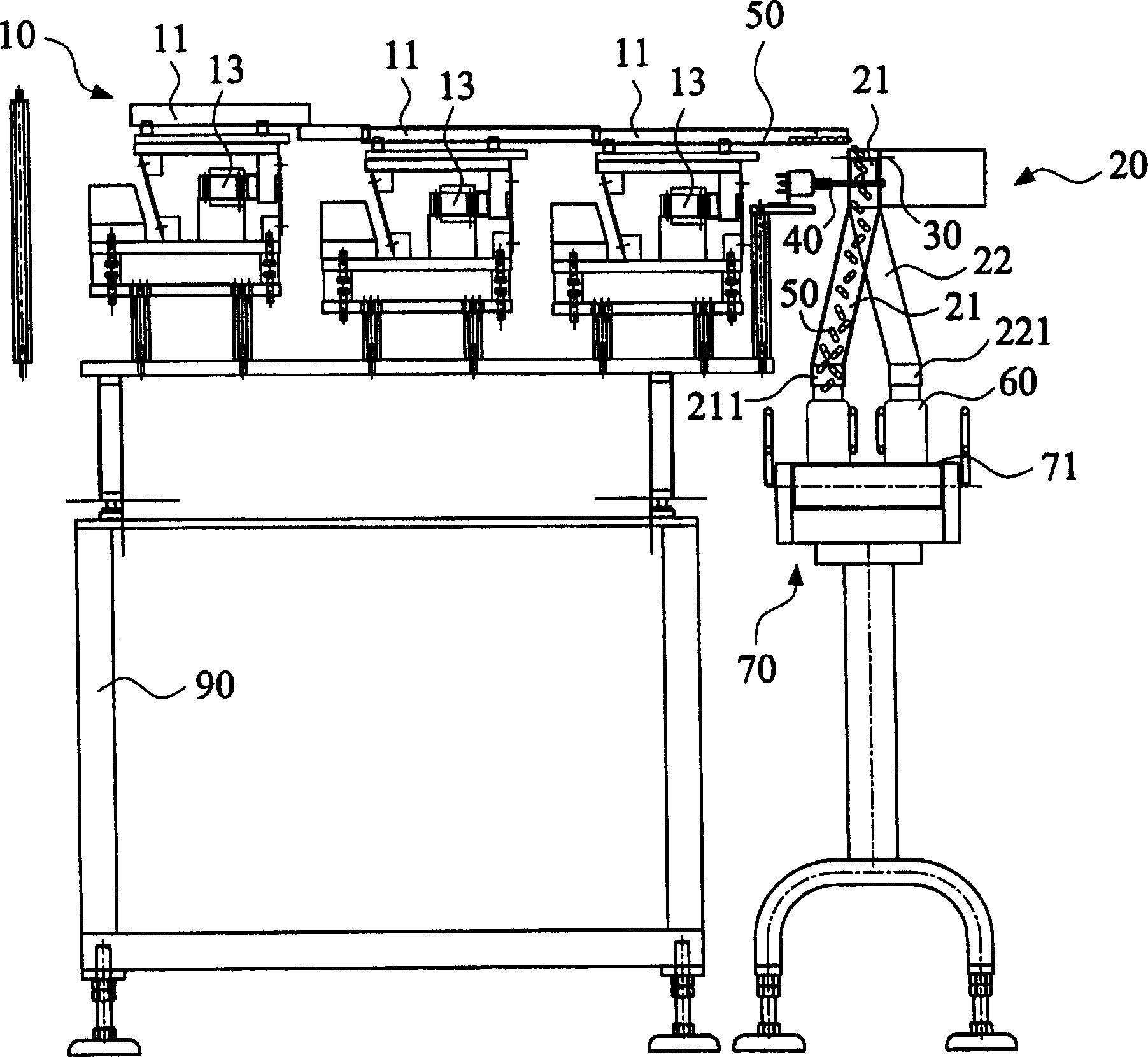

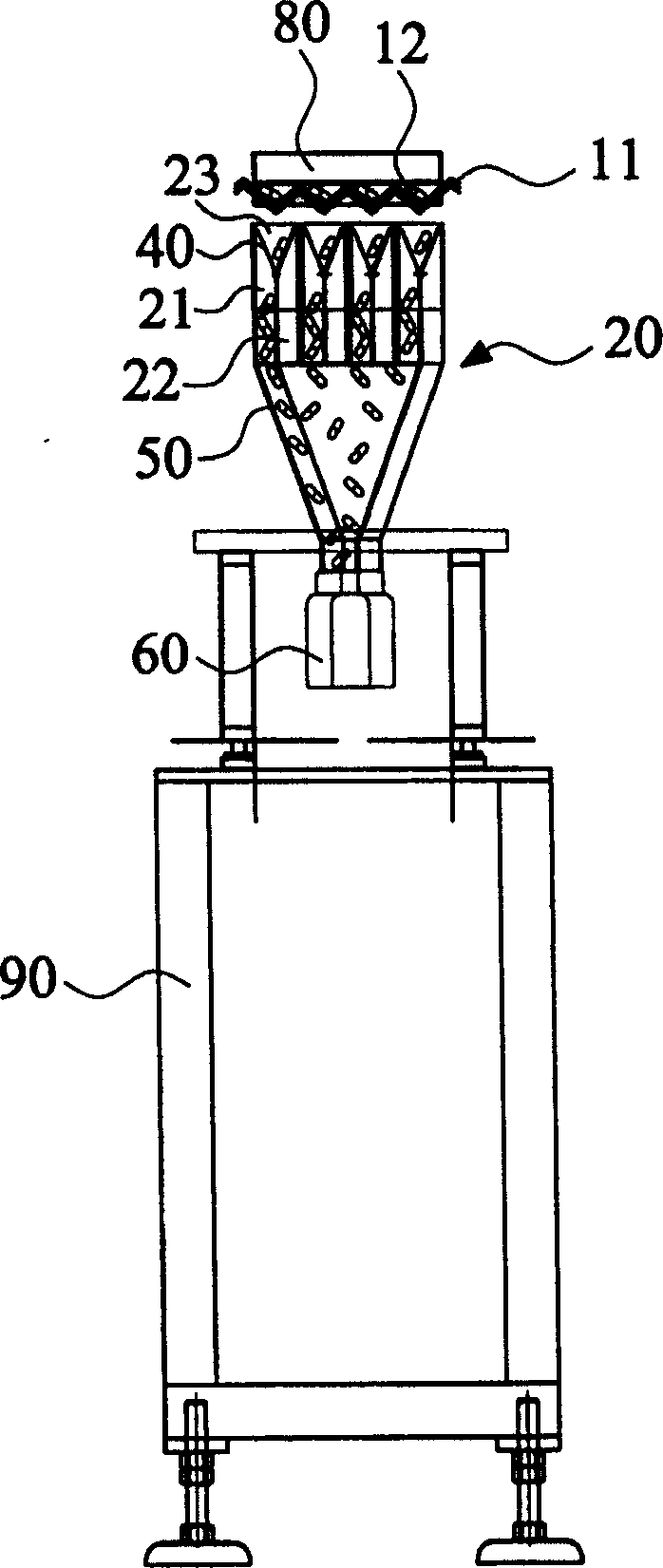

[0013] Please also see figure 2 , image 3 It is a schematic diagram and a side view of the continuous packaging mechanism for counting granular objects of the present invention. The continuous packaging mechanism for counting granular objects of the present invention includes a vibrating unloading mechanism 10, a distributing mechanism 20, a detector 30 and a material guide agency40. When the granular objects 50 vibrate and move forward for feeding through the vibrating feeding mechanism 10, the granular objects 50 are filled into a container 60 through the distributing mechanism 20, and the detector 30 detects and counts the number of the granular objects 50, while using The material guide mechanism 40 guides the granular objects 50 into the container 60 , and then the packaging of the granular objects 50 can be completed.

[0014] The distributing mechanism 20 is arranged at the discharge end of the vibrating feeding mechanism 10 to count and fill the granular objects 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com