Helical air intake channel of single-cylinder direct-injection diesel engine

A spiral air intake and direct injection technology, applied in the field of diesel engine parts, can solve the problems of reducing intake flow, increasing intake resistance, and not easy to high vortex, so as to achieve the effect of reducing intake flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

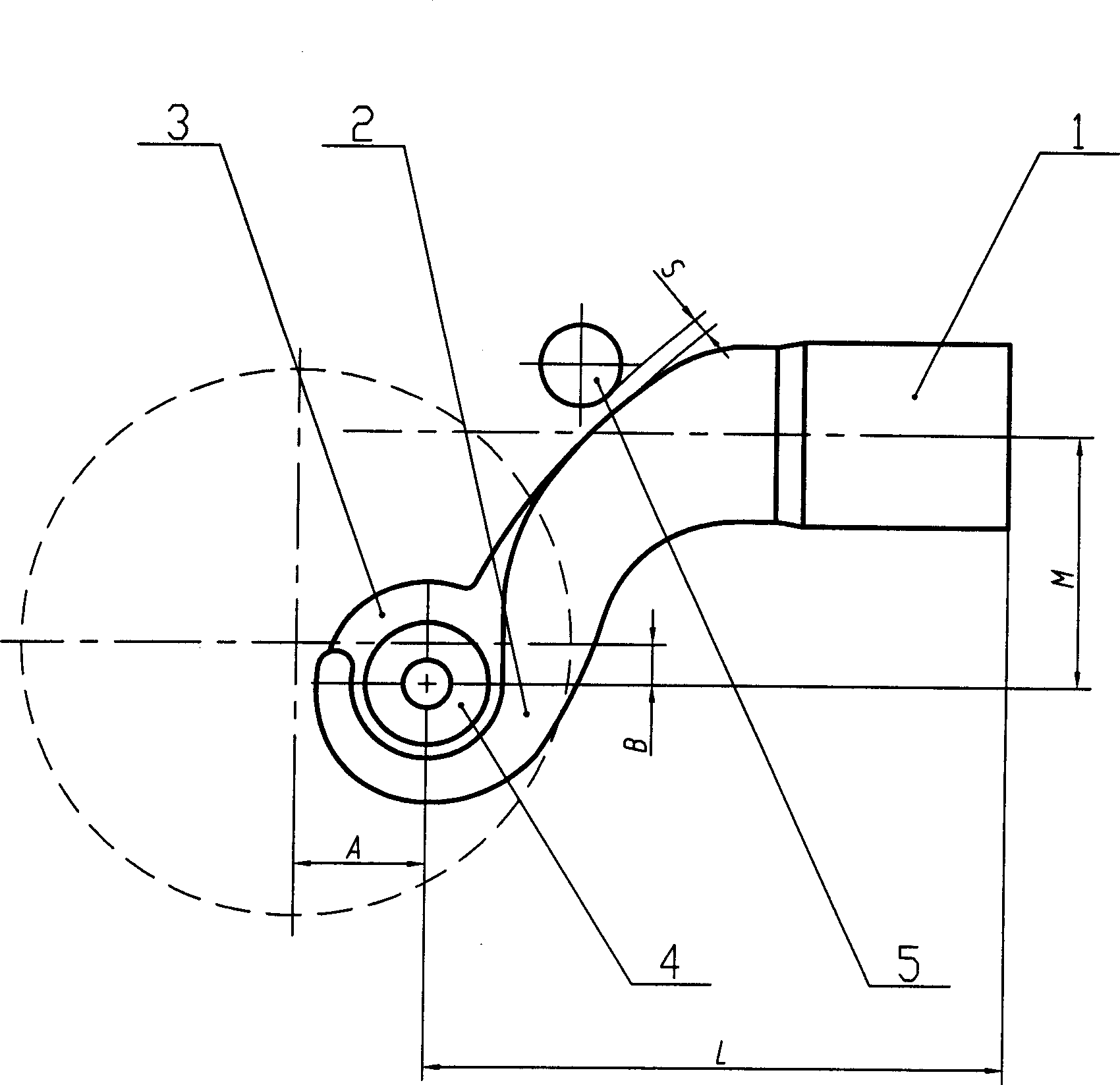

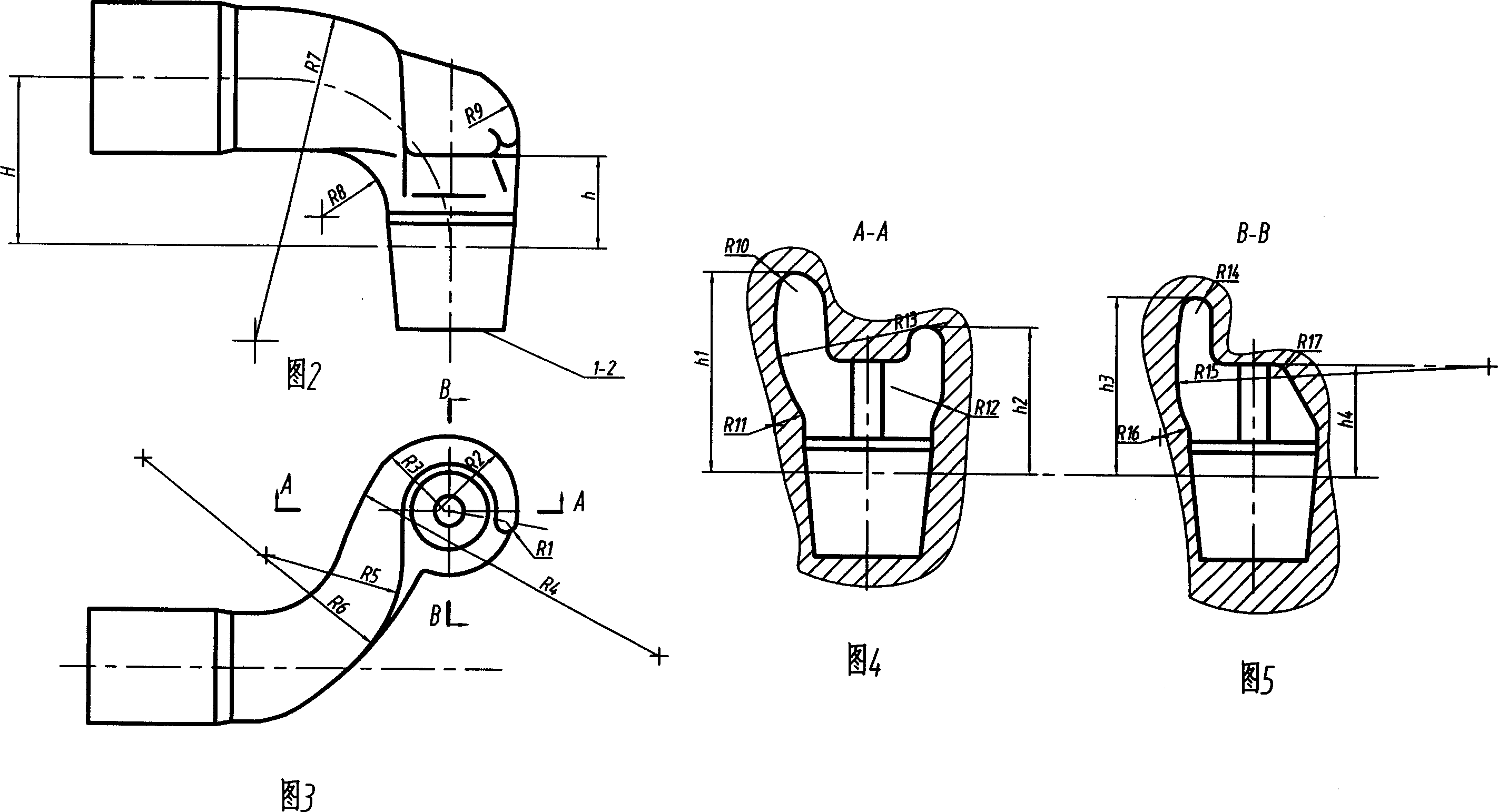

[0031] Such as figure 1 As shown in Figure 3, the spiral inlet of a single-cylinder direct-injection diesel engine is composed of the air inlet 1, the spiral chamber 2 and the spiral chamber outlet 3, and the abscissa from the center of the spiral chamber outlet 3 to the center line of the cylinder The distance A of x=18~20mm, the distance B=4~6mm from the center of the outlet 3 of the spiral chamber to the vertical coordinate y of the cylinder center line; the central axes of the airway inlet 1 and the outlet 3 of the spiral chamber are perpendicular to each other, and the vertical distance M=35~37mm , the vertical distance L between the inlet plane of the airway inlet 1 and the central axis of the spiral chamber outlet 3 is 83-86mm. The spiral chamber 2 is composed of tangent multi-section three-dimensional arcs R1, R2, R3, R4, R5, R6, R7, R8, R9, R1=1.5-2.5mm, R2=17-20m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com