Embossing station for an embossing installation

A technology of imprinting equipment and imprinting table, used in printing, printing presses, rotary printing presses, etc., can solve problems such as shortening the life of fixed rollers, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

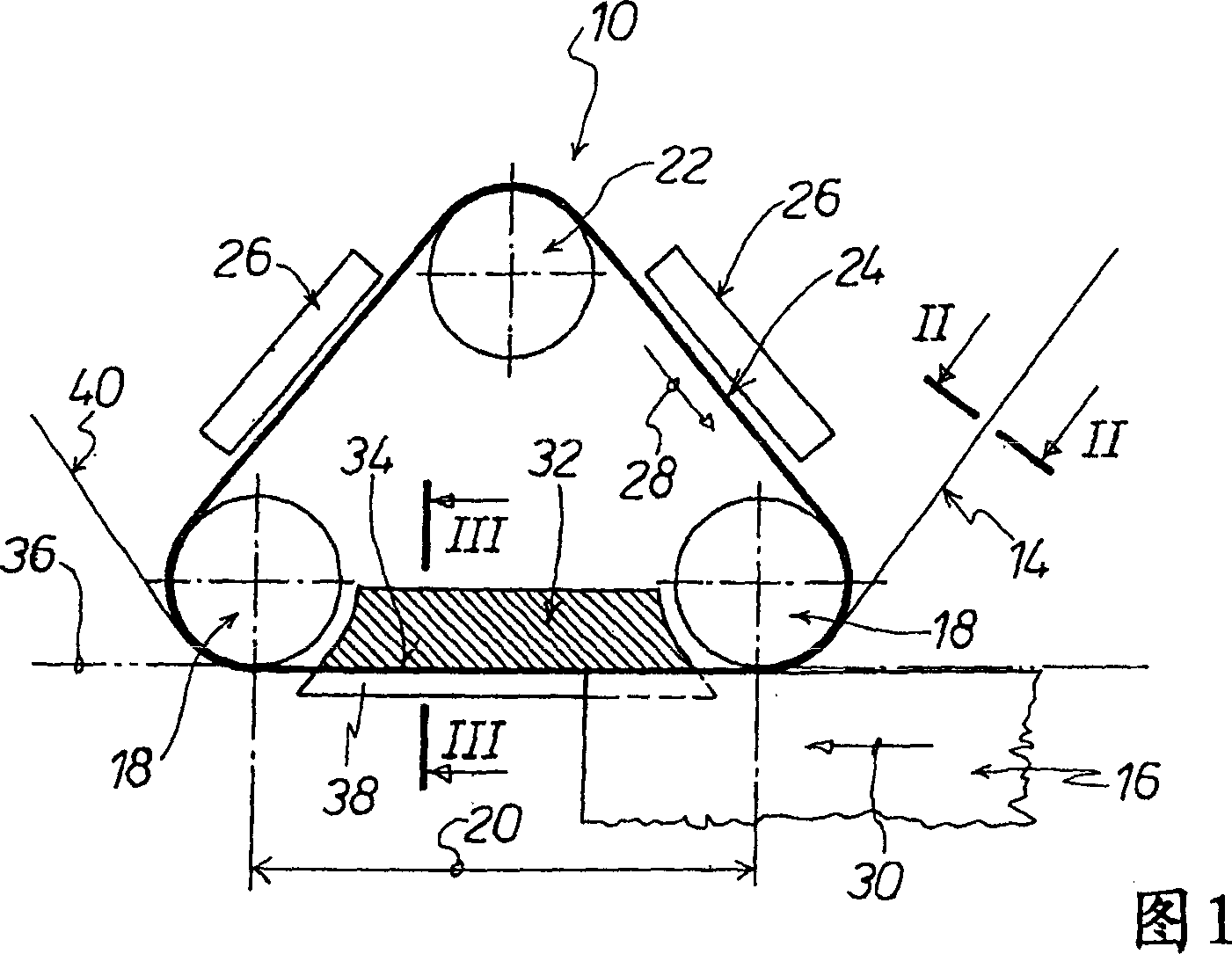

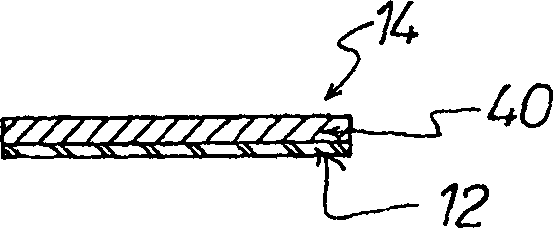

[0025] Figure 1 shows the construction of an embossing station 10 of an embossing apparatus, which is used as a transfer layer 12 for embossing a film 14 (see figure 2 ) is transferred to a component to be embossed, in particular a dimensionally stable planar component 16 to be embossed. Dimensionally stable flat components 16 are flat panels of furniture such as table tops and the like, or floor, wall or ceiling panels, or plastic moldings and the like.

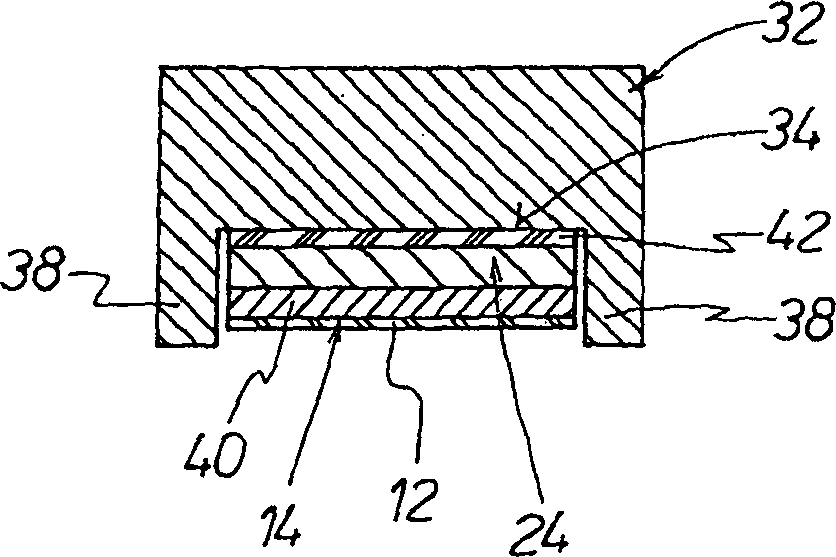

[0026] The embossing table 10 has two support rollers 18 spaced apart from one another and axially parallel to one another, whereby an embossing section 20 of the embossing table 10 is defined. A deflection roller 22 spaced apart from the two support rollers 18 and having axes parallel to each other is provided. A loop of embossed belt 24 rotates around two support rollers 18 and a turning roller 22 .

[0027] A heating device 26 schematically indicated by a block is provided for heating the embossed belt 24 . The embosse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com