Workpiece transmission device

A technology for conveying devices and workpieces, which is applied to metal processing machinery parts, manufacturing tools, metal processing, etc., can solve the problems of prolonged processing time, workers cannot easily feed in/take out workpieces, poor accessibility, etc., and achieve improved accessibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

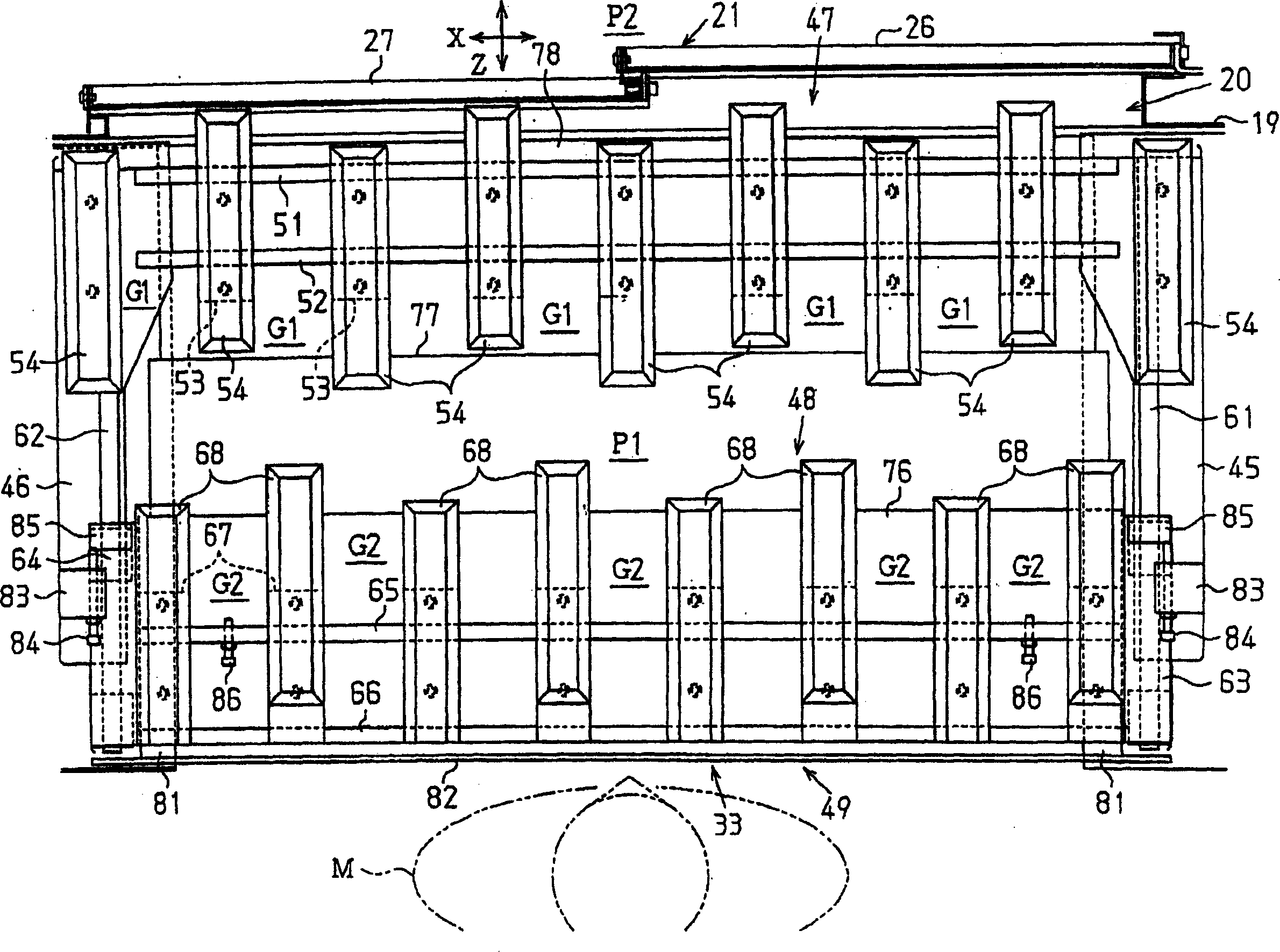

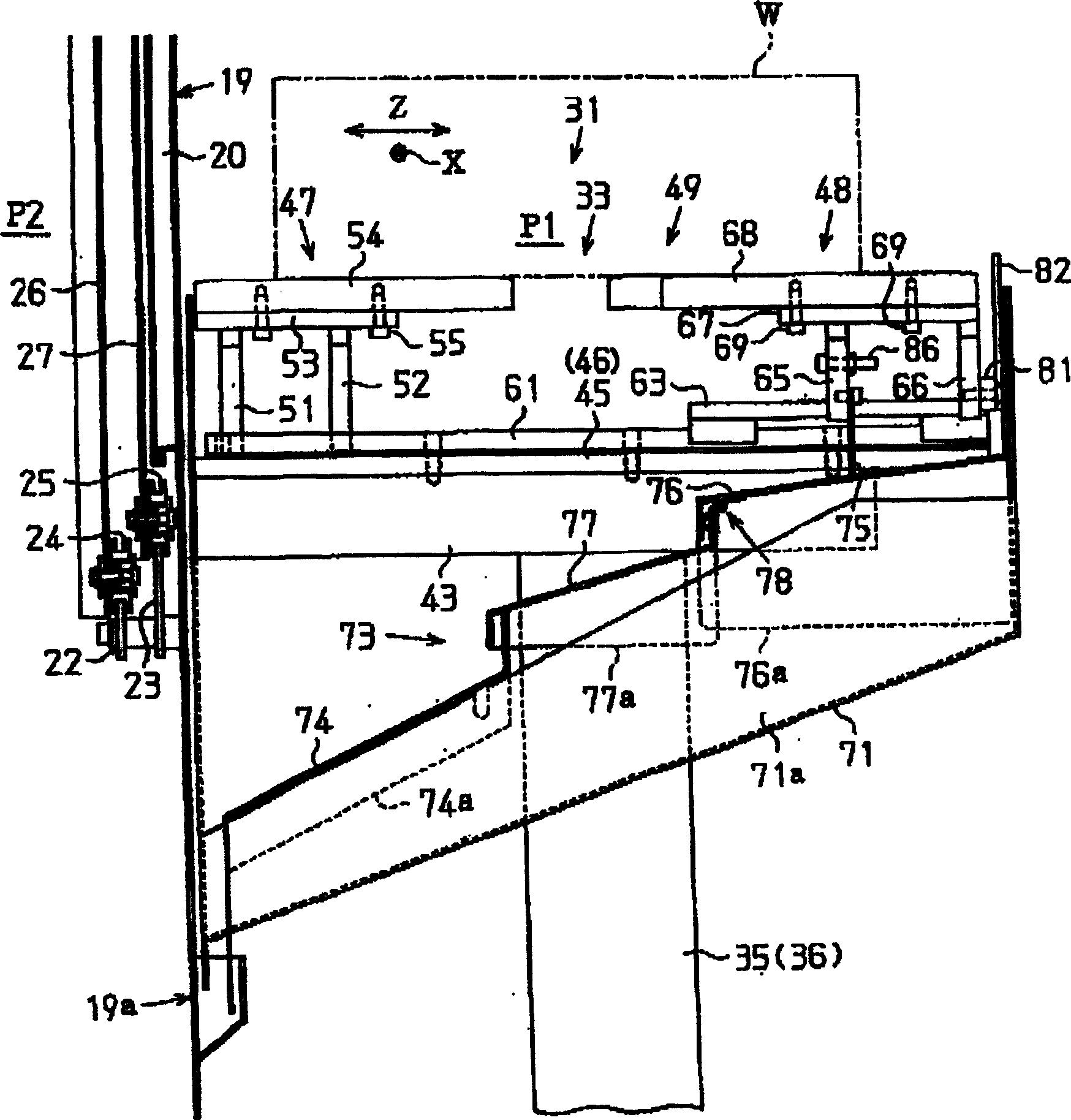

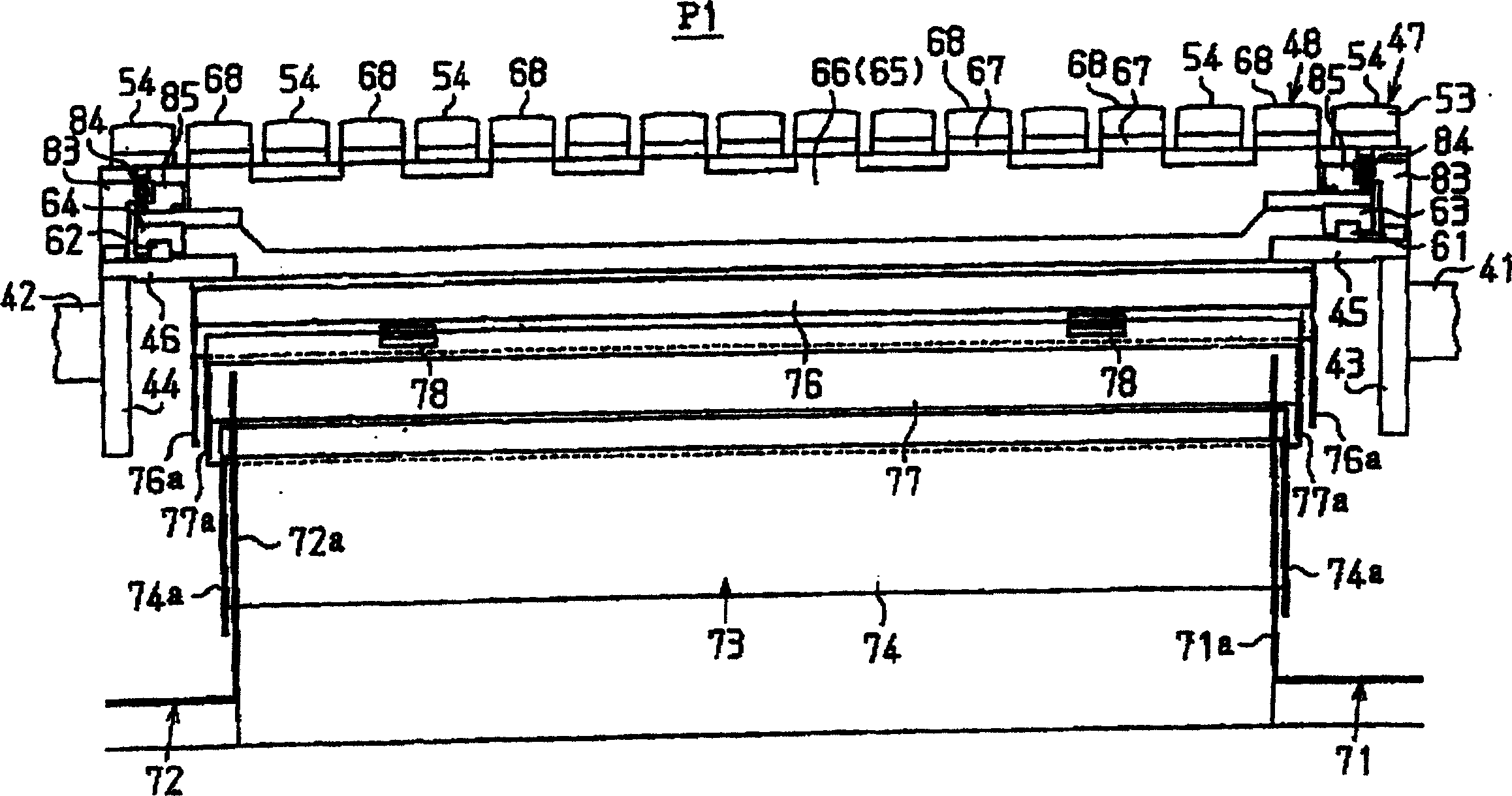

[0044] Below, refer to Figure 1 to Figure 8 , describing a workpiece transfer device according to an embodiment of the present invention.

[0045] Such as Figure 7 As shown, the support base 12 is vertically installed on the upper surface of the bed 11 . Such as Figure 8 As shown, through a pair of left and right bearings 13 , 13 , the workpiece support table 14 is installed on the upper surface of the support base 12 in a manner that can be indexed and rotated by a servo motor 15 . On the upper surface of the workpiece supporting table 14, clamping mechanisms 16 for clamping the workpiece W are provided at a plurality of positions. Such as Figure 7 As shown, the front side wall of the support base 12 ( Figure 7 The center is the right side wall), and the guide plate 18 is horizontally supported by the mounting post 17 for guiding the workpiece W when the workpiece is sent into / out of the workpiece support table 14 side. A machining device (not shown) is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com