Hand-operated binder

A technology of binding machine and frame, applied in binding, printing, metal processing and other directions, can solve the problems of troublesome operation, low reliability, and difficulty in obtaining the length of the binding tube, and achieves a simple structure, convenient riveting operation, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

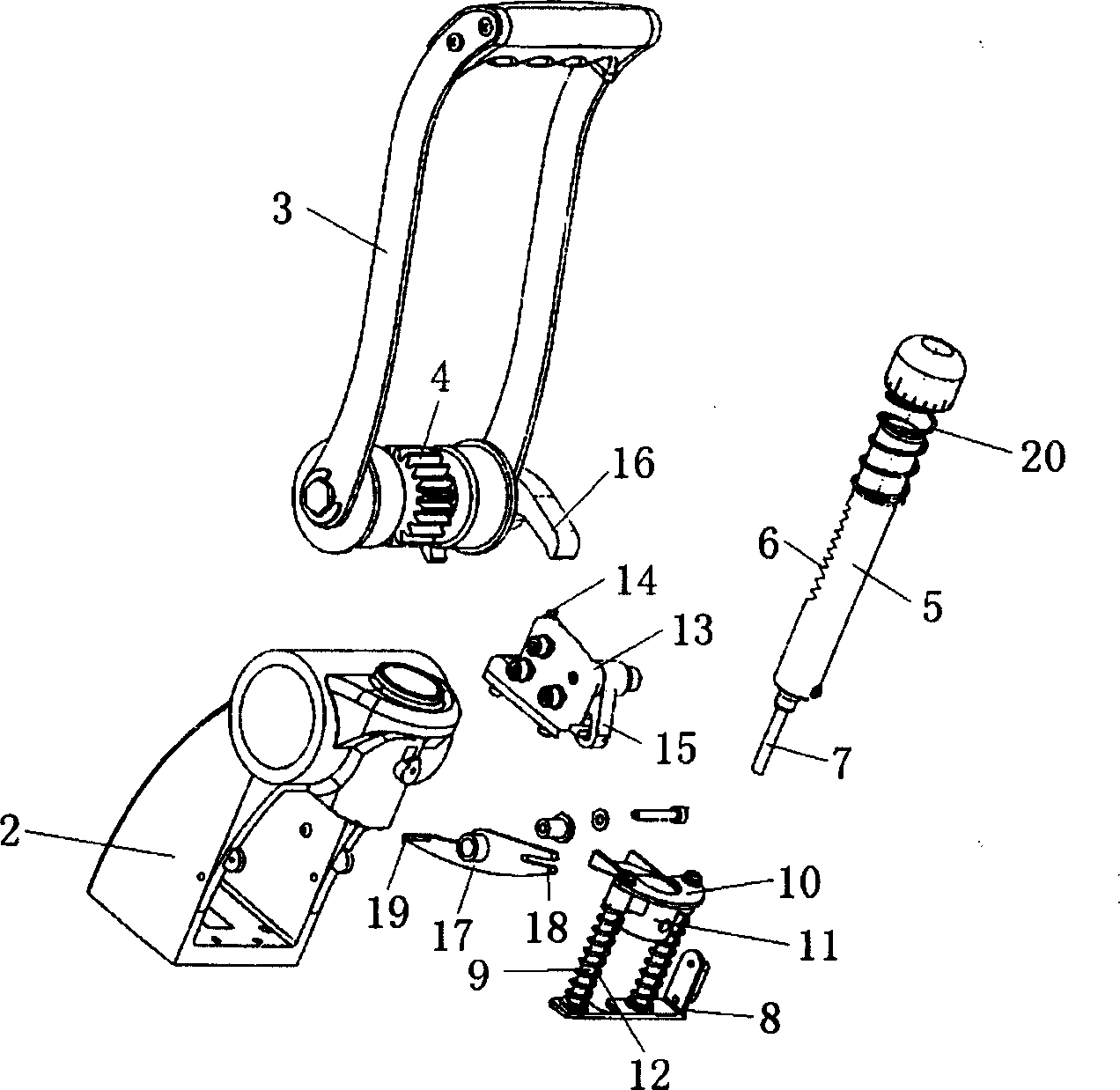

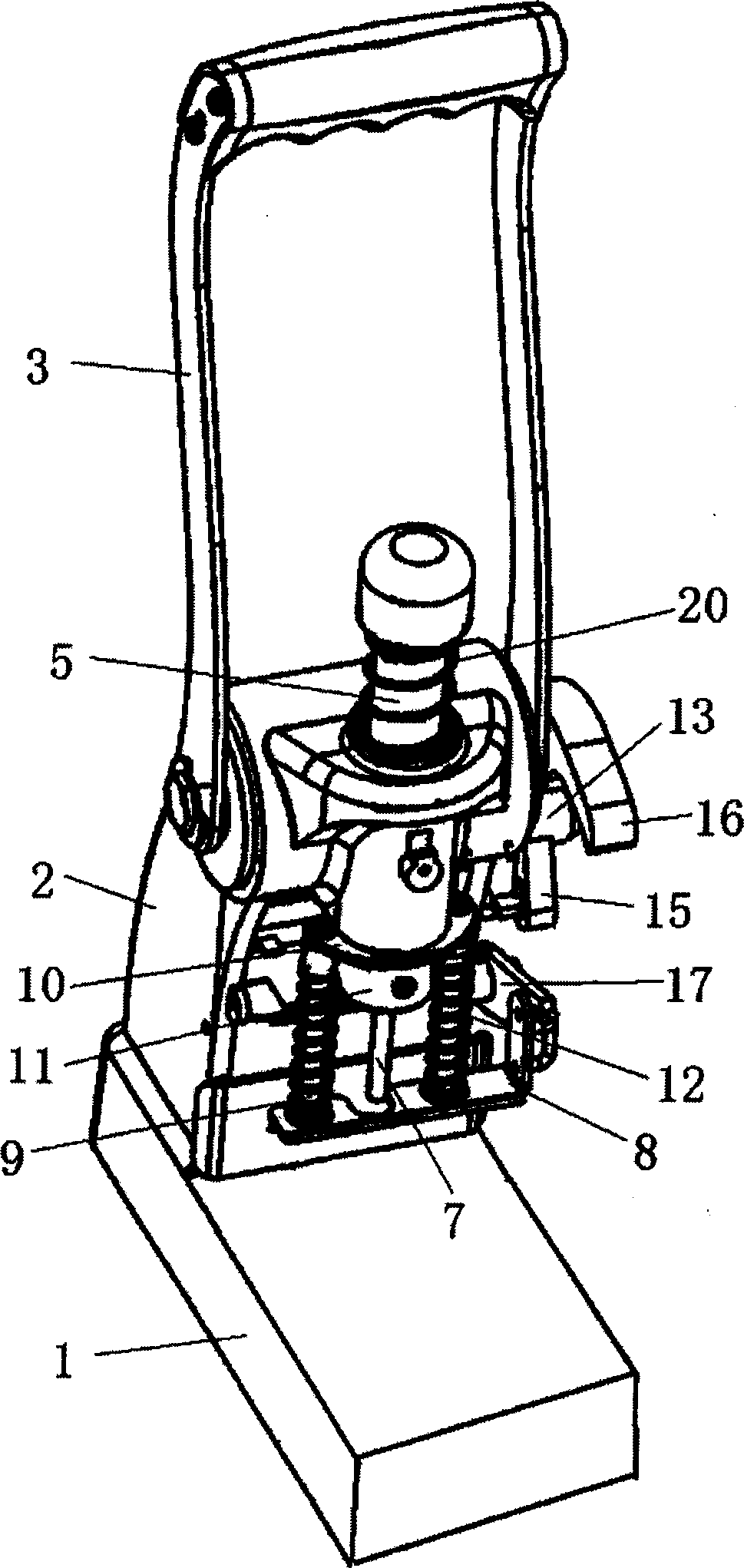

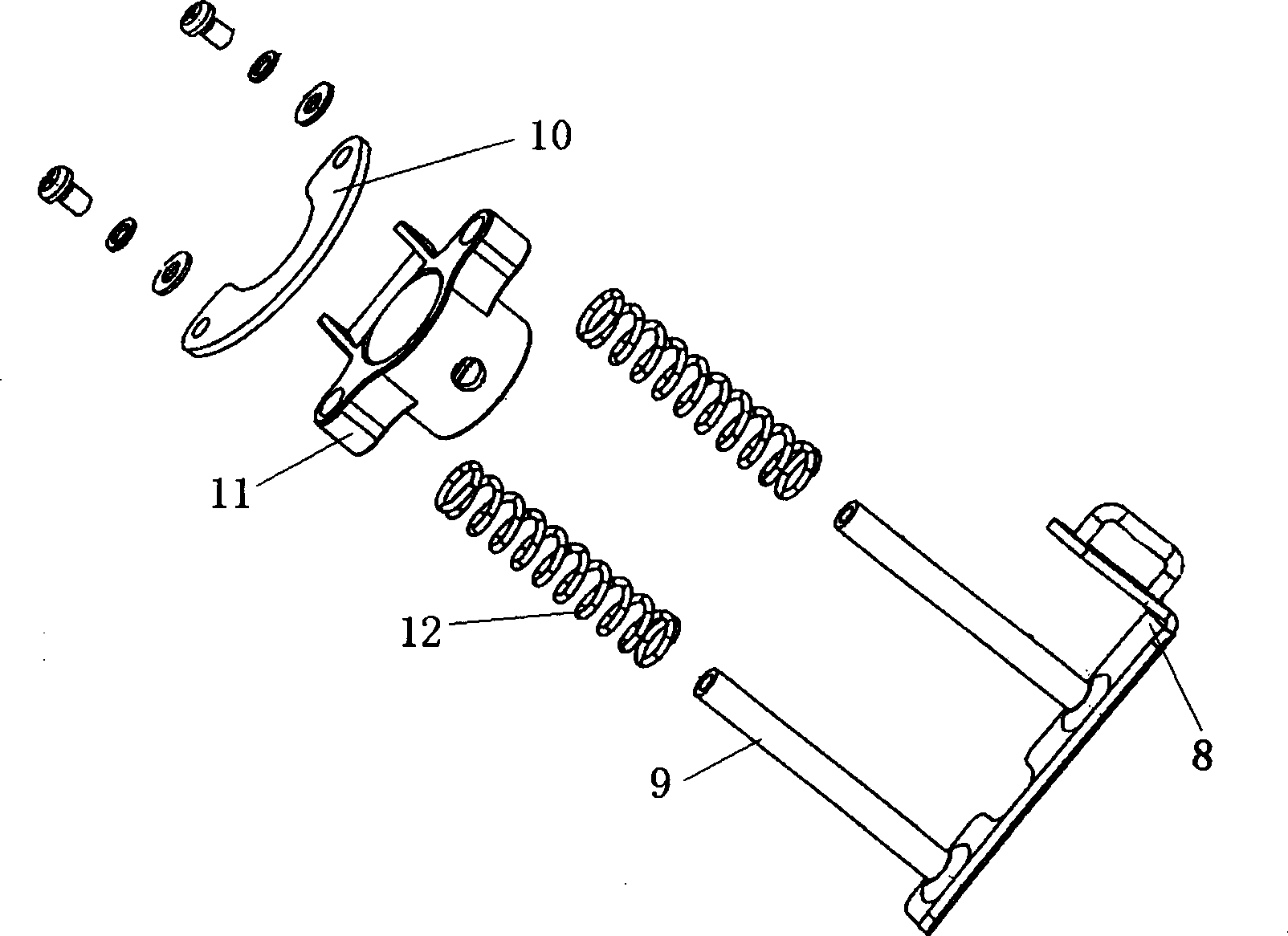

[0020] refer to Figure 1-3 , a manual binding machine, comprising a base 1, a frame 2 mounted on the base 1, an operating handle 3 hinged to the frame 2, the operating handle 3 is fixedly connected to a hinge shaft, and the hinge shaft There is a gear 4 on it, and a guide post 5 that can slide up and down is set inside the frame 1. The guide post 5 has a tooth mouth 6 that cooperates with the gear 4, and a drill is installed at the lower end of the guide post 5. 7. There is a cardboard 8 between the base 1 and the frame 2, the cardboard 8 has a guide rod 9 extending upward, and the upper end of the guide rod 9 is fixed to the baffle 10 through screws and nuts, The baffle 10 has an opening through which the guide post 5 can pass; the guide rod 9 is covered with a connecting sleeve 11 that can slide up and down, and the connecting sleeve 11 is located below the baffle 10 , the connecting sleeve 11 and the lower part of the guide column 5 are fixedly connected by screws; the gu...

Embodiment 2

[0024] refer to Figure 1-4 , the frame 2 is equipped with a knife seat 13, the knife seat 13 is provided with a slidable blade 21, the knife seat 13 is provided with a through hole 14 for inserting a pipe, and the through hole 14 is located in the On the outside of the edge of the blade 21, the knife seat 13 is also hinged with a shifting block 15 for controlling the sliding of the blade 21, and the operating handle 3 is fixedly connected with a shifting fork 16 matched with the shifting block 15;

[0025] The frame 2 below the knife block 13 is hinged with a lever 17, the front end 18 of the lever 17 is affixed to the pressboard 8, and the rear end 19 of the lever 17 has a supporting point of a pipe. The lower end of the tube is a reserved section, and the distance from the upper end of the reserved section to the blade 21 is equal to the distance from the pressboard 8 to the base 1 .

[0026] All the other structures are the same as in Embodiment 1.

[0027] The manual bi...

Embodiment 3

[0030] refer to Figure 1-4 , there are two guide rods 9, symmetrically located on both sides of the guide post 5. Symmetrically setting the guide rods 9 is conducive to uniform force. The rest of the structures and implementations are the same as in Embodiment 2.

[0031] Embodiment Three

[0032] refer to Figure 1-4 , The upper end of the guide post 5 is also equipped with a return spring 20 . The significance of setting the back-moving spring 20 is that the guide post 5 can be reset automatically after the operation is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com