Spiral-guided magnet-levitated motor vertical lifter

A lifter and helical duct technology, applied in the lifter field, can solve the problems of occupying a large space, out of control of the cable car, passive, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

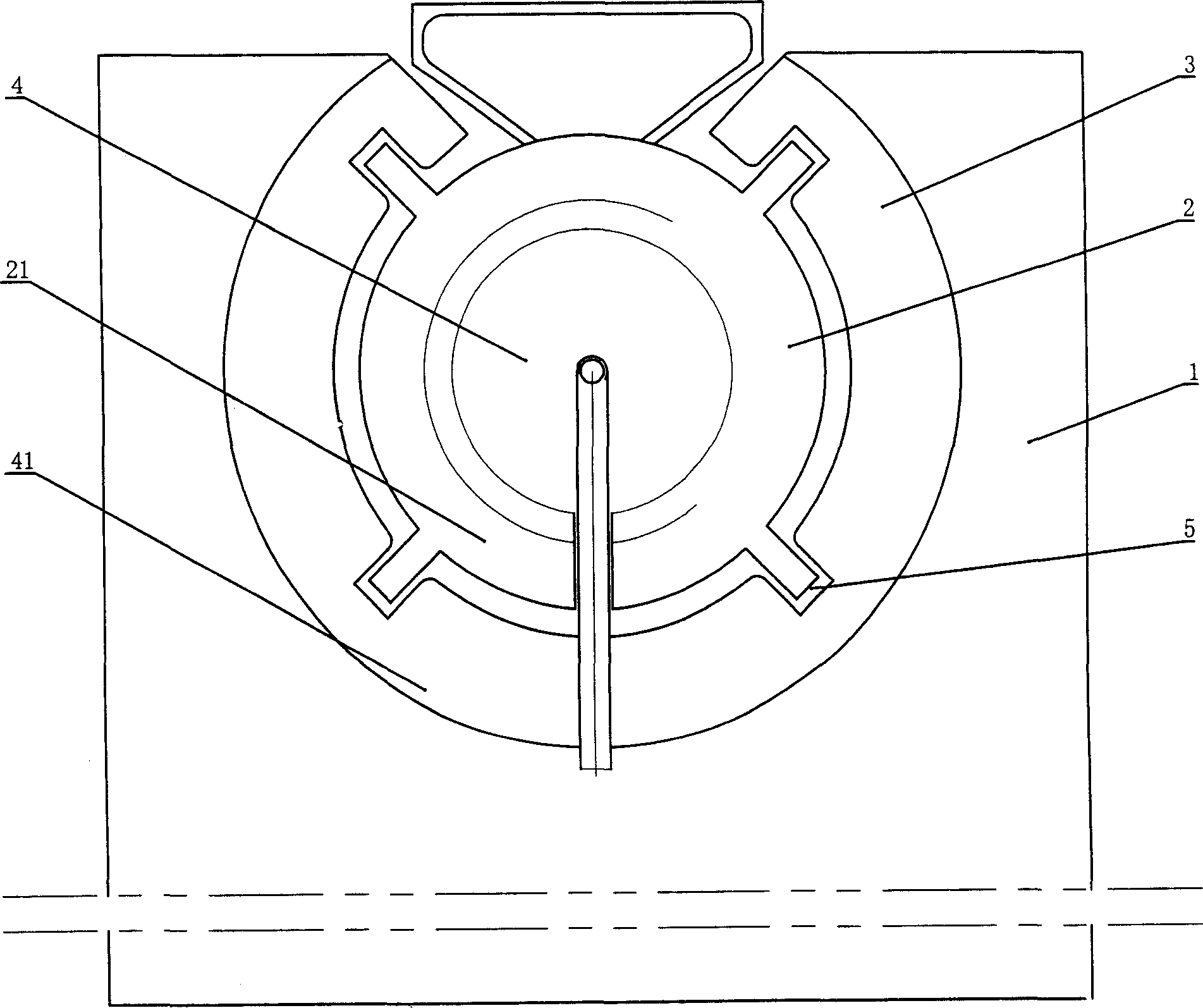

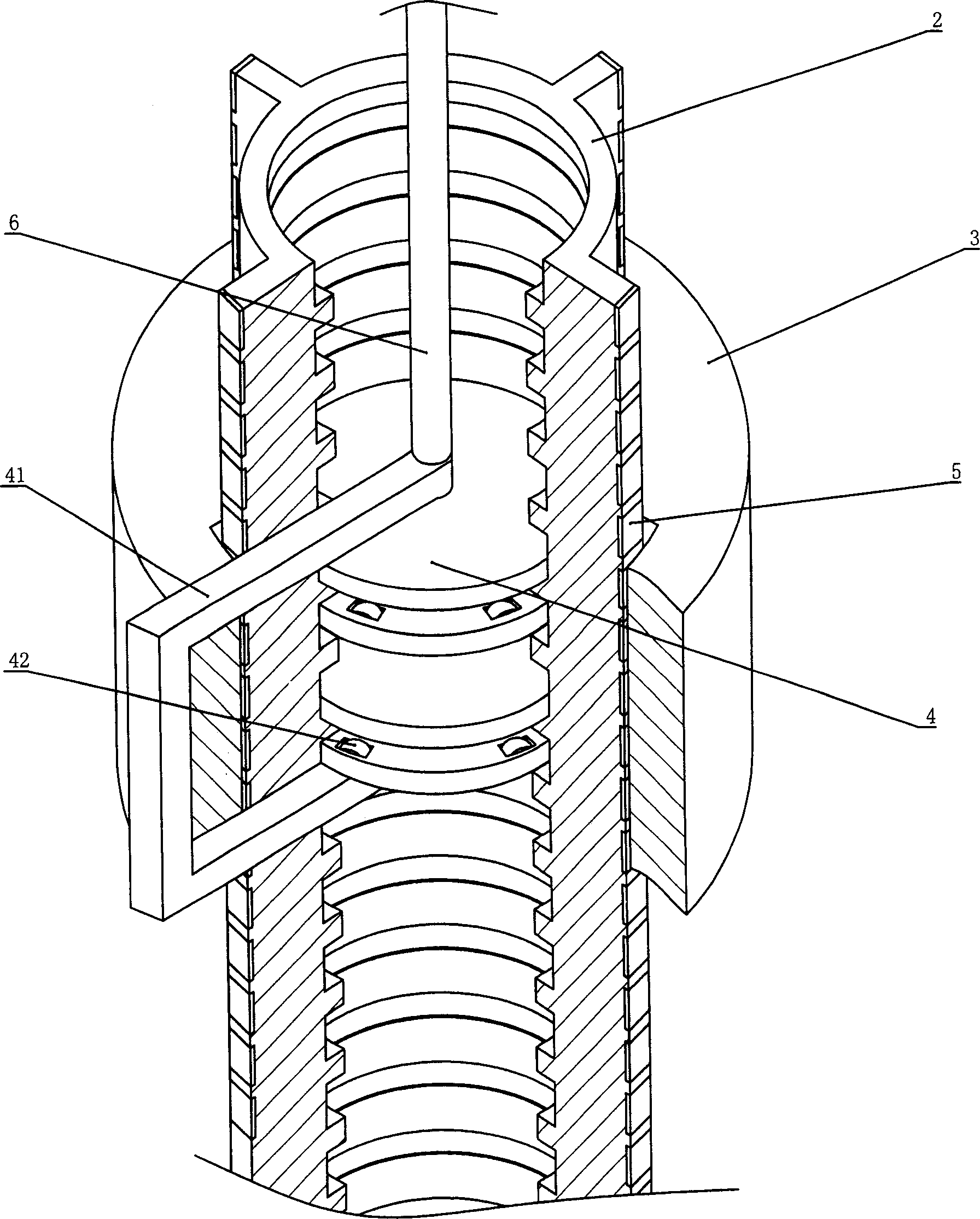

[0013] refer to figure 1 As shown in Fig. 3, a spiral-guided floating magnetic vertical motor lifter includes a car 1, a lifting mechanism fixedly connected to the car 1, and a control circuit for driving the lifting mechanism. The threaded helical conduit 2 and the linear motor formed by the loop 3 that is threaded outside the helical conduit 2 and can run longitudinally along the floating magnetic guide rail and has a single winding coil, and the passive positioning helical guide disc 4 screwed in the helical conduit 2, The spiral conduit 2 is provided with a power export groove 21 along the axial direction, and the guide plate 4 is provided with external threads, which can be screwed with the spiral conduit 2. Three rolling guide wheels 42 are embedded on the surface of the external threads, and the guide wheels 42 are slightly higher. On the surface of the external thread and in contact with the internal thread of the spiral conduit 2, the two ends of the guide plate 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com