Surface light source unit and device using the unit

A surface light source and light source arrangement technology, applied to lighting and heating equipment, light sources, electric light sources, etc., can solve the problems of unsightly, difficult to manufacture, and difficult to uniformly arrange light-emitting components 20, so as to reduce unevenness and suppress image quality Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

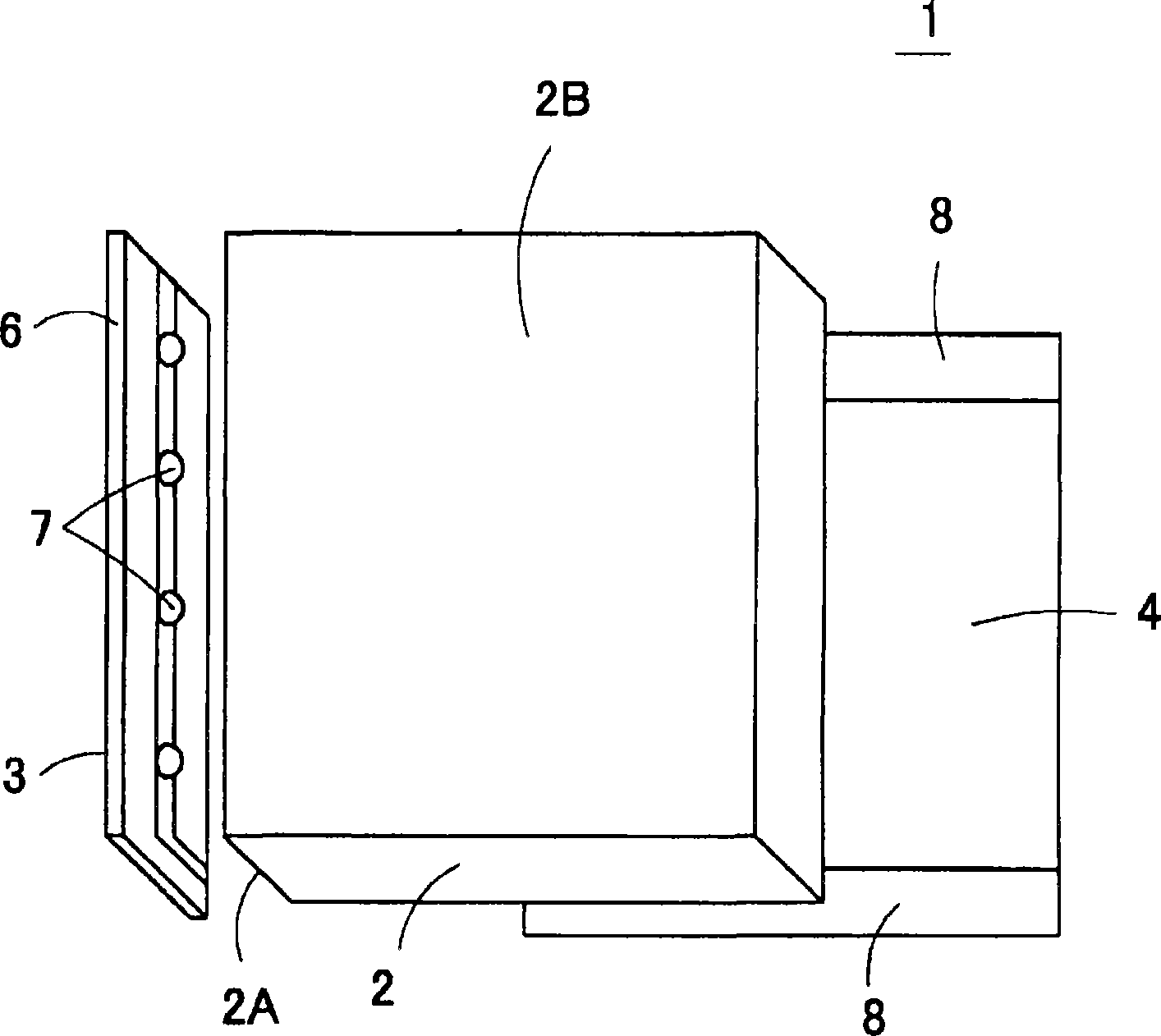

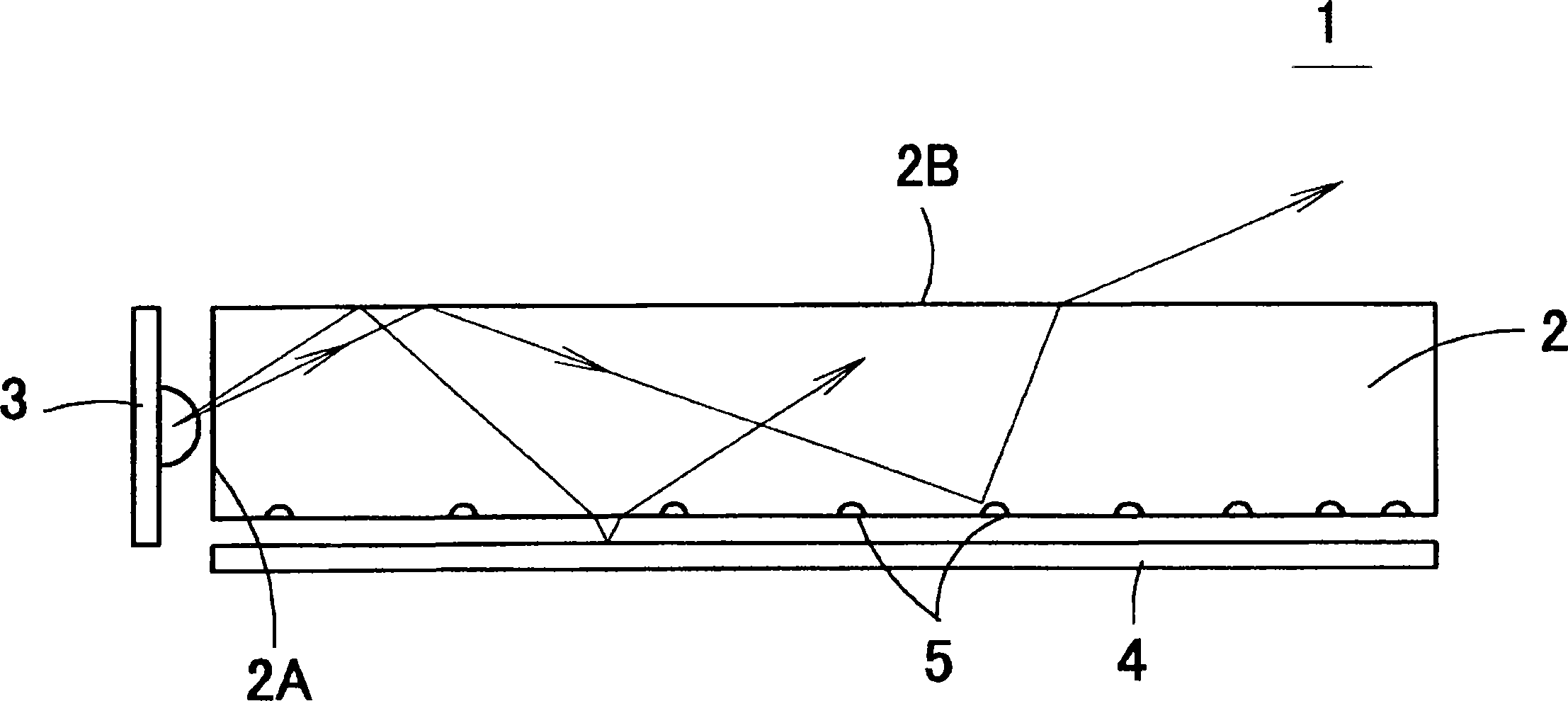

[0091] Figure 10 is an exploded perspective view showing the structure of the surface light source device 21 according to Embodiment 1 of the present invention, and Figure 11 is a sectional view showing the structure. The surface light source device 21 is used as a backlight of a liquid crystal display panel, and includes a light emitting part 22 in the form of a point light source, a light guide plate 23 and a reflective sheet 24 . The light emitting component 22 is embedded in a corner of the light guide plate 23 . The reflection sheet 24 is made of aluminum foil, white resin sheet, etc., and is disposed opposite to the back of the light guide plate 23 .

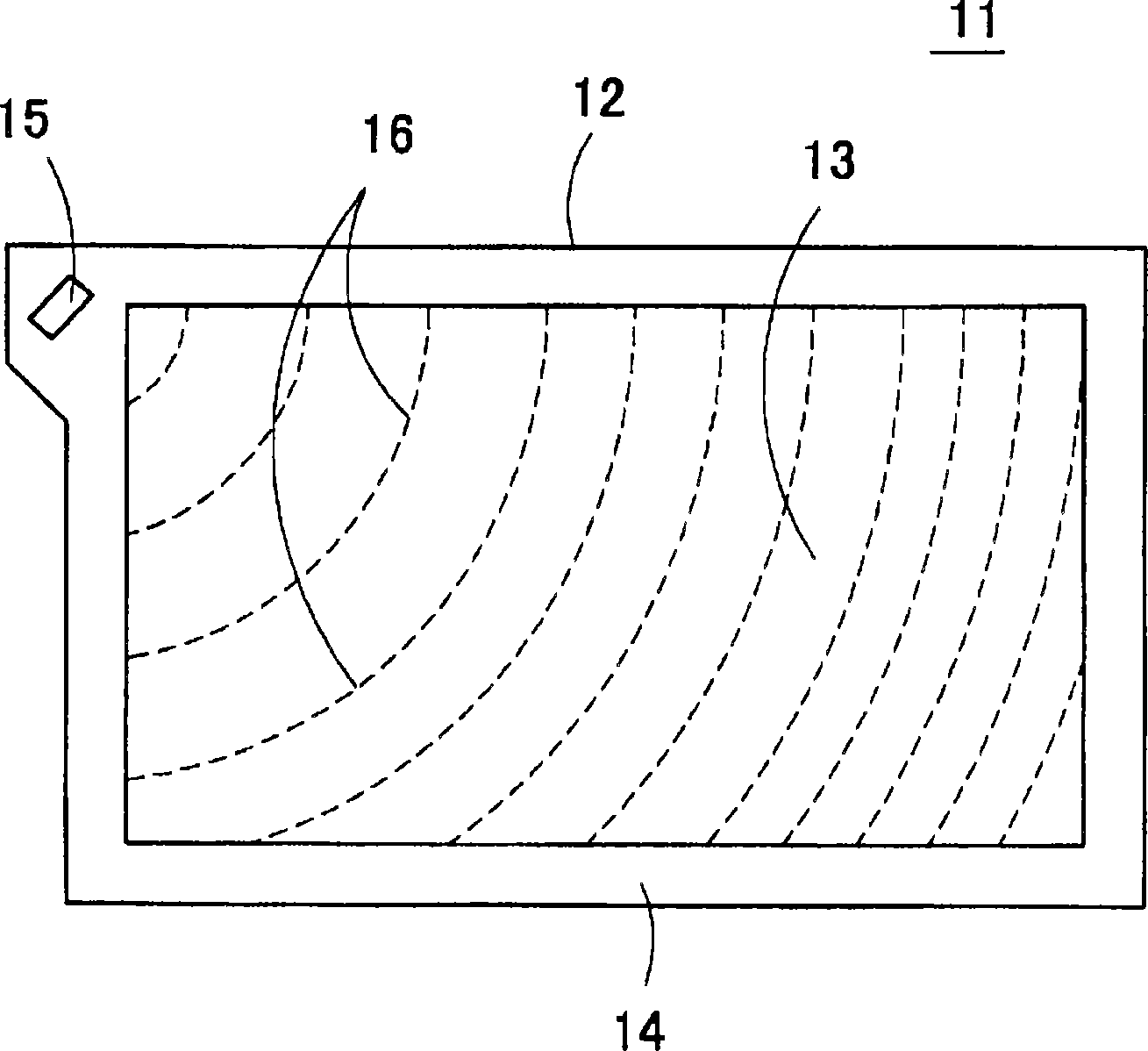

[0092] The light guide plate 23 is formed in a rectangular flat plate shape from a transparent resin having a high refractive index such as polycarbonate resin, acrylic resin, methacrylate resin, and glass. Figure 12is a schematic diagram showing the back side of the light guide plate 23 . The non-emission area 26 i...

Embodiment 2

[0136] Figure 30 is a schematic plan view showing a surface light source device according to Embodiment 2 of the present invention. The surface light source device includes a light emitting part 22 disposed centrally with respect to a side of the light guide plate 23 . The deflection pattern 34 is formed on the rear surface of the light guide plate 23 . In addition, although Figure 30 Only part of the deflection pattern 34 is shown, but the deflection pattern is formed in the entire surface emission area on the lower surface of the light guide plate 23 .

[0137] The pattern provided with the deflection pattern 34 in the surface light source device corresponds to that shown in Figure 23 Approximately 1 / 2 of the uniform basic pattern in the area, and the light emitting part 22 is arranged at the central point of the basic pattern.

Embodiment 3

[0139] Figure 31 is a sectional view showing a surface light source device 51 according to a third embodiment of the present invention. Figure 32 is a rear view showing the light guide plate 23 . The surface light source device is used as a lighting lamp for indoor lighting, photocopying lighting, etc., and includes: Figure 23 A uniform pattern shown in , which is formed on the entire back surface of the disc-shaped light guide plate 23; a tapered recess 52 for the light source formed in the center of the pattern; 52 in the light emitting component 22. Also, a reflective sheet 24 is provided on the entire back surface of the light guide plate 23 .

[0140] With this surface light source, the deflection pattern 34 can be uniformly arranged on the circular light guide plate 23 without intervals to achieve uniform light emission. This surface light source is

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com