Circular polarization plate, vertically-aligned liquid crystal display panel and manufacturing method thereof

A technology of liquid crystal display panels and manufacturing methods, which can be used in the direction of polarizing elements, thin material processing, instruments, etc., and can solve the problems of weakening black and white contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

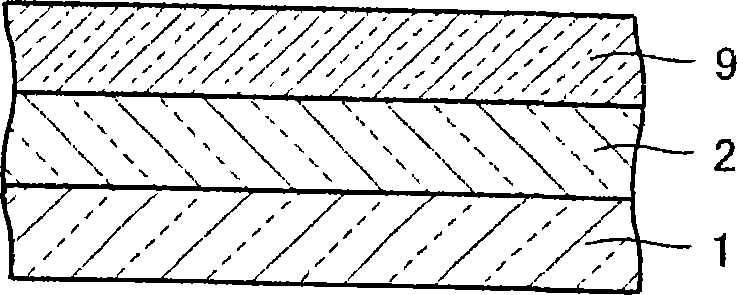

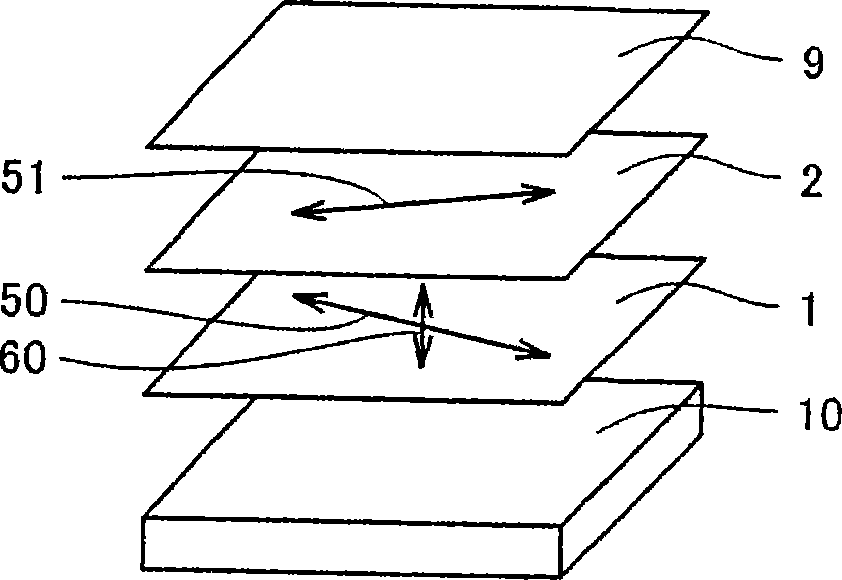

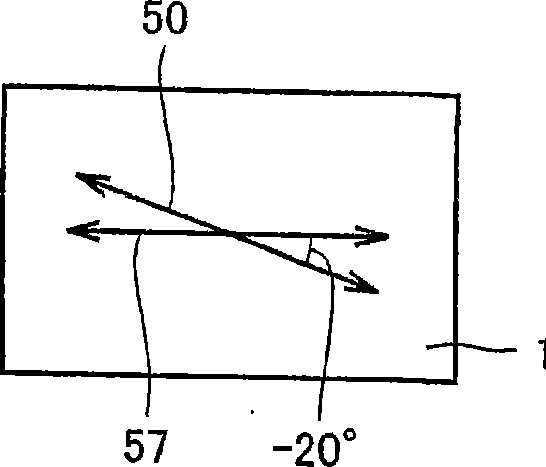

[0102] will now refer to figure 1 Through 8B, a description is given of the circularly polarizing plate and the vertical alignment type liquid crystal display panel according to the first embodiment of the present invention. The single or single liquid crystal display unit included in the liquid crystal display panel of this embodiment is basically the same as Figure 27 The single LCD unit shown is the same. Accordingly, the liquid crystal 23 fills the space surrounded by the substrate 20 on the display side, the substrate 21 on the opposite side, and the seal 22 . The substrate 20 is equipped with electrodes 24 and the substrate 21 is equipped with electrodes 25 .

[0103] For example, when the liquid crystal display panel is a color liquid crystal display panel, one of the substrates (ie, the substrate 20) is, for example, a so-called color filter substrate. The color filter substrate is provided with a color filter layer (not shown) having RGB hues. The electrode 24 is...

no. 2 example

[0149] will now refer to Figures 17 to 20 , a description is given about the circularly polarizing plate and the vertical alignment type liquid crystal display panel according to the second embodiment of the present invention. The single liquid crystal display unit included in the liquid crystal display panel of this embodiment and Figure 27 The individual LCD units shown in are basically the same. More specifically, the liquid crystal 23 fills a space hermetically surrounded by the substrate 20 on the display side, the substrate 21 on the other side opposite to the display side, and the sealing member 22 . The substrate 20 is equipped with electrodes 24 and the substrate 21 is equipped with electrodes 25 .

[0150] The liquid crystal display panel of this embodiment is of vertical alignment type. The liquid crystal display panel uses a circular polarizing plate composed of a linear polarizing plate and a λ / 4 retardation plate bonded together. The circular polarizing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com