Sealed volumetric vane pump

A vane pump and volumetric technology, applied in the direction of rotary piston pumps, pumps, rotary piston machines, etc., can solve the problems of increasing manufacturing difficulty and use cost, reducing the effective power of volumetric vane pumps, etc., and achieving the goal of reducing machining accuracy Requirements, cost-effective manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

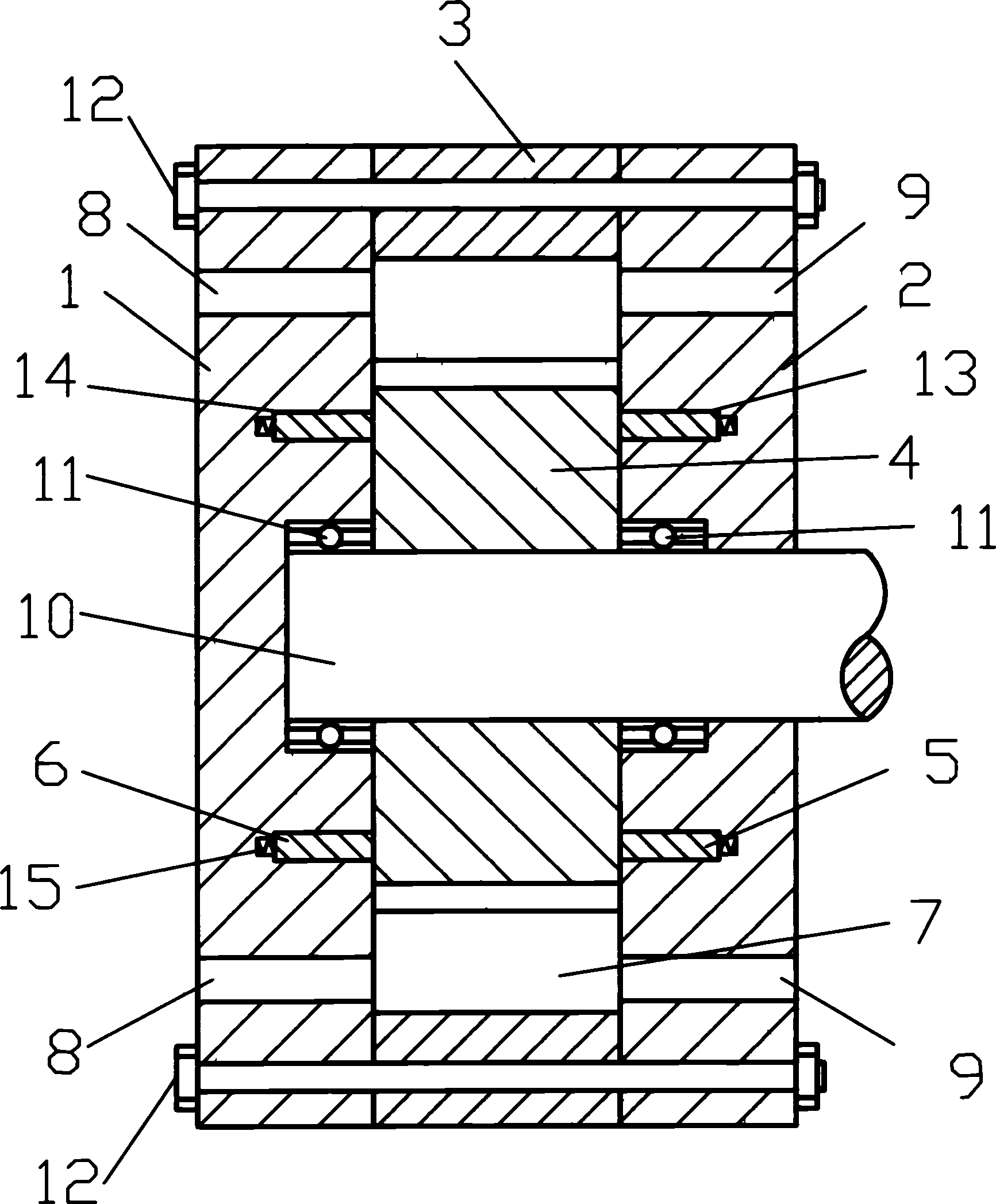

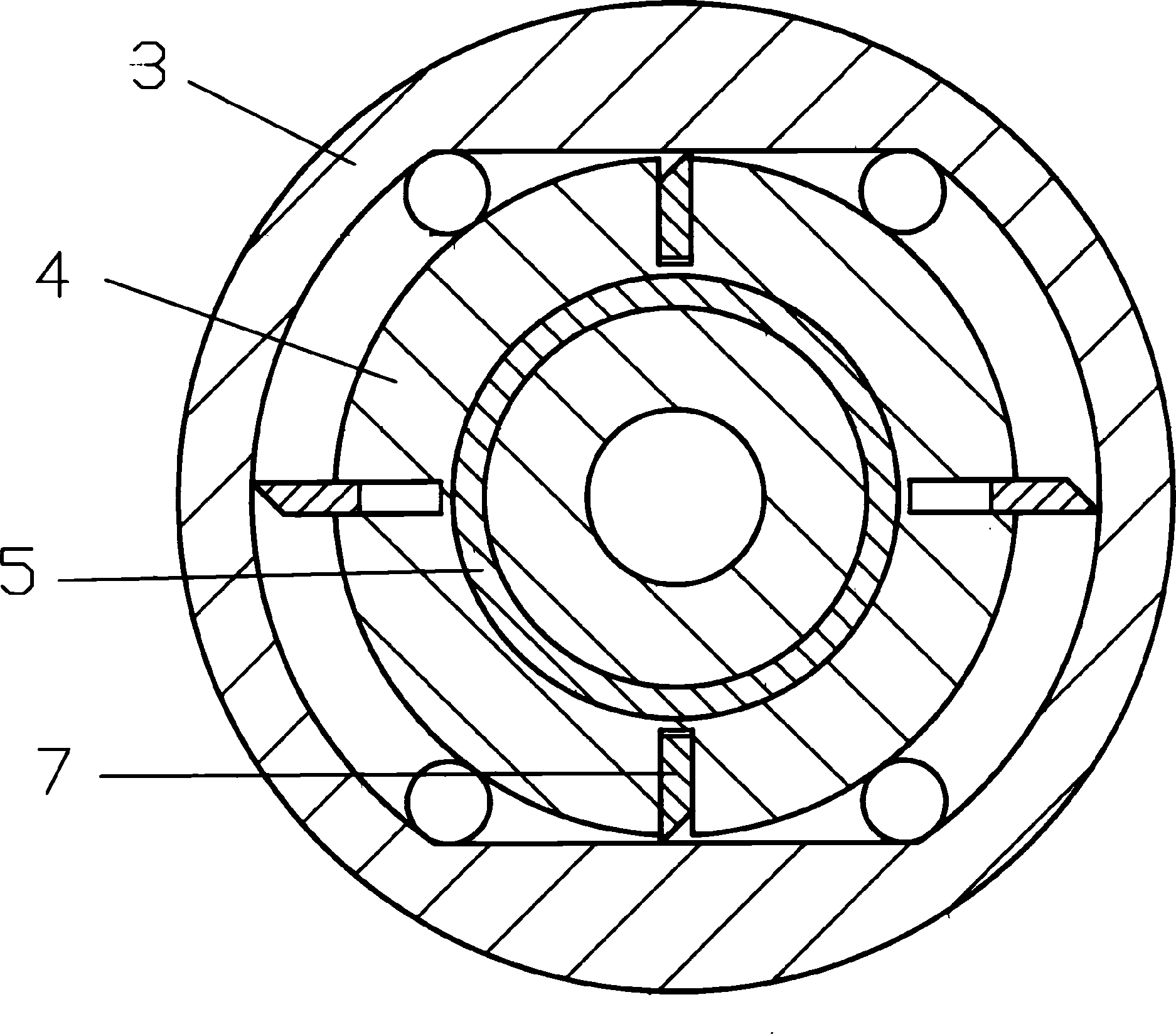

[0013] The sealed displacement vane pump of the present embodiment is as figure 1 , 2 As shown, 1 and 2 in the figure represent both end covers; 3 represents the stator; 4 represents the rotor; 5 and 6 represent two sealing rings; 7 represents the sliding vane; 8 represents two oil inlet holes; 9 represents two oil discharge holes 10 represents the rotating shaft; 11 represents two bearings; 12 represents two bolts fixedly connecting the two end caps; 13 and 14 represent the sealing ring grooves on the inside of the two end caps; 15 represents the spring.

[0014] The rotor 4 driven by the shaft 10 is installed in the pump cavity formed by the end covers 1 , 2 and the stator 3 fixedly connected by bolts 12 . Blades 7 that can slide are housed in the radial slots of the rotor 4 . A seal ring 5,6 that can slide axially in the groove is respectively housed in the seal ring groove 13,14 of the end cover 1,2 inner side by means of oil pressure or spring action. The shaft 10 is s...

Embodiment 2

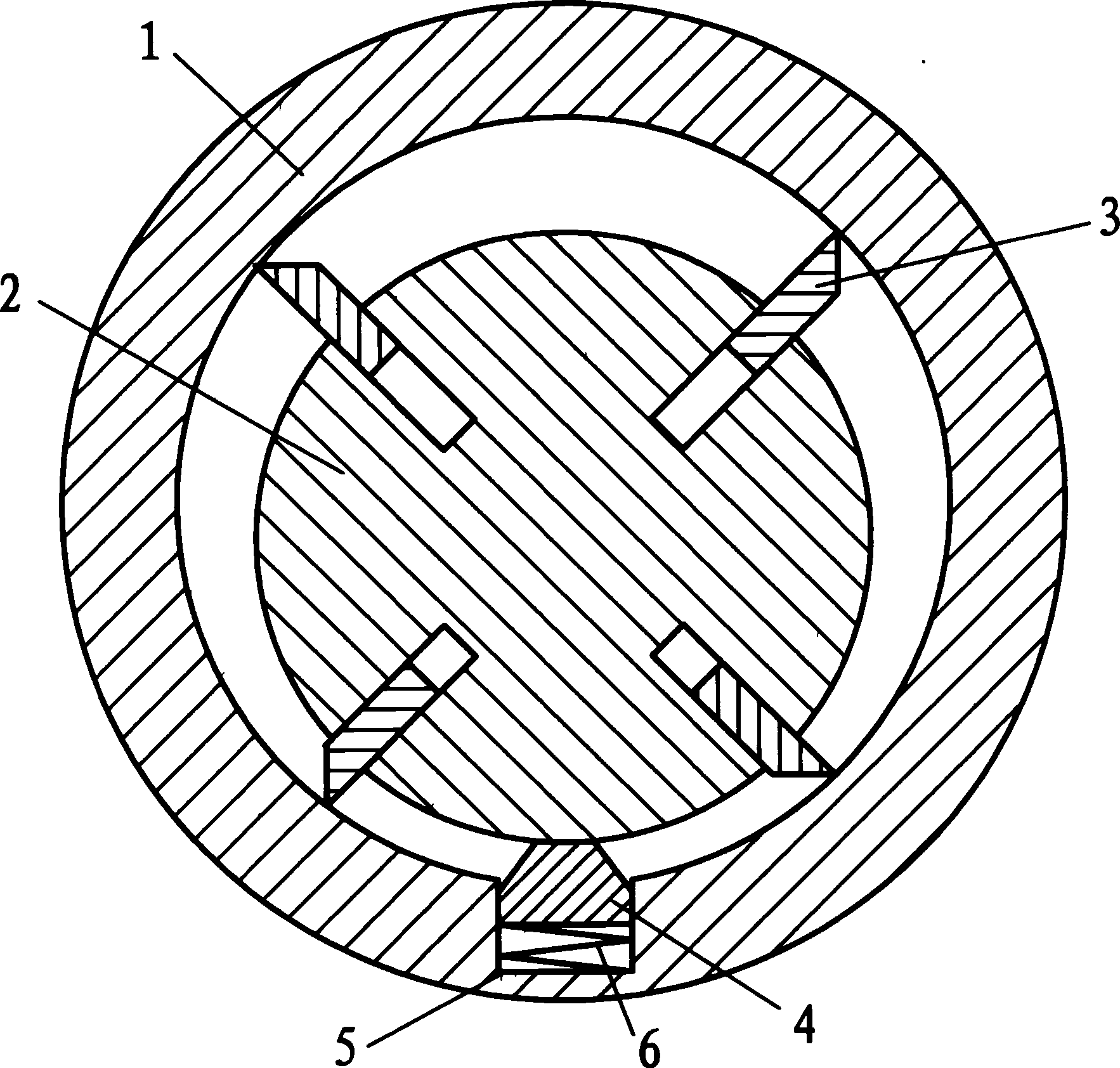

[0017] The sealed displacement vane pump of the present embodiment is as Figure three shown. In the figure, 1 represents the stator with a sealing plate groove processed on the inner surface; 2 represents the rotor; 3 represents the blade installed in the blade groove of the rotor 2; 4 represents the sealing plate that can slide radially in the sealing plate groove; 5 represents the sealing plate Groove; 6 represents spring.

[0018] When the rotor 2 rotates with the vane 3, the tip of the vane 3 touches the inner surface of the stator to start pumping oil, and at this time, a multi-directional oil pressure difference is formed in the pump chamber. Especially, there is a tendency to leak from the high-pressure area to the low-pressure area on the outer surface of the rotor 2 and the inner surface of the stator 1, but the inner end of the sealing plate 4 is tightly attached to the outer surface of the rotor 2 under the action of elastic force or oil pressure up, thereby bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com