Light tube wire structure

A wire and lamp technology, applied in the field of lamp wire structure, can solve problems such as deformation or fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

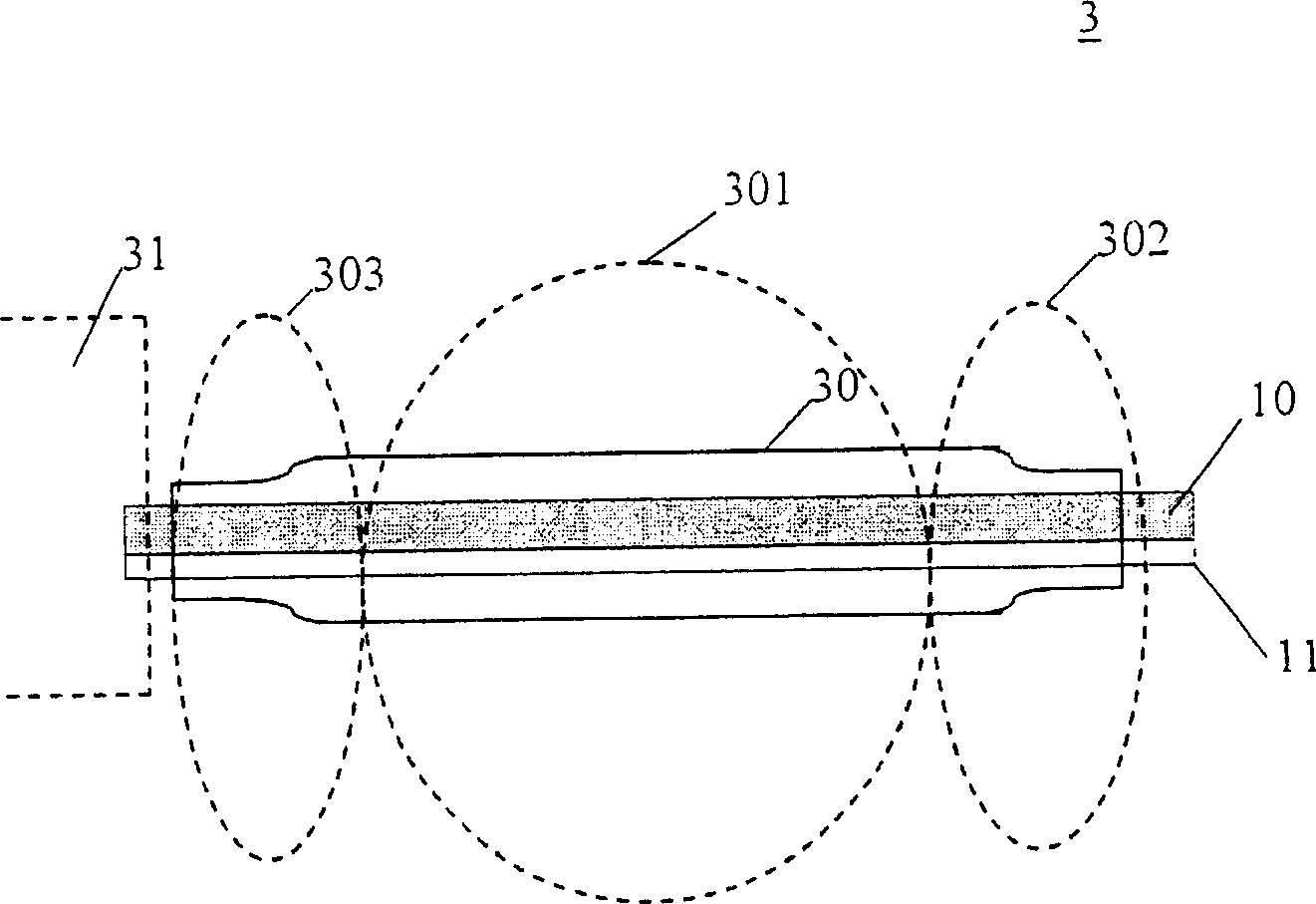

[0035] Please refer to image 3 It is a schematic diagram of an embodiment of the lamp tube wire structure of the present invention. exist image 3 Among them, the lamp tube wire structure 3 includes a high-voltage wire 10 , a low-voltage wire 11 and a first heat-shrinkable sleeve 30 . Wherein, the high voltage wire 10 can be a copper wire, and is used to transmit a high voltage value to a lamp group 31 . The low voltage wire 10 can also be a copper wire, and is used to transmit a low voltage value to the lamp group 31 . In this embodiment, the high-voltage wire 10 transmits a larger voltage value than the low-voltage wire 11 , and the diameter of the wire is generally larger. In addition, the first heat-shrinkable sleeve 30 has a first end 302, a second end 303, and an intermediate region 301 between the first end 302 and the second end 303, for covering the high-voltage wire 10 and the low-voltage wire 10. The wire 11, and the middle area 301 thereof is not baked, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com