A kind of antifreeze-thaw concrete interface agent and preparation method

A concrete and anti-freeze-thaw technology, applied in the field of concrete interface agent, can solve problems such as poor freeze-thaw resistance of interface agent, achieve the effect of large cross-linking bond energy, avoid damage stress, and reduce water saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

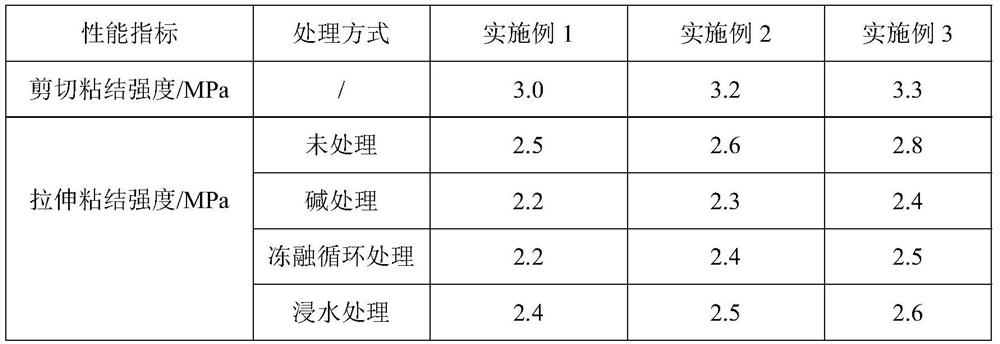

Examples

preparation example Construction

[0061] The preparation method of antifreeze-thaw concrete interface agent of the present invention is as follows:

[0062] 1. Raw materials

[0063] Cement, fly ash, nano silica, kaolin, quartz sand, diethylenetriamine, thiourea, trimethylolpropane triacrylate, hydroxypropyl methacrylate, thiopropylmethyldimethoxysilane , Epoxy Resin E-44, Glycerin, Sodium Dodecyl Sulfonate, Alkylphenol Polyoxyethylene Ether, Sodium Sulfate Decahydrate, Dibenzoyl Peroxide, Isobutyl Trimethoxysilane, Butyl Glycidol Ether, hydroxypropyl methylcellulose ether, amide-modified hydrogenated castor oil, polyamide wax, dispersant SK-5040, calcium lignosulfonate, defoamer DF849, paraffin wax.

[0064] 2. Description of main materials

[0065] (1) Cement: Ordinary Portland cement 42.5 grade.

[0066] (2) Fly ash: Class II ash.

[0067] (3) Diethylenetriamine: analytically pure, purity ≥ 98%, purchased from Tianjin Damao Chemical Reagent Factory.

[0068] (4) Thiourea: analytically pure, purity ≥ 98...

Embodiment 1

[0091] The preparation steps of the antifreeze-thaw concrete interface agent of the present embodiment are as follows:

[0092]1) Preparation of emulsifier A: 0.5 g of sodium dodecylsulfonate and 1.0 g of alkylphenol polyoxyethylene ether were mixed and added to deionized water to obtain emulsifier A.

[0093] 2) Preparation of initiator B: 0.5 g of sodium sulfate decahydrate and 0.4 g of dibenzoyl peroxide were weighed and dissolved in 100 g of deionized water to obtain initiator B.

[0094] 3) Preparation of mixed monomer C: Quantitatively weigh 20g of diethylenetriamine, 15g of thiourea, 8g of thiopropylmethyldimethoxysilane, 10g of trimethylolpropane triacrylate, and 10g of hydroxypropyl methacrylate Ester, 5g of epoxy resin, 3g of glycerin, 0.6g of isobutyltrimethoxysilane, and 0.6g of butyl glycidyl ether were mixed uniformly to obtain mixed monomer C.

[0095] 4) Preparation of pre-emulsion D: Add mixed monomer C and 1 / 2 volume of emulsifier A into a four-neck flask, s...

Embodiment 2

[0101] The preparation steps of the antifreeze-thaw concrete interface agent of the present embodiment are as follows:

[0102] 1) Preparation of emulsifier A: 0.8 g of sodium dodecylsulfonate and 1.6 g of alkylphenol polyoxyethylene ether were mixed and added to deionized water to obtain emulsifier A.

[0103] 2) Preparation of initiator B: 0.8 g of sodium sulfate decahydrate and 0.2 g of dibenzoyl peroxide were dissolved in 110 g of deionized water to obtain initiator B.

[0104] 3) Preparation of mixed monomer C: Weigh quantitatively 18g of diethylenetriamine, 16g of thiourea, 9g of thiopropylmethyldimethoxysilane, 9g of trimethylolpropane triacrylate, 6g of methacrylic acid hydroxy Propyl ester, 8g of epoxy resin, 4g of glycerin, 0.5g of isobutyltrimethoxysilane, and 0.8g of butyl glycidyl ether were uniformly mixed to obtain mixed monomer C.

[0105] 4) Preparation of pre-emulsion D: Add mixed monomer C and 1 / 2 volume of emulsifier A into a four-neck flask, stir at a spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com