Sheet metal frame cabinet for installing frame or cabinet and method for installing frame or cabinet

A technology for installation and chassis, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of inconvenient operation, narrow nut installation and operation space, etc., achieve high work efficiency, low engineering cost, and overcome the effect of narrow operation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

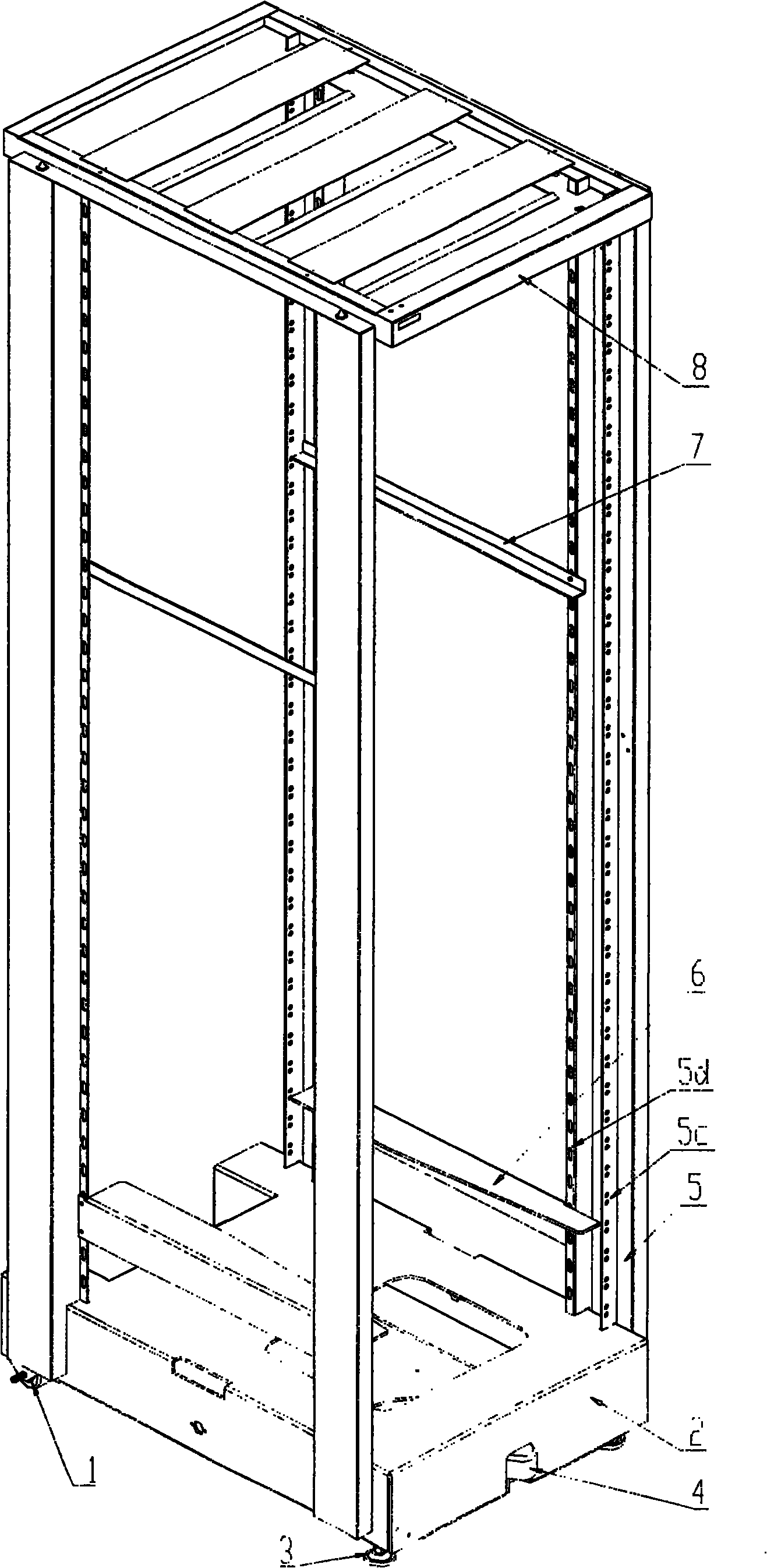

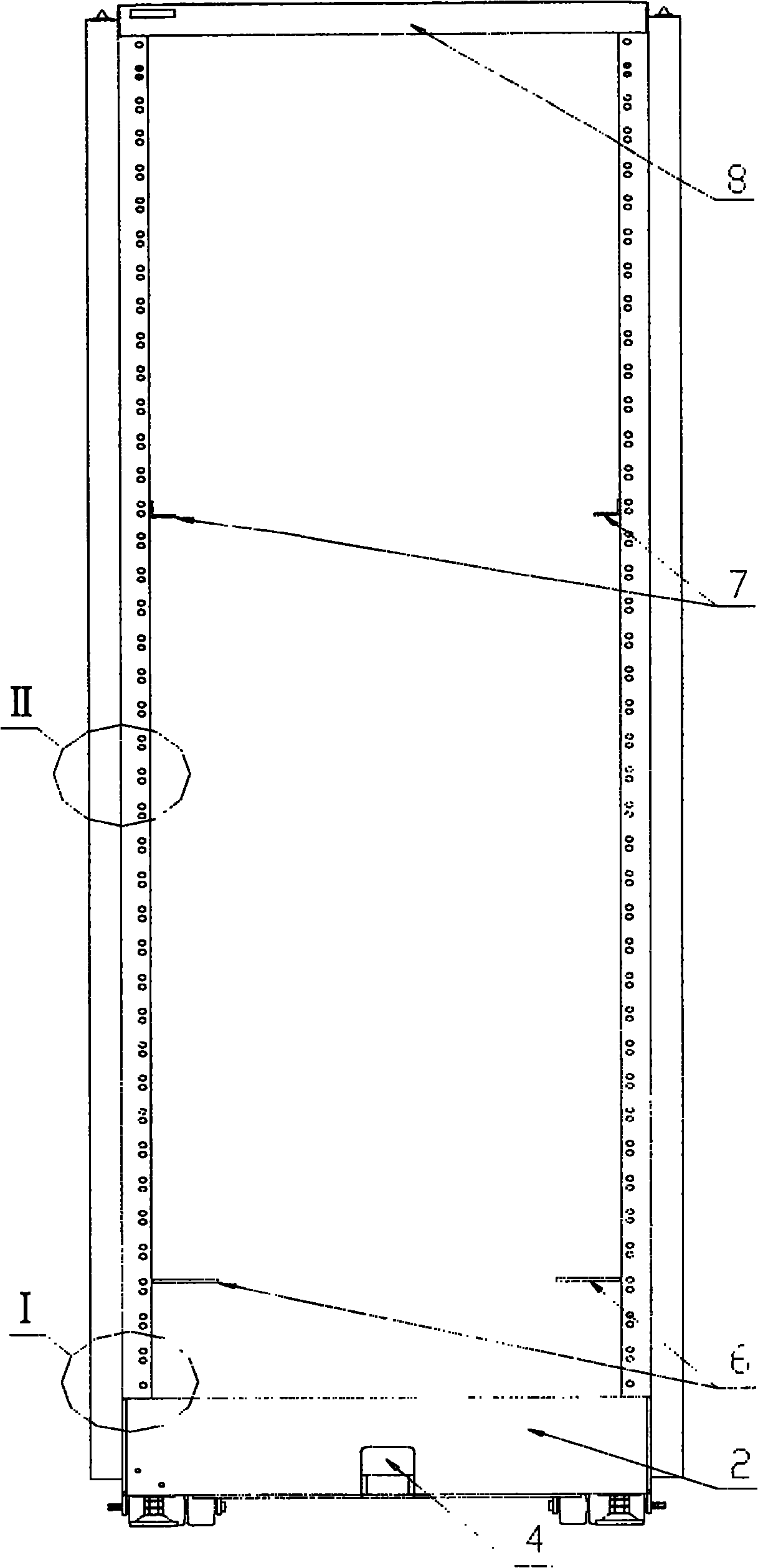

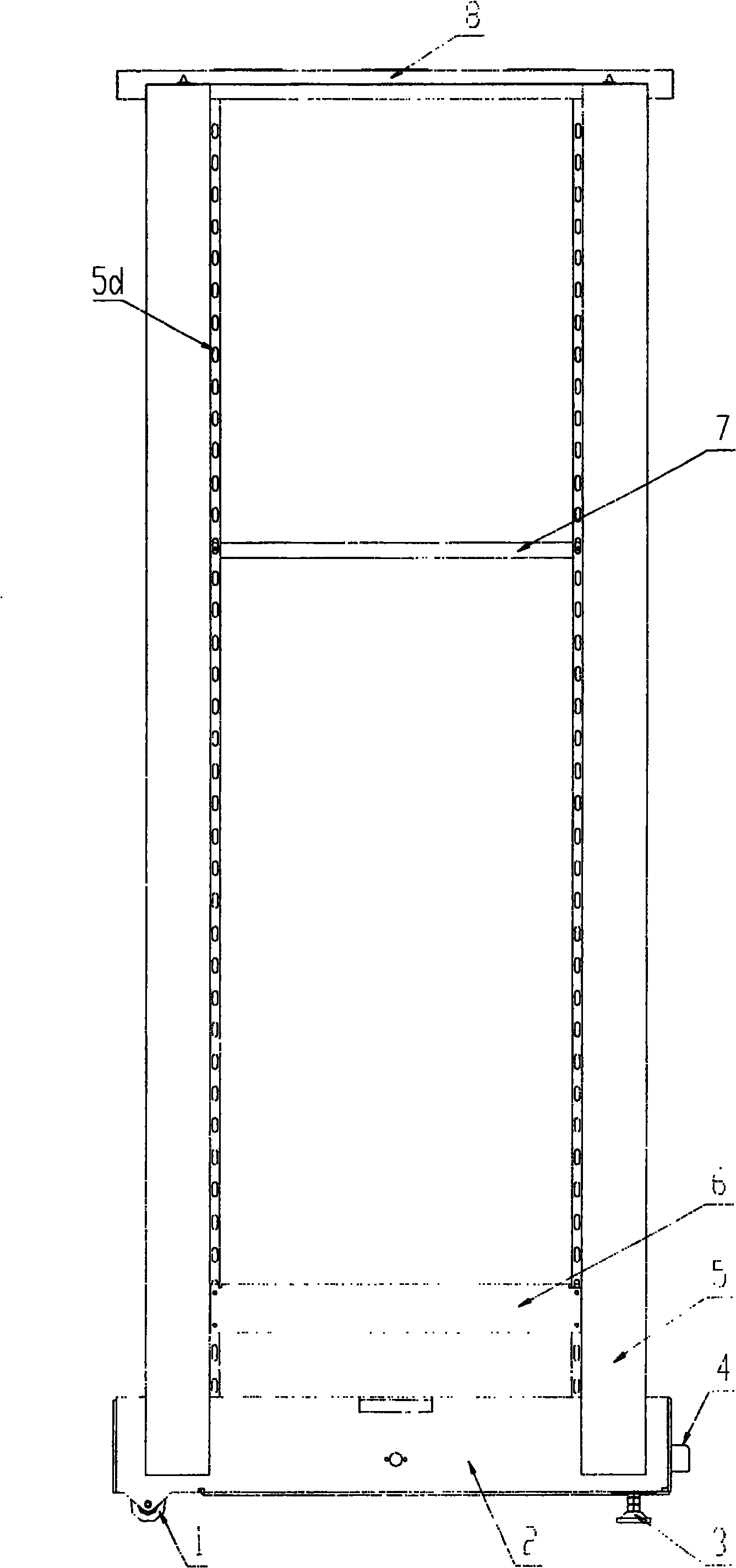

[0038] see figure 1 , with reference to Figure 2 to Figure 7 , the rack of the present invention shown in the figure or the sheet metal frame cabinet that cabinet is installed usefulness, whole cabinet structure is provided with circular through hole 5c and waist of fixed modulus respectively on it by base 2, top cover 8 and four The column 5 of the circular through hole 5d is welded, and two caster adjustment blocks 3 at the front and two fixed casters 1 at the rear are correspondingly provided at the bottom of the base 2, and there is also a set in the middle of the front of the base 2. A skid tool fulcrum 4 is arranged.

[0039] In the working state (fixed), the fixed caster 1 and the caster adjustment block 3 are in contact with the ground and kept horizontally fixed. If you want to move the cabinet, you only need to use the pry tool to pry the cabinet up to a certain height through the pry fulcrum 4 Just drag and drop, very flexible. The fulcrum 4 of the prying tool i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com