Oscillatory actuator

A transmission device, vibration type technology, applied in electromechanical devices, fluids utilizing vibration, generators/motors, etc., can solve the problem of increasing the weight and cost of the amplitude control spindle 14, difficult to achieve miniaturization, and difficult to achieve light weight and low cost. issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manner of the present invention will be described below in combination with schematic diagrams. In addition, the parts with the same structures or functions as those described in the background art are given the same reference numerals, and will not be described in detail.

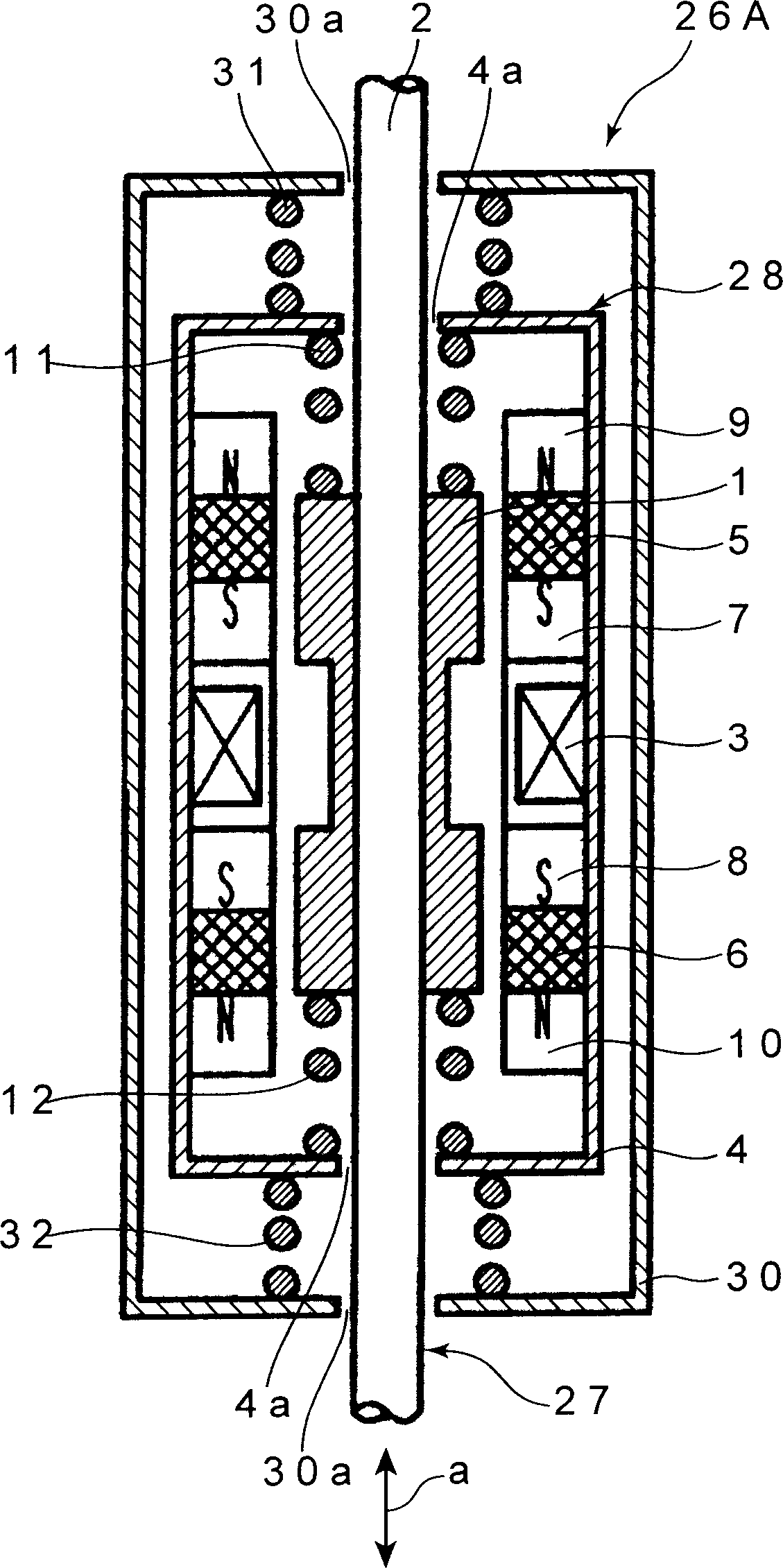

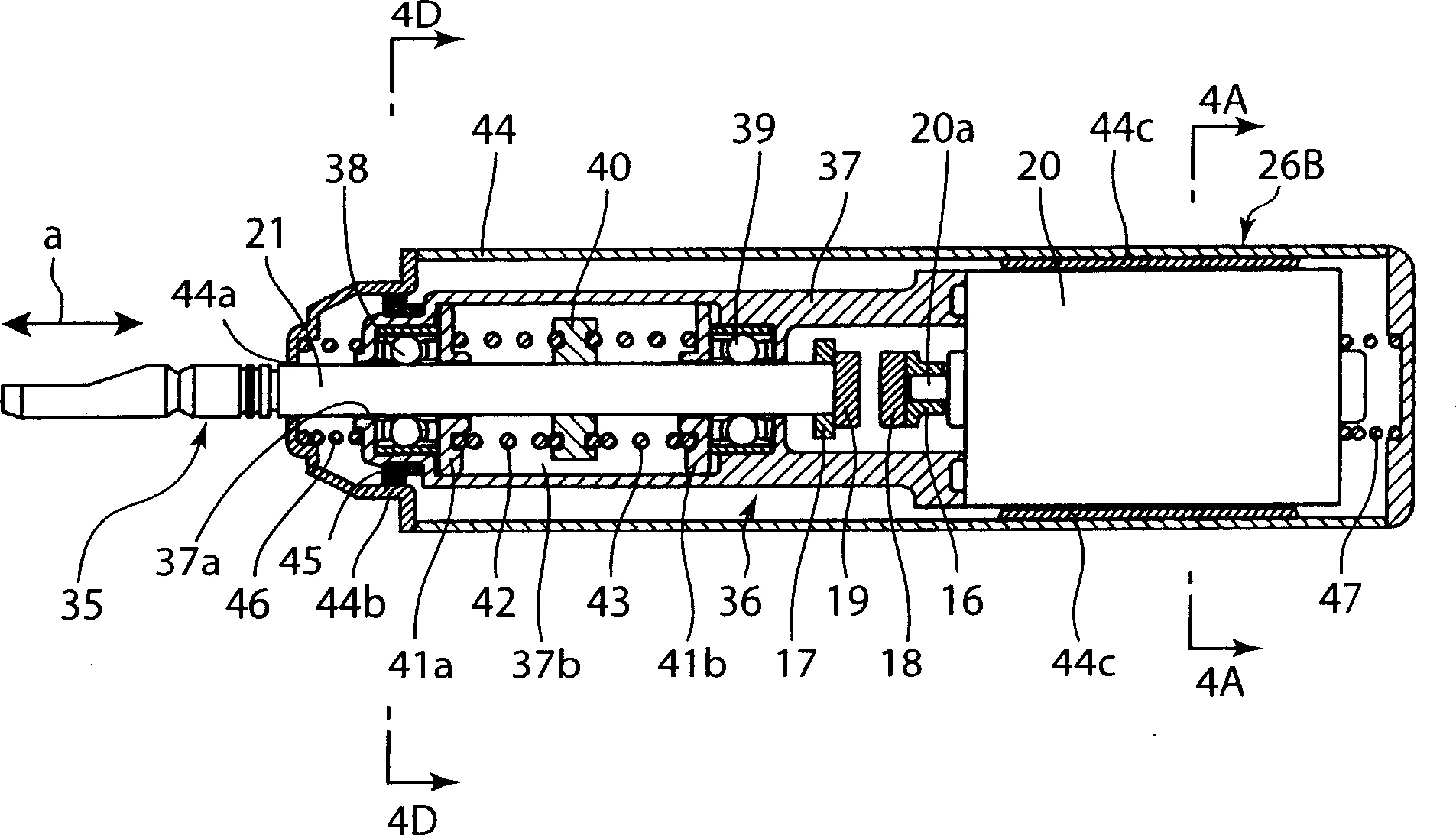

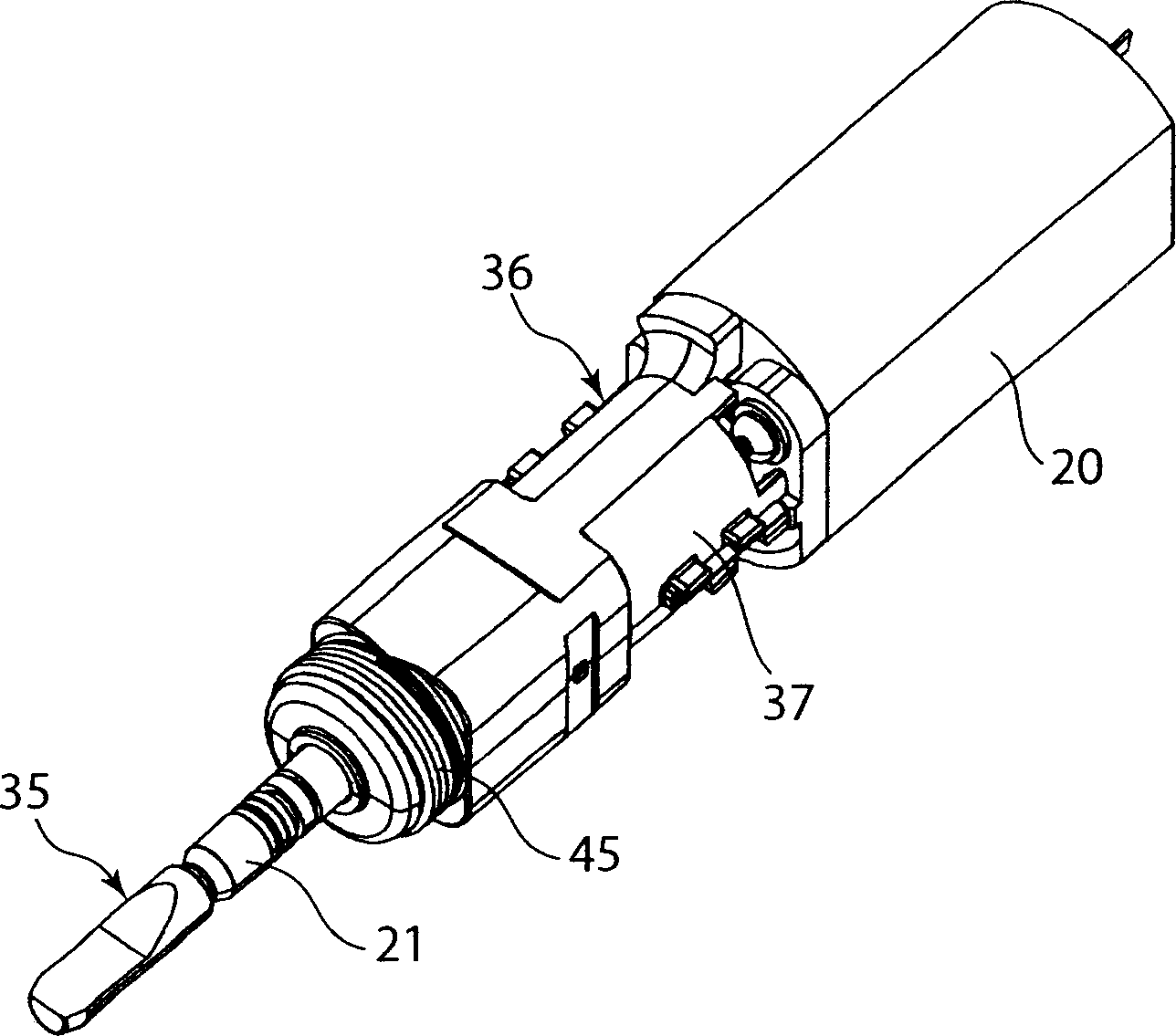

[0043] First, in figure 1 The vibration type actuator 26A related to Embodiment 1 of the present invention is described in . The transmission device 26A is developed on the basis of the transmission device described in the above-mentioned Patent Document 1 in combination with the present invention.

[0044] This vibration-type transmission device 26A is equipped with a movable part 27, an electromagnetic drive part 28 that uses electromagnetic force to make the movable part 27 reciprocate in a specific direction (in the figure, the up-down direction, that is, the axial direction), and the main box. 30.

[0045] The movable part 27 is constituted by the plunger 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com