Continuously variable transmission

A continuously variable speed change device, the technology of speed change device, applied in the direction of hoisting device, transmission device, transmission device control, etc., to achieve the effect of accurately controllable and predictable changing speed, economical production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

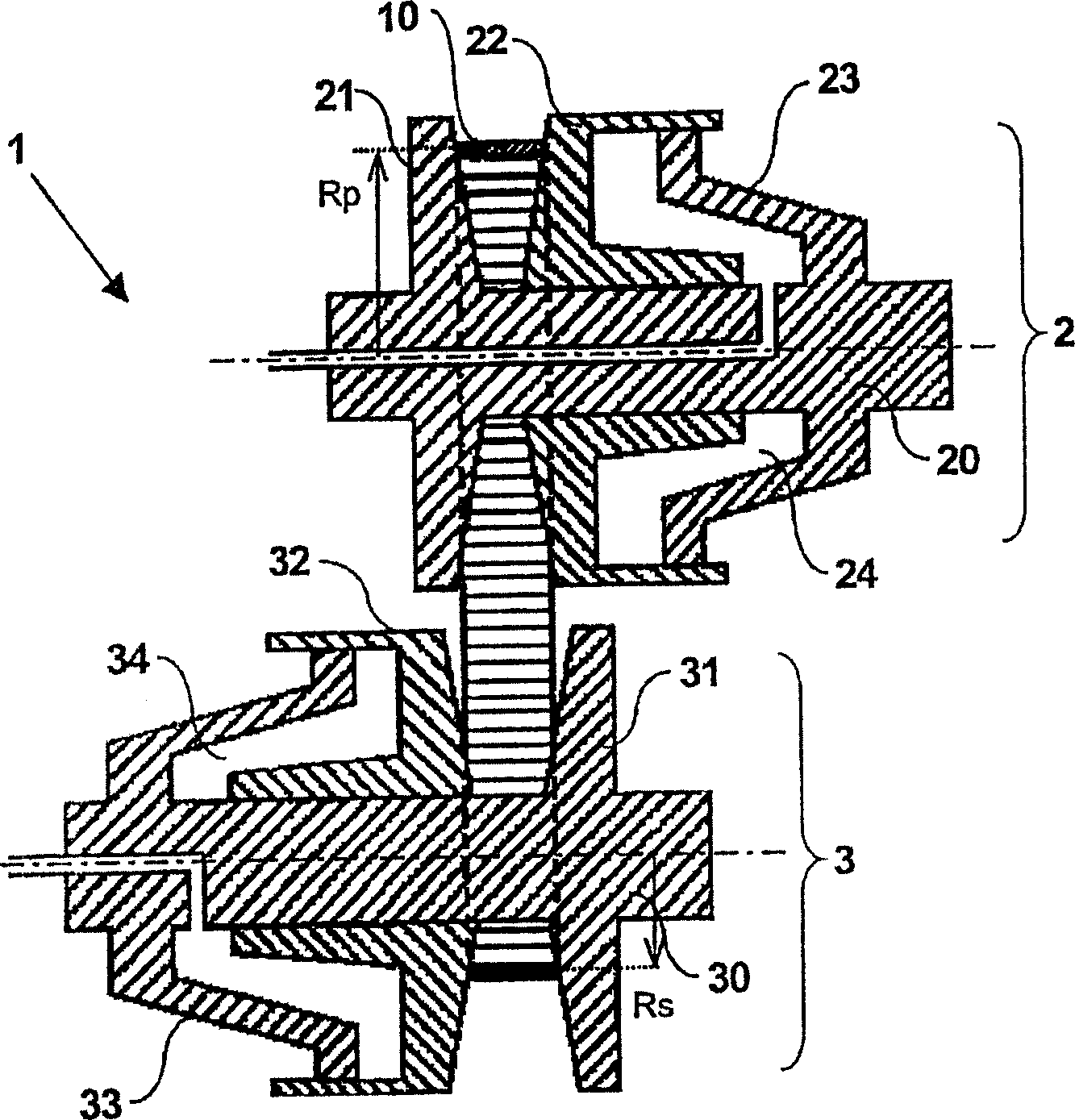

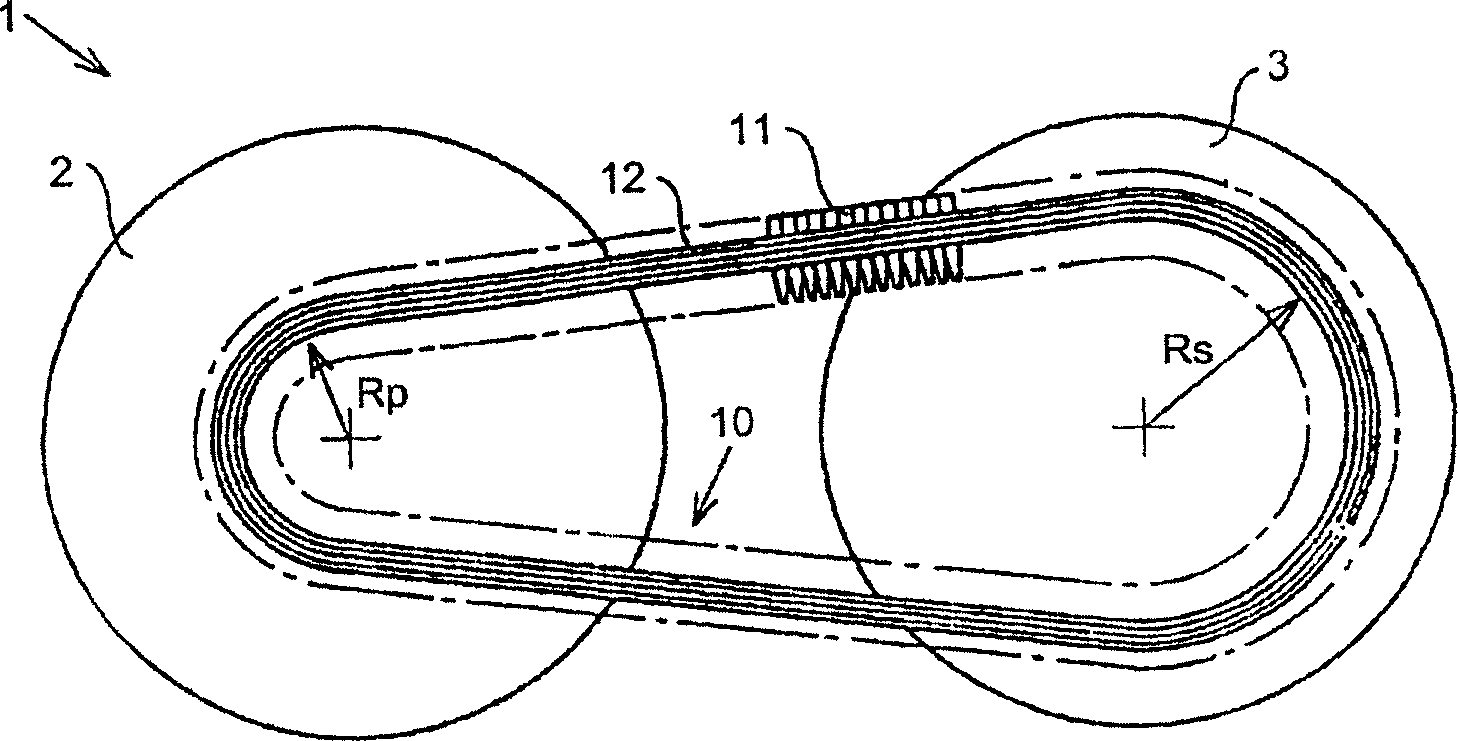

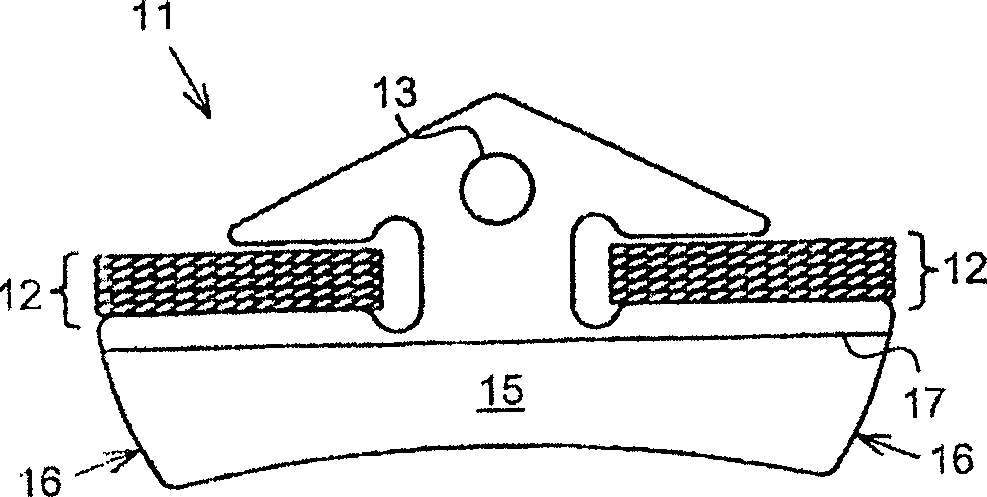

[0046] figure 1 A cross-sectional view through a continuously variable transmission 1 according to the prior art is schematically depicted. A known speed change device 1 includes a primary pulley 2 that can be driven by an engine (not shown) with two forces Tp and a secondary pulley 3 that can drive a load with a pair of forces Ts (not shown). show). The pulleys 2 and 3 are provided with pulley disks 21 and 31 fixed to respective pulley shafts 20 , 30 and with pulley disks 22 , 32 displaceable relative to said shafts 20 , 30 in the axial direction. The drive belt 10 , more specifically the pressure belt 10 , is clamped between pulley discs 21 , 22 , 31 , 32 so as to be able to be driven between the two shafts 20 , 30 by means of frictional mechanical energy. In this case, the axially directed force with which the drive belt 10 uses for each The pulleys 2, 3 are clamped in place, said forces hereinafter referred to as primary clamping force Kp and secondary clamping force Ks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com