Wet magnetic separator

A technology of wet magnetic separator and magnetic system, which is applied in the field of magnetic separator, can solve the problems of poor beneficiation accuracy and low selection rate, and achieve the effects of improving beneficiation grade, reducing water supply, and reducing tailing

Inactive Publication Date: 2007-01-03

柳州市远健磁力设备制造有限责任公司

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The wet magnetic separator provided by the present invention mainly solves the problems of poor beneficiation accuracy and low selection rate of existing magnetic separators

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0014] Example 1: This machine can increase the low-grade symbiotic manganese from 20% to 23% to 30% to 35% (the original ore of Li Jianzhong in Xi'an was increased from 24.05% to 32.87%)

example 2

[0015] Example 2: This machine can improve 35% to 45% of low-grade limonite to 50% to 60% of medium-high grade (44% of the original ore in Li Pingsi, Wuding City, Yunnan Province was increased to 60.7%).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

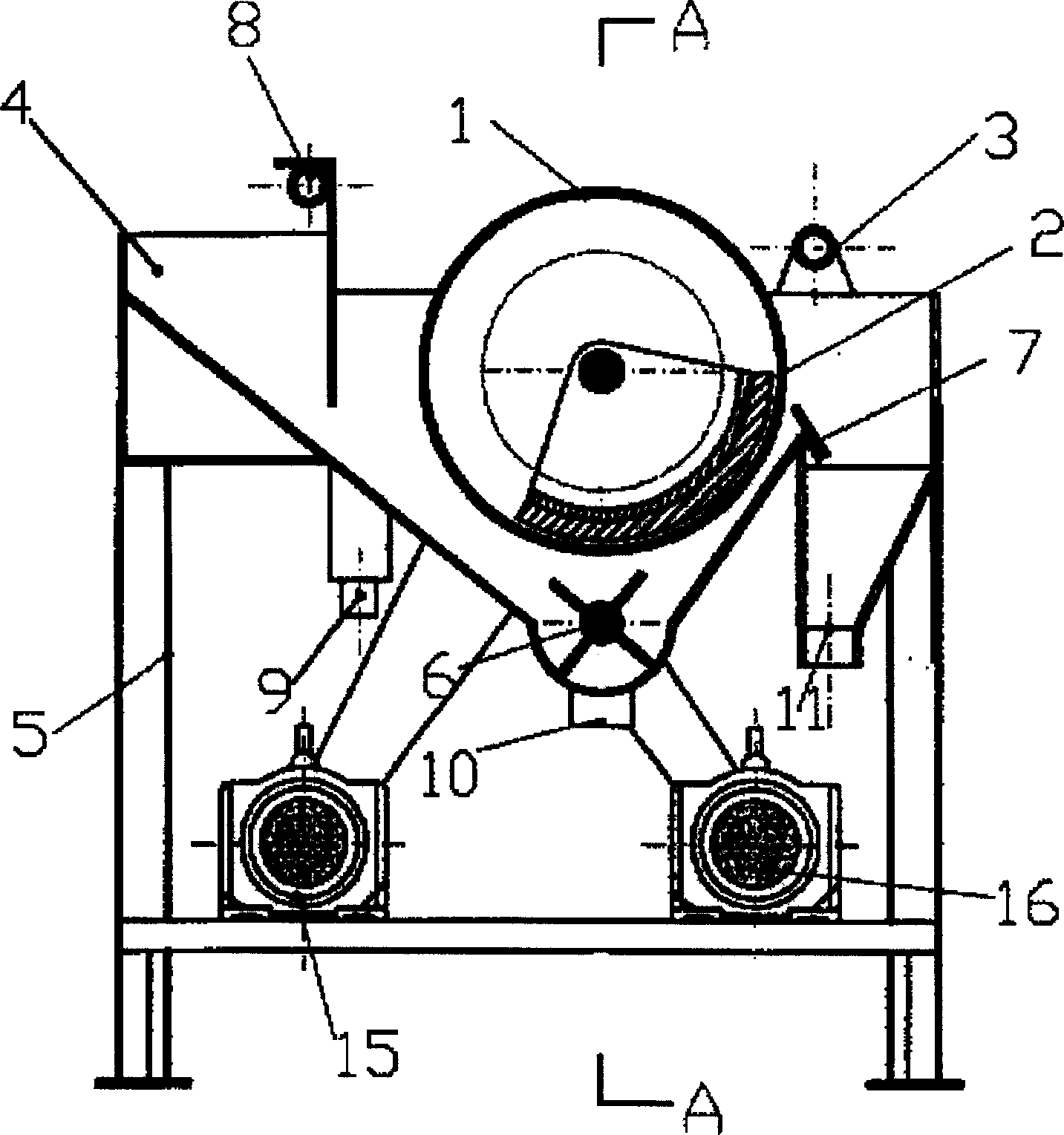

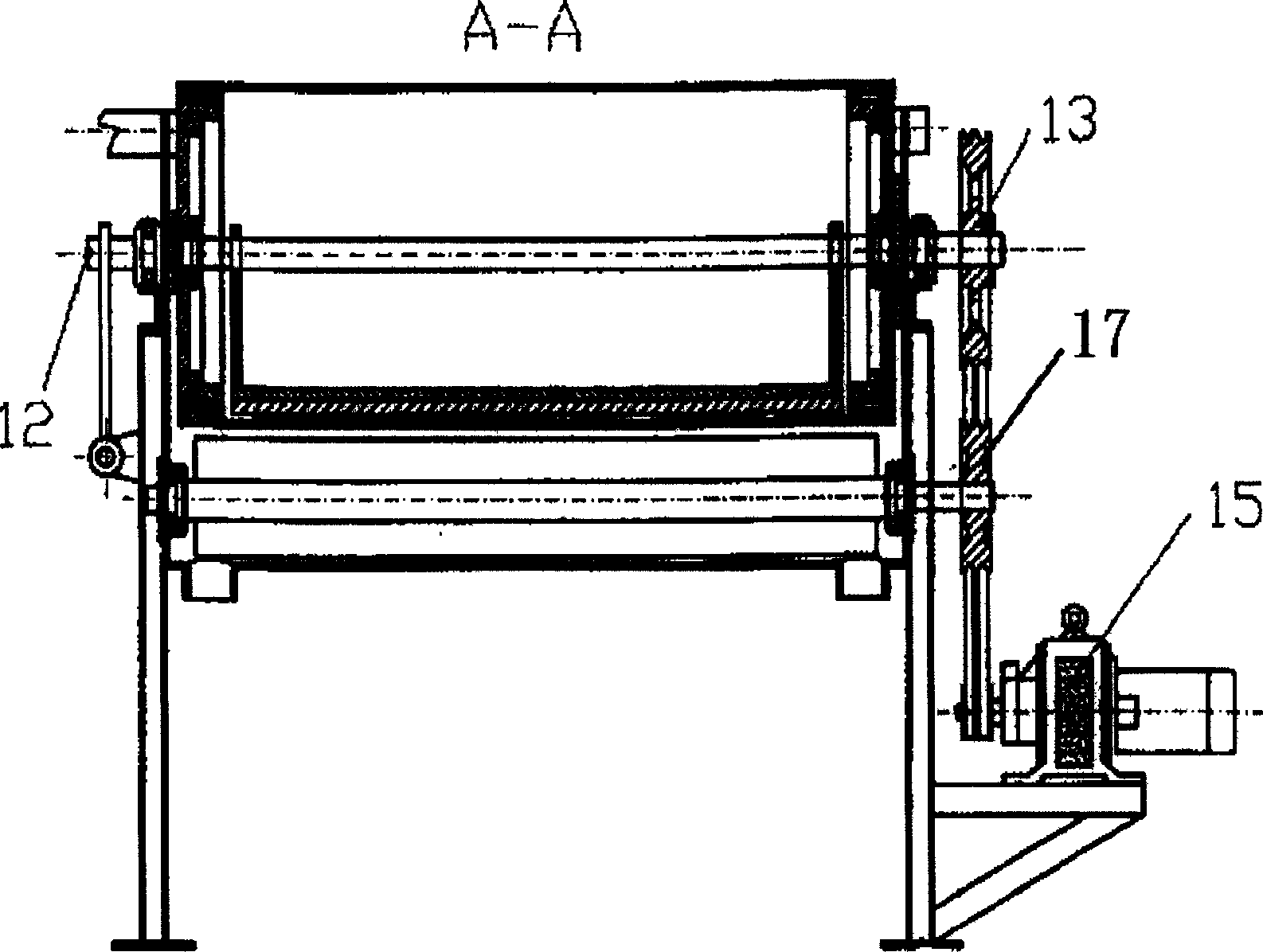

The present invention relates to magnetic separating technology, and is especially one kind of wet magnetic separator. The wet magnetic separator includes a rotating drum with a magnetic system, a tank below the rotating drum, a stirrer inside the tank and comprising rotating shaft and blades on the shaft, a mechanical driving unit and a power mechanism connected through the mechanical driving unit to the shaft. The wet magnetic separator is used in separating magnetic material compounded in water, and has the advantages of high separating efficiency, high separating precision, low water consumption, etc.

Description

technical field [0001] The invention relates to the technical field of magnetic separators, in particular to a magnetic separator for distributing water and feeding materials, and having a magnetic drum containing a magnetic system and an ore separation tank body. Background technique [0002] The existing wet magnetic separators are roughly divided into downstream magnetic separators, countercurrent magnetic separators, and countercurrent magnetic separators according to the difference in the feeding direction determined by the structure of the feed port and the material selection tank relative to the rotating direction of the drum with a collision system. Separator and semi-countercurrent magnetic separator in several forms. The three kinds of magnetic separators all include a drum with a magnetic system and a tank under the drum. Regardless of the ore feeding method, the existing water magnetic separator has serious shortcomings: the ore sinks at the bottom of the tank b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B03C1/10

Inventor 韦威信

Owner 柳州市远健磁力设备制造有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com