Electromagnet pull-in circuit for industrial sewing machine

An electromagnet pull-in and sewing machine technology, applied in the field of industrial sewing machines, can solve the problems of high cost and complicated circuit, and achieve the effect of simple circuit and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

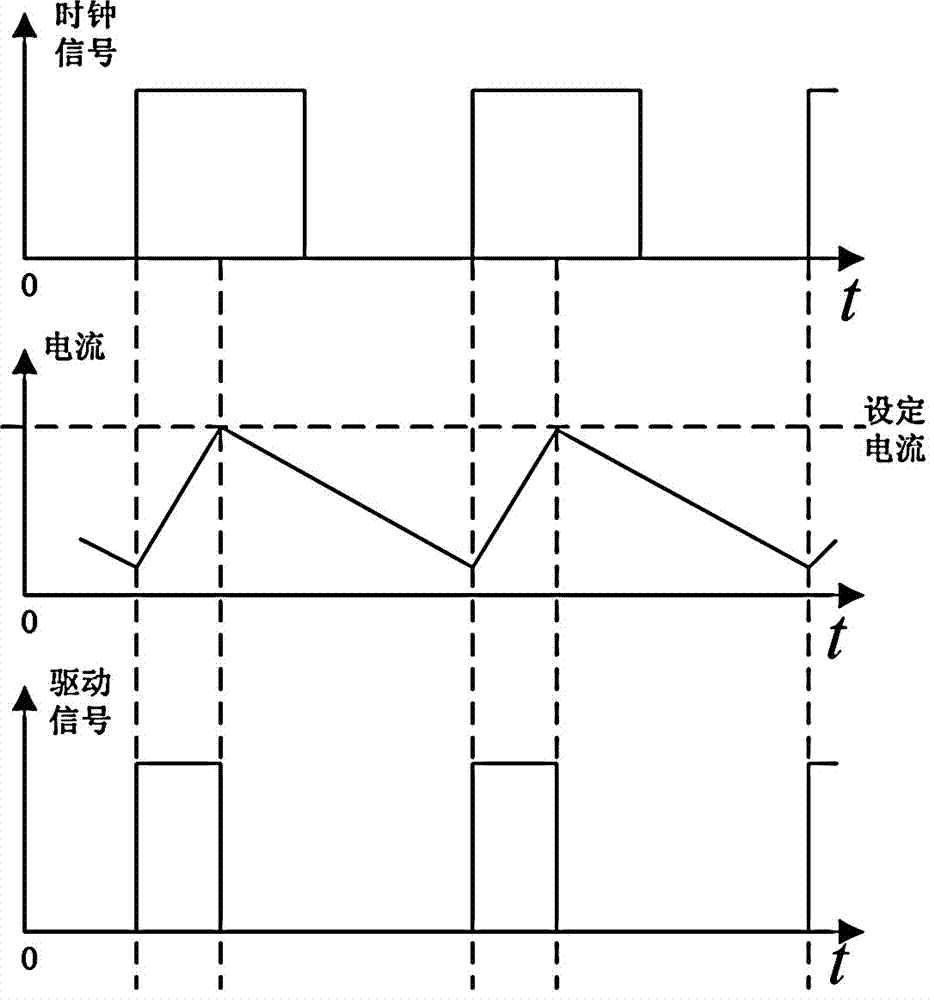

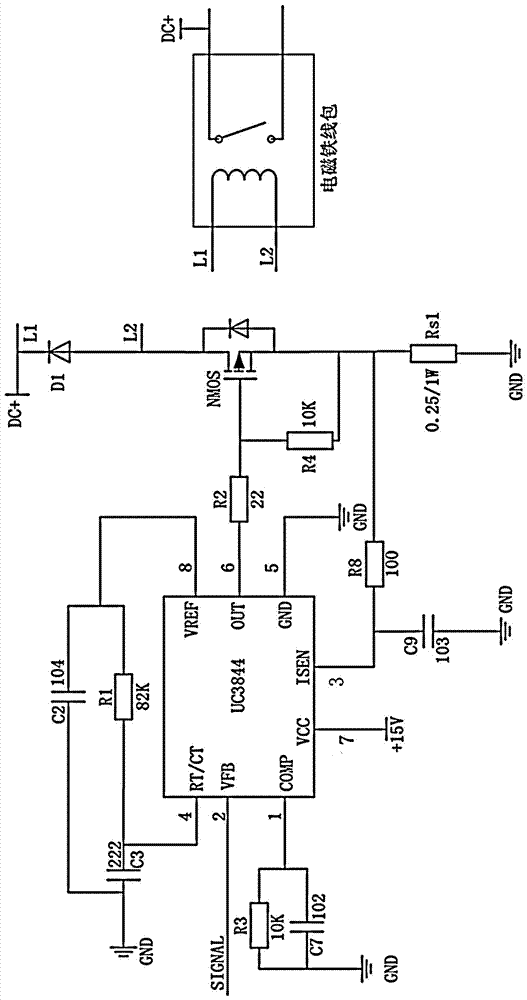

[0018] figure 1 It is an electromagnet pull-in circuit for industrial sewing machines, including a main circuit circuit, a chip UC3844, an NMOS tube drive circuit, a sampling filter circuit, an RC oscillating circuit, a freewheeling circuit, and a compensation circuit.

[0019] The main loop circuit is composed of power supply DC+, electromagnet wire package L, freewheeling diode D1, NMOS tube, sampling resistor Rs1 and ground. Power supply DC+ is the DC bus voltage for driving industrial sewing machine motors, and is connected to the cathode of freewheeling diode D1. The anode of D1 is connected to the drain of the NMOS tube, the two ends of the electromagnet wire package L are connected in parallel with the freewheeling diode D1, and the source of the NMOS tube is connected to the ground through the sampling resistor Rs1.

[0020] Among them, the freewheeling circuit is composed of the electromagnet wire package L and the freewheeling diode D1. When the NMOS tube is turned o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com